High-light-transmittance fabric and preparation method thereof

A light transmittance and fabric technology, applied in textiles and papermaking, fiber treatment, fiber type, etc., can solve problems such as unstable joints of fabrics, easy deformation, and reduced mechanical properties of fibers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The second aspect of the present invention provides a method for preparing a high light transmittance fabric, comprising the following specific steps:

[0031] (1) Preparation of pretreated polyester fibers: after polyester fibers are co-spun with polyvinylpyrrolidone, they are etched with an alkaline solution, and then polyvinylpyrrolidone is hydrolyzed to obtain pretreated polyester fibers;

[0032] (2) Preparation of pre-modified polyester fibers: the pre-treated polyester fibers obtained in the above step (1) are grafted with polyacrylamide under the catalysis of dimethyl sulfoxide to obtain pre-modified polyester fibers;

[0033] (3) Preparation of modified fiber: the pre-modified polyester fiber obtained in the above step (2) is processed at high temperature under the catalysis of a catalyst to obtain a modified fiber;

[0034] (4) Preparation of high light-transmitting fabric: After the modified fiber obtained in the above step (3) is double twisted, spun, dyed, ...

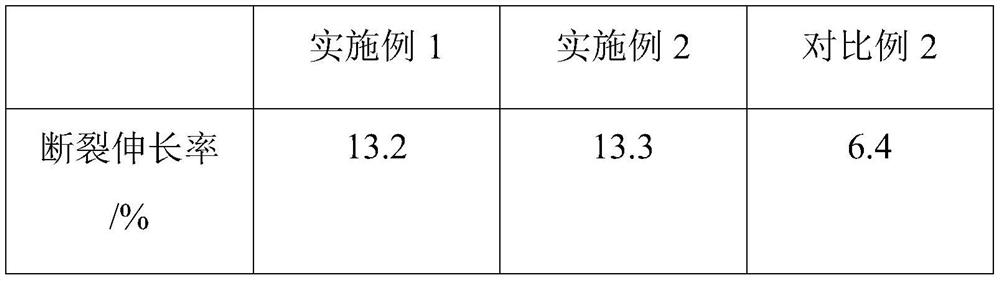

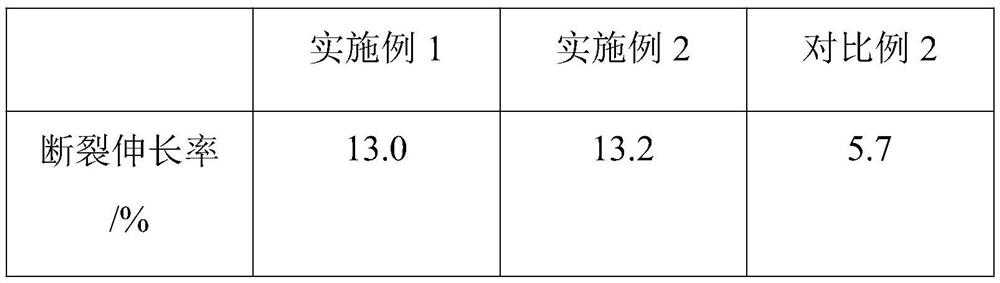

Embodiment 1

[0039] Embodiment 1: a kind of high light transmission fabric one:

[0040] A high light transmittance fabric, the fabric components in parts by weight:

[0041] 33 parts modified fiber, 7 parts conditioner.

[0042] The preparation method of this fabric is as follows:

[0043] (1) Preparation of pretreated polyester fibers: after polyester fibers are co-spun with polyvinylpyrrolidone, they are etched with an alkaline solution, and then polyvinylpyrrolidone is hydrolyzed to obtain pretreated polyester fibers;

[0044] (2) Preparation of pre-modified polyester fibers: the pre-treated polyester fibers obtained in the above step (1) are grafted with polyacrylamide under the catalysis of dimethyl sulfoxide to obtain pre-modified polyester fibers;

[0045] (3) Preparation of modified fiber: the pre-modified polyester fiber obtained in the above step (2) is processed at high temperature under the catalysis of a catalyst to obtain a modified fiber;

[0046] (4) Preparation of high l...

Embodiment 2

[0051] Embodiment 2: a kind of high light transmission fabric two:

[0052] A high light transmittance fabric, the fabric components in parts by weight:

[0053] 38 parts modified fiber, 8 parts conditioner.

[0054] The preparation method of this fabric is as follows:

[0055] (1) Preparation of pretreated polyester fibers: after polyester fibers are co-spun with polyvinylpyrrolidone, they are etched with an alkaline solution, and then polyvinylpyrrolidone is hydrolyzed to obtain pretreated polyester fibers;

[0056] (2) Preparation of pre-modified polyester fibers: the pre-treated polyester fibers obtained in the above step (1) are grafted with polyacrylamide under the catalysis of dimethyl sulfoxide to obtain pre-modified polyester fibers;

[0057] (3) Preparation of modified fiber: the pre-modified polyester fiber obtained in the above step (2) is processed at high temperature under the catalysis of a catalyst to obtain a modified fiber;

[0058] (4) Preparation of high...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com