Continuous production method and production line of flat steel heald

A production method and technology of steel sheet healds, applied in healds, textiles, textiles, and papermaking, can solve problems such as poor quality, environmental pollution, and low efficiency, and achieve high production efficiency, reduce production costs, and reduce environmental pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

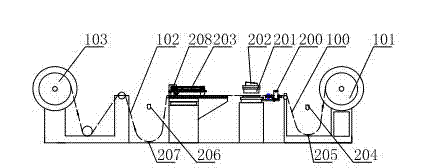

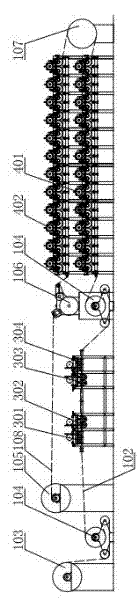

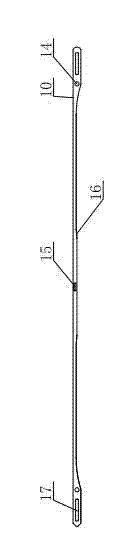

[0052] The specific implementation of the method and production line of the present invention will be comprehensively described below in conjunction with the accompanying drawings.

[0053]The steel sheet heald continuous production line of the present invention comprises four parts: a continuous die stamping device connected in series, a strip material inner edge polishing device, a strip material plane polishing device and a cutting die stamping device; these four parts can be automatically controlled by electrification, Coordinate the production speed of each part and set up a buffer space between them to form a continuous production line, which can greatly improve production efficiency; each part can also work independently, using trays for buffering and transfer, and its control system is relatively simple and reliable. In this embodiment, according to the actual production environment and economic requirements, it is divided into figure 1 The stamping module of the conti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com