Device and method for monitoring locating precision of continuous wire unwinding trolley

A positioning accuracy and monitoring device technology, applied in vehicle position/route/height control, two-dimensional position/channel control, non-electric variable control, etc., can solve the problem of inability to determine the deterioration trend of trolley positioning accuracy, inability to travel mechanism and track Check and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

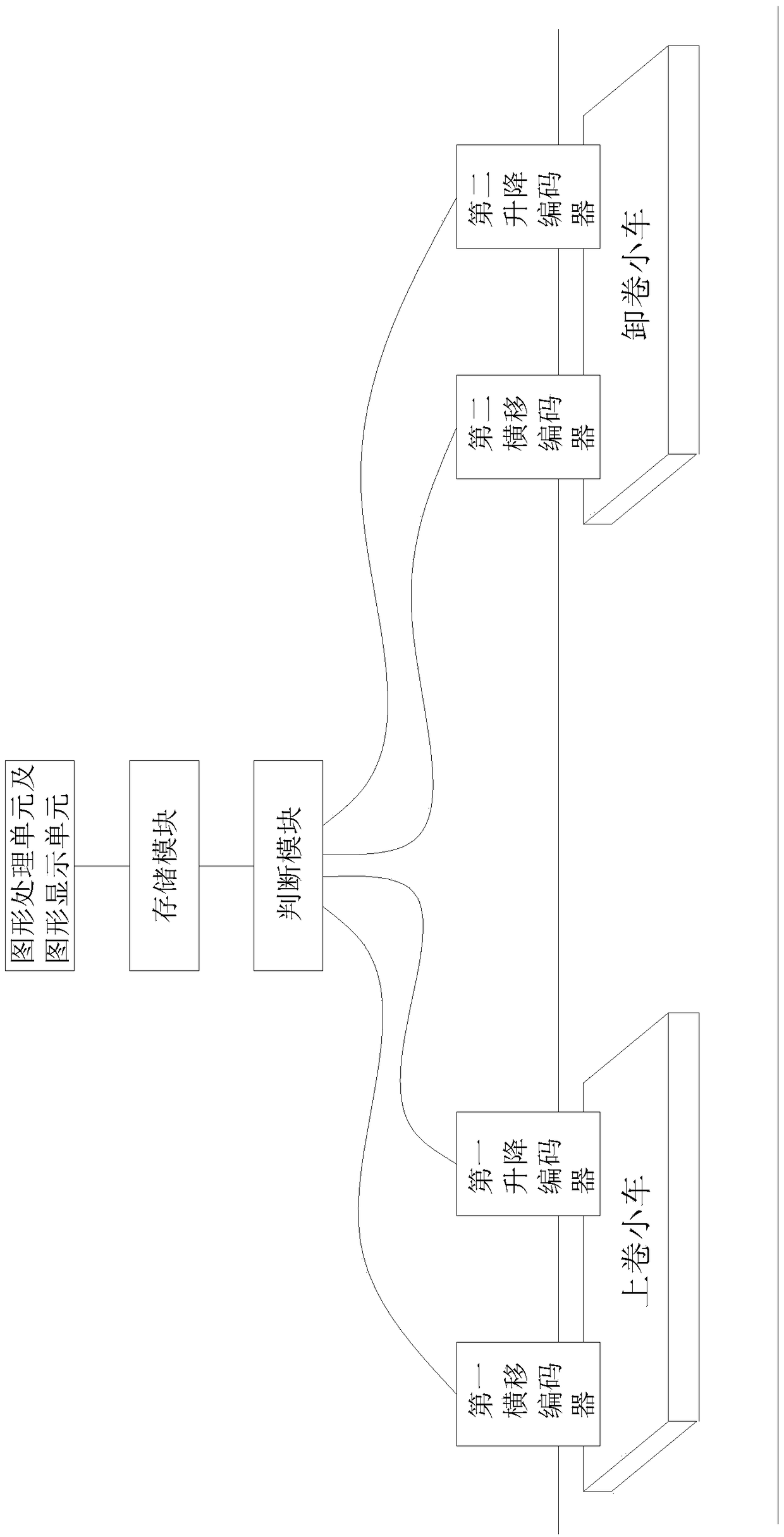

[0042] See attached figure 1 , the present embodiment provides a monitoring device for the positioning accuracy of the continuous unwinding trolley. The continuous unwinding trolley includes: a winding trolley and an unwinding trolley. The positioning accuracy monitoring device for the continuous unwinding trolley includes: a first traverse encoder, a first Lifting encoder, second traverse encoder, second lifting encoder, judging module and storage module, wherein:

[0043] The first traversing encoder is set on the winding trolley to obtain the horizontal position value of the winding trolley; the first lifting encoder is set on the winding trolley to obtain the vertical position value of the winding trolley; the second traversing encoder Set on the unloading trolley to obtain the horizontal position value of the unloading trolley; the second lift encoder is set on the unloading trolley to obtain the vertical position value of the unloading trolley.

