Unibract fritillary bulb lung-heat-clearing syrup and production process thereof

A technology of syrup and Chuanbeimu, which is applied in the field of Chuanbeiqingfei syrup and its production technology, can solve the problem of destroying heat-sensitive active ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] A Chuanbei clearing lung syrup, take 250 parts of loquat leaves, 50 parts of bitter almonds, 5 parts of Chuan Fritillaria, 50 parts of Ophiopogon japonicus, 50 parts of rehmannia glutinosa, 50 parts of licorice, 30 parts of bellflower, 15 parts of mint, 3 parts of sodium benzoate Parts, including the following steps: add water to decoct twice, combine the decoction, filter to obtain the filtrate, settle the filtrate naturally, extract the natural sediment supernatant to concentrate, filter; take 600 parts of sucrose, add water to boil, dissolve and filter, and make a simple syrup into Prepare a tank, dissolve sodium benzoate, filter, mix the obtained filtrate with simple syrup and filtrate evenly, add water to dilute to 1.5 times, stir evenly, potting, and packaging to obtain Chuanbei Qingfei Syrup.

[0077] Embodiment 1,

[0078] A Chuanbei clearing lung syrup, its raw materials are 200 parts of loquat leaves, 40 parts of bitter almonds, 3 parts of Chuan Fritillaria, 3...

Embodiment 2

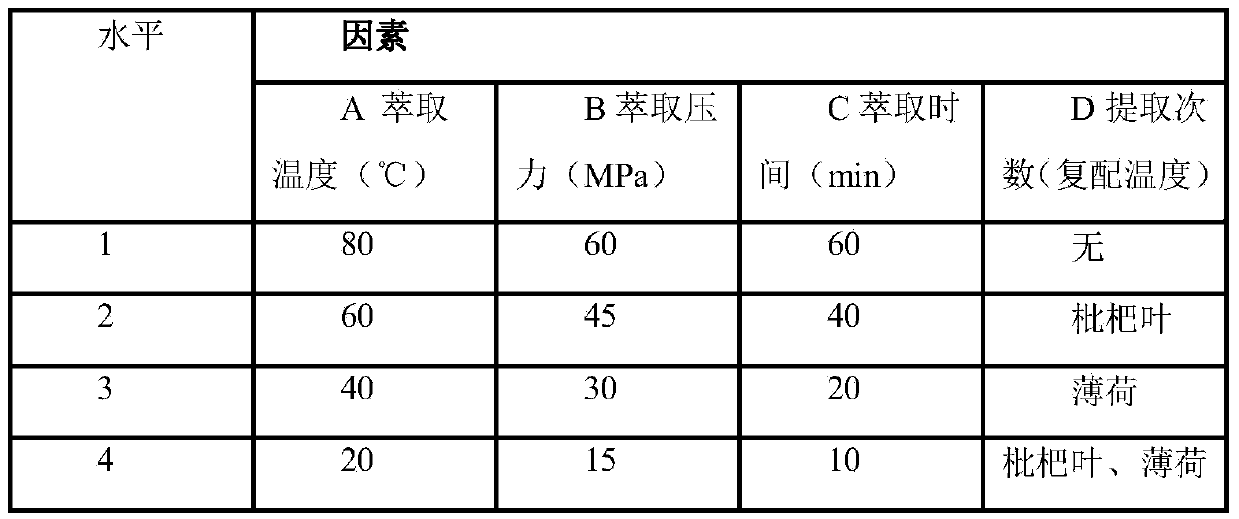

[0084] A preparation of Chuanbei clearing lung syrup, which is prepared from the following raw materials in parts by weight: 250 parts of loquat leaves, 50 parts of bitter almonds, 5 parts of Chuanbeimu, 50 parts of Radix Radix, 50 parts of Rehmannia glutinosa, 50 parts of licorice, and 30 parts of bellflower , 15 parts of peppermint, 200 parts of sucrose, and 400 parts of isomaltooligosaccharide. The production process is (1) take Chuan Fritillaria, bitter almonds, loquat leaves and mint, grind them at 10°C, pass through a 30-mesh sieve, and use Supercritical CO 2 The extraction method is for extraction, and the extraction is carried out in three stages. The process parameters of each stage are: the first stage pressure is 60MPa, the temperature is 30°C, and the extraction time is 30min; the second stage pressure is 40MPa, the temperature is 50°C, and the extraction time is 20min; The three-stage pressure is 15MPa, the temperature is 80°C, and the extraction time is 10 minute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com