Gear transmission type film synchronous two-way stretching device and matched technological method thereof

A biaxial stretching and transmission technology, which is applied in the field of film stretching and processing, can solve the problems of film peeling, inability to meet the production and processing of special films, and limited friction coefficient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] This example is a specific implementation method for preparing a biaxially stretched polyvinyl alcohol film with a transverse stretch ratio of 2.5 and a longitudinal stretch ratio of 2.5, wherein the raw materials of the polyvinyl alcohol film are self-made:

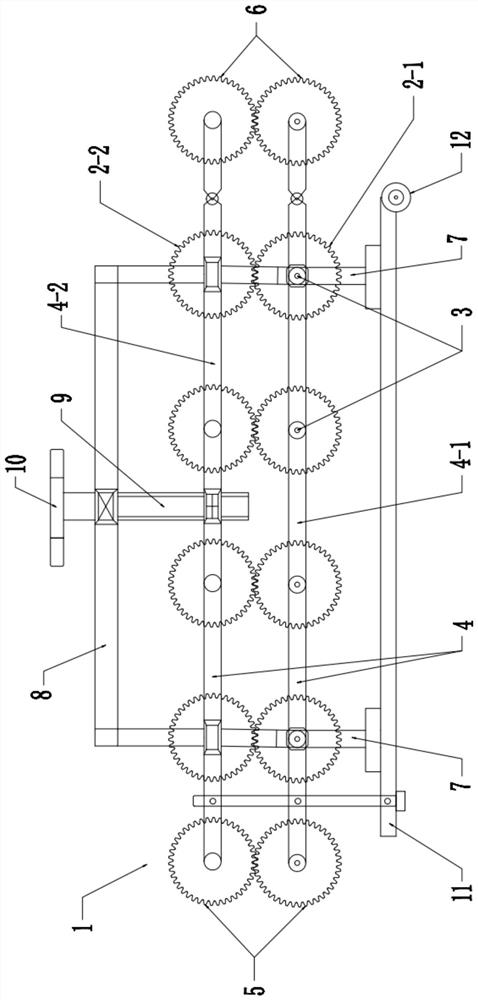

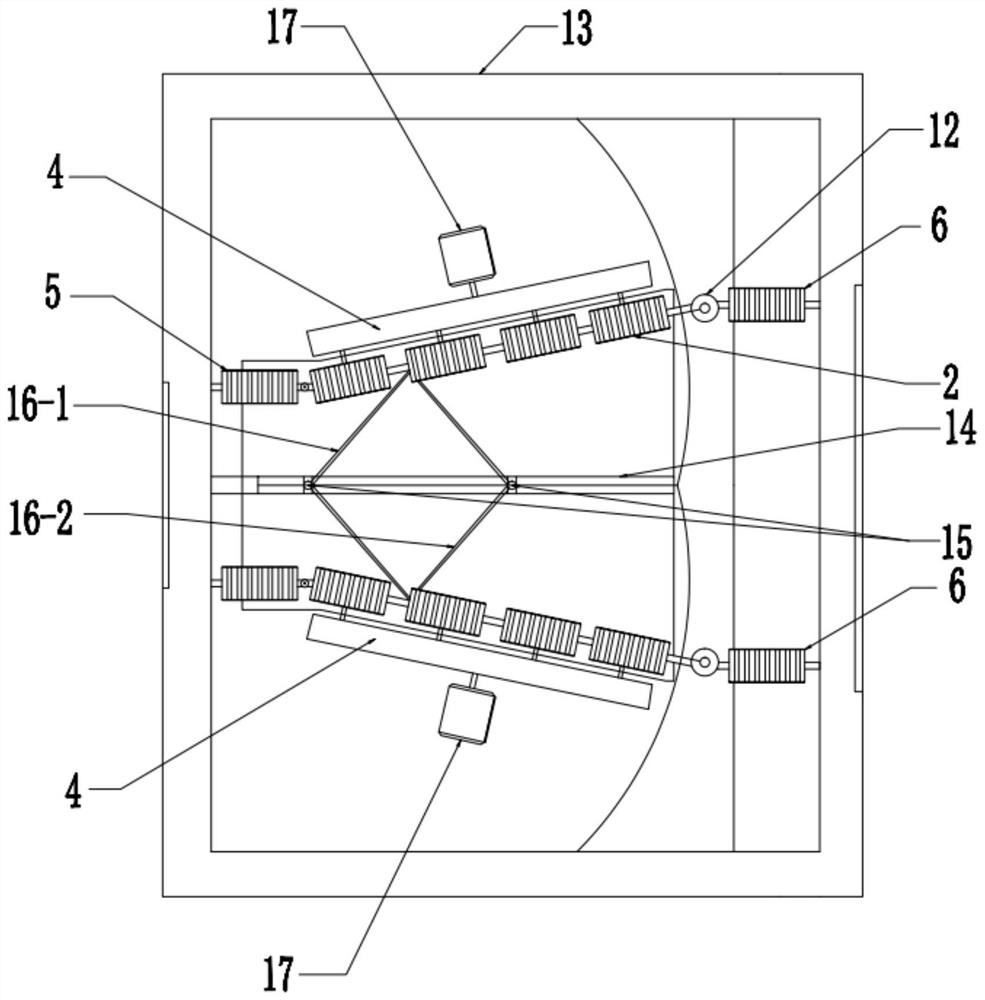

[0070] Such as figure 1 , figure 2As shown, a gear-driven film synchronous biaxial stretching device includes a differential meshing gear mechanism 1, an meshing clamping force adjustment assembly, an opening angle adjustment assembly, a main body base 13 and a transmission motor 17,

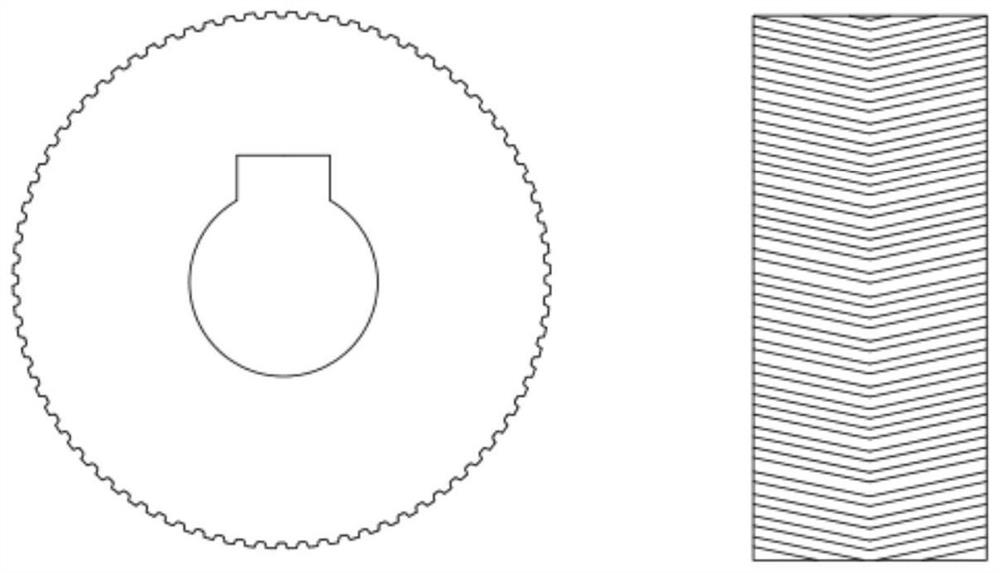

[0071] The differential meshing gear mechanism 1 includes 8 sets of clamping gear sets 2, the clamping gear set 2 is mainly composed of two clamping gears (2-1, 2-2) meshing with each other, and the gear shaft 3 Drive one of the clamping gears 2-1 to rotate, and drive the other clamping gear (2-2) to rotate at the same speed and reverse at the same speed, and the film to be processed is clamped and transmitted through the contact ...

Embodiment 2

[0097] This example is a specific implementation method for preparing a biaxially stretched polyvinyl alcohol film with a transverse stretch ratio of 3.0 and a longitudinal stretch ratio of 3.0, wherein the raw materials of the polyvinyl alcohol film are self-made:

