Fillet feeding diaphragm filter plate assembly constituted by flat membrane and filter board

A membrane filter plate and feeding technology, which is applied in the direction of filtration separation, separation method, chemical instrument and method, etc., can solve the problem of not being able to improve the purification rate of the effective components of the slurry, and unable to realize the organic combination of the filter cloth filter plate and the membrane filter plate , Unable to achieve high-efficiency filtration of filter cloth and diaphragm, etc., to achieve the effect of improving the clean rate, fast filtration, and improving the clean rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

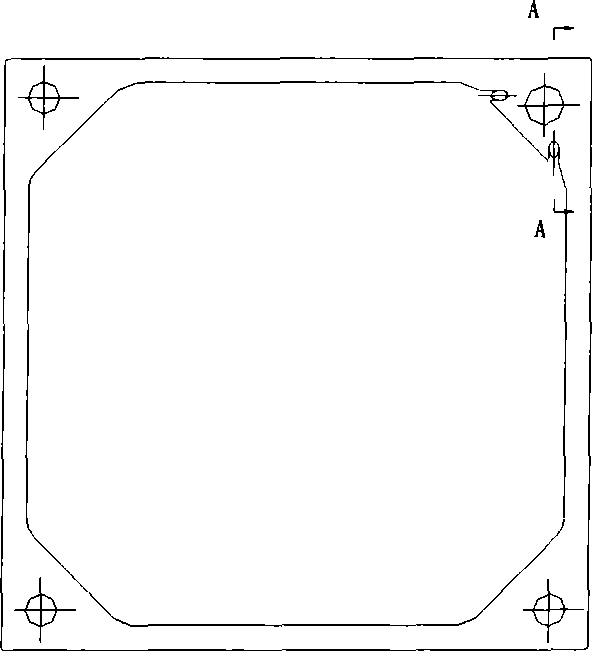

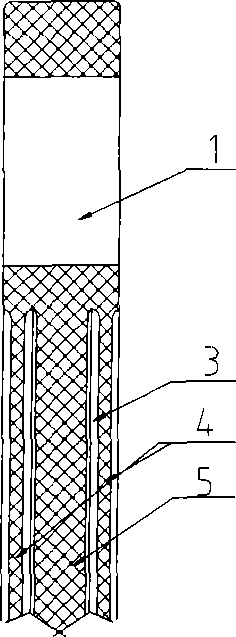

[0031] Embodiment 1: with reference to attached figure 1 and 2 . Flat membrane single-angle feeding through-hole filter plate, which includes a core plate 5 and a flat membrane 4, the flat membrane 4 and the core plate 5 are processed and formed by the prior art, the flat membrane 4 is located on the core plate 5, and the corner of the core plate 5 is opened There is a feeding through hole 1, and there is a feeding branch hole 2 between the groove wall (inclined groove wall) of the groove of the core plate and communicates with the feeding through hole 1, and the bottom surface of the groove groove of the core plate 5 (core plate groove bed) ---Equivalent to the river bed) and the flat diaphragm 4 to form the tympanic membrane cavity 3, the feeding branch hole 2 is obliquely connected with the feeding through hole, and the orifice of the feeding branch hole 2 is open to the atmosphere.

[0032] Refer to attached image 3 and 4 . The integral angle-feeding filter cloth fil...

Embodiment 2

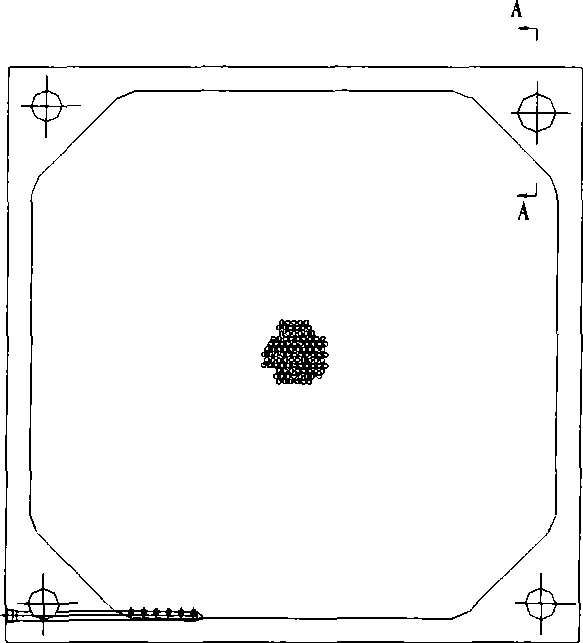

[0034] Embodiment 2: with reference to attached Figure 6 and 7 . The flat diaphragm diagonally feeds through-hole filter plate, which includes a core plate 5 and a flat diaphragm 4. The flat diaphragm 4 and the core plate 5 are processed and formed by the existing technology. The flat diaphragm 4 is located on the core plate 5, and the diagonal part of the core plate 5 Feed through hole 1 is provided, a pair of diagonals of the filter plate formed by flat diaphragm 4 and core plate 5 are discharge holes, a pair of diagonals are feed through hole 1, the groove wall of the groove of core plate 5 ( There is a feed branch hole 2 between the inclined surface groove wall and it is connected with the feed through hole 1, and the bottom surface of the groove groove of the core plate 5 (core plate groove bed---equivalent to the river bed) and the flat diaphragm 4 form the tympanic cavity 3 , the feed branch hole 2 is obliquely communicated with the feed through hole, and the orifice...

Embodiment 3

[0037] Embodiment 3: with reference to attached Figure 11 and 12 . Flat diaphragm double-angle feeding through-hole filter plate, which includes a core plate 5 and a flat diaphragm 4, the flat diaphragm 4 and core plate 5 are processed and formed by the prior art, the flat diaphragm 4 is located on the core plate 5, and the corners of the core plate 5 are opened There is a feeding through hole 1, and there is a feeding branch hole 2 between the groove wall (inclined groove wall) of the groove of the core plate and communicates with the feeding through hole 1, that is to say, the flat diaphragm 4 and the core plate 5 constitute The double corners on one side of the filter plate are discharge holes, and the double corners on one side are feed through holes 1, and the feed through holes 1 communicate with the feed branch holes 2 between the groove walls of the core plate 5. The tympanic membrane cavity 3 is formed between the groove bottom surface of the core plate 5 (core pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com