Chameleonic colored coating steel plate and machining method thereof

A processing method and color coating technology, applied in coatings, chemical instruments and methods, layered products, etc., can solve the problems of high temperature resistance and high-speed, large-area, mass production, etc., to achieve concise process steps, prolong service life, Guaranteed full effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

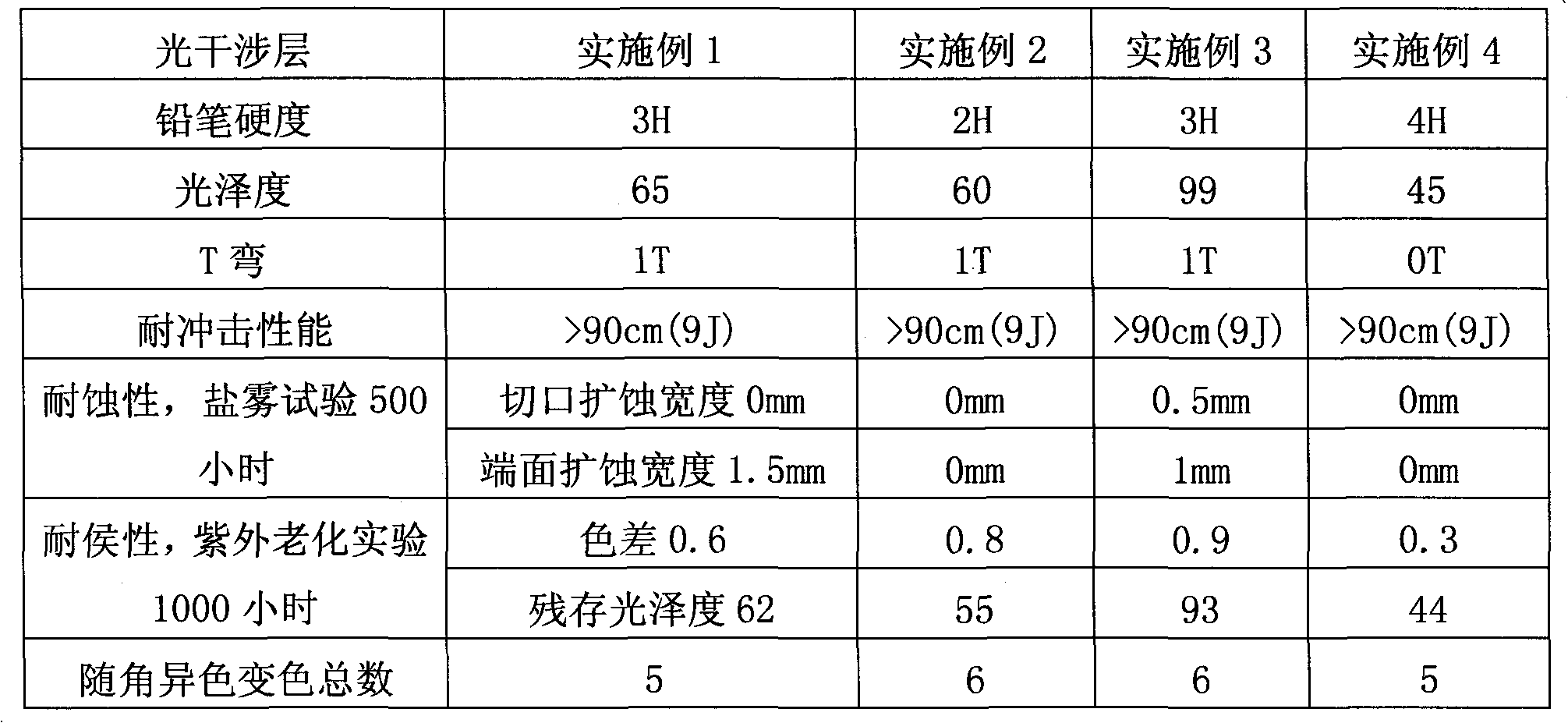

Embodiment 1

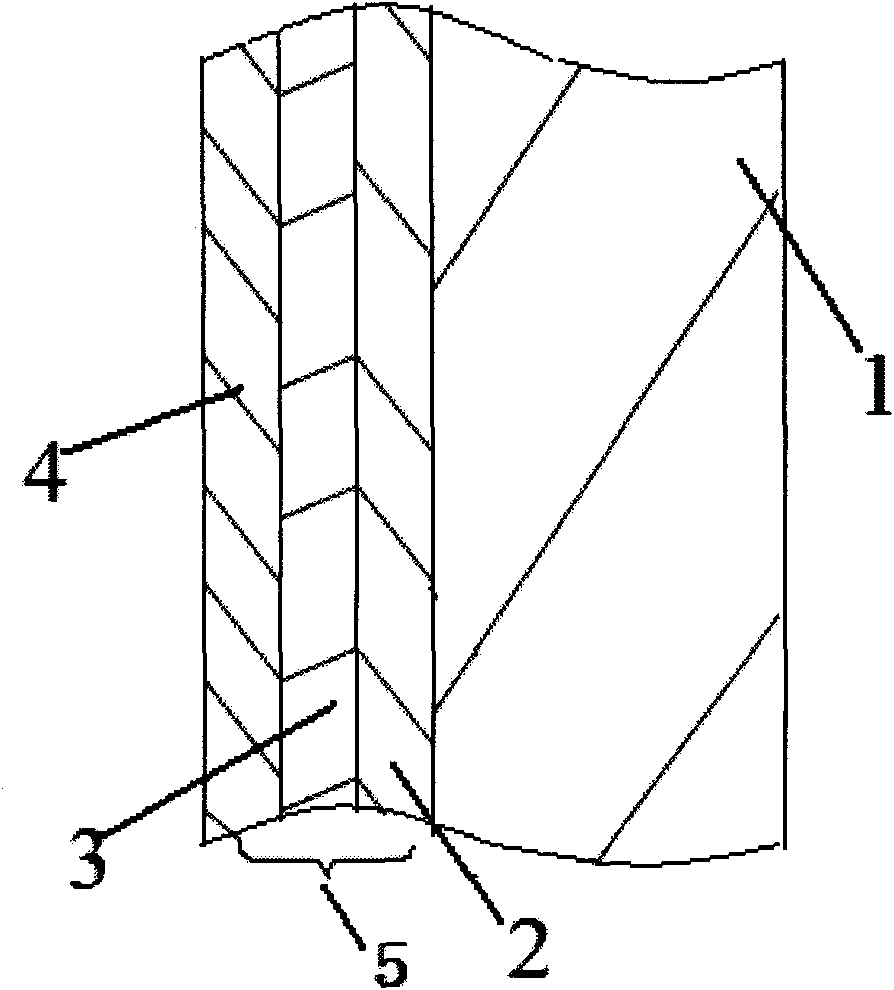

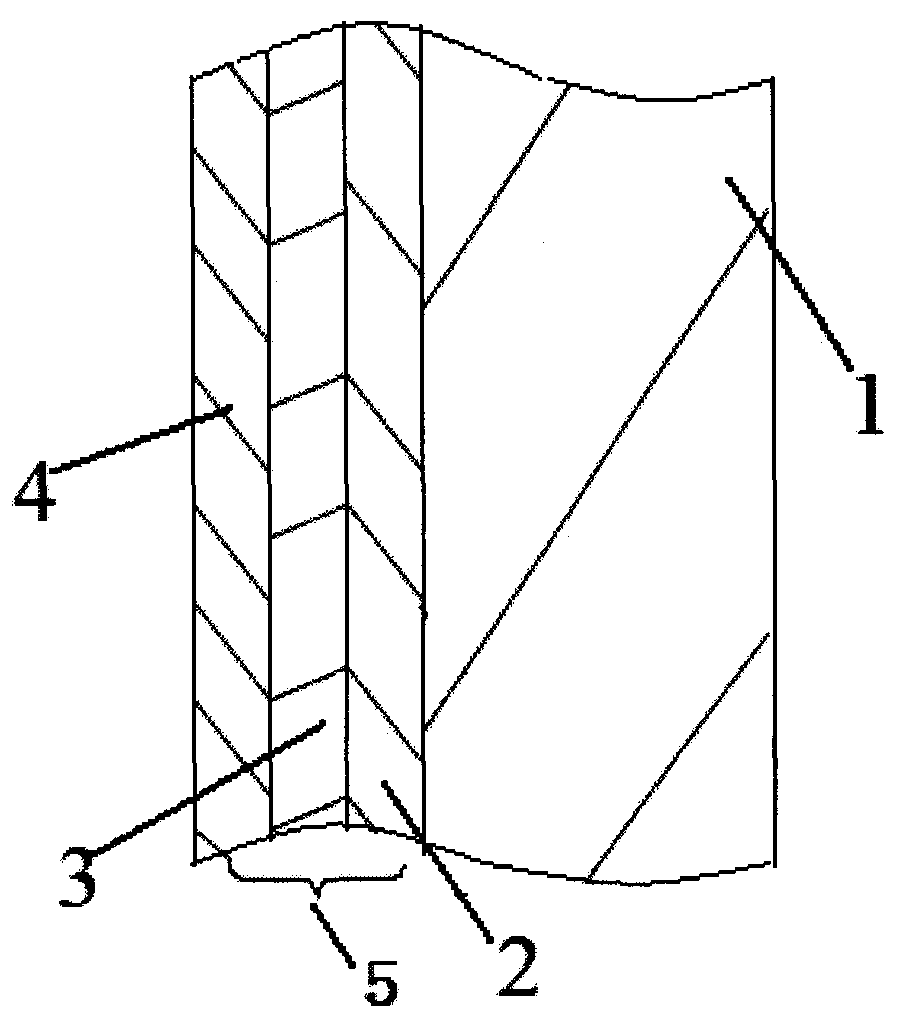

[0027] As shown in the accompanying drawings, a chameleon colored coated steel plate comprises a colored coated steel plate substrate 1 with a colored coated layer 5 on at least one side of the surface, the colored coated layer 5 includes a color shielding layer 2, an angle-dependent Heterochromic layer 3 , the angle-dependent heterochromatic layer 3 is disposed on the color-shielding layer 2 , and an optical interference layer 4 is disposed on the surface of the angle-dependent heterochromatic layer 3 . The steps of its processing method are:

