Driving structure and periscope type camera module

A driving structure and mover technology, applied in electric components, image communication, TV and other directions, can solve the problems of inability to rotate in multiple dimensions, affecting the appearance of mobile phones, poor anti-shake effect, etc., to save time, adjust the function sensitively, reduce high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

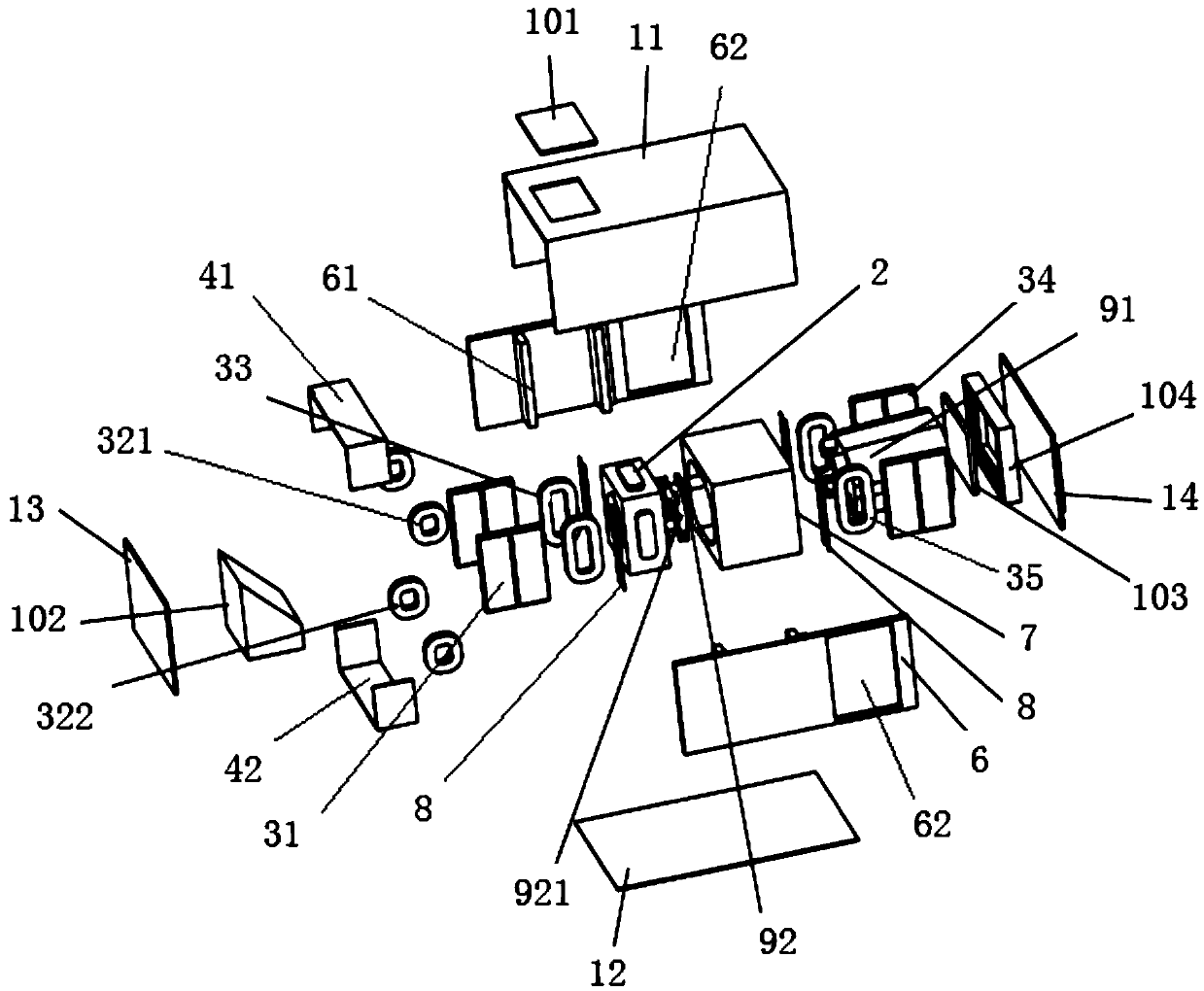

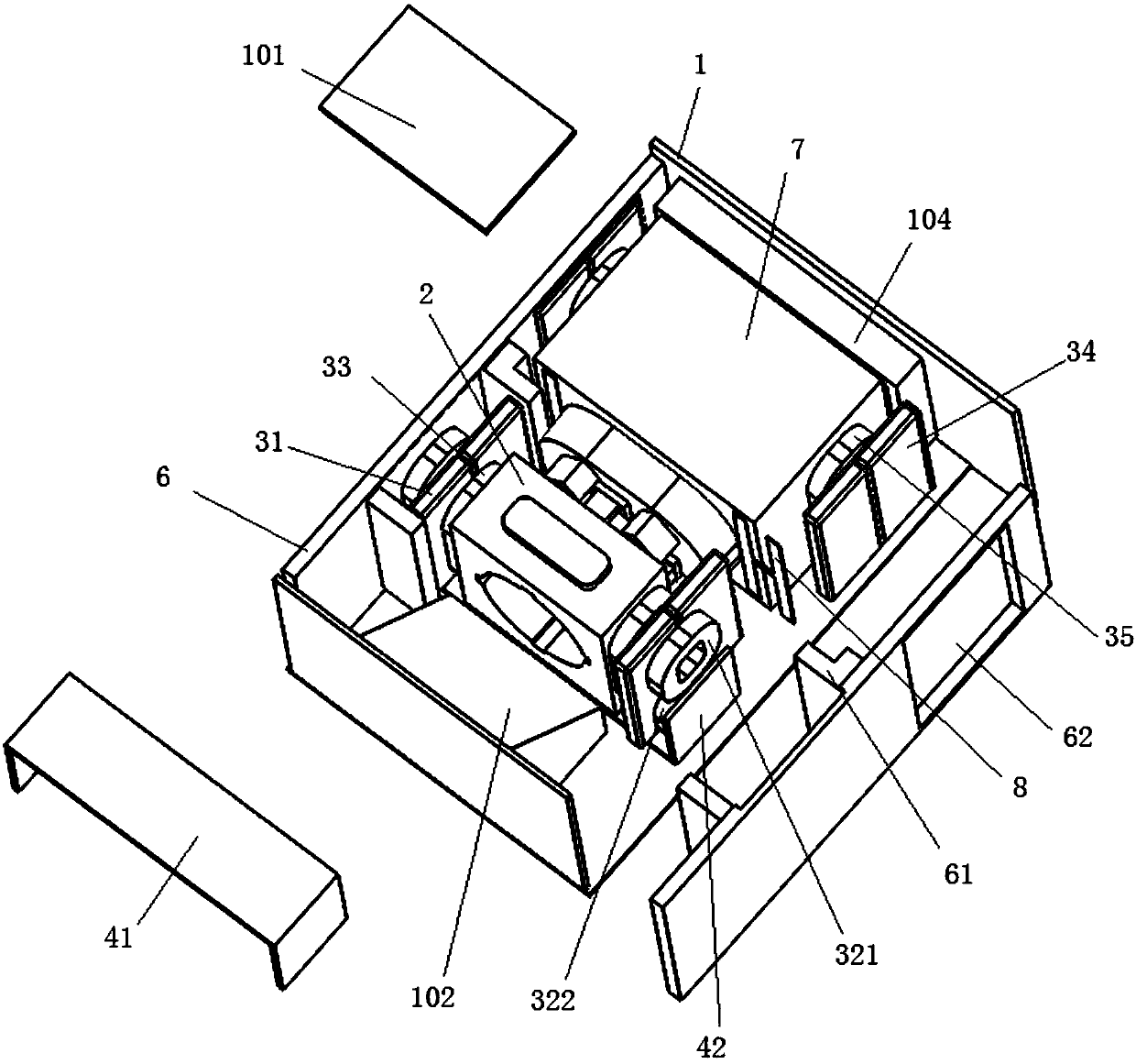

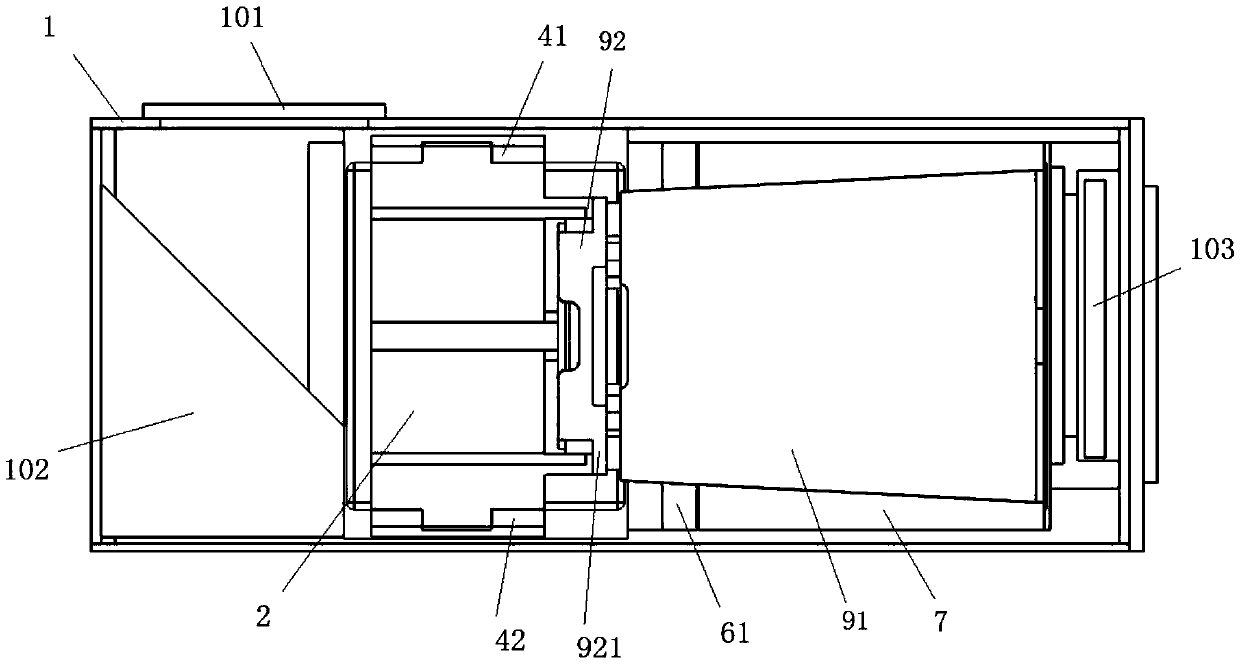

[0034] For the driving structure of this embodiment, refer to figure 1 - Figure 4 , including a seat body 1 , a carrier 2 , a drive assembly, a mounting frame 7 , a reset member 8 and a spacer 6 .

