RF antenna, electronic label and method for making RF antenna

A radio frequency antenna, electronic label technology, applied in the direction of antenna, loop antenna, antenna parts, etc., can solve the problems of increased load of conductive sheet, poor bending characteristics of label, separation of carrier and coil, etc., to reduce thickness, reduce load, Connection for reliable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 2

[0062] Embodiment 6 of the radio frequency antenna As shown in Figure 10, the coil 1001 is approximately circular, the position 1002 where the integrated circuit chip is installed is close to the coil 1001, and the distance between the two ends of the head and tail wire ends 1003 connected by the bridge is shorter than that of the embodiment of the radio frequency antenna. The second is to be close.

[0063] Embodiment 7 of the radio frequency antenna is shown in Figure 11, the coil 1101 is approximately circular, the part where the integrated circuit chip is installed 1102 connected to the coil is close to the coil 1101, and the other part is located in the center of the coil, and the head and tail ends connected by bridges The distance between the two ends of 1103 is closer than that in Embodiment 2 of the radio frequency antenna.

[0064] Embodiment 8 of the radio frequency antenna As shown in Figure 12, the coil 1201 is approximately circular, the position 1202 where the i...

specific Embodiment approach

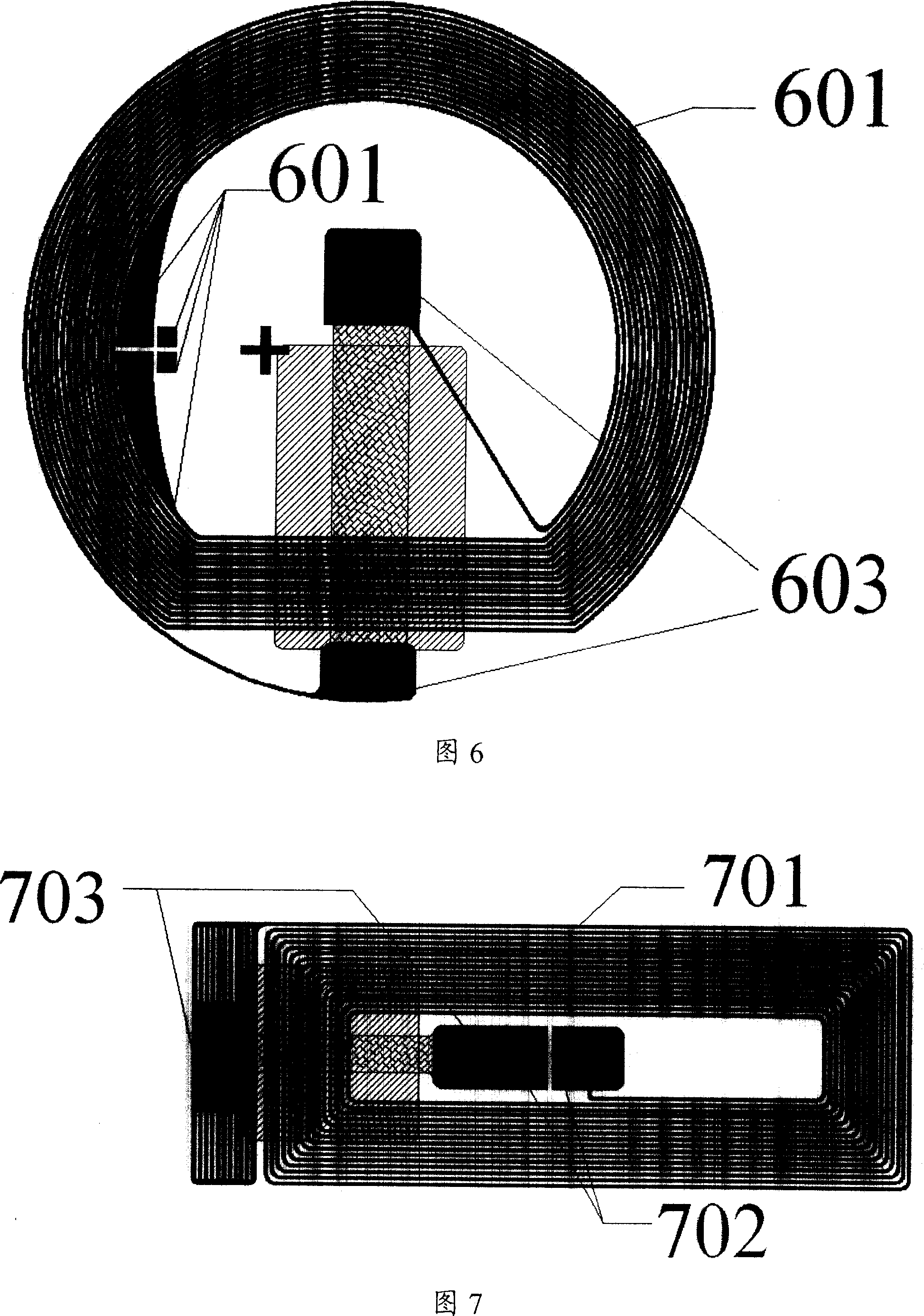

[0073] Embodiment 2 of the radio frequency antenna of the electronic tag is shown in Figure 6;

[0074] The third embodiment of the radio frequency antenna of the electronic tag is shown in Figure 7;

[0075] Embodiment 4 of the radio frequency antenna of the electronic tag is shown in Figure 8;

[0076] Embodiment five of the radio frequency antenna of the electronic tag is shown in Figure 9;

[0077] Embodiment six of the radio frequency antenna of the electronic tag is shown in Figure 10;

[0078] Embodiment 7 of the radio frequency antenna of the electronic tag is shown in Figure 11;

[0079] The eighth embodiment of the radio frequency antenna of the electronic tag is shown in Figure 12;

[0080] Embodiment 9 of the radio frequency antenna of the electronic tag is shown in Figure 13;

[0081] Embodiment 10 of the radio frequency antenna of the electronic tag is shown in Figure 14;

[0082] The eleventh embodiment of the radio frequency antenna of the electronic tag i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com