Device and method for producing paper for daily use and paper for daily use

A technology for household paper and manufacturing equipment, applied in household appliances, machining/deformation, etc., can solve the problems of increasing the surface roughness of the paper, the thickness of the household paper cannot meet the demand, and affecting the performance of the hand feel of the household paper. Good hand feeling, the effect of solving the thickness of the paper body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

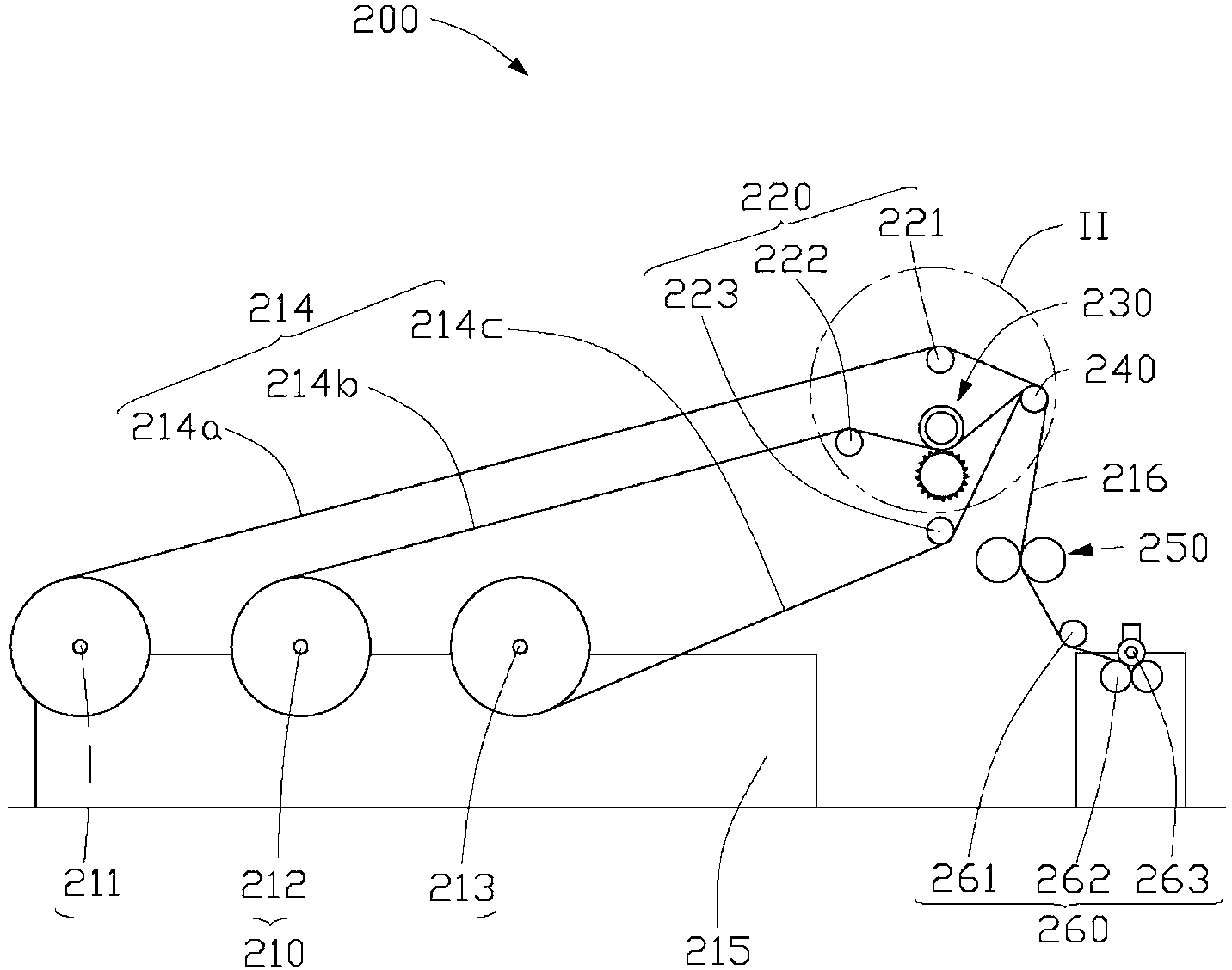

