Patents

Literature

42results about How to "Reduce friction factor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing high-density iron-base powder metallurgy parts

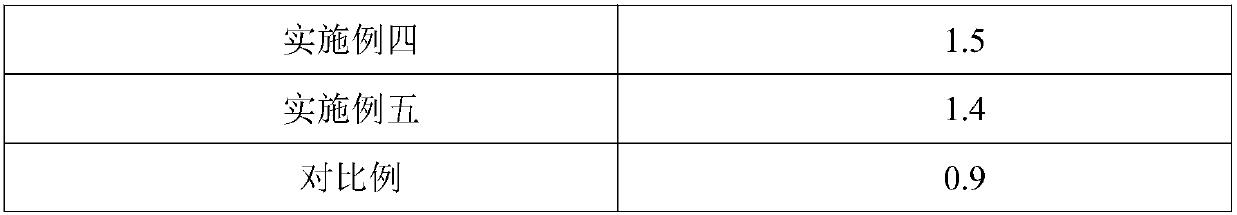

The invention provides a method for preparing high-density iron-base powder metallurgy parts, and belongs to the technical field of powder metallurgy molding. The compaction density of iron-base powder can be increased by utilizing the special stratified structure, the low friction factor and the good lubricating property of MoS2 (molybdenum disulfide). The method comprises the following steps: uniformly mixing the iron powder with MoS2 powder, carrying out annealing treatment, and causing MoS2 to be uniformly distributed on the surface of the iron powder; and uniformly mixing annealed mixed powder with a certain amount of metal powder, graphite powder and the like, and pressing and sintering to obtain the high-density iron-base parts. In the pressing process, the friction force among powder particles is reduced and the friction state among the powder particles is improved through the MoS2, the pressing performance is increased, and the iron-base powder metallurgy parts with the density of 7.2g / cm3-7.5g / cm3 can be obtained. The method has the advantages that the pressing performance of the iron-base powder is improved; the high-density iron-base powder metallurgy parts is obtained on the premise of cost reducing; the friction factor is reduced, the loss of abrasive tools is decreased, and meanwhile, the adverse influence of sulphur on the iron-base parts does not exist; and the process is simple and suitable for industrial production.

Owner:UNIV OF SCI & TECH BEIJING

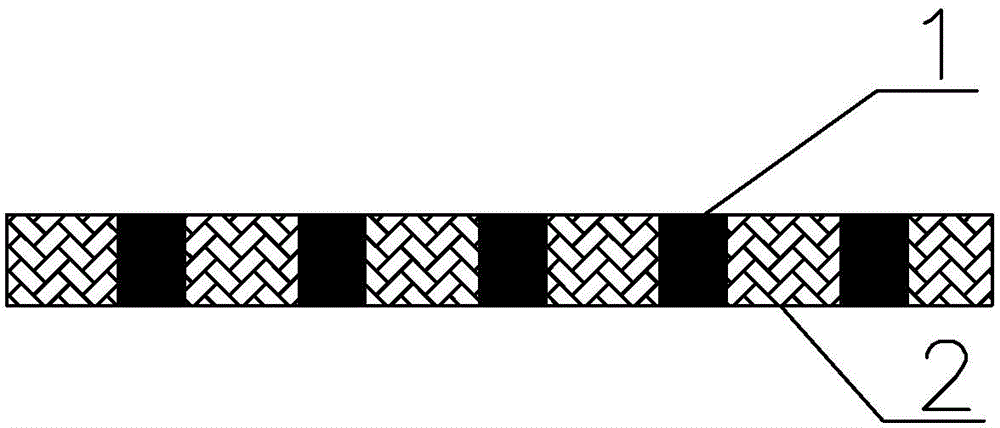

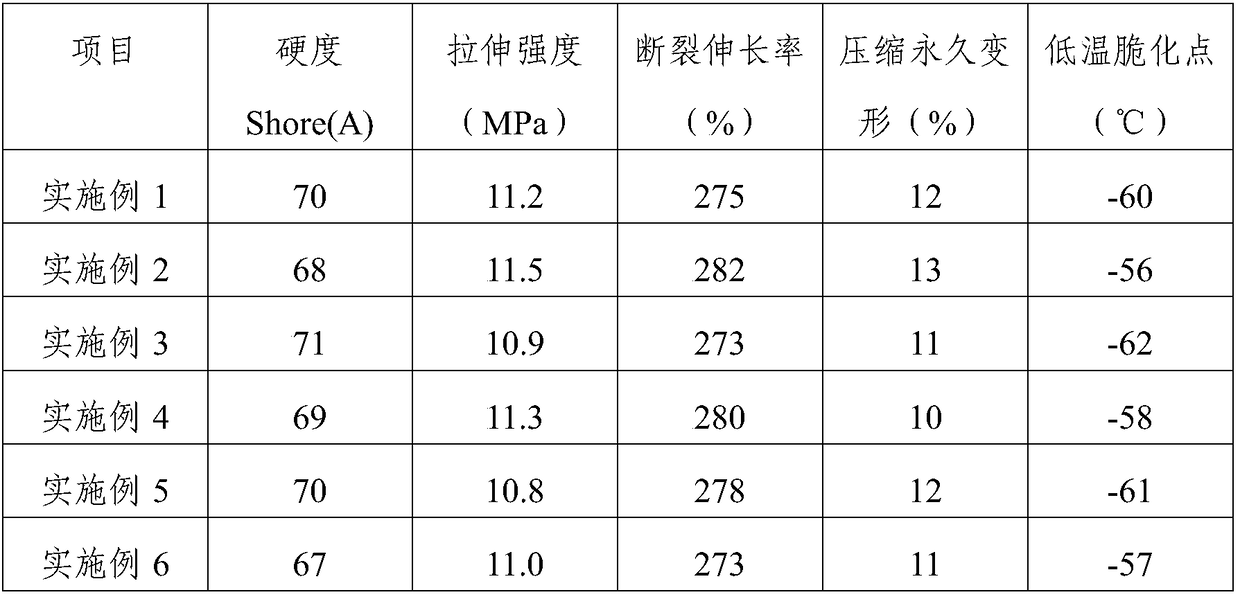

Preparation method of TPU and PVC blended improved composite fabrics

ActiveCN102729559AGood weather resistanceImprove wear resistanceSynthetic resin layered productsLaminationEngineeringOxygen

The invention discloses a preparation method of TPU and PVC blended improved composite fabrics. According to the method, TPU and PVC are blended to fully perform respective characteristics of TPU and PVC, so as to achieve the purpose of complementary advantages; calendaring molding is carried out by a four roll calender method to obtain a TPU and PVC blended film; and on-line lamination is carried out on the TPU and PVC blended film and glued base cloth on a calendar so as to obtain the TPU and PVC blended improved composite fabrics. The composite fabrics have characteristics of excellent mechanical property, wear resistance, environmental protection and the like. The coating of the composite fabrics is uniform and thickness error is less than 0.015mm. The composite fabrics has advantages of firm adhesion, wear resistance and flexing resistance, and can be widely used in application fields of inflatable life jacket, chemical splash suit, water pot, oil tank, sphygmomanometer, medical bed, oxygen bag, inflatable cushion, airbed, inflatable tent, air bag, air cushion ship, waterproof moisture permeable high-grade costuming and the like.

