Forming method of temporary metallic mold

A metal mold and molding method technology, applied in other manufacturing equipment/tools, turbines, engine components, etc., can solve the problems of low mold times and high production costs, and achieve the effects of low cost, easy processing and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

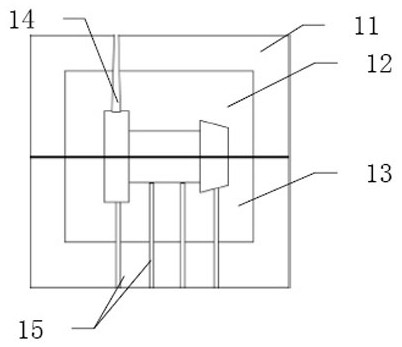

[0040] Goal is to form figure 1 A temporary metal mold shown, specifically, in the mold frame 11, a front temper straightener 12, and a store insert 13, in front of the front modes 12, except for the product cavity, there is also an adhesive The aperture 14, in addition to the product cavity, in addition to the product cavity, in addition to the product cavity, the material of the product is HDPE (high density polyethylene), and the melting point is approximately 135 ° C.

[0041] The pretty tutore 12 is similar to the molding method of the compulsion 13, in which the product type cavity formation process is used as an example, the forming method of the temporary metal mold is explained.

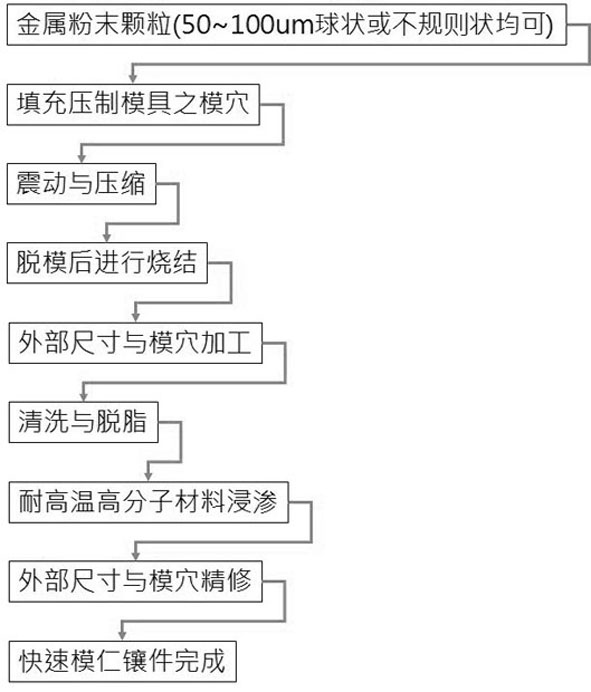

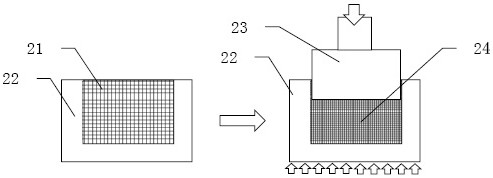

[0042] like figure 2 As shown, the molding process generally includes: first filled the metal powder and the binder into the model to heat the metal green body, then release sintering, followed by roughing according to the mold design of the product, cleaning the degreasing with polymer material...

Embodiment 2

[0053] Example 2 Comparative Experiment

[0054] Example 1, Comparative Example 1 and a modulus of ratio 2 were intensified, the processing duration, cost, and modules were tested, and the experimental data was shown in Table 1.

[0055] Among them, the hardness test is specified by the Rockwalk hardness meter;

[0056] The length of the five model inserts of the processing is processed as an example;

[0057] Cost is an example of the cost of 5 model inserts of the same processing;

[0058] Module Test For processing of modes inserts for injection molding.

[0059] Table 1

[0060]

[0061] Through the above experiment, the technical solution provided by the present invention is not as low as 3D printing product, but the alignment ratio 2 is significantly dominant, while the length and processing cost of processing, the first embodiment is approximately, but the ratio ratio 1 Nice should be less and low, the most important thing is that the mold in the modulation test is fully ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com