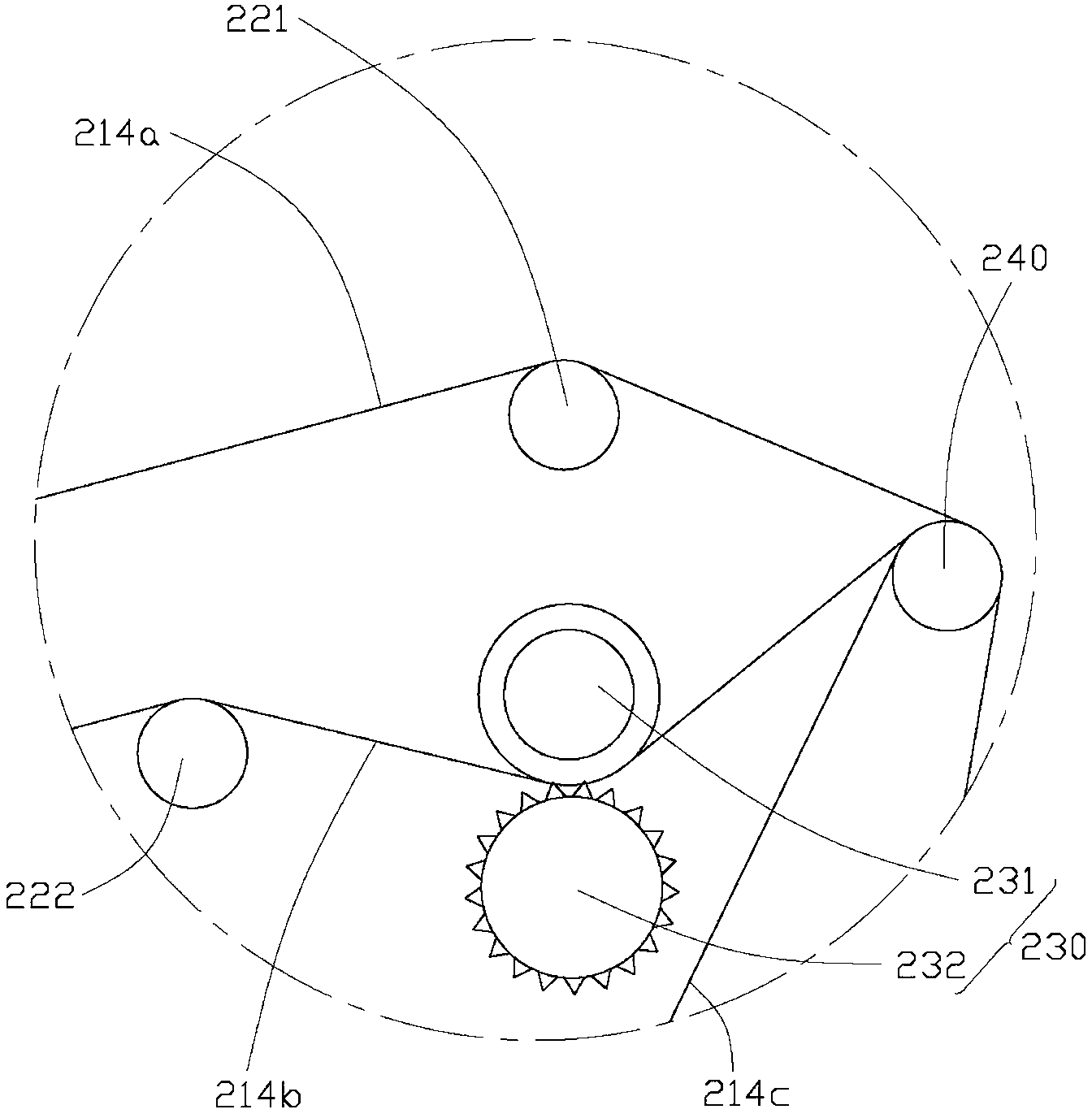

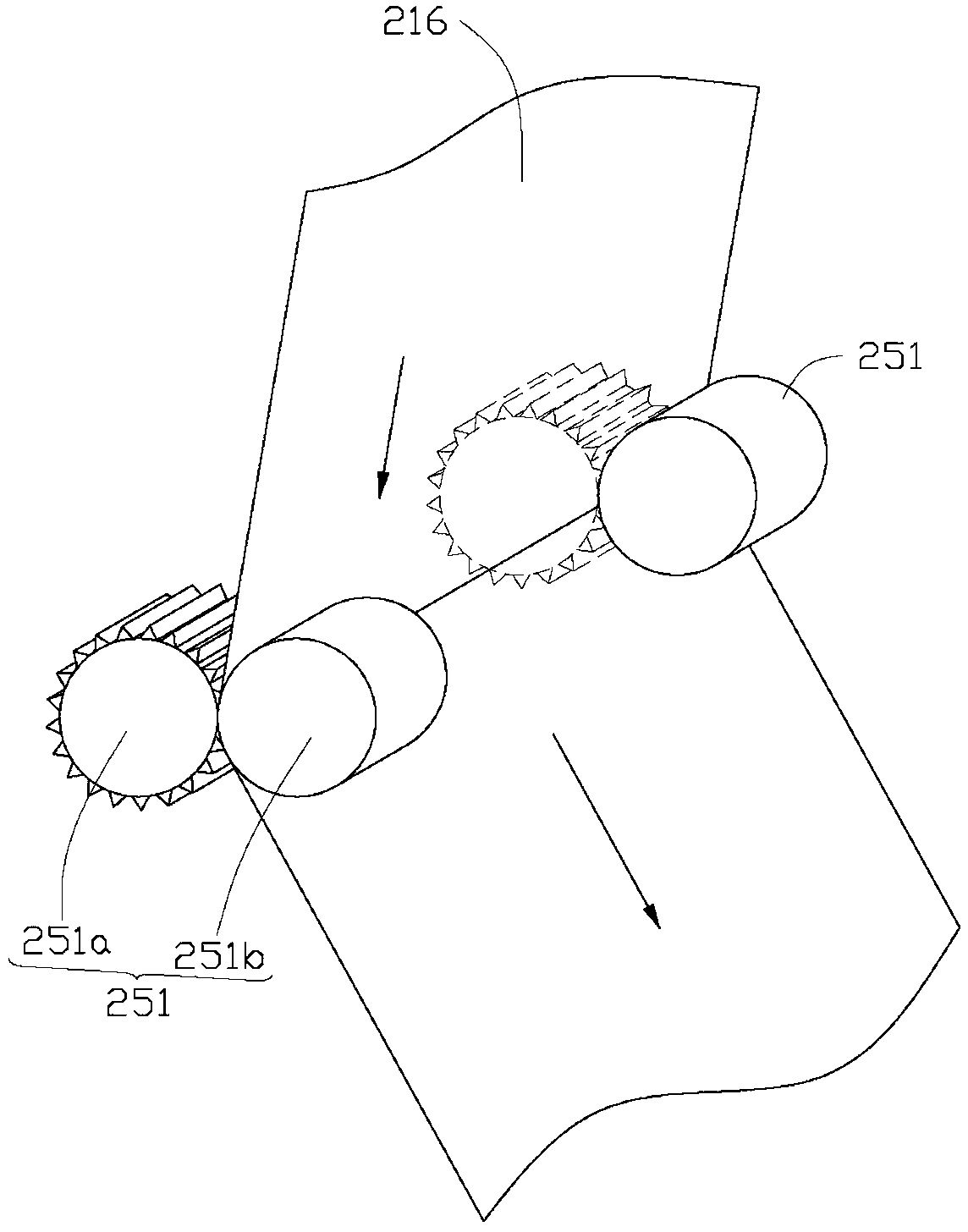

[0018] Please also see Figure 1 to Figure 4 , the household paper manufacturing equipment 200 provided by the present invention includes an unwinding device 210 , a set of guide rollers 220 , a pair of embossing rollers 230 , a laminating roller 240 , a set of edge rollers 250 and a winding device 260 .

[0019] This unwinding device 210 comprises outer layer paper unwinding roller 211, middle layer paper unwinding roller 212 and inner layer paper unwinding roller 213, and this outer layer paper unwinding roller 211, middle layer paper unwinding roller 212 and inner layer paper unwinding roller The base paper 214 is wound on the roller 213, and it is respectively used for feeding the outer layer paper 214a, the middle layer paper 214b and the inner layer paper 214c.

[0020] In this embodiment, the number of the outer layer paper unwinding roller 211, the middle layer paper unwinding roller 212 and the inner layer paper unwinding roller 213 is one respectively, and the outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com