Owner:无锡翔隆高分子面料有限公司

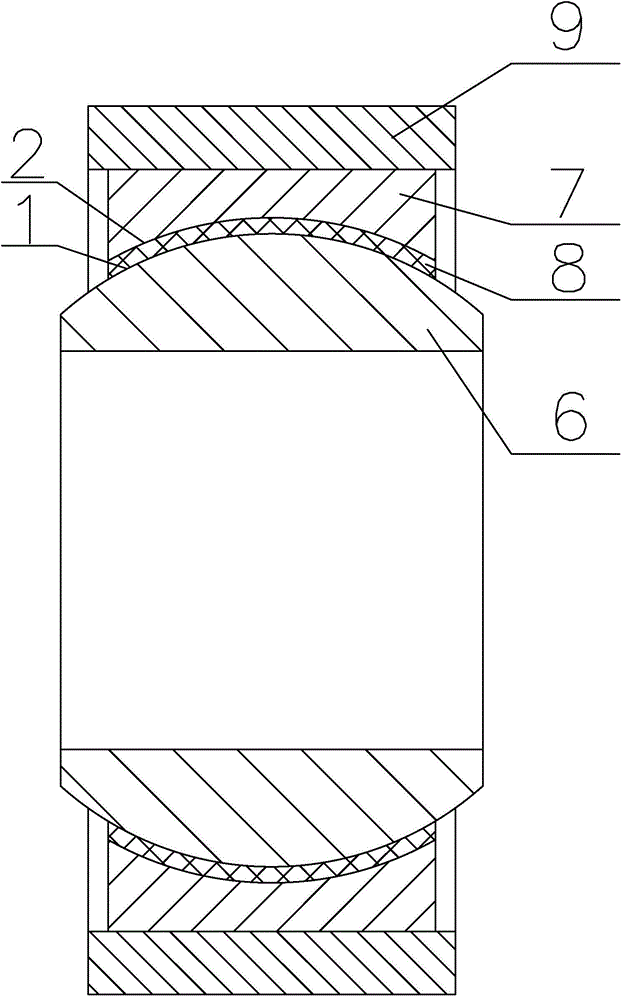

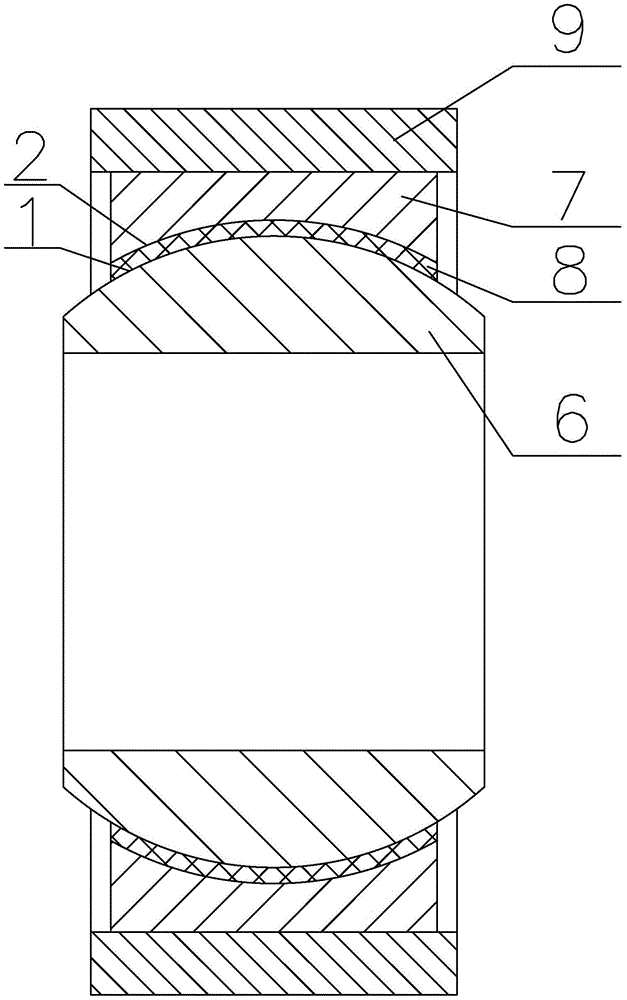

Manufacturing method of PTFE (polytetrafluoroethylene) fabric self-lubricating spherical plain bearing

ActiveCN104149364AGuaranteed StrengthGuaranteed wear resistanceBearing componentsCouplingEngineering

The invention discloses a manufacturing method of a PTFE (polytetrafluoroethylene) fabric self-lubricating spherical plain bearing. The manufacturing method comprises the following steps: one surface of a PTFE fabric liner is coated with glue A which is irreversible after curing; the fabric coated with the glue A is subjected to rolling treatment; the fabric liner is cured by adopting a panel hot-pressing technology; the cured fabric liner is cut into a size suitable for an inner spherical surface of an outer ring of the spherical plain bearing; the inner spherical surface of the outer ring or the other surface of the fabric liner is coated with glue B; then the fabric liner is adhered to the inner spherical surface of the outer ring through the glue B; an inner ring of the spherical plain bearing is sleeved into the outer ring of the spherical plain bearing, which is adhered to the fabric liner; the cured surface of the fabric liner faces to an outer spherical surface of the inner ring for mutual coupling and contact; the periphery of the outer ring is sleeved with a curing lantern ring; and the bearing is put into an oven for oven heating. The curing method not only can ensure the strength and abrasion resistance of the fabric liner, but also avoids the step of coating the outer spherical surface of the inner ring with a mold release agent.

