Intelligent maintenance system in field of engineering machinery

A construction machinery and field technology, applied in the field of intelligent maintenance systems, can solve the problems of delaying the normal operation of vehicles, untimely maintenance, and excessive maintenance, and achieve the effect of avoiding untimely or excessive maintenance, avoiding stagnation, and improving utilization efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

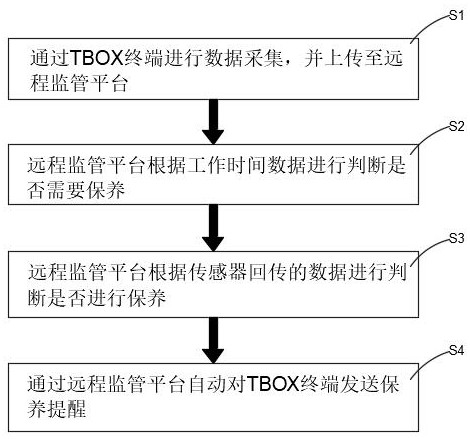

[0052] refer to Figure 1-5 , an intelligent maintenance method in the field of construction machinery, characterized in that the steps are as follows:

[0053] S1. Collect data through the TBOX terminal and upload it to the remote monitoring platform, specifically including:

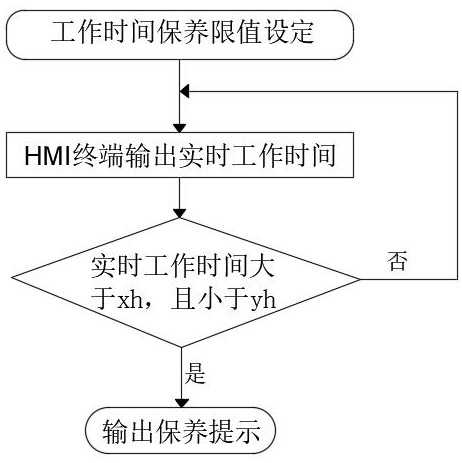

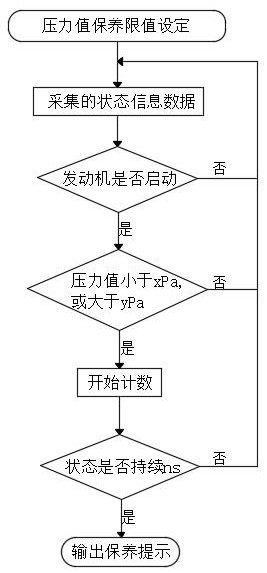

[0054] First, use the HMI terminal to collect and output the working time of each component of the machine, collect the working time output by the HMI terminal and the status information data received by CAN through the TBOX terminal, and transmit the above data to the remote monitoring platform;

[0055] Among them, the HMI data acquisition system is composed of sensors, signal conditioning ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com