Method for processing automobile buffer block and special clamp used by method

A special fixture and processing method technology, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of low production efficiency, flash, insufficient filling, etc., achieve high processing accuracy, smooth surface, improve production The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

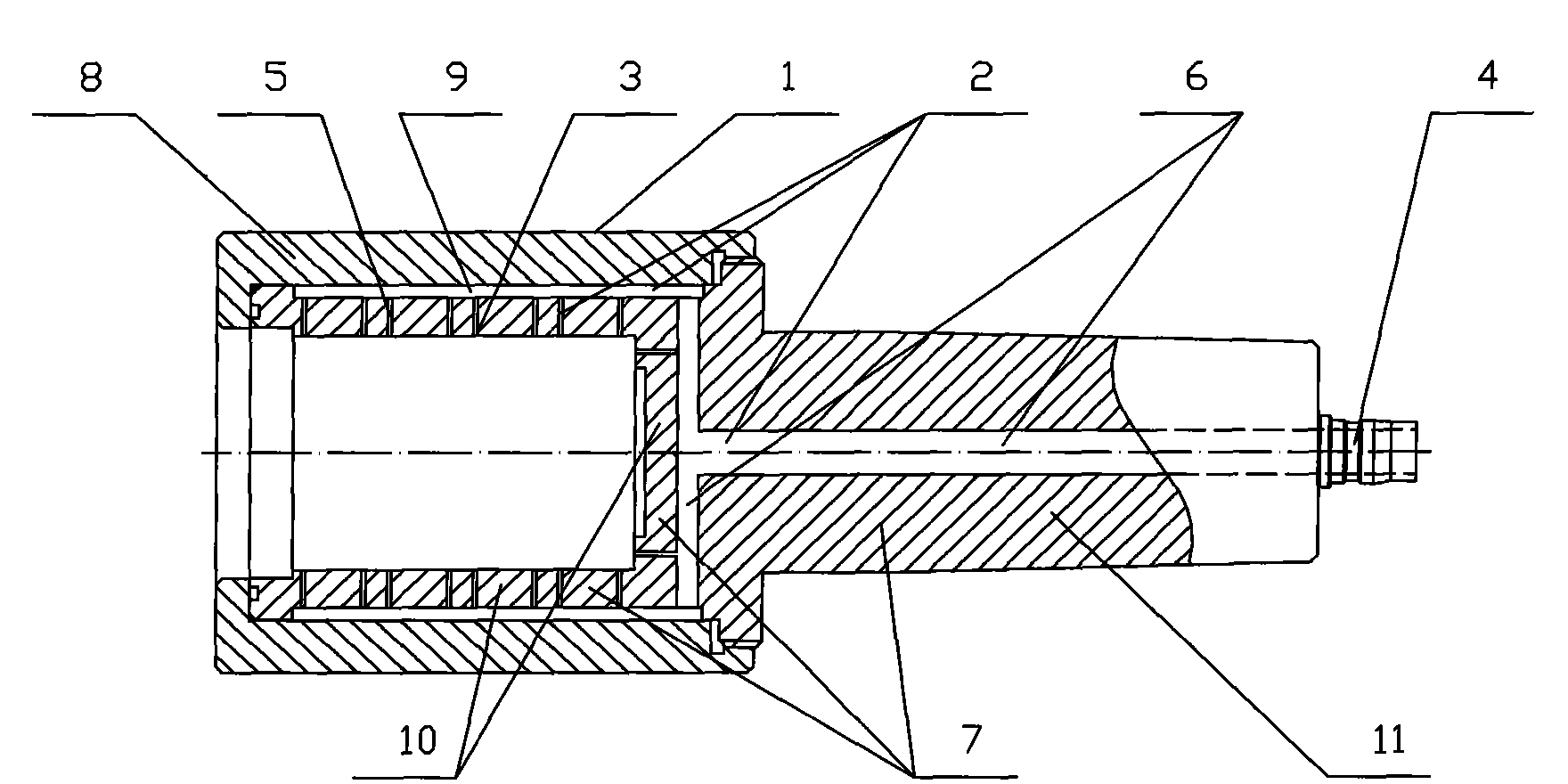

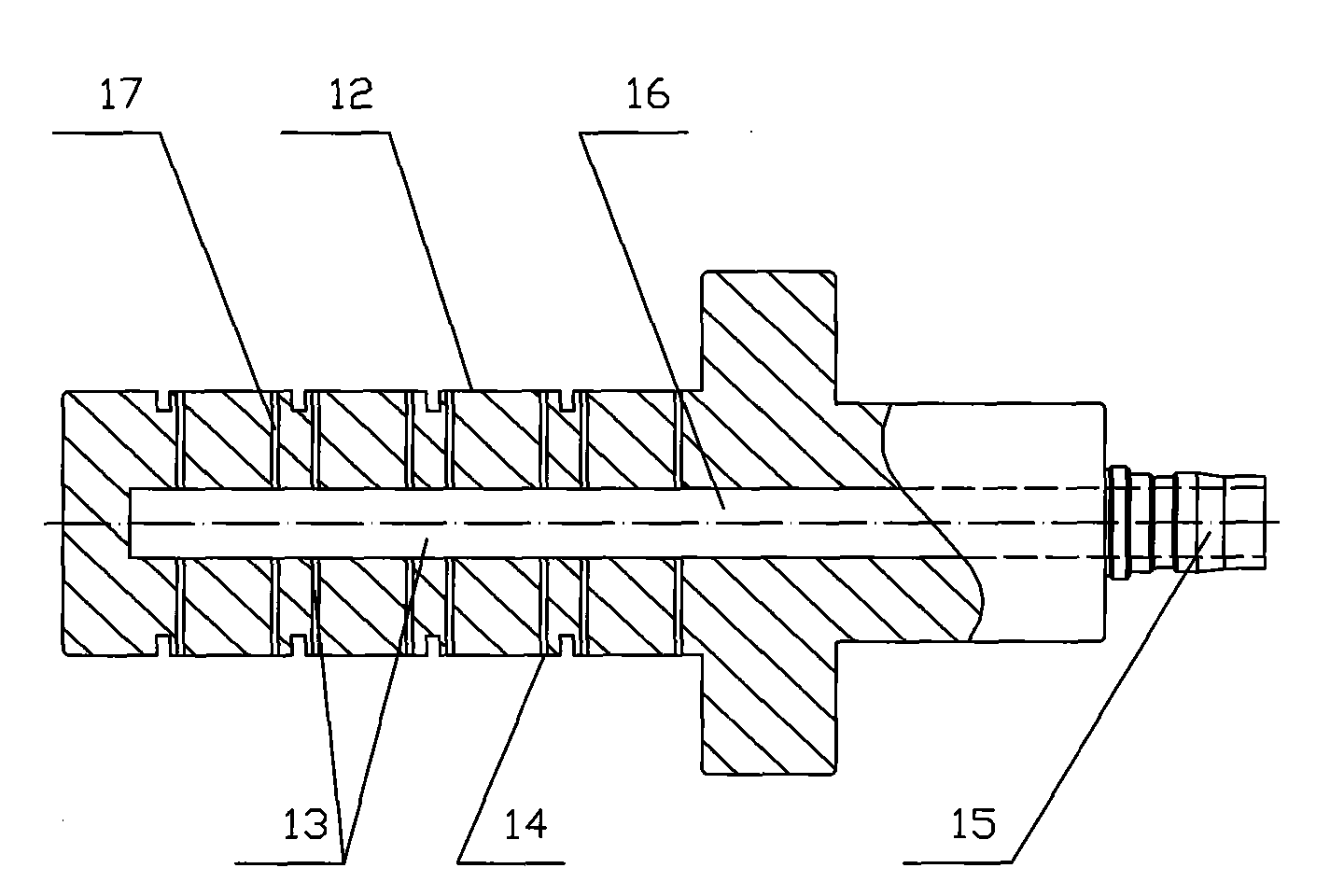

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0031] The processing method of the outer elastic body of the automobile buffer block of the present invention comprises the following steps:

[0032] (1) A plurality of continuous buffer block blanks are injection molded by an injection molding machine;

[0033] (2) Fix the first special fixture capable of clamping the outer circular surface of the buffer block on the lathe, fix the tool with the groove on the inner surface of the car on the lathe carriage, then put the blank into the first special fixture, and turn on the power switch ;

[0034] (3) The turning tool enters the inner hole of the buffer block, and performs groove processing on the inner surface of the first buffer block until the preset groove depth and groove width requirements are reached, then stop feeding and withdraw the tool;

[0035] (4) After the tool is ret...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com