Owner:FUJIAN LONGXI BEARING (GROUP) CO LTD

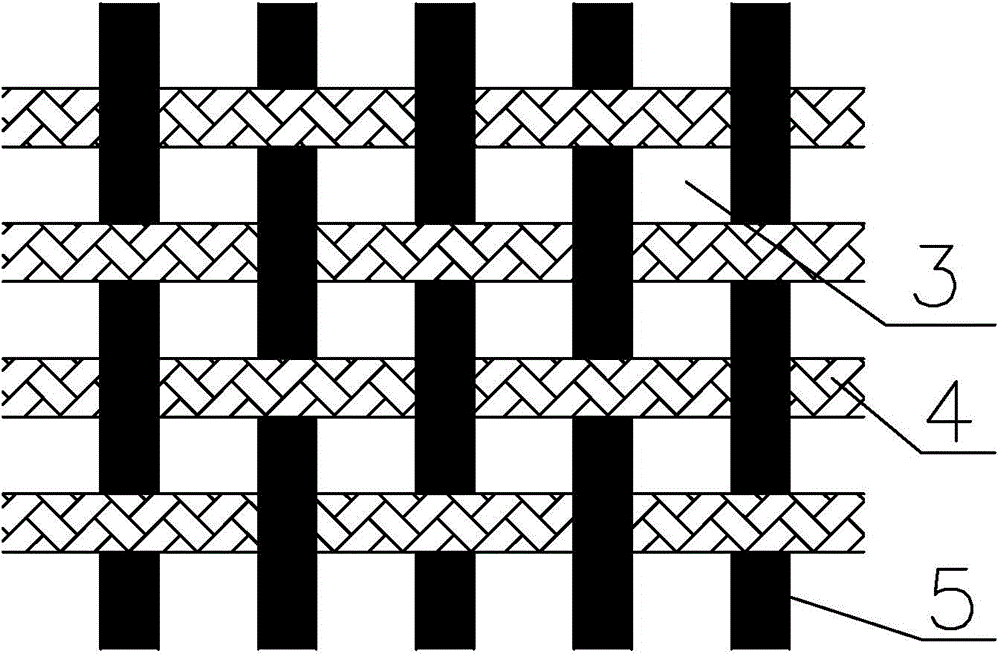

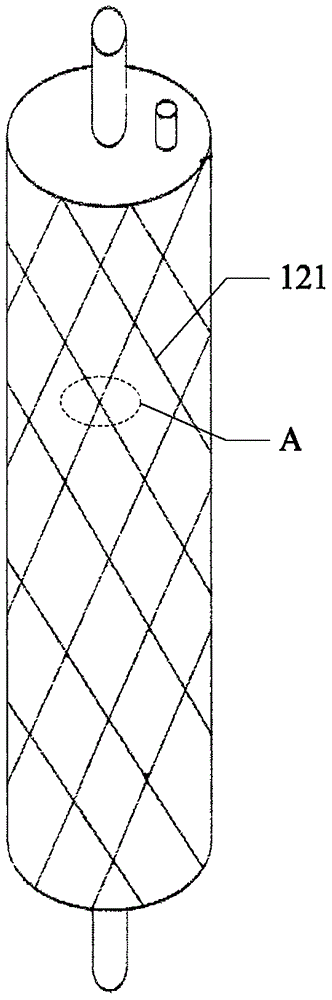

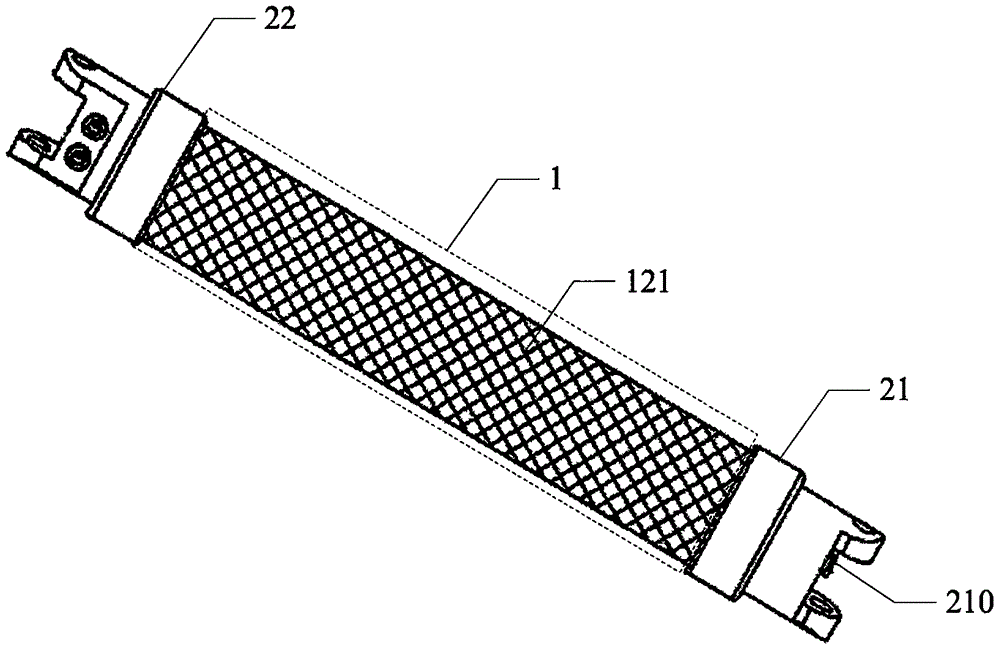

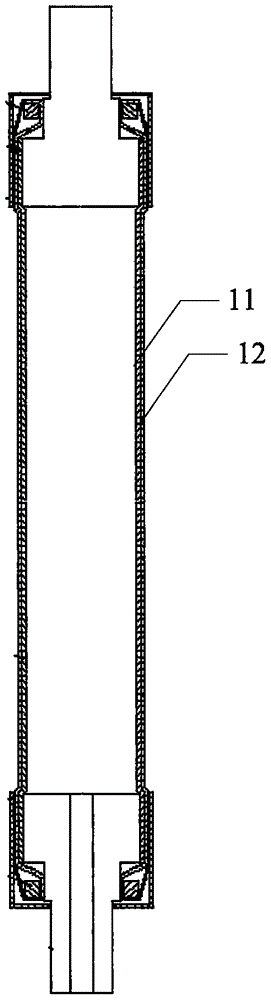

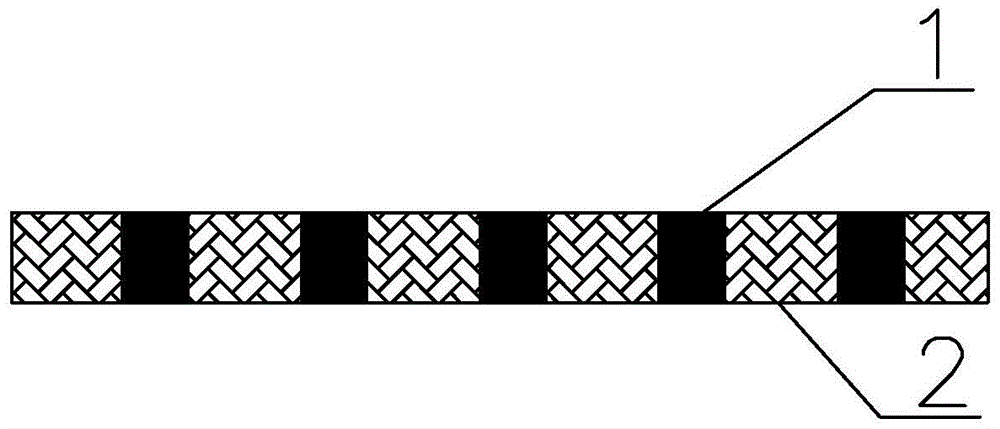

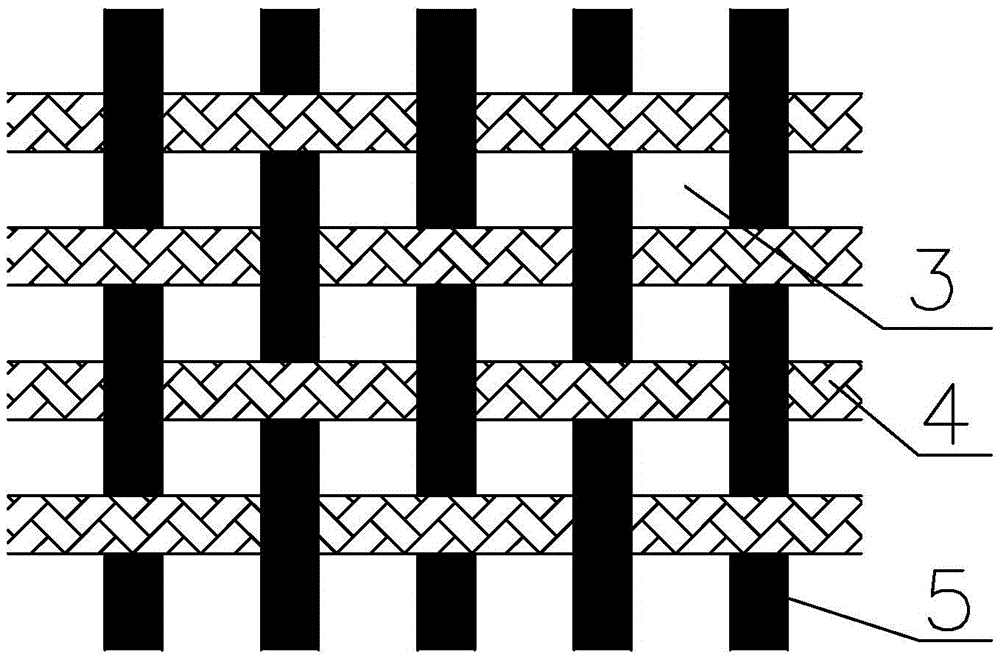

Pneumatic muscle and realized driving mechanism thereof

InactiveCN105805076AReduce frictionSmall hysteresisFluid-pressure actuatorsPull forceMathematical model

The invention relates to a pneumatic muscle and a realized driving mechanism thereof. The pneumatic muscle comprises a pneumatic muscle body, wherein the pneumatic muscle body is provided with an axial cavity which is used for charging / discharging compressed gas so as to provide a pulling force along the axial direction of the pneumatic muscle body; the pneumatic muscle body comprises an elastic hose with an axial activity and a woven mesh pipe which wraps the outer layer of the elastic hose and is used for restraining the axial deformation of the elastic hose; the woven mesh pipe comprises a plurality of lubricating pipes which are woven in a staggered mode; and restraining silks are respectively arranged in the lubricating pipes. According to the pneumatic muscle, the frictional force at the staggered positions is reduced when the pneumatic muscle body is deformed; the retardance caused by the body frictional force of the pneumatic muscle can be reduced; and therefore, the accuracy of pneumatic muscle mathematical models can be increased and the position control precision of the pneumatic muscle is increased.

