Preparation method of perovskite quantum dot film

A quantum dot film and perovskite technology, applied in the field of perovskite quantum dot film, can solve the problems of low fluorescence efficiency, poor photostability, high requirements, etc., and achieve simple process, ultra-high photostability, and high fluorescence quantum yield. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

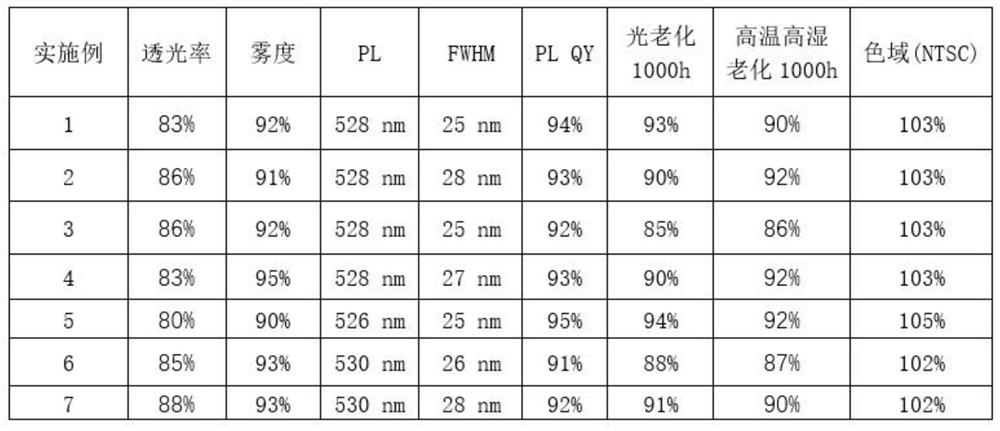

Examples

Embodiment 1

[0019] Embodiment 1: A kind of preparation method of perovskite quantum dot film

[0020] 1) Preparation of perovskite quantum dot polymer particles

[0021] 4.0mmol of PbBr 2 , oleic acid (32mmol), and oleylamine (32mmol) were charged into a 10L stirring tank, and vacuum-dried at 120° C. for 30 minutes to remove moisture in the raw materials. The resulting mixture was heated to 150 °C under nitrogen until the PbBr 2 completely dissolved. Then the temperature was raised to 180° C. and 4 kg of thermoplastic elastomer SEBS G1657M was added. After it was completely melted, 0.16 mmol of cesium oleate precursor was injected. Subsequently, 0.1kg of titanium dioxide diffusion particles and 0.01kg of antioxidant 1010 were mixed thoroughly, and the uniformly mixed product was vacuum defoamed and then added to a twin-screw extruder, and the extruded product was cooled and granulated to obtain the desired product. perovskite quantum dot polymer particles;

[0022] 2) Preparation of ...

Embodiment 2

[0024] Embodiment 2: a kind of preparation method of perovskite quantum dot film

[0025] 1) Preparation of perovskite quantum dot polymer particles

[0026] 4.0mmol of PbBr2, oleic acid (32mmol), and oleylamine (32mmol) were charged into a 10L stirred tank, and vacuum-dried at 120°C for 30min to remove the moisture in the raw materials. The resulting mixture was heated to 150 °C under nitrogen until the PbBr2 was completely dissolved. Then raise the temperature to 180° C. and add 4 kg of acrylic block copolymer LA2330. After it is completely melted, inject 0.16 mmol of cesium oleate precursor. Subsequently, 0.1 kg of titanium dioxide diffusion particles and 0.01 kg of antioxidant 1010 were added respectively, and after being fully stirred, the uniformly mixed product was vacuum defoamed and then added to a twin-screw extruder, and the extruded product was cooled and granulated to obtain the obtained The required perovskite quantum dot polymer particles;

[0027] 2) Prepara...

Embodiment 3

[0029] Embodiment 3: a kind of preparation method of perovskite quantum dot film

[0030] Repeat Example 1, the difference is only in step 1) in the preparation of perovskite quantum dot polymer particles, the thermoplastic elastomer is EVA, and the brand is Levamelt@686.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com