Multilayer multifunctional composite fabric and composite process thereof

A composite cloth and multi-functional technology, applied in layered products, metal layered products, synthetic resin layered products, etc., can solve the problems of affecting the appearance, poor shading effect of curtains, easy peeling or fading of fabrics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0098] A multi-layer multifunctional composite cloth comprises a first surface layer, a middle interlayer and a second surface layer which are sequentially connected. The middle interlayer includes a first light-shielding layer, an inner core and a second light-shielding layer connected in sequence. The first light-shielding layer includes at least one layer of colored masterbatch and one layer of black masterbatch, the second light-shielding layer includes at least one layer of colored masterbatch and one layer of black masterbatch, and the inner core is PP polyethylene.

[0099] The colored masterbatch layer is extruded from the masterbatch through a multi-layer extruder. For example, the composition of white masterbatch is as follows: titanium dioxide 60%-70%, modified silicon powder 10%-15%, antioxidant 0.1%- 2%, polyethylene wax 0.1%-2%, zinc stearate 0.1%-2%, slip agent 0.1%-2%, flame retardant 10%-15%. Its component content is determined according to customer needs.

...

Embodiment 2

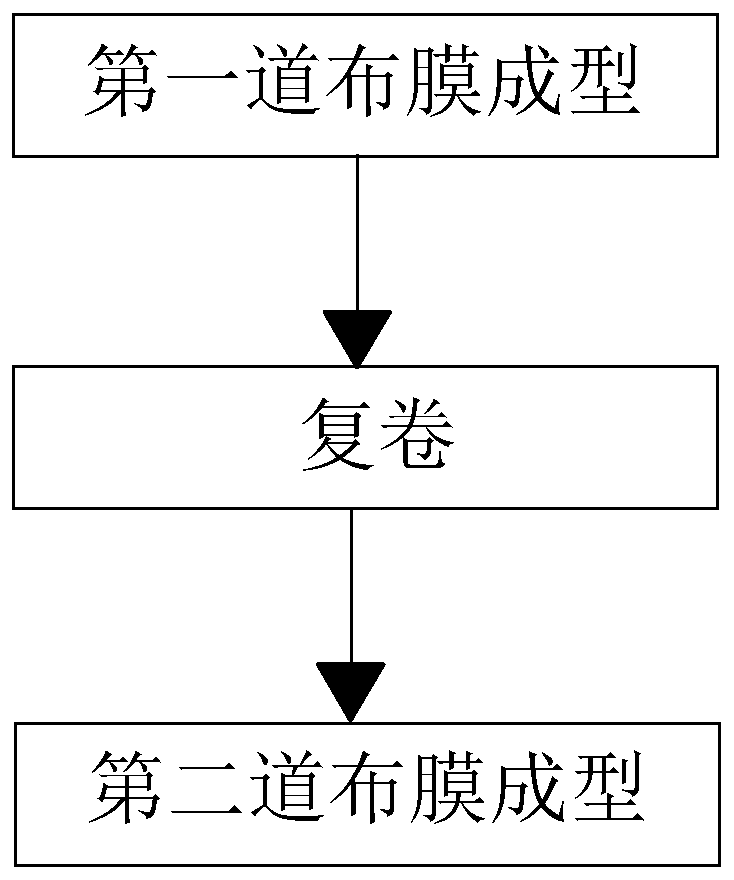

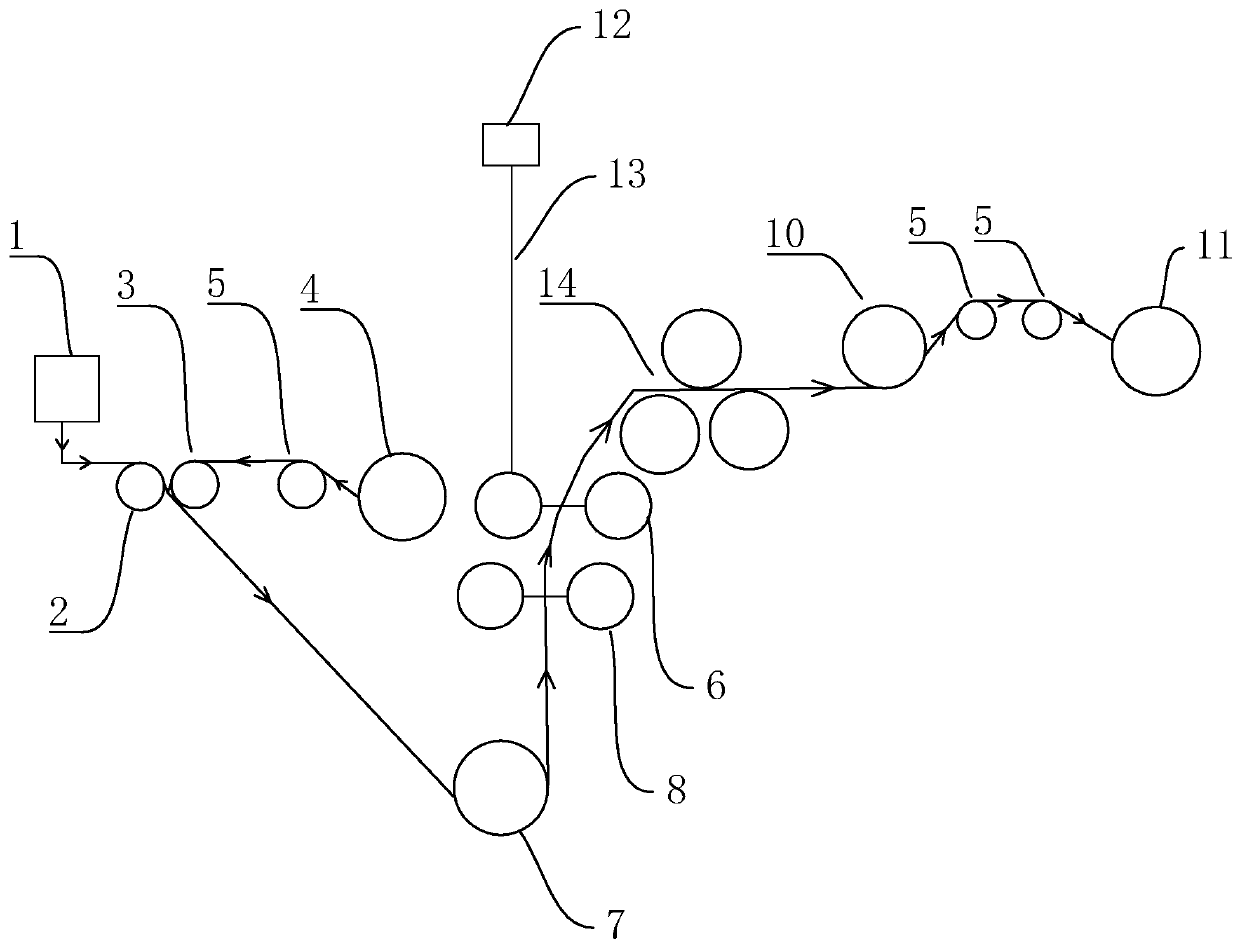

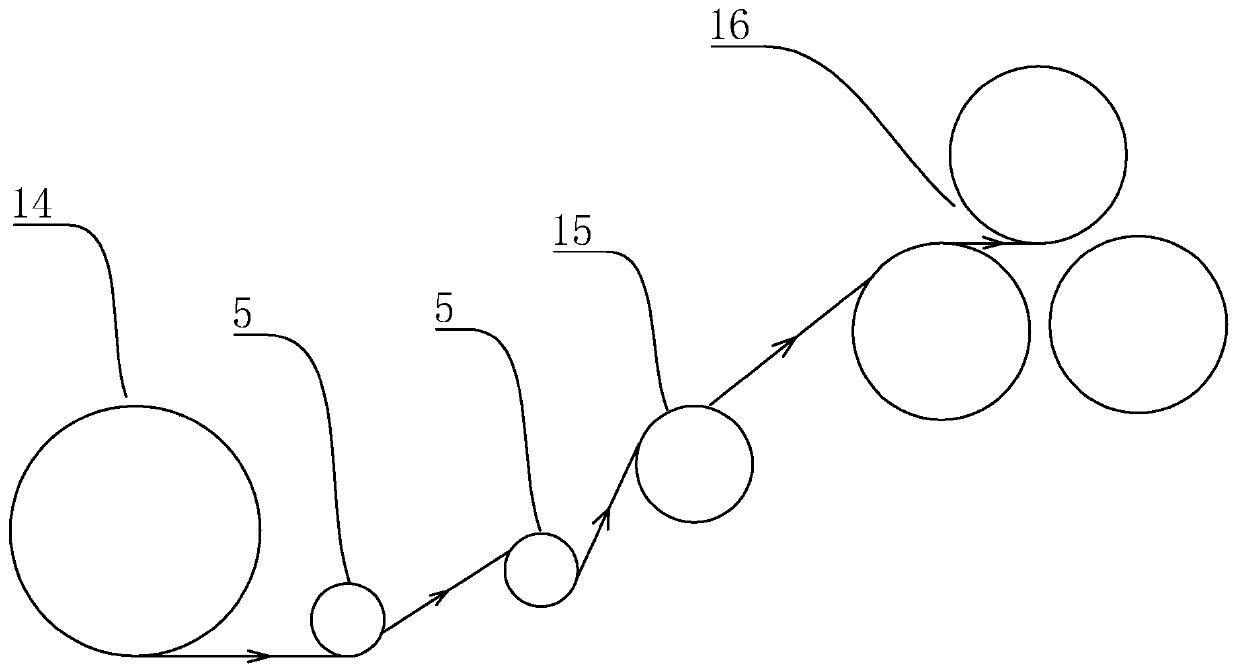

[0122] The present invention provides another processing method for multi-layer multifunctional composite cloth, the process of which is as follows: S01, co-extrusion heat bonding to form the first light-shielding layer; S02, co-extrusion heat bonding to form the second light-shielding layer; S03, the second light-shielding layer One-time hot-sol lamination with film cloth; S04, second hot-sol lamination with film cloth.

[0123] Wherein, step S01 co-extrusion thermal bonding to form the first light-shielding layer is the same as step S02 co-extrusion thermal bonding to form the second light-shielding layer, and the steps are as follows:

[0124] S011, the third extruder, and the fourth extruder respectively extrude the color masterbatch layer and the black masterbatch layer;

[0125] S012, the third extruder, and the fourth extruder are equipped with a double-station spreading frame, and the extruded color masterbatch layer and black masterbatch layer are respectively combine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com