Microemulsified watered diesel, additive used thereby and preparation process thereof

A technology of microemulsion and additive, which is applied in the preparation process of microemulsion water-mixed diesel oil, microemulsion diesel oil additive, microemulsion water-mixed diesel oil, and can solve the problem of unqualified microemulsion water-mixed diesel technology, unstable performance, cetane Low value and other problems, to achieve huge economic value and social value, good stability, high cetane number effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] 70% fatty acid, 7% diethylammonia, 12% methanol, 6% potassium chloride, and 5% tetrahydrofuran; at room temperature, add the above proportions into the container and stir evenly (about 30 minutes), and then obtain the multifunctional emulsifying additive .

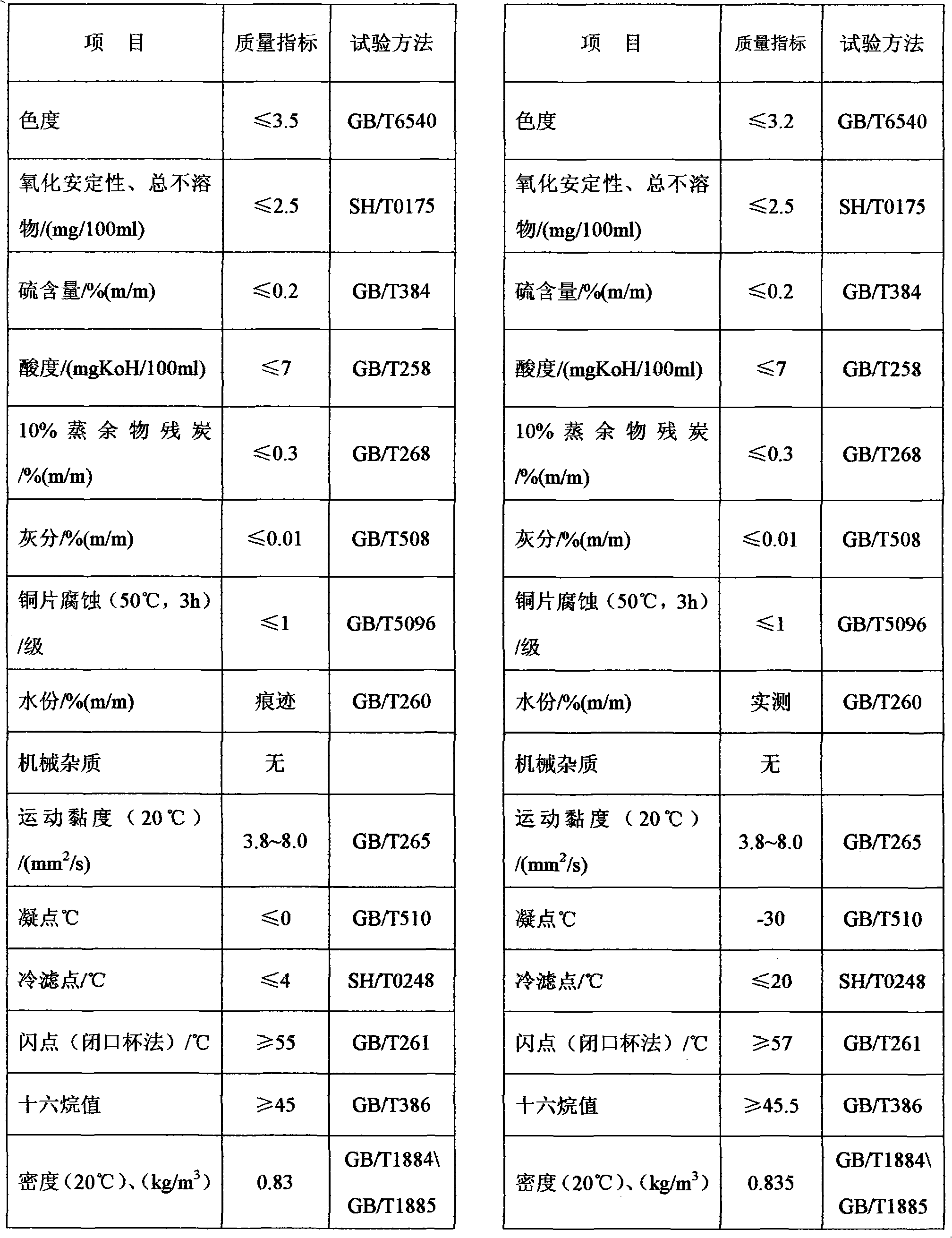

[0045] Take 80% of diesel oil, 10% of multi-functional emulsifying additive, and 10% of water, add the above into the container in order at room temperature and stir until it is completely transparent, then mix 80% of micro-emulsified diesel with water, 20% of aviation kerosene, cetane number The proportion of the improver is 0.5‰ and the mixture is evenly stirred to obtain the qualified micro-emulsion water-mixed diesel oil. The density of the oil is 835kg / m 3 , Flash point 60°C (closed), freezing point -34°C.

Embodiment 2

[0047] Fatty acid 80%, diethylammonia 4%, methanol 7%, potassium chloride 4%, tetrahydrofuran 5%;

[0048] At normal temperature, add the above proportions into the container and stir evenly (for about 30 minutes), to obtain the multifunctional emulsifying additive.

[0049] Take 70% of diesel oil, 15% of multi-functional emulsifying additive, and 15% of water, and add the above into the container at room temperature and stir until it is completely transparent. The proportion of improver 0.8‰ is stirred evenly to obtain the qualified micro-emulsion water-mixed diesel oil, and the density of the oil is 835kg / m 3 , Flash point 58°C (closed), freezing point -33°C.

Embodiment 3

[0051] Fatty acid 85%, diethylammonia 4%, methanol 4%, potassium chloride 3%, tetrahydrofuran 4%;

[0052] At normal temperature, add the above proportions into the container and stir evenly (for about 30 minutes), to obtain the multifunctional emulsifying additive.

[0053] Take 60% of diesel oil, 20% of multi-functional emulsifying additive, and 20% of water, and add the above into the container at room temperature and stir until it is completely transparent. Mix the ratio of improver 1‰ and stir evenly to get qualified micro-emulsion water-mixed diesel oil with a density of 840kg / m 3 , Flash point 62°C (closed), freezing point -30°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| dew point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com