Modification method for flip-chip packaging integrated circuit

An integrated circuit and flip-chip technology, applied in the field of modification of integrated circuits, can solve the problem of inability to observe the chip structure, and achieve the effect of meeting thickness requirements, high thinning precision and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

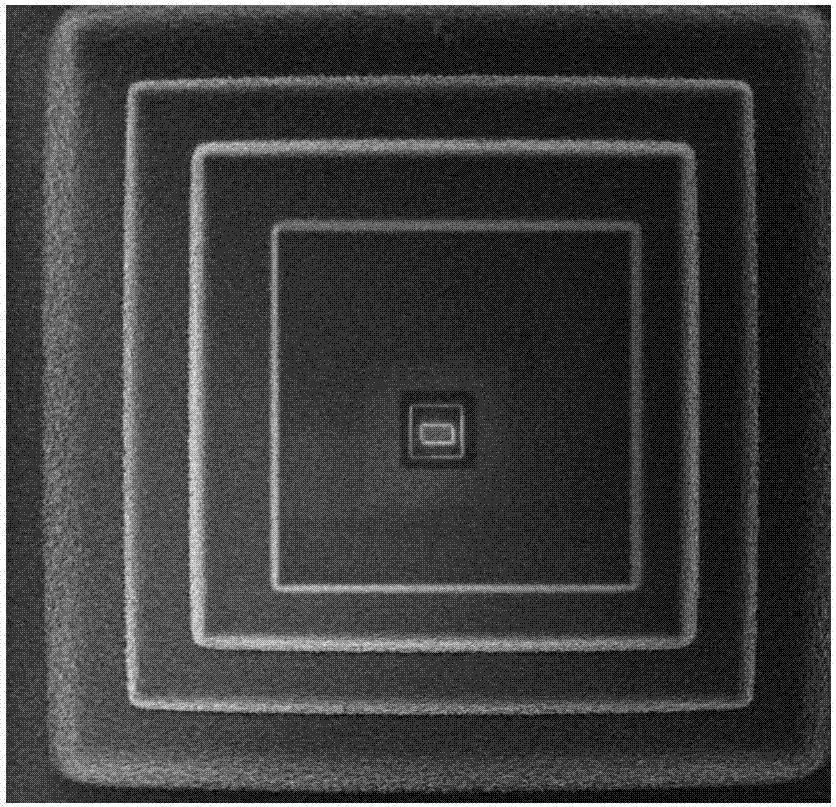

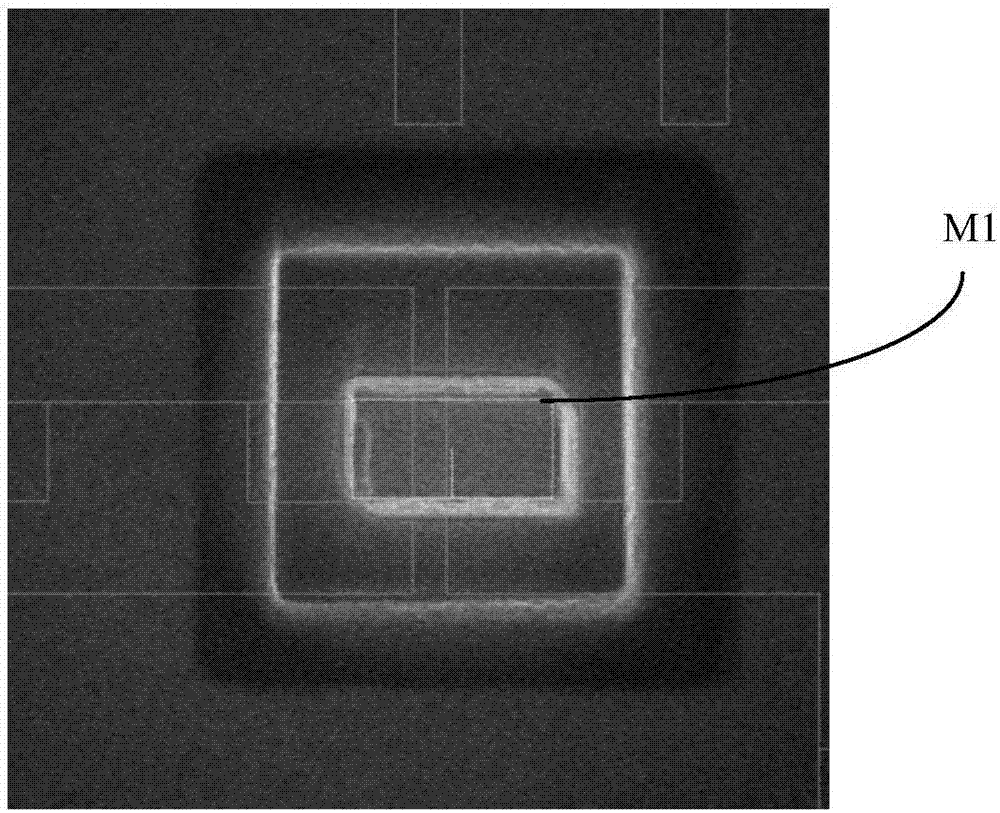

[0044] This embodiment is a method for modifying a circuit of a flip-chip packaged integrated circuit. The integrated circuit includes a substrate and a chip that is flip-chip packaged on the substrate. area.

[0045] The circuit modification method includes the steps of:

