Glass wall paper composite board and producing method thereof

A composite board and glass wall technology, applied in glass/slag layered products, chemical instruments and methods, layered products, etc., can solve the problems of not long enough service life, unsuitable decorative materials, easy to be damaged by moisture, etc. Long service life, better protection, better moisture and water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

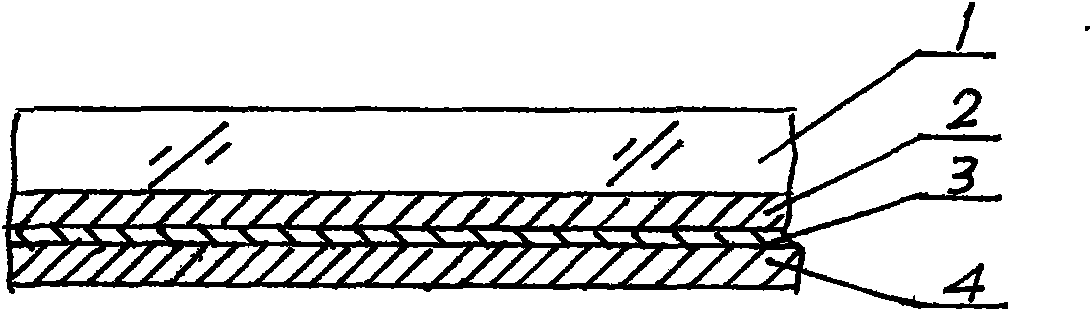

[0032] see figure 1 As shown, a glass wallpaper composite board with a four-layer structure is composed of a glass layer 1, a transparent adhesive layer 2, a wallpaper surface pattern layer 3, and a complementary color protective layer 4 in sequence. The glass layer 1 adopts transparent flat glass, the transparent adhesive layer 2 adopts PA hot-melt film, the wallpaper surface pattern layer 3 selects the paper quality surface layer of paper wallpaper, and the pigment color selected for the complementary color protection layer 4 is consistent with the color of the wallpaper surface pattern layer. The basic color of the pattern is coordinated. The pigment is mixed with thermosetting acrylic resin and sprayed behind the pattern layer on the surface of the wallpaper, which has the effect of complementary color and weather protection.

[0033] The production process of the glass wallpaper composite board is as follows:

[0034] (1) PA hot-melt film is hot-pressed on the bottom sur...

Embodiment 2

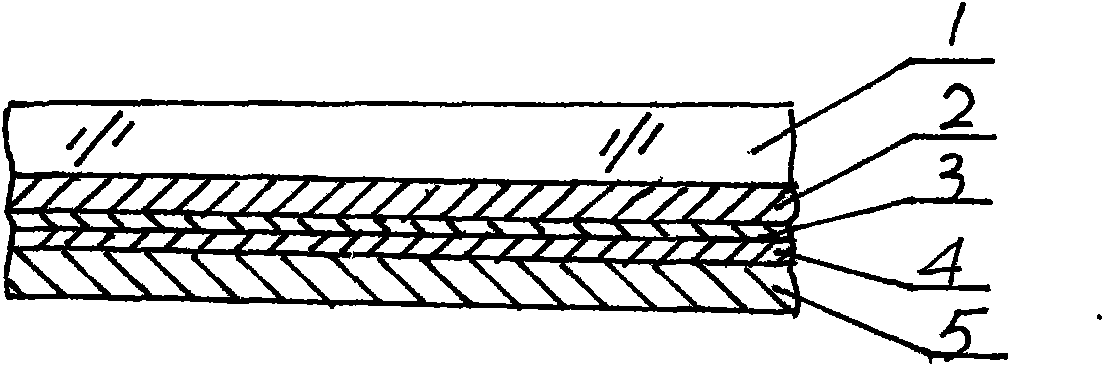

[0037] see figure 2 As shown, a glass-wallpaper composite panel with a five-layer structure is composed of a glass layer 1, a transparent adhesive layer 2, a wallpaper surface pattern layer 3, a complementary color protective layer 4, and a paint protective layer 5. The glass layer 1 adopts transparent flat glass, the transparent adhesive layer 2 adopts epoxy AB adhesive, the wallpaper surface pattern layer 3 selects the PVC film surface layer of paper PVC film composite wallpaper, and the pigment color selected for the complementary color protective layer 4 is consistent with the surface pattern of the wallpaper. The basic color of the pattern of the layer is coordinated. The paint is mixed with vinyl resin and sprayed on the back of the wallpaper surface pattern layer 3. Finally, a paint protective layer 5 is sprayed on the bottom surface of the complementary color protective layer 4. The paint protective layer 5 adopts thermosetting acrylic resin.

[0038] It is also possi...

Embodiment 3

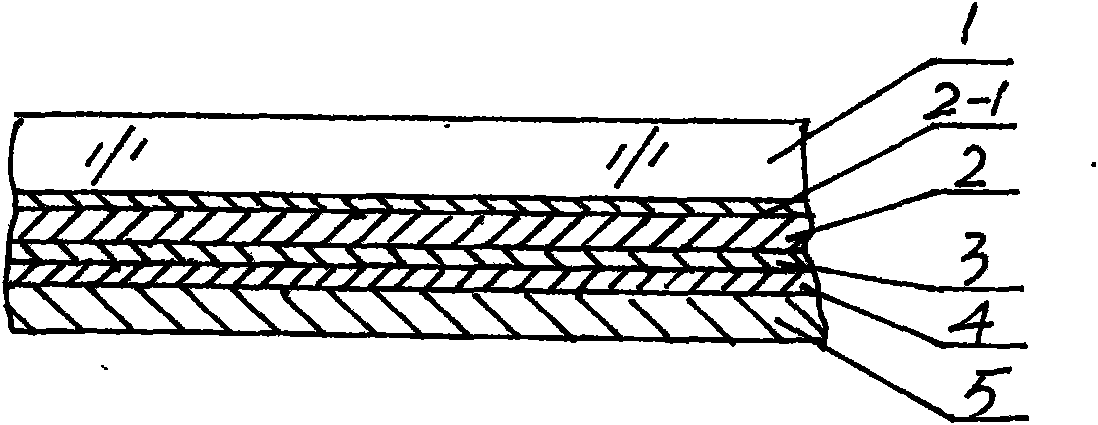

[0041] see image 3 As shown, a glass wallpaper composite board with a six-layer structure is composed of a glass layer 1, a pattern layer 2-1, a translucent adhesive layer 2, a wallpaper surface pattern layer 3, a complementary color protective layer 4, and a paint protective layer 5. . The pattern layer 2-1 is made of ink, and the pattern is printed on the bottom surface of the glass layer 1 by screen printing, the translucent adhesive layer 2 is made of UV light-curable resin, and the pattern layer 3 of the wallpaper surface is made of PVC film composite wallpaper. The color of the pigment selected for the film surface layer and the complementary color protective layer 4 is coordinated with the basic color of the pattern of the wallpaper surface pattern layer. After the pigment is mixed with hydroxyacrylic resin, it is sprayed on the back of the wallpaper surface pattern layer 3, and finally sprayed on the bottom surface of the complementary color protective layer 4 There ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com