Secondary control rolling force forecasting method of hot mill

A technology of secondary control and rolling force, applied in the direction of rolling force/roll gap control, etc., to achieve the effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

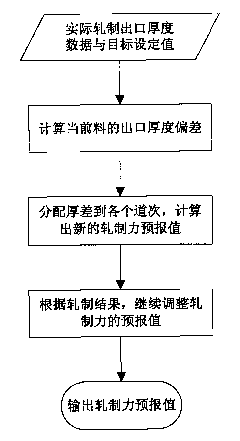

[0023] figure 1 It is a schematic diagram of the rolling force prediction method of the present invention. First, set the roll gap under the forecasted value of the initial rolling force, roll, and calculate the deviation between the actual exit thickness of the current material and the set target value according to the exit thickness of the strip at the last pass of rolling; These deviations are allocated to each pass in proportion, and the adjustment amount of rolling force on each pass is calculated to obtain a new forecast value of rolling force; then, according to the rolling results under the new forecast value of rolling force, further determine the rolling force. The amount of adjustment of the braking force, such a cycle makes the final outlet thickness meet the production requirements through a limited number of adjustments.

[0024] figure 2 It is a schematic diagram of the thickness difference distribution rate curve of each pass. The figure shows the distribut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com