Integral molding method of plasticizing trunk lid of automobile

A trunk lid and integral molding technology, applied in household components, applications, household appliances, etc., can solve the problems of heavy trunk lid, high manufacturing cost, accident-prone, etc., and achieve simple and feasible processing technology and good collision safety sex, reducing the overall quality of the

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

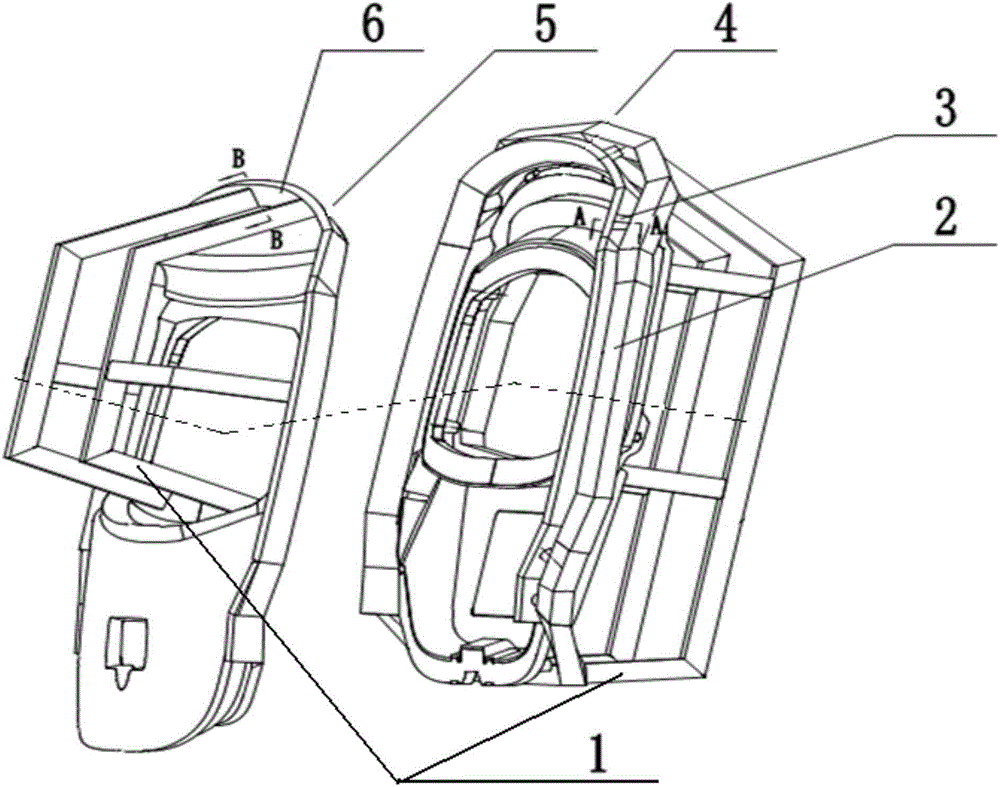

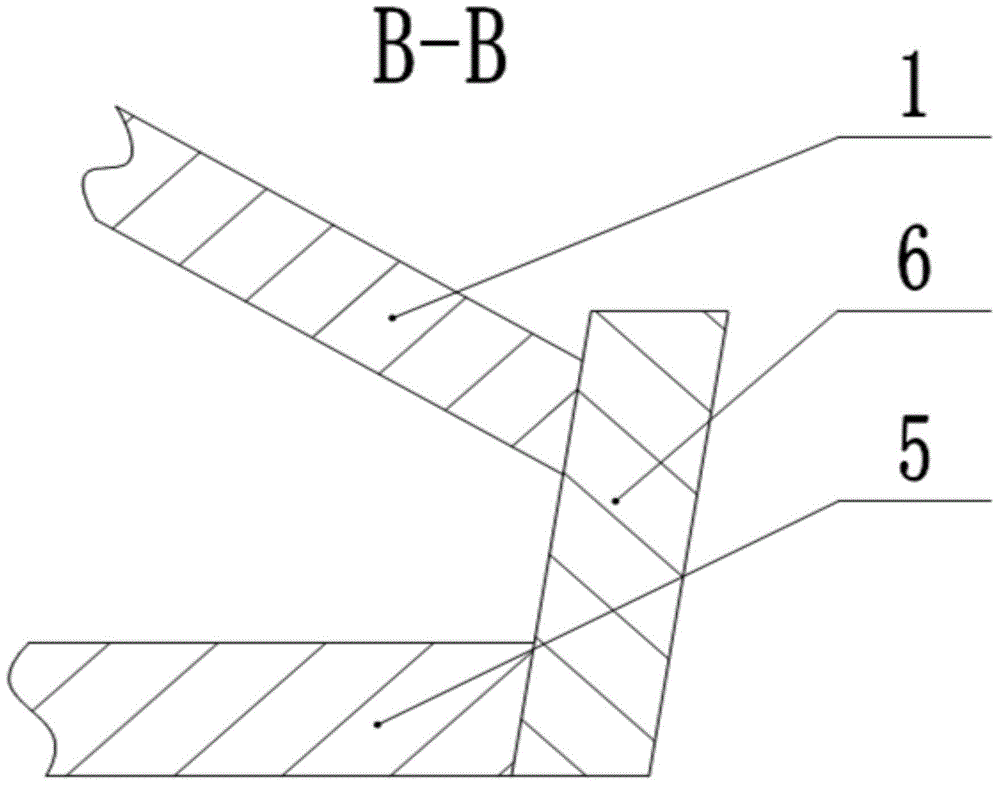

Image

Examples

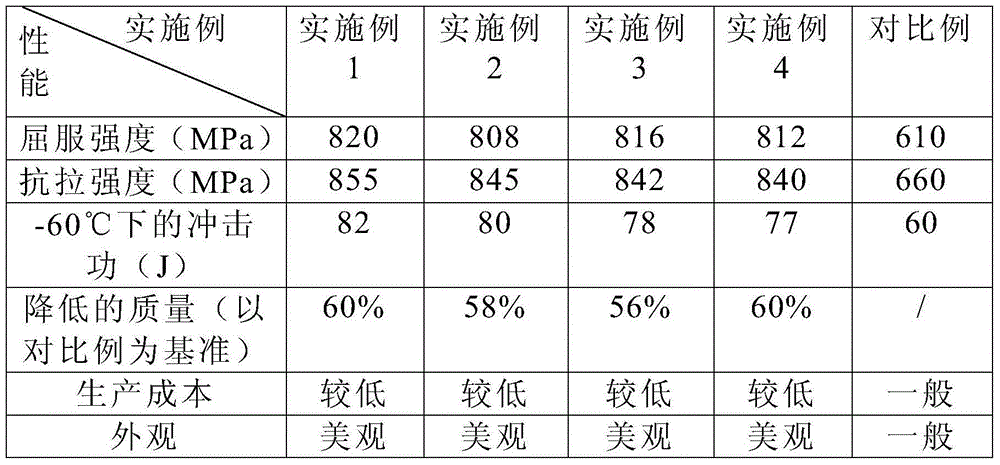

Embodiment 1

[0030] A method for integral molding of a plasticized automobile trunk lid, said molding method comprising the steps of:

[0031] Mold treatment: clean the inner surface of the mold and apply a release agent;

[0032] Mold closing: the raw material of the plasticized automobile trunk lid is added in the mold in step (1), the mold is closed, and the mold is locked to form a mold cavity with a clamp, and a pressure of 0.10MPa is applied to the mold cavity; the raw material is The fiber-reinforced composite material after modification includes the composition of the following percentages by weight: 40% epoxy resin, 45% polyamide resin, and 15% surface-modified carbon fiber; wherein, the surface-modified carbon fiber is passed as follows Method for modification treatment: soak the long carbon fiber with 63% nitric acid at room temperature for 25 minutes, then soak it in deionized water for 15 minutes, then rinse it with deionized water, and dry it at 170°C for 2 hours. Cut into c...

Embodiment 2

[0036] A method for integral molding of a plasticized automobile trunk lid, said molding method comprising the steps of:

[0037] Mold treatment: clean the inner surface of the mold and apply a release agent;