Owner:CHINA JILIANG UNIV

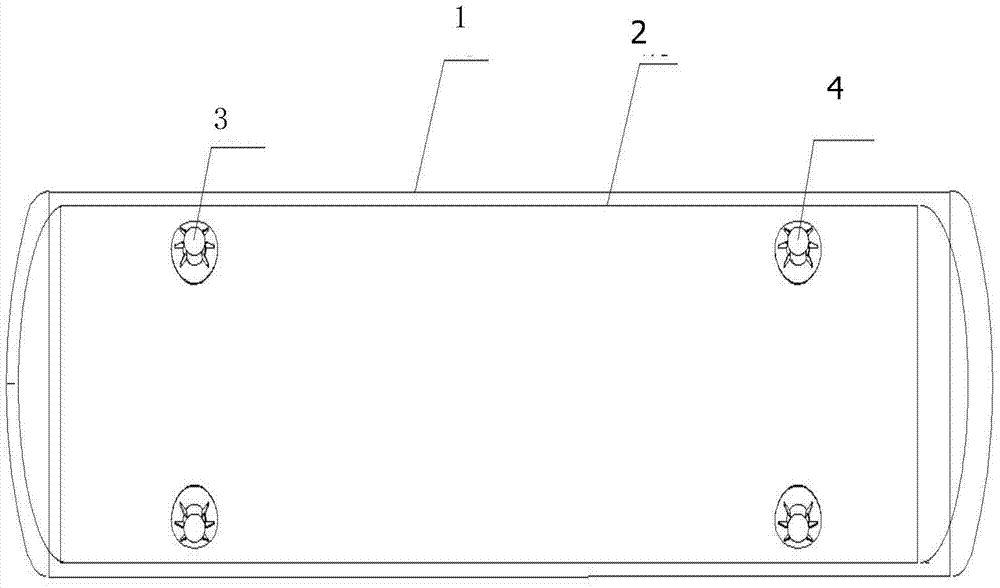

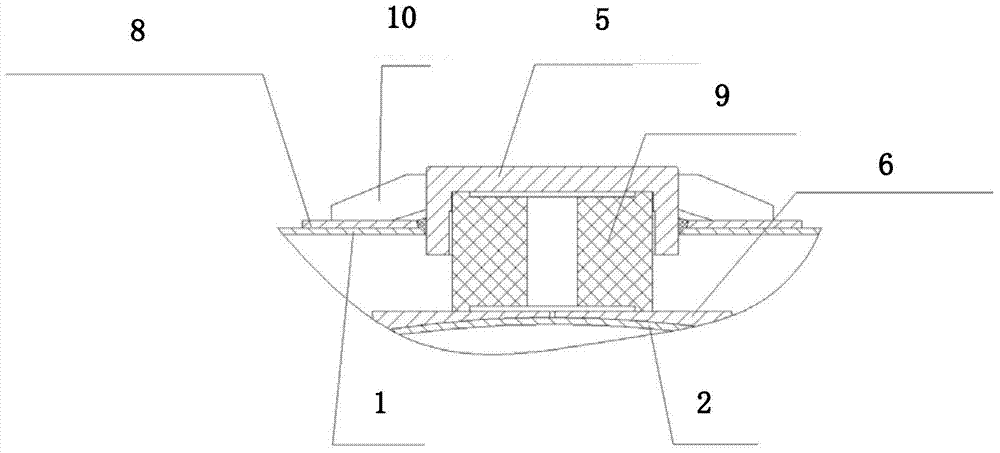

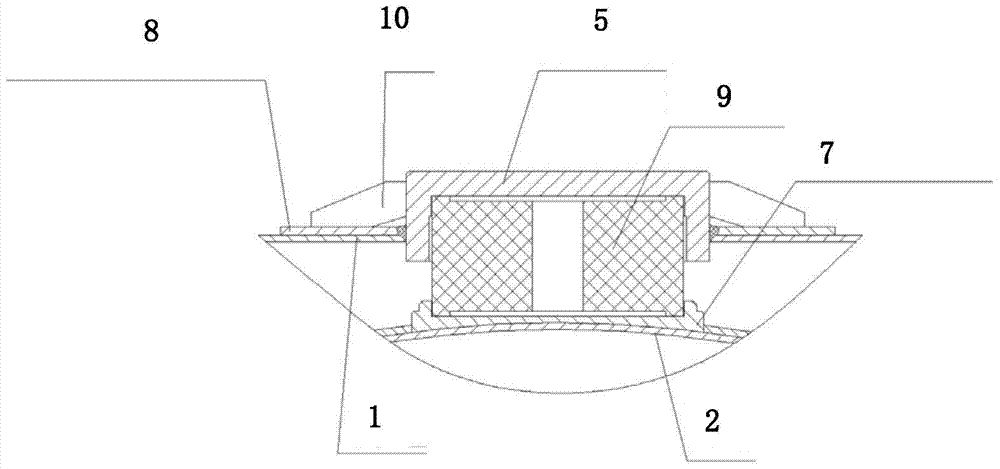

Inner tank and outer tank structural support

The invention relates to an inner tank and outer tank structural support comprising a sliding support component and a fixing support component between the inner tank and the outer tank. The sliding support component comprises an outer tank support cover arranged on the outer tank, an inner tank sliding support arranged on the inner tank, and a glass fiber reinforced plastics support used for connecting the outer tank support cover and the inner tank sliding support; the fixing support component comprises an outer tank support cover arranged on the outer tank, an inner tank fixing support arranged on the inner tank and a glass fiber reinforced plastics support used for connecting the outer tank support cover and the inner tank fixing support; an outer tank support cover stiffening ring and rib plate sets are arranged on the outer tank, and the rib plate sets are respectively connected with the outer tank support cover stiffening ring and the outer tank support cover. The inner tank and outer tank structural support is capable of reducing welding quantity, improving reliability and increasing braced force.

Owner:XI AN RAILWAY TRANSPORTATION EQUIP

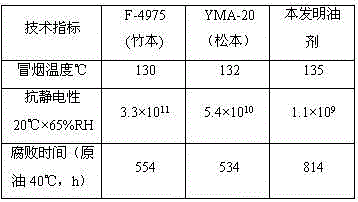

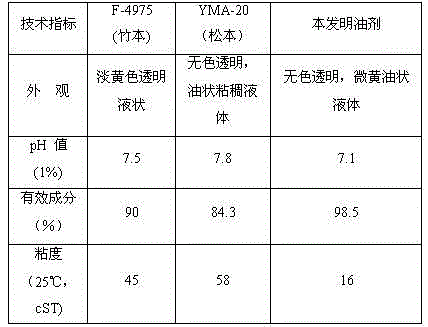

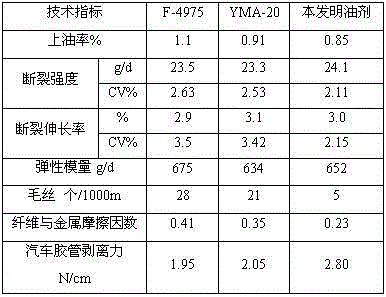

Aramid fiber oiling agent

The invention provides an aramid fiber oiling agent. The aramid fiber oiling agent comprises, by weight, 92-82% of a lubricating agent, 3-10% of a bundling agent, 5-8% of a composite antistatic agent, and the balance is an annexing agent. The lubricating agent is fatty acid sebacate. The aramid fiber oiling agent has the good antistatic property in various humidity conditions, corrosion is not likely to happen, the requirements for reducing of fiber corrosion and enhancing of composite performance of fibers and rubber of aramid fibers with various standards in the spinning procuding or secondary processing process can be met, the aramid fiber quality can be effectively improved, and continuous processing quality can be effectively improved.

Owner:CHINA BLUESTAR CHENGRAND CO LTD

Nanoparticle lubricating agent, preparation method thereof, and application of lubricating agent in ultrasonic lubrication technology

InactiveCN103275797AReduce friction factorReduce volumeMechanical vibrations separationLubricant compositionLubricationNanoparticle

The invention discloses a nanoparticle lubricating agent, a preparation method thereof and the application of the lubricating agent in ultrasonic lubrication technology. The nanoparticle lubricating agent comprises the following components in percentage by weight: 85 to 95 percent of base lubricating oil, 0.1 to 1.2 percent of nanoparticle, and 4 to 14.5 percent of dispersing agent. The preparation method comprises the steps: performing mixing and ultrasonic treatment to the base lubricating oil and the dispersing agent, so as to obtain solution A; performing mixing, ultrasonic treatment and high-speed stirring to the base lubricating oil, the nanoparticle and the dispersing agent, so as to obtain solution B; and performing mixing, ultrasonic treatment and grinding to the solution A and the solution B, so as to obtain the nanoparticle lubricating agent. When the nanoparticle lubricating agent is used for ultrasonic lubrication, the nanoparticle plays a rolling role between a friction pair, so that sliding friction of the friction pair becomes rolling friction, and the nanoparticle lubricating agent has excellent antifriction performance and a recovery effect on microdamge on a friction surface. By adopting the nanoparticle lubricating agent, the problem of wear failure of mechanical sliding moving pieces in severe environment can be solved, and the nanoparticle lubricating agent provides an innovative approach for improving and increasing the stability and the service life of equipment, reducing the maintenance time and reducing the maintenance cost.

