Injection molding equipment for hollow pipe fitting

A technology for injection molding equipment and hollow pipe fittings, which is applied in the field of injection molding equipment for hollow pipe fittings, can solve problems such as the surface finish of products that cannot guarantee material flow compactness, and achieve the effect of ensuring the overall compactness of products, ensuring product quality, and reducing equipment failure rates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] The injection molding equipment of the hollow pipe fitting of the present embodiment, the device comprises:

[0054] Injection molding machine 1000, the material flow for injection molding hollow pipe fittings;

[0055] Cooling and shaping unit 2000, which is arranged on the side of the product outlet of the injection molding machine 1000, to cool and shape the injection molding product;

[0056] Traction unit 3000, which is arranged on one side of the cooling and shaping unit 2000, and pulls the injection molded product for cooling and shaping;

[0057] A cutting unit 4000, which is arranged on one side of the traction unit 3000, cuts the injection molded product into a specified length;

[0058] The injection molding machine 1000 is provided with an injection mold 100 for forming a hollow pipe, and the injection mold 100 includes:

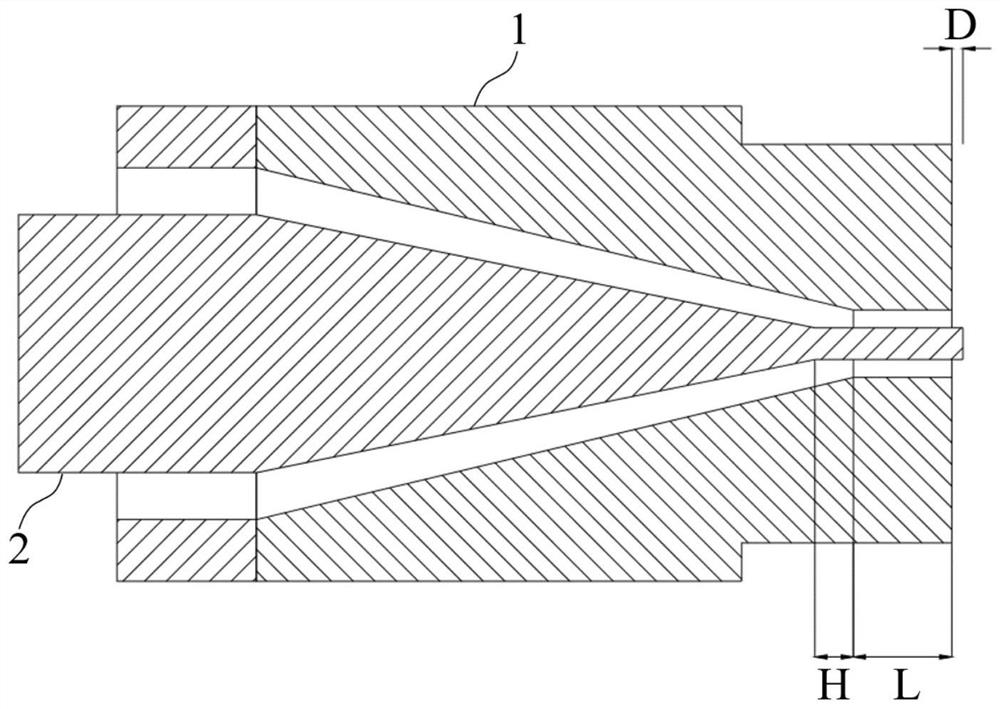

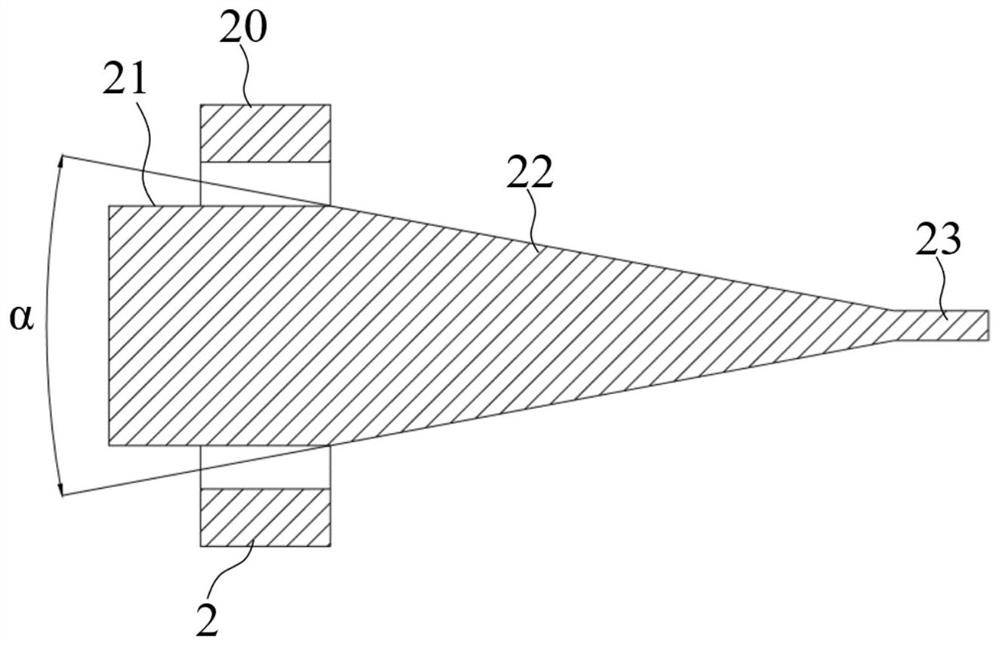

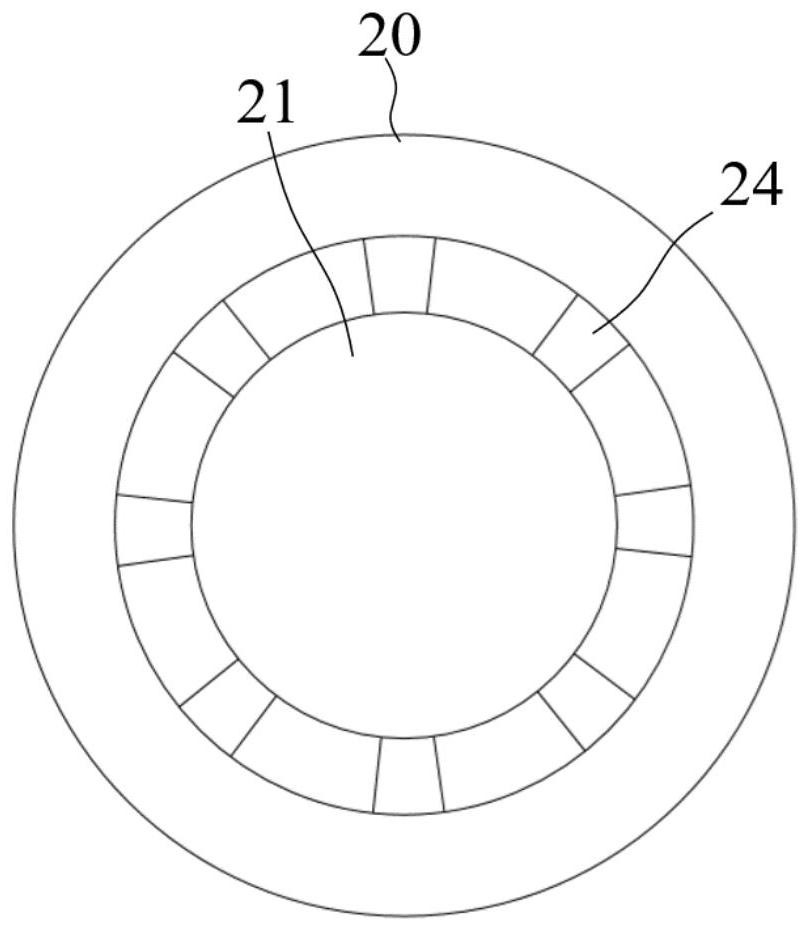

[0059] Die cover 1, which is hollow columnar;

[0060] Cone angle hole section 10, which is opened in the middle of one end face of di...

Embodiment 2

