Safety valve and oil filter integrated assembly

A technology of components and filter screens, which is applied in the direction of filtration and separation, engine components, chemical instruments and methods, etc., and can solve the problems of limited application range and large installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

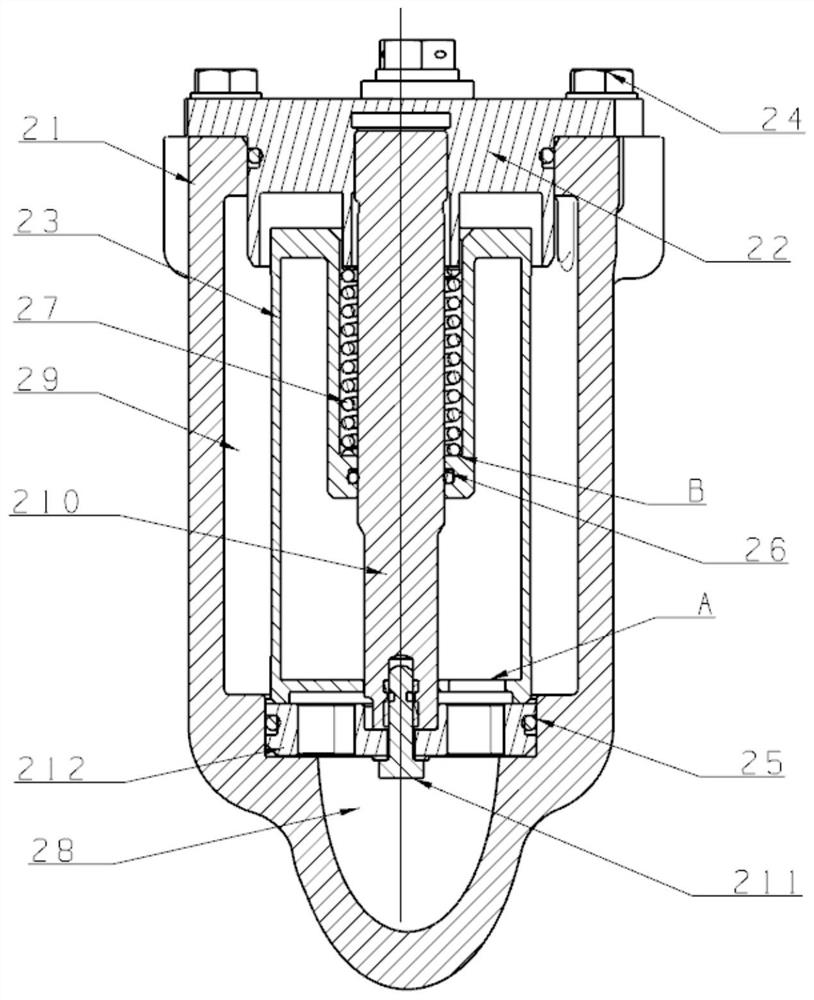

[0027] Such as figure 2 As shown, the oil filter assembly with its own bypass function, the self-cleaning oil filter assembly is used for aero-engine fuel accessories, and the self-cleaning oil circuit assembly includes a housing 21, an oil filter cover 22, and a filter screen assembly 23 , Hex head screw 24, sealing ring 25, sealing ring 26, spring 27, inlet oil circuit 28, outlet oil circuit 29, guide column 210, hexagon head screw 211, end cover 212. The filter screen assembly 23 is a hollow ring structure, which cooperates with the guide post 210 and is sealed by a sealing ring 26 . When the pressure difference between the inlet oil passage 28 and the outlet oil passage 29 is less than the pre-tightening force of the spring 27, the fuel enters the self-cleaning oil filter from the inlet oil passage 28, and reaches the outlet oil passage 29 through filtering by the filter assembly 23; When the pressure difference between the outlet oil passage 28 and the outlet oil passag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com