[0038] Mold closing: the raw material of the plasticized automobile trunk lid is added in the mold in step (1), the mold is closed, and the mold is locked to form a mold cavity with a clamp, and a pressure of 0.11MPa is applied to the mold cavity; the raw material is The fiber-reinforced composite material after modification includes the following composition by weight: 50% epoxy resin, 35% polyamide resin, and 15% surface-modified carbon fiber; wherein, the surface-modified carbon fiber passes through the following steps: Method for modification treatment: soak the long carbon fiber with 65% nitric acid at room temperature for 20 minutes, then soak it in deionized water for 20 minutes, then rinse it with deionized water, and dry it at 160°C for 1 hour. Cut into carbon...

Embodiment 3

[0042] A method for integral molding of a plasticized automobile trunk lid, said molding method comprising the steps of:

[0043] Mold treatment: clean the inner surface of the mold, and apply a normal amount of release agent and phosphor in turn;

[0044] Mold closing: the raw material of the plasticized automobile trunk lid is added in the mold in step (1), the mold is closed, and the mold is locked to form a mold cavity with a clamp, and a pressure of 0.12MPa is applied in the mold cavity; the raw material is The fiber-reinforced and modified composite material comprises the following composition by weight percentage: 60% of epoxy resin, 30% of polyamide resin, and 20% of surface-modified carbon fiber; wherein, the surface-modified carbon fiber is passed as follows Method for modification treatment: soak the long carbon fiber with 60% nitric acid at room temperature for 30 minutes, then soak it in deionized water for 10 minutes, then rinse it with deionized water, and dry i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com