Owner:ACADEMY OF ARMORED FORCES ENG PLA +1

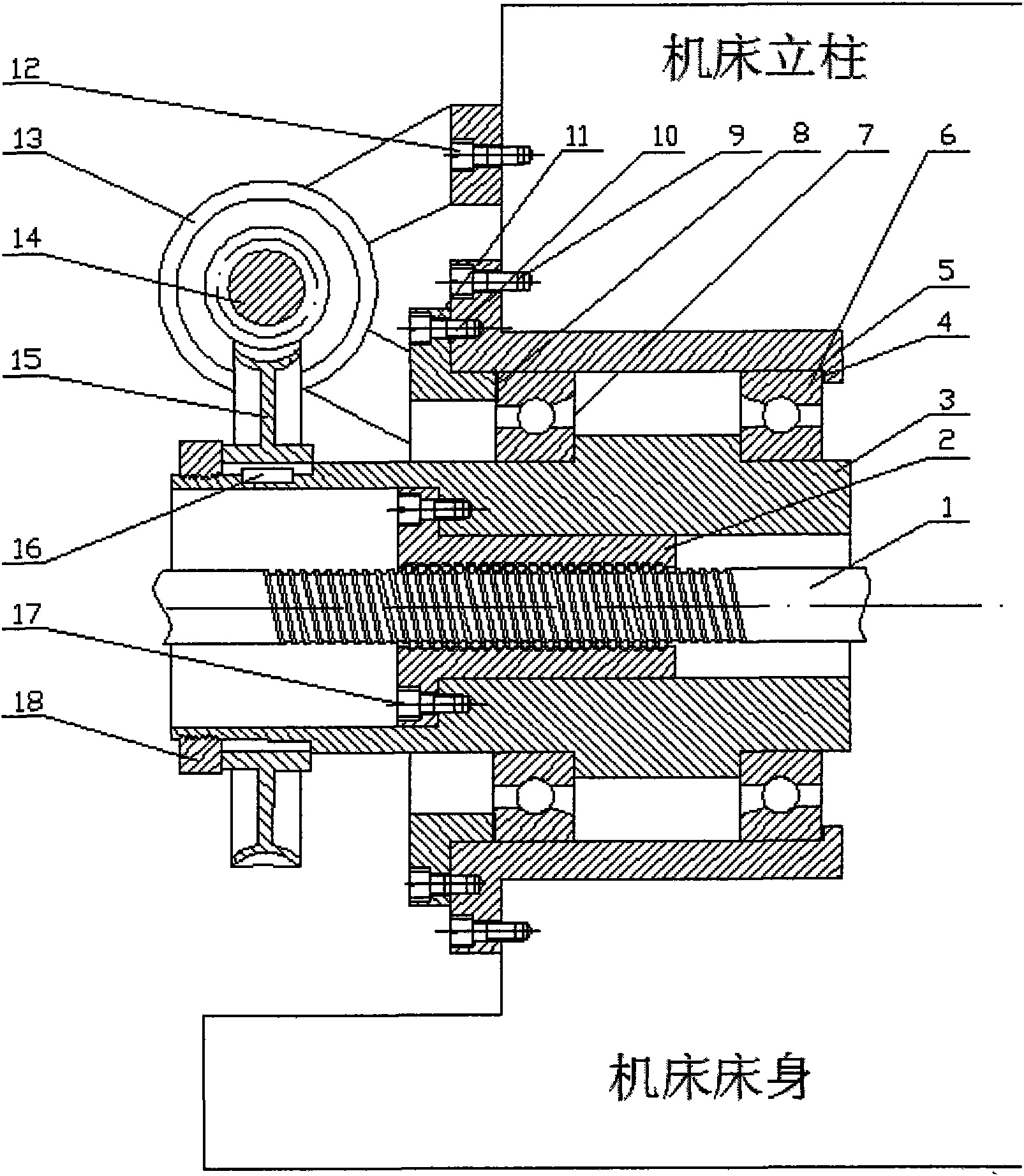

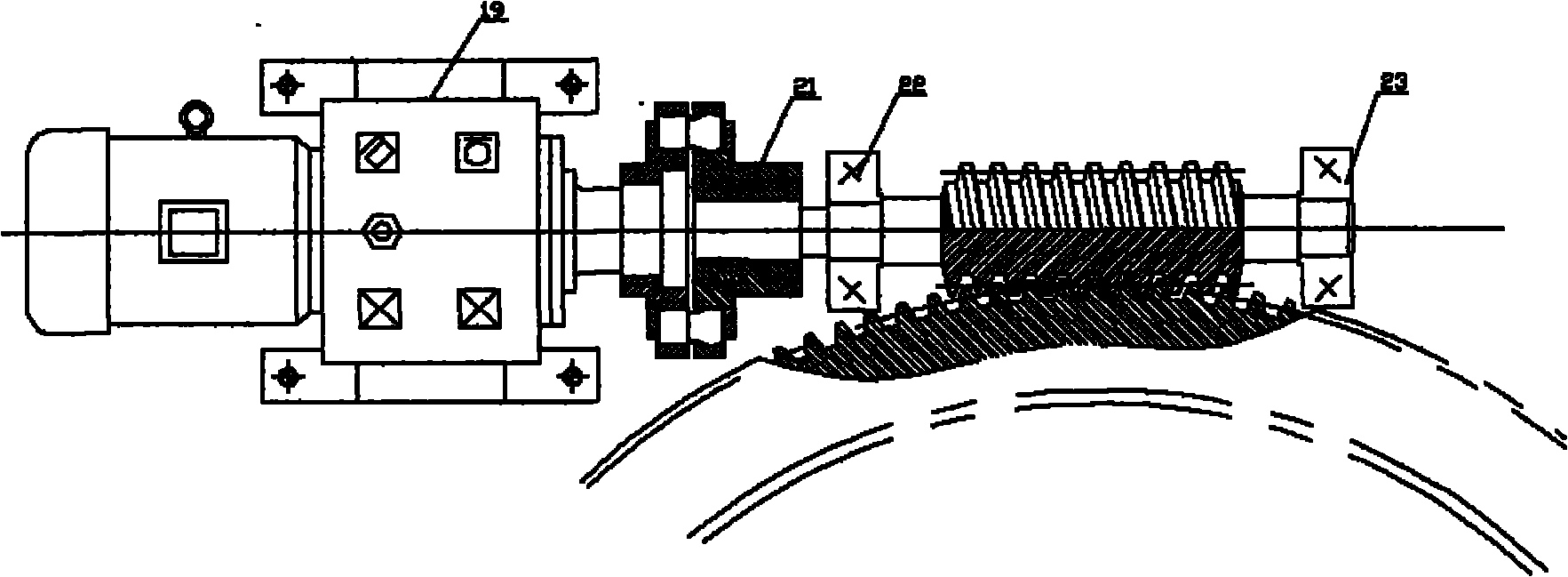

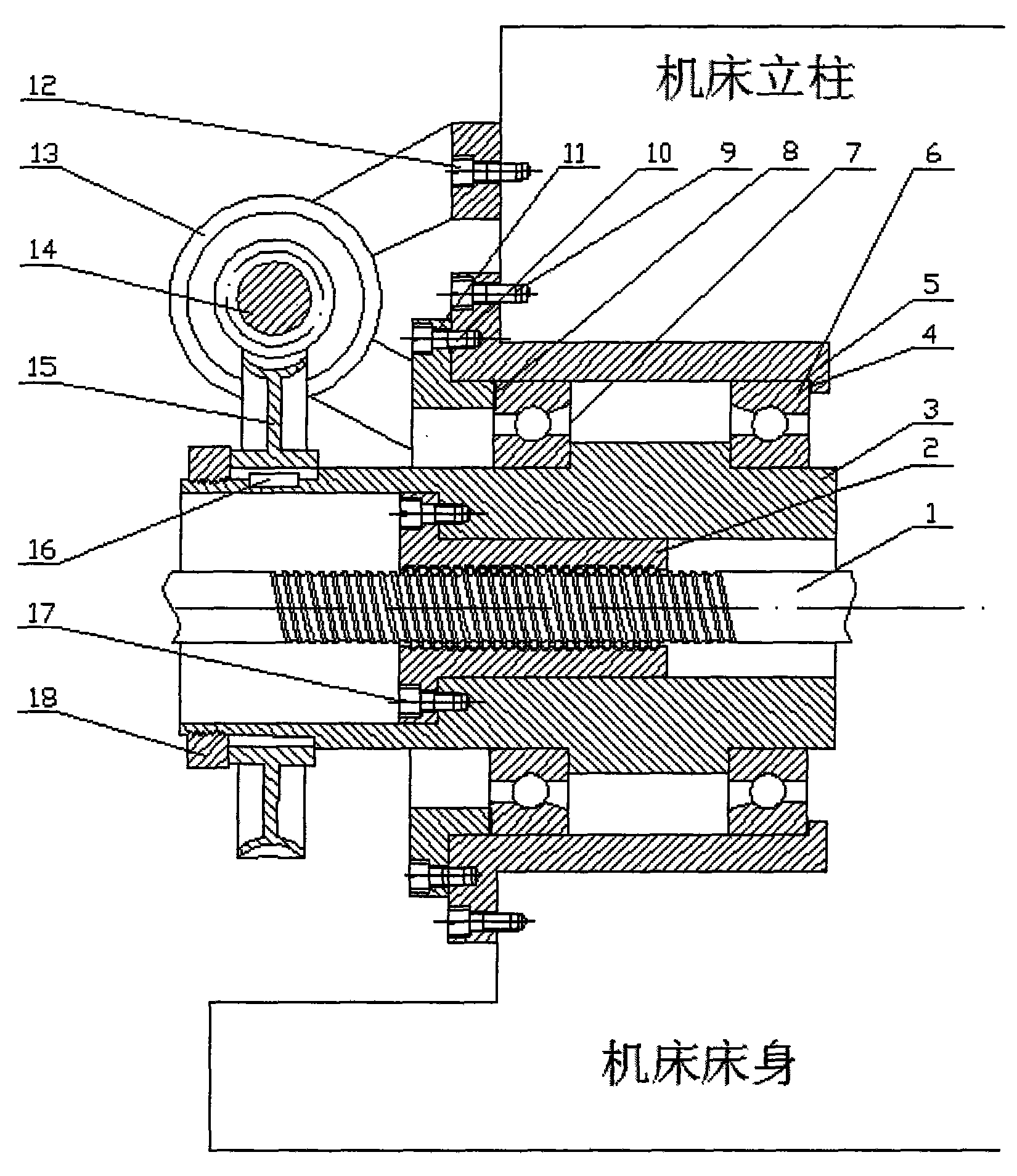

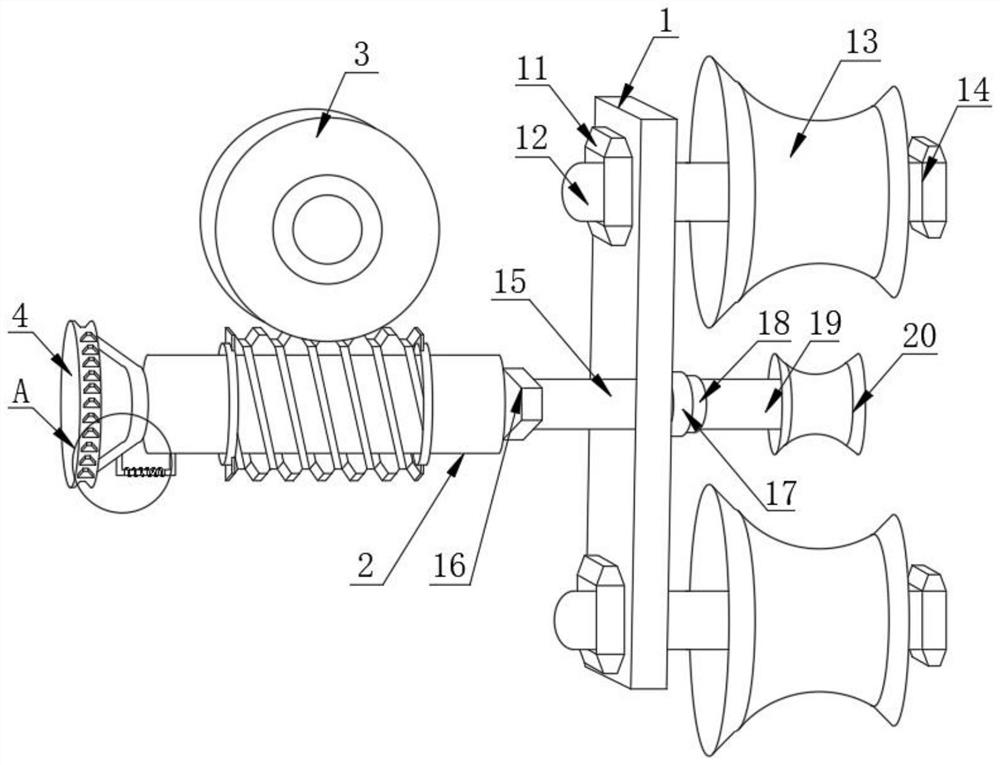

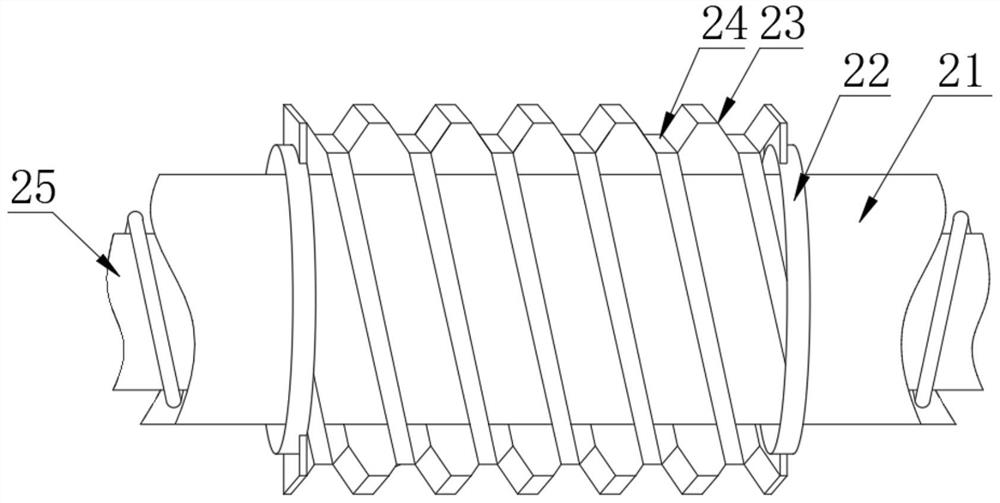

Thermal error differential screw compensating device and using method thereof

ActiveCN101791771AImprove versatilityImprove anti-interference abilityOther manufacturing equipments/toolsDifferential screwReduction drive

The invention discloses a thermal error differential screw compensating device comprising a screw rod nut drive system, a worm gear compensating system, and a fastening nut (18), wherein the screw rod nut (2) is fixedly connected with a first sleeve (3) by six first attachment screws (17) which are evenly distributed on the circumstance; a right bearing (6) and a left bearing (7) are installed on the first sleeve (3) to bear radial load and unidirectional axial load; the left bearing (7) utilizes the shaft shoulder of the first sleeve (3) and a second sleeve (11) to realize axial positioning; the right bearing (6) utilizes a third sleeve (5) and the shaft shoulder to realize axial positioning; the third sleeve (5) is connected with a machine tool stand column by six third attachment screws (9) which are evenly distributed on the circumferential direction; the second sleeve (11) is installed on the first sleeve (3) and is connected with the third sleeve (5) by six second attachment screws (10); a worm gear (15) in the worm gear compensating system is connected with the first sleeve (3) by a flat key (16); a motor coupled-type reducer engine base (13) is connected with the stand column by four fourth attachment screws (12); a motor coupled-type reducer (19) is connected with a worm (14) by a coupler (20); the motor directly drives the worm (14) to drive the worm gear (15) to rotate; and the fastening nut (18) are sued for axially positioning the worm gear (15) through screw thread.

