Rotatable milling blade for sidewall machining

An insert and indexing technology, applied in milling cutting inserts, milling cutters, metal processing equipment, etc., can solve the problems of low vertical accuracy and smoothness, and the impact of tool pick marks on processing efficiency, so as to improve the overall cutting performance and improve cutting. Quality, the effect of reducing knife marks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0027] The invention provides an indexable milling insert for side wall processing in view of the problems that the vertical accuracy and smoothness of the processed side surface of the existing insert are not high, and the cutting marks obviously affect the processing efficiency under the condition of large cutting depth.

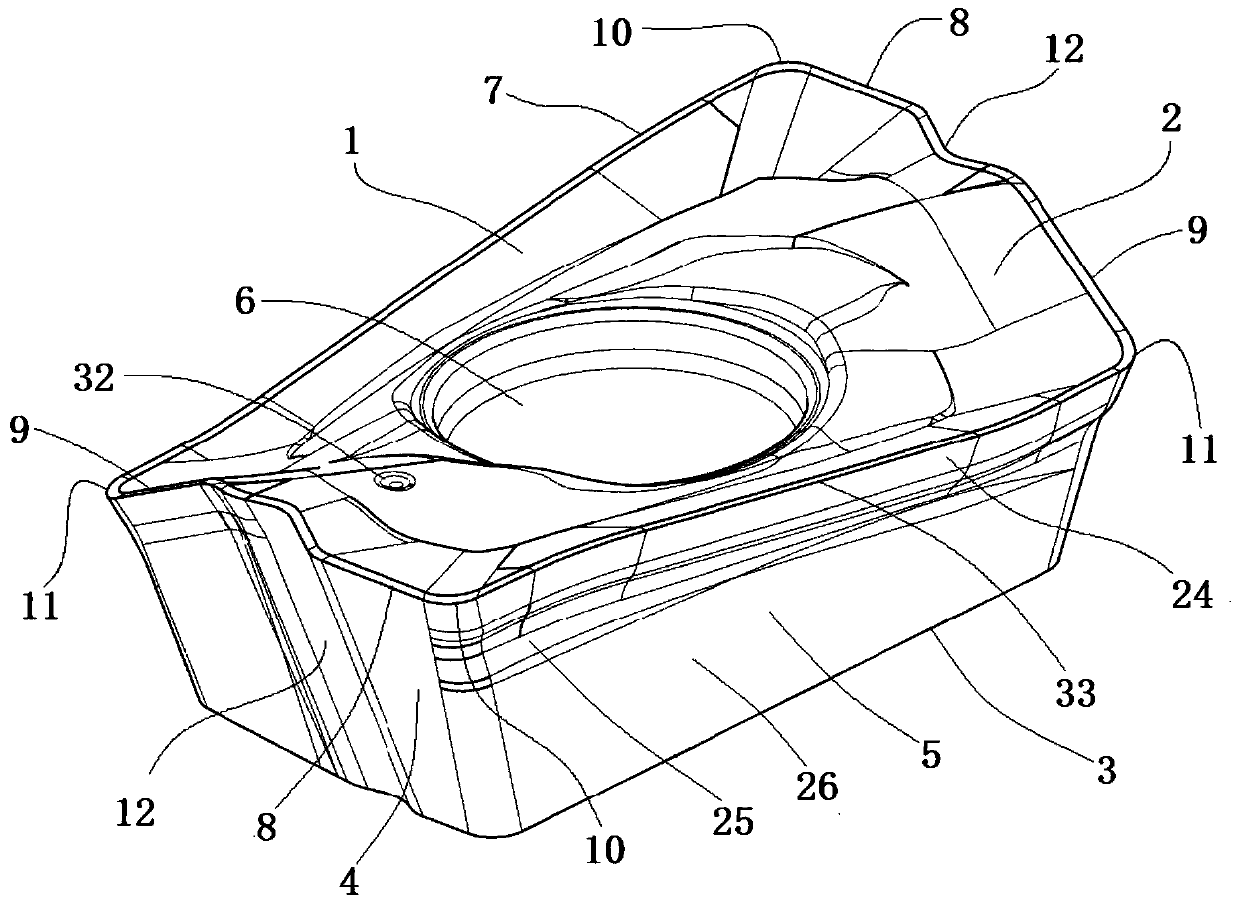

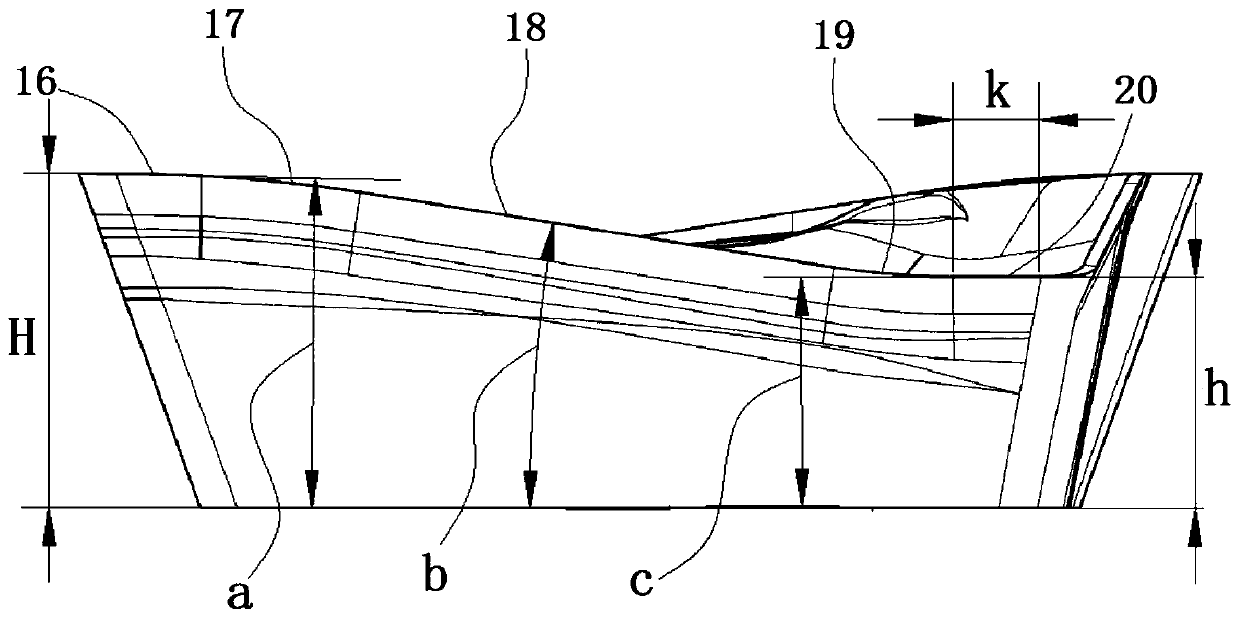

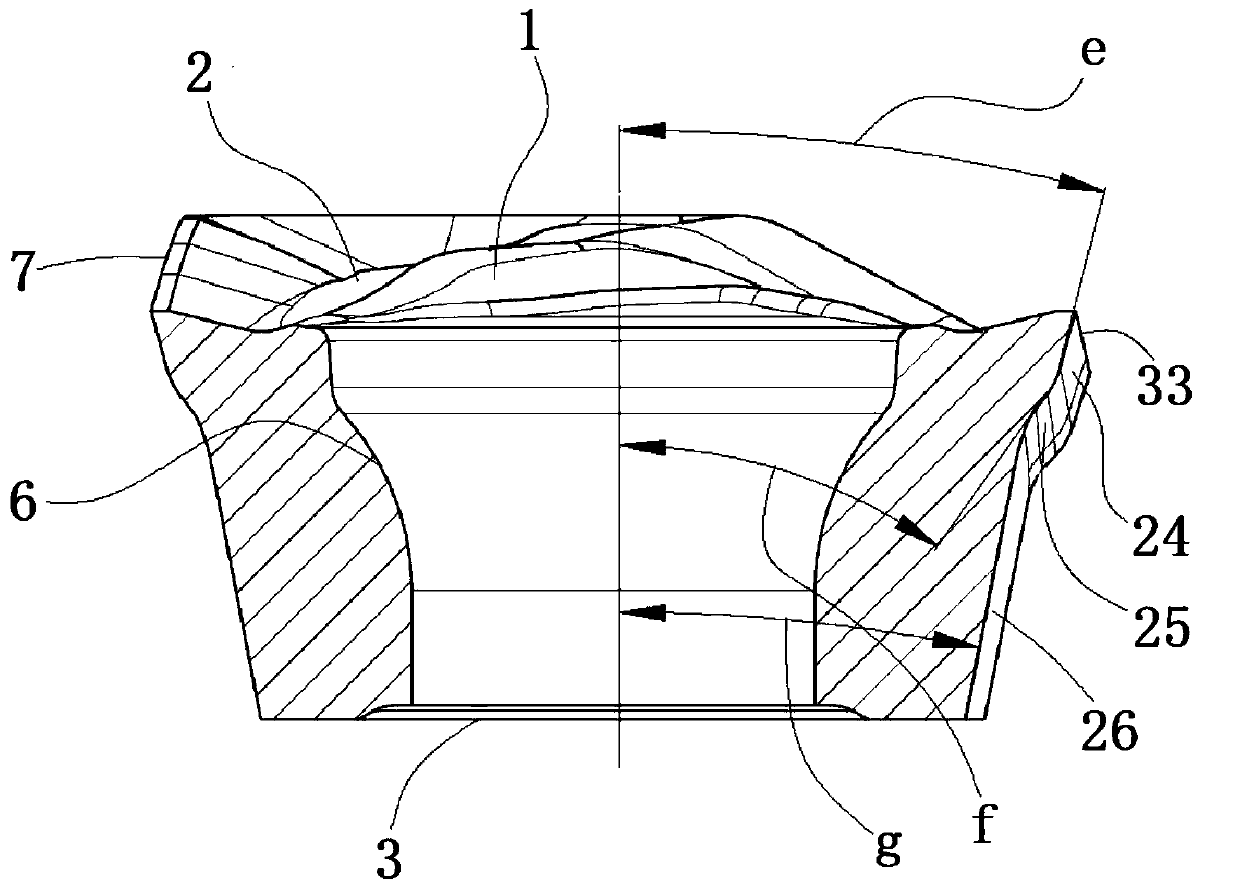

[0028] like figure 1 , Figure 4 and Figure 5 As shown, the embodiment of the present invention provides an indexable milling insert for side wall processing, including an upper top surface 2, a lower bottom surface 3 and a Two end surfaces 4 and two side surfaces 5 surround an approximately cuboid blade main body 1, said blade main body 1 is provided with a central hole 6 at its axisymmetric center, said upper top surface 2 and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com