[0046] (1) Grinding the chip, reducing the original thickness of the chip from 393 μm to 70-80 μm; specifically, the grinding method is: firstly use diamond abrasive paper with a particle size of 25-35 μm for rough grinding; Finely grind with diamond abrasive paper with a diameter of 10-20 μm; then polish with a diamond suspension with a particle size of 4-8 μm and a polishing cloth, and then polish and fine-grind with a diamond suspension with a particle size of 0.5-2 μm and a flocking cloth;

[0047] (2) Using FIB combined with etching auxiliary gas (such as XeF 2 ) performing the first etching on the chip after grinding, and thinning the chip to about 4 μm;

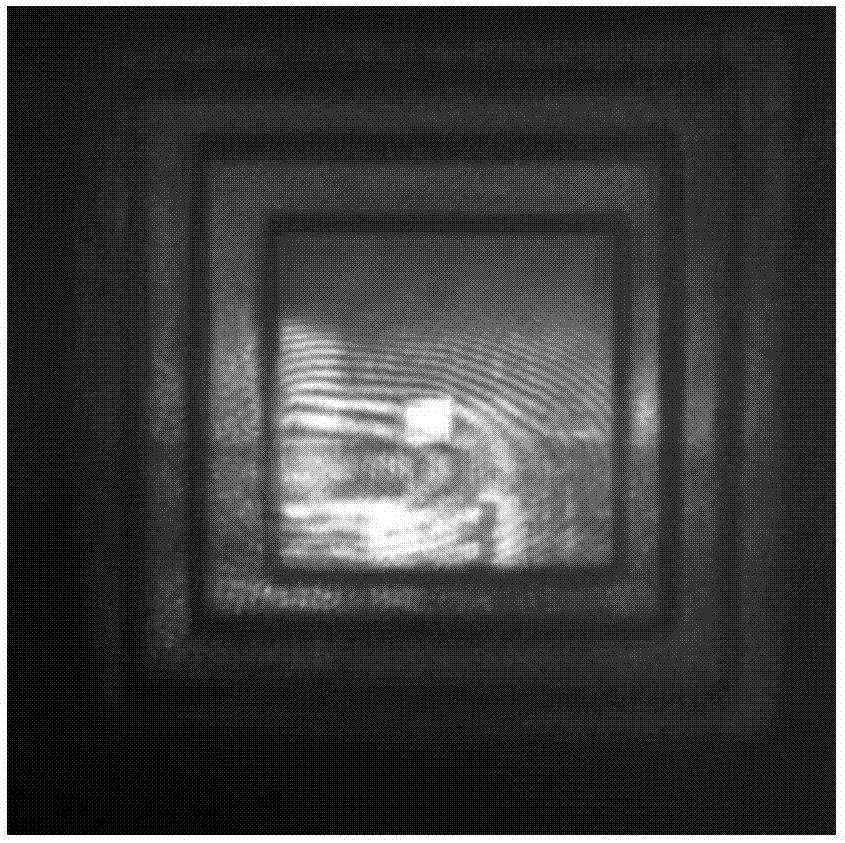

[0048] (3) Imaging the chip after etching, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com