[0035] The base body 1 is used for installing the first lens 91 and the liquid lens 92 arranged along the optical axis and corresponding to each other. The seat body 1 includes an upper shell 11, a lower shell 12, a front shell 13 and a rear shell 14. The carrier 2, the drive assembly, the mounting frame 7, the reset member 8 and the gasket 6 are arranged on the upper shell 11, the lower shell The body 12, the front shell 13 and the rear shell 14 enclose the installation cavity.

[0036] The carrier 2 can move toward or away from the first lens 91 and is arranged in the seat body 1. When the carrier 2 moves, it can abut against the moving plate of the liquid lens 92 to drive the moving plate to move to The curvature of the liquid lens 92 is adjusted. In this embodiment, the br...

Embodiment 2

[0058] The periscope camera module of the present embodiment, such as Figure 1 to Figure 4 As shown, it includes the driving structure, the first lens 91 , the liquid lens 92 , the dustproof mirror 101 and the reflection mirror 102 in the first embodiment.

[0059] The first lens 91 and the liquid lens 92 are arranged in the housing 1 along the optical axis. In this embodiment, the liquid lens 92 is fixedly arranged on the first lens 91, that is, the first lens 91 is suspended in the base body 1 through the reset member 8 , and the carrier 2 , the first mover and the second mover are suspended in the base body 1 through the bracket 921 .

[0060] The dust-proof mirror 101 is arranged on the upper side wall of the base body 1 , and the light enters into the base body 1 through the dust-proof mirror 101 .

[0061] The reflector 102 is arranged in the seat body 1 corresponding to the dust-proof mirror 101, and is located on one side of the optical axis direction of the first le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com