Circuit substrate and method of manufacturing same

A technology for circuit boards and circuit parts, applied in the directions of printed circuit manufacturing, printed circuits, printed circuits, etc., can solve the problems of increasing the overall thickness of components and reducing the installation area, and achieve the effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach >

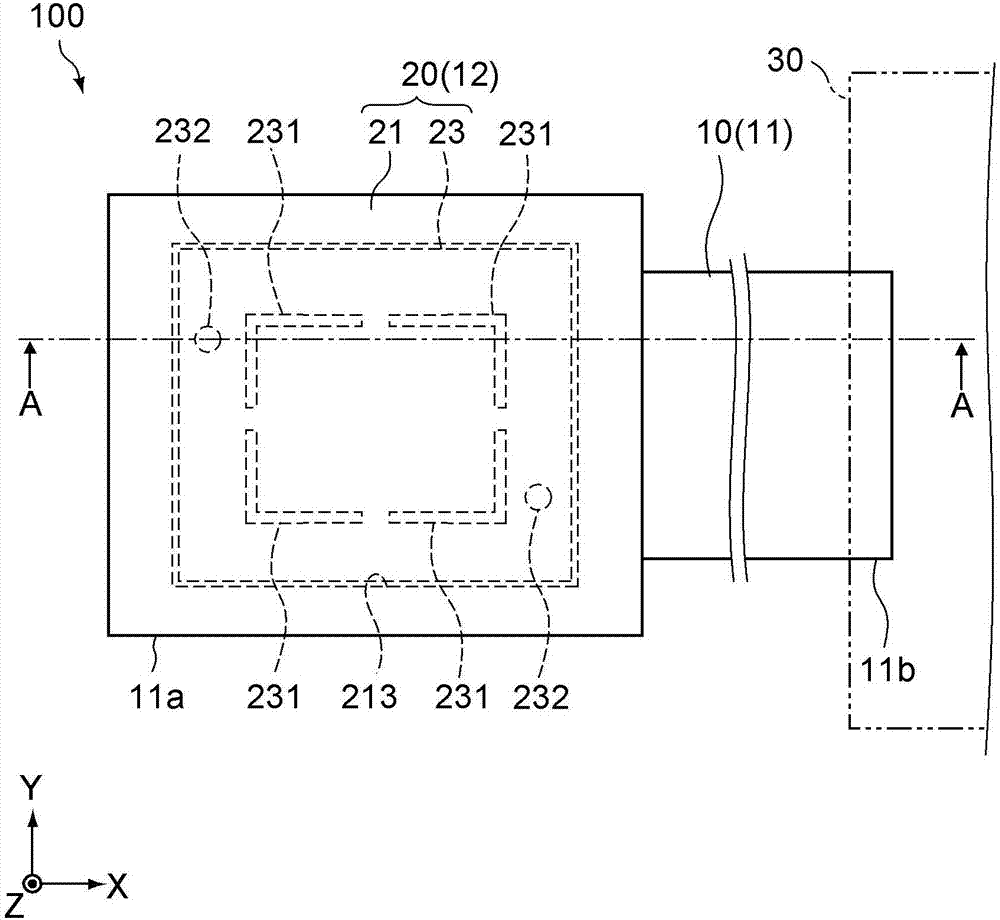

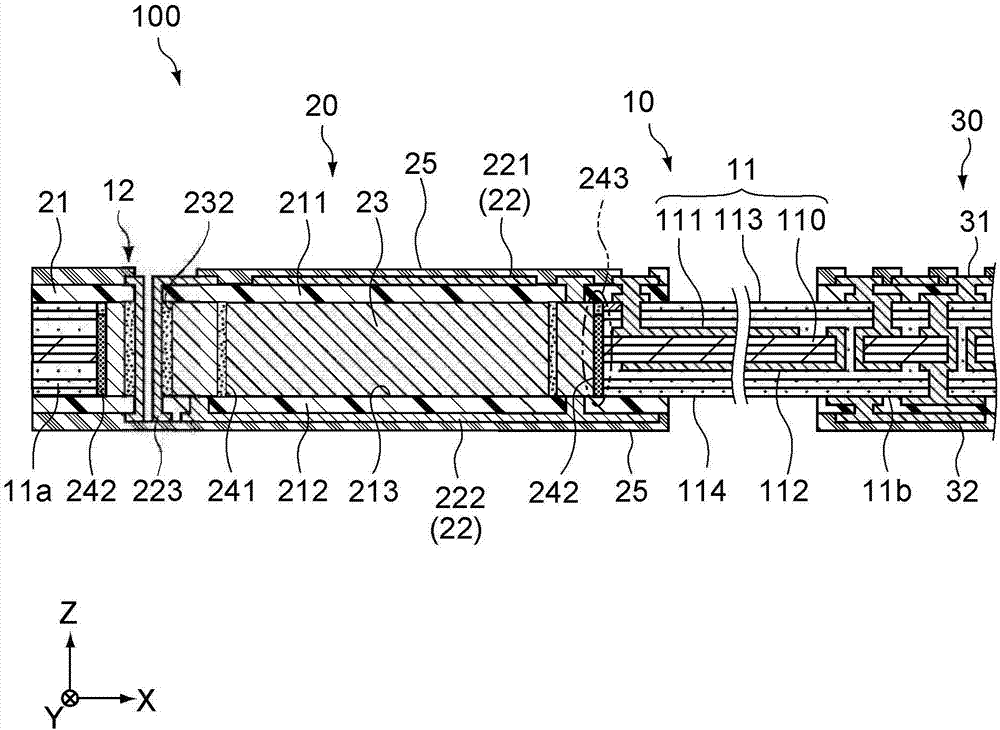

[0040] figure 1 It is a schematic plan view showing the structure of a circuit board according to an embodiment of the present invention. figure 2 Yes figure 1 A-A line direction sectional view of . Wherein, the X-axis, Y-axis and Z-axis in each figure represent the three-axis directions orthogonal to each other, and the Z-axis direction corresponds to the thickness direction of the circuit board.

[0041] [circuit board]

[0042] The circuit board 100 of this embodiment has a first circuit board body 10 and a second circuit board body 20 . The circuit board 100 is typically formed integrally with the control circuit board 30 , but may be formed as a separate component from the control circuit board 30 .

[0043] (first circuit board main body)

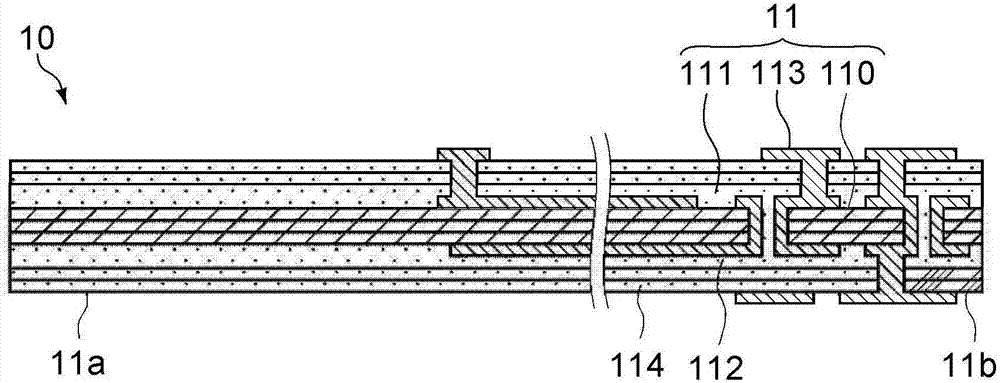

[0044] The first circuit board main body 10 is composed of a flexible wiring base 11 connecting the second circuit board main body 20 and the control circuit board 30 , and constitutes a flexible portion in the circuit board 100...

no. 2 approach >

[0084] Figure 5 It is a schematic side sectional view showing the structure of a circuit board 200 according to another embodiment of the present invention. The following description will mainly focus on the configurations different from those of the first embodiment, and the descriptions of the same configurations as those of the first embodiment will be omitted or simplified by assigning the same symbols.

[0085] The circuit board 200 of this embodiment is the same as that of the first embodiment in that it has a first circuit board body 10 and a second circuit board body 20 , but this embodiment includes electronic components 26 buried in the second circuit board body 20 This point is different from the first embodiment.

[0086] In this embodiment, the second circuit board main body 20 includes: a resin layer 21 selectively covering the first end portion 11a of the flexible wiring base material 11; a circuit portion 22 provided on the resin layer 21; The reinforcing me...

no. 3 approach >

[0093] Image 6 It is a schematic side sectional view showing the structure of a circuit board 300 according to another embodiment of the present invention. The following description will mainly focus on the configurations different from those of the first embodiment, and the descriptions of the same configurations as those of the first embodiment will be omitted or simplified by assigning the same symbols.

[0094] The circuit board 300 of this embodiment is the same as the first embodiment in that it has a first circuit board body 10 and a second circuit board body 20 , but in this embodiment, a reinforcement member 270 is embedded in the second circuit board body 20 The point that the multilayer substrate 27 is the core differs from the first embodiment.

[0095] In this embodiment, the second circuit board main body 20 includes: a resin layer 21 selectively covering the first end portion 11a of the flexible wiring base material 11; a circuit portion 22 provided on the res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com