Owner:CHONGQING UNIV +1

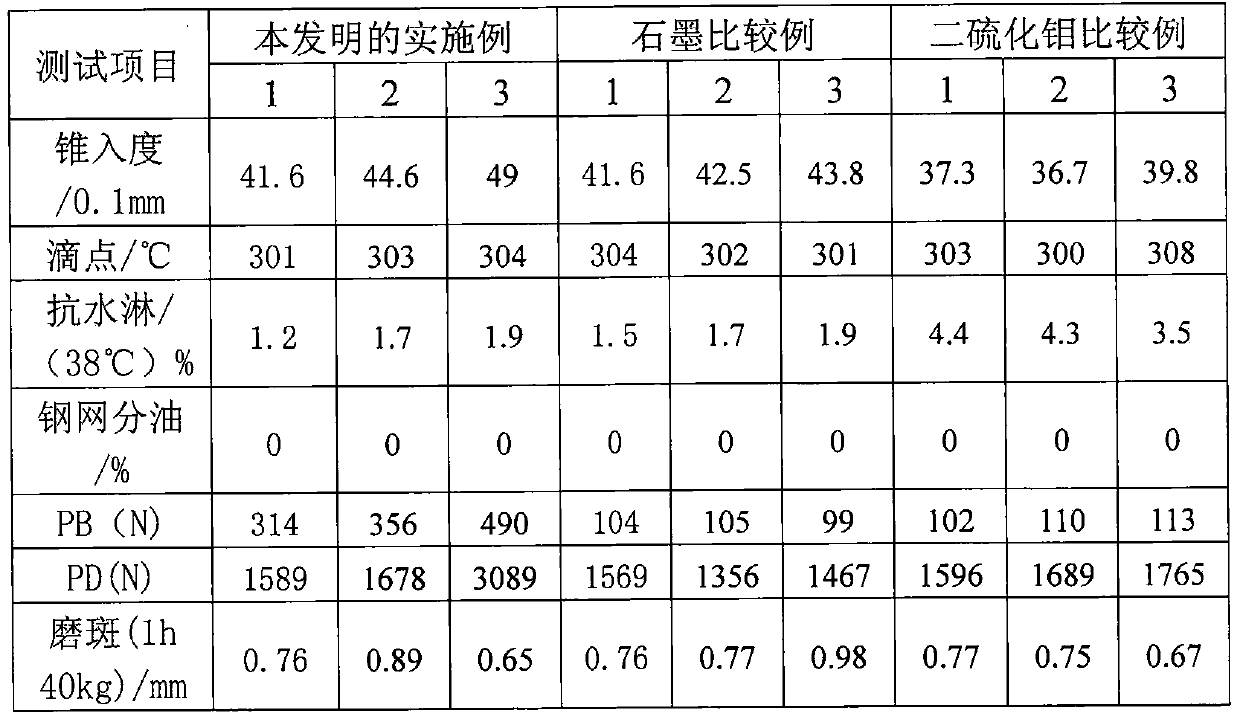

Polyurea lubricating grease and preparation method thereof

InactiveCN103740443AReduce key energyReduce friction factorLubricant compositionCarbon monofluorideHeat stability

The invention provides a polyurea lubricating grease and a preparation method thereof, and belongs to the technical field of lubricating grease. The polyurea lubricating grease comprises the following components in percentage by weight of polyurea lubricating grease: 10 to 30% of urea-based thickener, 54 to 89% of base oil, and 1 to 16% of additive, wherein the additive is carbon monofluoride. The polyurea lubricating grease has the advantages that the friction is reduced; the lubricating performance is improved; the performances on resisting abrasion, reducing friction and resisting extreme pressure are improved; the friction factors of a bearing running under a high temperature are reduced; the energy consumption is lowered; the consumption of lubricating grease is reduced, and thus the service life of the lubricating grease is prolonged; in addition, the oxidization stability, heat stability and comprehensive performances of the polyurea lubricating grease are also improved. The preparation method is simple in process and small in requirements on process factors, and realizes overall embodiment of the technical effect of the polyurea lubricating grease.

Owner:SUZHOU HUIFENG LUBRICANT

High-temperature-resistant and wear-resistant fluororubber sealing element and preparation method thereof

InactiveCN108504004AHigh strengthImprove performanceOther chemical processesCalcium silicateWear resistant

The invention provides a high-temperature-resistant and wear-resistant fluororubber sealing element and a preparation method thereof. The high-temperature-resistant and wear-resistant fluororubber seal element is prepared from the following raw materials in parts by weight: 50-70 parts of 26 type fluororubber, 20-45 parts of 23 type fluororubber, 12-20 parts of medium-particle pyrolysis carbon black, 5-8.5 parts of organic modified attapulgite, 1-1.8 parts of calcium silicate, 0.5-1 part of a talc powder, 1.5-2.5 parts of hydroxyl fluorosilicone oil, 1.5-2.5 parts of magnesium oxide, 0.3-0.5 part of a silane coupling agent, 2-3 parts of perfluoromethyl phenyl hydroxyl peroxide, 0.4-0.7 part of triallyl isocyanurate, and 0.5-1 part of a processing aid. The prepared sealing element has excellent high-temperature resistance and wear resistance and high strength, and the service life of the sealing element can be effectively prolonged.

Owner:ANHUI PROPELLENT HEAT TRANSFER TECH CO LTD

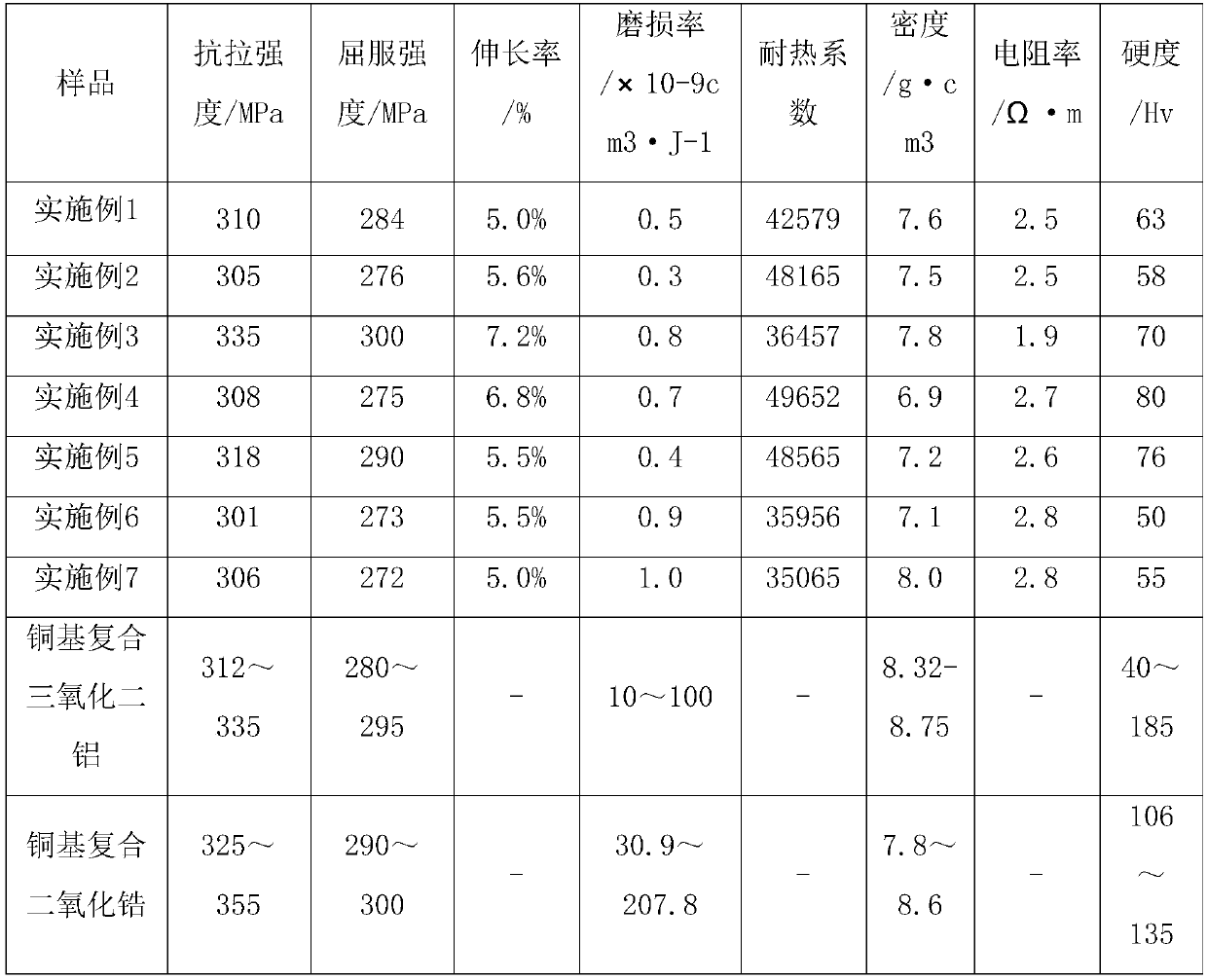

Copper-based aerogel enhanced copper alloy and preparation method thereof

InactiveCN109593987ATensile mechanical properties are equivalent toImprove thermal conductivityWear resistantMetallic materials