[0070] The injection molding equipment for hollow pipe fittings of this embodiment is further improved on the basis of Embodiment 1. The cutting unit 4000 is slidably connected to the slideway 4001, and the length direction of the slideway 4001 is set parallel to the moving direction of the injection molded product. At this time, the cutting unit 4000 moves along the length direction of the slideway 4001 through the driving member, and the moving speed is the same as that of the injection molded product.

[0071] Since the injection molding machine 1000 is in uninterrupted production, the injection molded product is constantly moving under the traction of the traction unit 3000, and the cutting action of the cutting unit 4000 is perpendicular to the moving direction of the injection molded product. During the period from the product to the completion of cutting, the injection molded product cannot be moved, which will inevitably affect the action of the traction unit 3000 and t...

Embodiment 3

[0073] The injection molding equipment for hollow pipes in this embodiment is further improved on the basis of Embodiment 2. The core segment 23 of the mold core 2 protrudes from the mold sleeve 1 at a distance D, and 1mm≤D≤2mm.

[0074] like figure 1 As shown, the core section 23 protrudes out of the mold sleeve 1 to a suitable length, which can play a certain guiding role for the hollow pipe fittings produced by molding, and can also effectively prevent the hollow part from closing and deforming after the pipe fittings protrude. However, the core section 23 The distance D extending out of the mold sleeve 1 is too long, which will cause the inner wall to shrink during the extrusion process of the hollow pipe fittings, which will affect the product quality. If D is too short, it will not play its due role. 1mm≤D≤2mm, the best effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com