[0044] The judging modu...

Embodiment 2

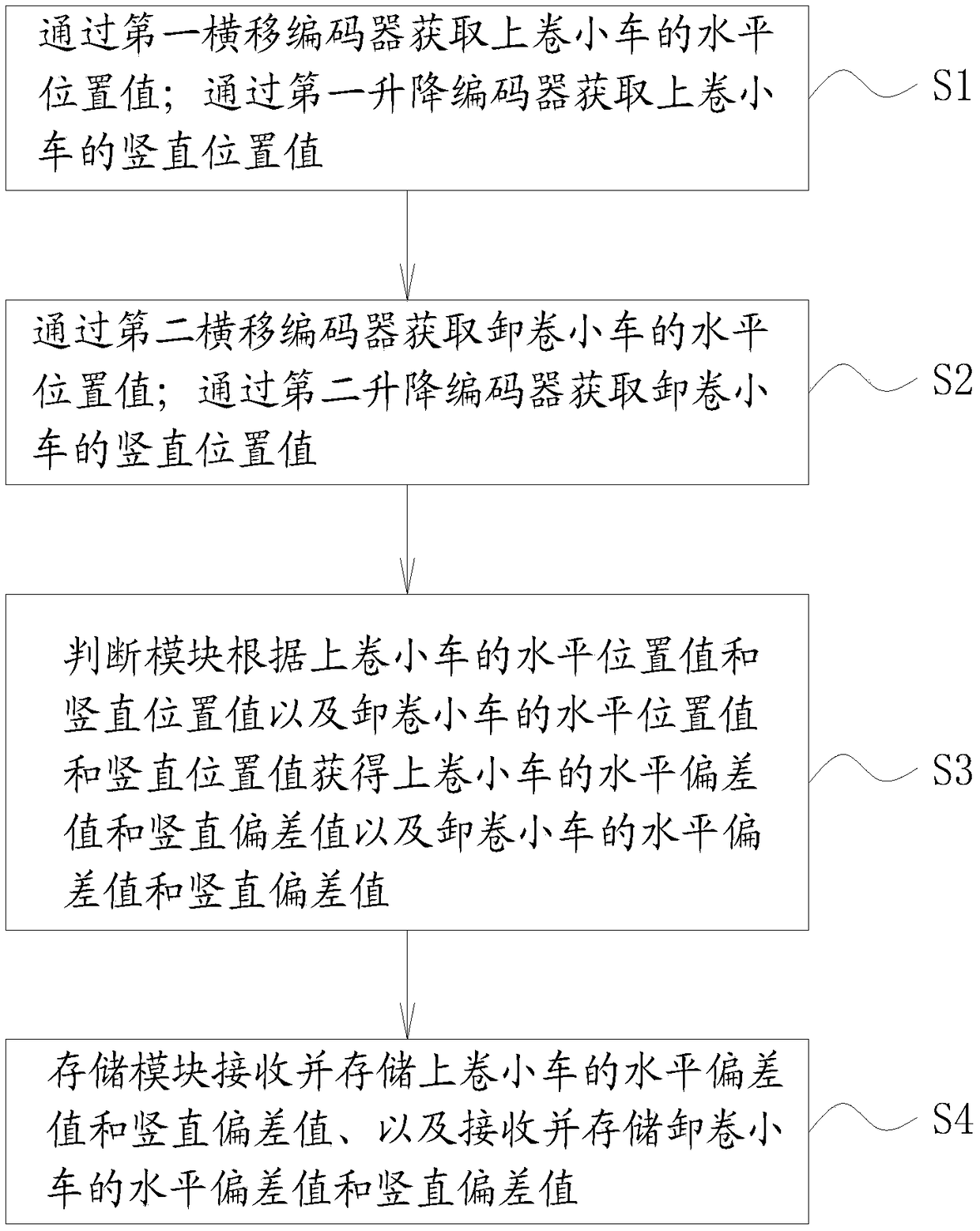

[0052] This embodiment provides a method for monitoring the positioning accuracy of a trolley on a continuous withdrawal line, which is realized by the monitoring device for the positioning accuracy of a trolley on a continuous withdrawal line provided in Embodiment 1. Please refer to the attached figure 2 , including the following steps:

[0053] S1: Obtain the horizontal position value of the winding trolley through the first traverse encoder; obtain the vertical position value of the winding trolley through the first lifting encoder.

[0054] S2: Obtain the horizontal position value of the coil unloading trolley through the second traverse encoder; acquire the vertical position value of the coil unloading trolley through the second lifting encoder.

[0055] S3: The judging module obtains the horizontal deviation value and vertical deviation value of the winding trolley and the horizontal deviation of the unwinding trolley according to the horizontal position value and vert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com