Variable-speed constant-voltage generator

A generator and rotor technology, applied in asynchronous induction motors, electrical components, electromechanical devices, etc., can solve problems such as electrical components not working properly, and achieve the effect of taking into account economic performance and ensuring technical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

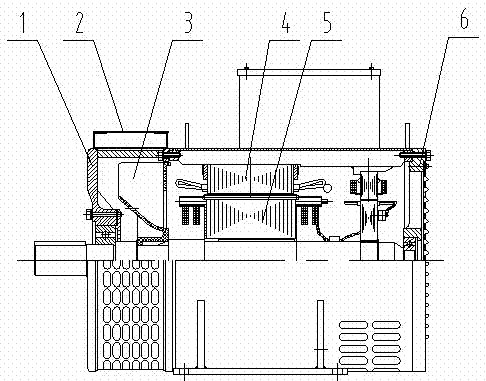

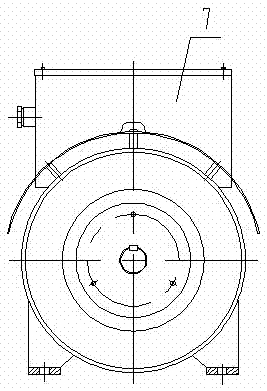

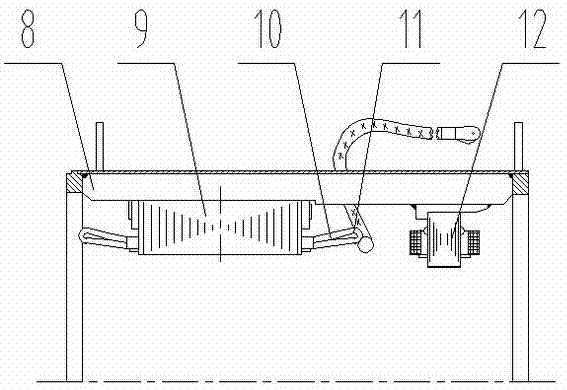

[0014] The present invention is realized like this, as Figure 1-Figure 5 As shown, a variable-speed constant-voltage generator includes a front end cover 1, a protective cover 2, a fan 3, a stator 4, a rotor 5, a rear end cover 6, and an outlet box 7; the rotor 5 is installed through the bearing hole of the rear end cover 6 On the stator 4, the front end cover 1 and the coupling piece 3 are fixed on the rotor 5 through keys, the protective cover 2 is fixed on the front end cover 1, and finally the outlet box 7 is installed on the stator 4; in the fundamental wave and harmonic winding The part 11 is distributed according to the harmonic winding part 20 and the fundamental wave winding part 21, and the stator main winding 10 is embedded in the slot of the stator core 9, and the exciter stator winding core 12 and the stator core 9 are installed on the base 8; the rotor winding 17 is in The rotor core 16 is on and off the assembly line, the front bearing 14, the fan 15, the rotor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com