Plastic housing manufacturing method and product thereof

A technology of plastic shell and manufacturing method, which is applied in the direction of coating, etc., can solve the problems of not being able to play a reinforcing role, not being resistant to high temperature, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

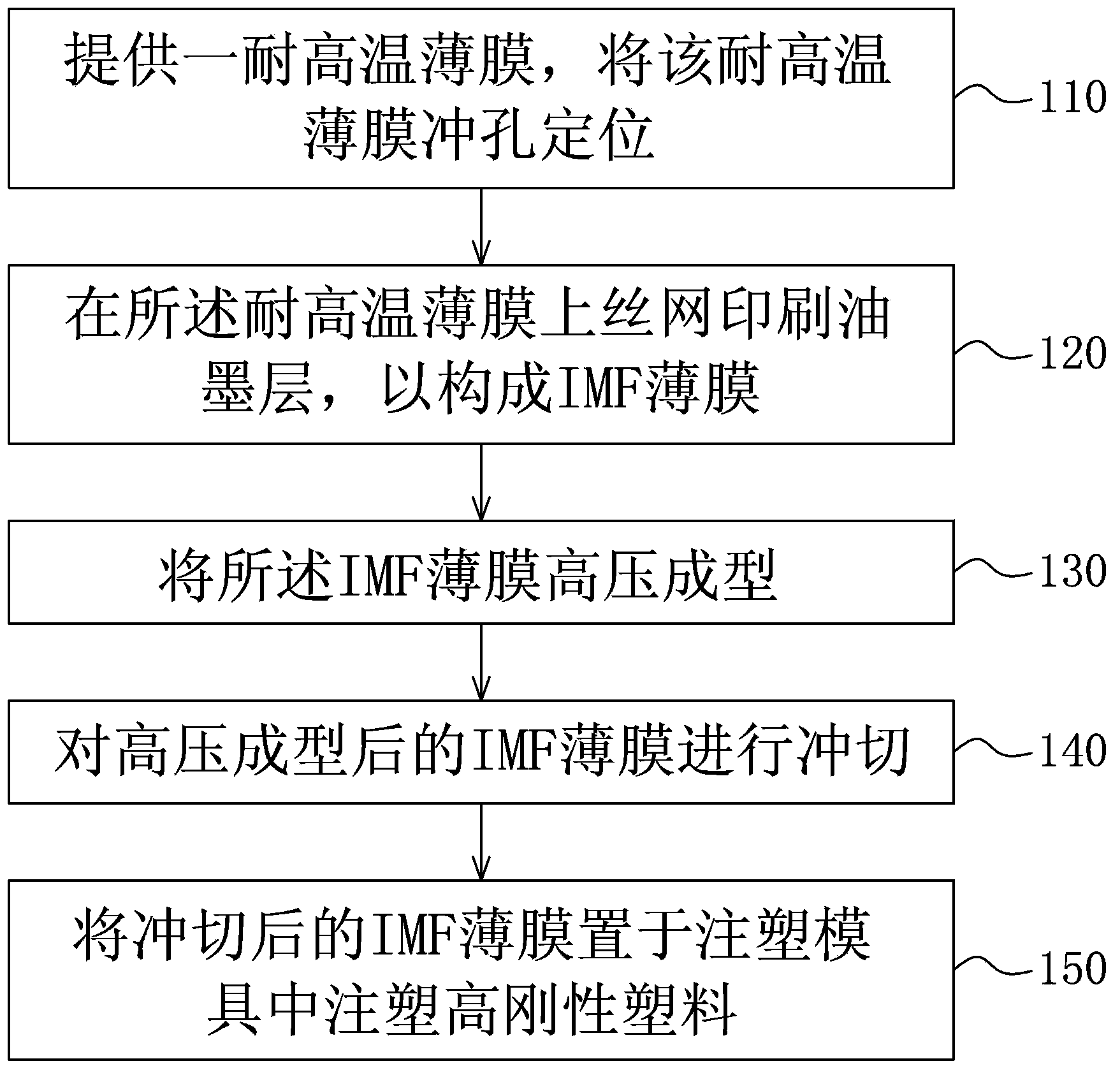

[0022] For having further understanding to the object of the present invention, method step and effect, now in conjunction with accompanying drawing, describe in detail as follows:

[0023] see figure 1 Shown, the manufacturing method of plastic case of the present invention, it comprises the following steps:

[0024] Step 110: Provide a high-temperature resistant film, and pre-bake the high-temperature-resistant film. The formed product plays a reinforcing role, and the thickness of the high temperature resistant film is 0.08mm ~ 0.30mm. The high temperature resistant film can be nylon PA4T, PA6T or PA9T. The high temperature resistant film can be treated with various textures according to requirements;

[0025] Step 120: screen printing ink layer on the high temperature resistant film to form an IMF film, and bake the IMF film after printing the ink layer, the ink layer can be directly a transparent hardened layer, or various according to customer needs Color pattern layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com