B-grade anti-acid pipeline steel plate and production process

A production process and steel plate technology, applied in the field of B-grade acid-resistant pipeline steel plate and production process, can solve the problems of high cost and large micro-alloying effect, and achieve refined structure and grain size, fine and uniform structure, and reduced production cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

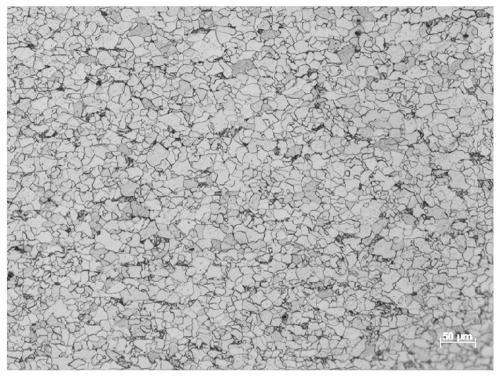

Embodiment 1

[0041] A grade B acid-resistant pipeline steel plate provided in this example has the following chemical composition and mass percentage: C: 0.010%-0.017%, Si: 0.10%-0.20%, Mn: 0.80%-0.89%, P≤0.012% , S≤0.0008%, Ni: 0.10%~0.18%, Cu: 0.10%~0.15%, Nb: 0.030%~0.040%, Mo: 0.10%~0.15%, Ti: 0.010%~0.016%, Ca: 0.001% ~0.002%, Al: 0.010%~0.036%, the balance is Fe and unavoidable impurities, Ceq: 0.16~0.23%, Pcm: 0.07~0.13%.

[0042] The production process of above-mentioned steel plate is as follows:

[0043] S1. Using top-bottom double-blowing converter smelting, LF+RH refining treatment to obtain vacuum-treated molten steel whose composition meets the design requirements, and casting it through a slab casting machine to obtain a low-magnification structure with a low-magnification Mannesmann standard rating of 2 or better;

[0044] S2. The slab heating temperature is 1103°C, the heating time is 10.1min / cm based on the thickness of the slab, and the soaking time is more than 40min; ...

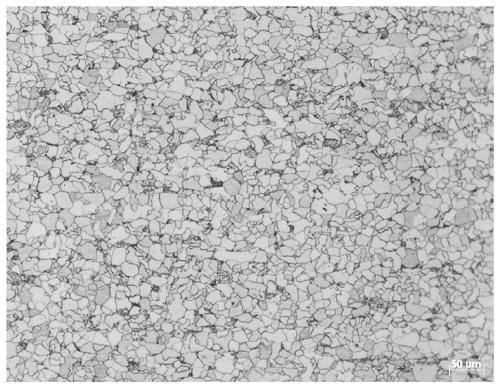

Embodiment 2

[0049] A grade B acid-resistant pipeline steel plate provided in this example differs from Example 1 in that its chemical composition and mass percentage are as follows: C: 0.020%-0.030%, Si: 0.20%-0.30%, Mn: 0.80% ~0.90%, P≤0.015%, S≤0.0010%, Ni: 0.15%~0.20%, Cu: 0.15%~0.20%, Nb: 0.025%~0.035%, Mo: 0.08%~0.13%, Ti: 0.010% ~0.020%, Ca: 0.001%~0.003%, Al: 0.020%~0.040%, the balance is Fe and unavoidable impurities, Ceq: 0.16~0.23%, Pcm: 0.07~0.13%.

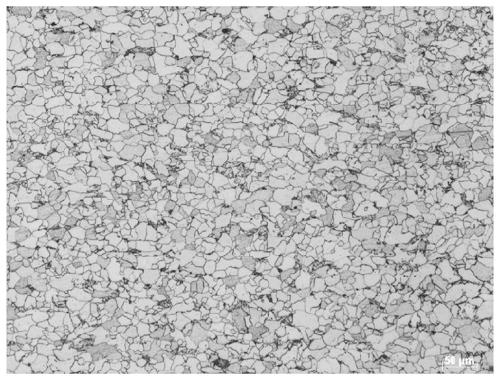

Embodiment 3

[0051] A grade B acid-resistant pipeline steel plate provided in this example has the following chemical composition and mass percentage: C: 0.030%-0.040%, Si: 0.15%-0.25%, Mn: 0.80%-0.90%, P≤0.015% , S≤0.0010%, Ni: 0.10%~0.15%, Cu: 0.10%~0.15%, Nb: 0.020%~0.030%, Mo: 0.10%~0.15%, Ti: 0.010%~0.020%, Ca: 0.001% ~0.003%, Al: 0.010%~0.030%, the balance is Fe and unavoidable impurities, Ceq: 0.16~0.23%, Pcm: 0.07~0.13%.

[0052] The production process of above-mentioned steel plate is as follows:

[0053] S1. Using top-bottom double-blowing converter smelting, LF+RH refining treatment to obtain vacuum-treated molten steel whose composition meets the design requirements, and casting it through a slab casting machine to obtain a low-magnification structure with a low-magnification Mannesmann standard rating of 2 or better; S2. The heating temperature of the slab is 1108°C, the heating time is calculated as 10.6min / cm based on the thickness of the slab, and the soaking time is more ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com