[0098] A gear-driven film synchronous bidirectional stretching device, including a differential meshing gear mechanism, an meshing clamping force adjustment component, an opening angle adjustment component, a main body base and a transmission motor,

[0099] The differential meshing gear mechanism includes 12 sets of clamping gear sets, the clamping gear sets are mainly composed of two clamping gears meshing with each other, one of them is driven to rotate by the gear shaft, and the other clamping gear is driven The holding gear rotates in the opposite direction at the same speed, and the film to be processed is clamped and transmitted by the contact surface at the meshing point. The width of the contact surface me...

Embodiment 3

[0120] This example is a specific implementation method for preparing a biaxially stretched polyvinyl alcohol film with a transverse stretch ratio of 2.0 and a longitudinal stretch ratio of 4.0, wherein the raw materials of the polyvinyl alcohol film are self-made:

[0121] A gear-driven film synchronous bidirectional stretching device, including a differential meshing gear mechanism, an meshing clamping force adjustment component, an opening angle adjustment component, a main body base and a transmission motor,

[0122] The differential meshing gear mechanism includes 16 sets of clamping gear sets, the clamping gear sets are mainly composed of two clamping gears meshing with each other, one of them is driven to rotate by the gear shaft, and the other clamping gear is driven to engage with it. The holding gear rotates in reverse at the same speed, and the film to be processed is clamped and transmitted by the contact surface at the meshing point. The width of the contact surfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com