[0028] A) Uncoiling and docking, the color-coated steel plate substrate 1 that is in the steel coil state and has been coated with the color coating layer 5 on the outward side surface in the use state is uncoiled with an uncoiler, so that the steel coil is unrolled. Steel plates, after uncoiling, use welding to carry out end-to-end welding of the steel plates unrolled on each steel coil, that is to say, connect the steel plates unroll...

Embodiment 2

[0035] Only change the amount of the degreasing agent in step B) to 5.5g / L, change the temperature of the degreasing agent solution to 75°C, change the water temperature of the washing tank to 75°C; change the drying temperature in step C) to 85°C; change the thickness of the color-shielding layer in step D) to 50 μm, the traveling speed of the steel plate is 30m / min, the line speed of the coating roller is 50m / min, the baking temperature of the oven is changed to 330°C, and the hot air is blown dry Change the temperature to 75°C; change the thickness of the angle-dependent layer 3 in step E) to 200 μm, and change the material used in the angle-dependent layer 3 to 10% by mass and have a particle size of 60-200nm Polyurethane coating with angle-dependent color powder. The angle-dependent color powder is flaky alumina powder and flaky magnesium fluoride powder in a weight ratio of 1:1. The flaky magnesium fluoride powder is developed by Beijing Nachen Technology in China. The b...

Embodiment 3

[0037] Only change the amount of the degreasing agent in step B) to 4.5g / L, change the temperature of the degreasing agent solution to 65°C, change the water temperature of the washing tank to 65°C; change the drying temperature in step C) to 100°C ℃; change the thickness of the color-shielding layer 2 in step D) to 25 μm, change the traveling speed of the steel plate to 120m / min, change the linear speed of the coating roller to 225m / min, change the baking temperature to 320°C, Change the drying temperature to 65°C; change the thickness of the angle-dependent layer 3 in step E) to 10 μm, and change the material used in the angle-dependent layer 3 to 40% by mass and have a particle size of 35- The 45nm angle-following powder is the epoxy coating of flaky chromium oxide, the traveling speed of the steel plate is changed to 150m / min, the linear speed of the coating roller is changed to 400m / min, the baking temperature is changed to 400°C, and the hot air is dried Change the tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com