The invention discloses a copper-based aerogel enhanced copper alloy and a preparation method thereof, and belongs to the technical field of metal materials and preparation thereof. The copper-based aerogel reinforced copper alloy comprises, by mass, 0.5%-10% of zinc, 2%-8% of silicon dioxide and the balance copper. The preparation method comprises the following steps of burdening, ball milling, material mixing, cold pressing forming, pressure sintering and finished products. According to the copper-based aerogel enhanced copper alloy, the tensile strength of the prepared copper-based composite material is higher than 300 MPa, the yield strength is equivalent to that of a common copper-based aluminum oxide composite material, the wear rate is lower than 1*10<-9>cm<3>.J<-1>, the heat resistance coefficient is higher than 35000, and the heat resistance and the wear resistance can be better than those of the copper-based aluminum oxide composite material, so that the wear-resistant part made of the material can meet the requirements of long-term normal operation of products or equipment under the condition of high temperature.

Owner:BEIJING HONGWEINAJIN SCIENTIFIC & TECHNOLOGICAL CO LTD

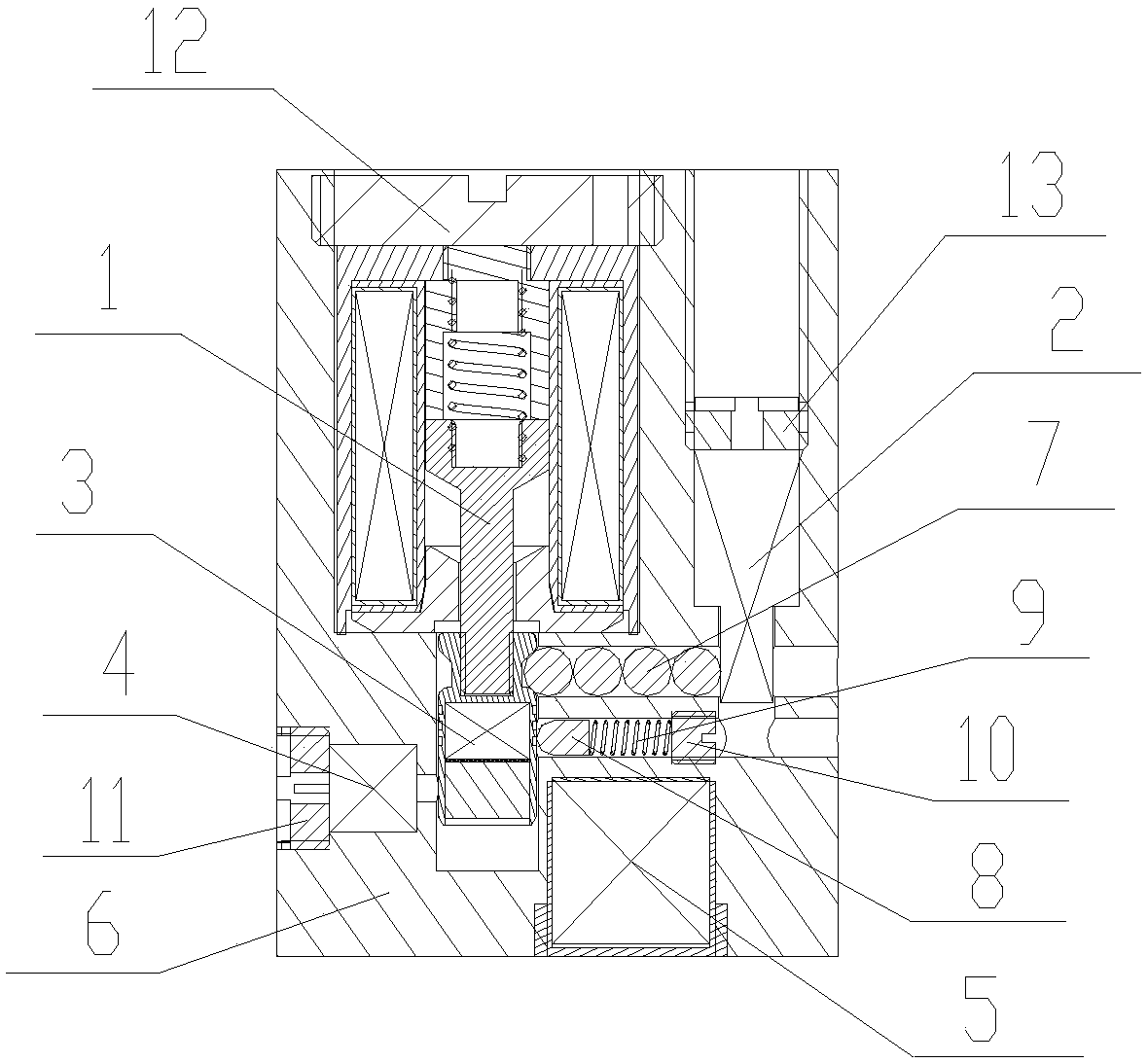

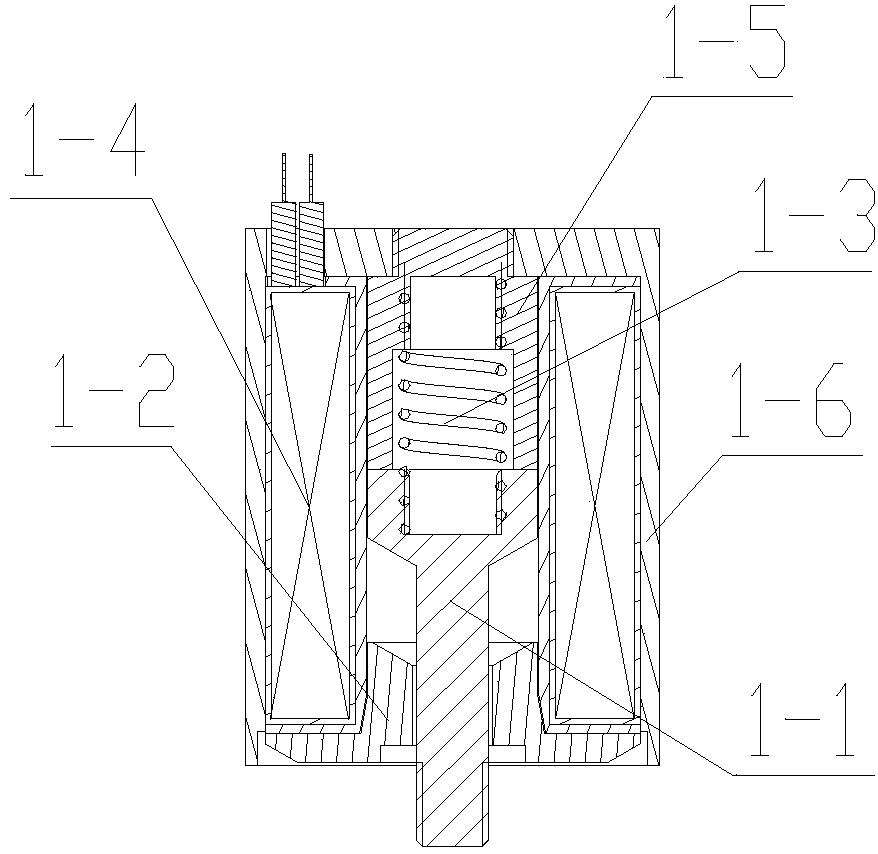

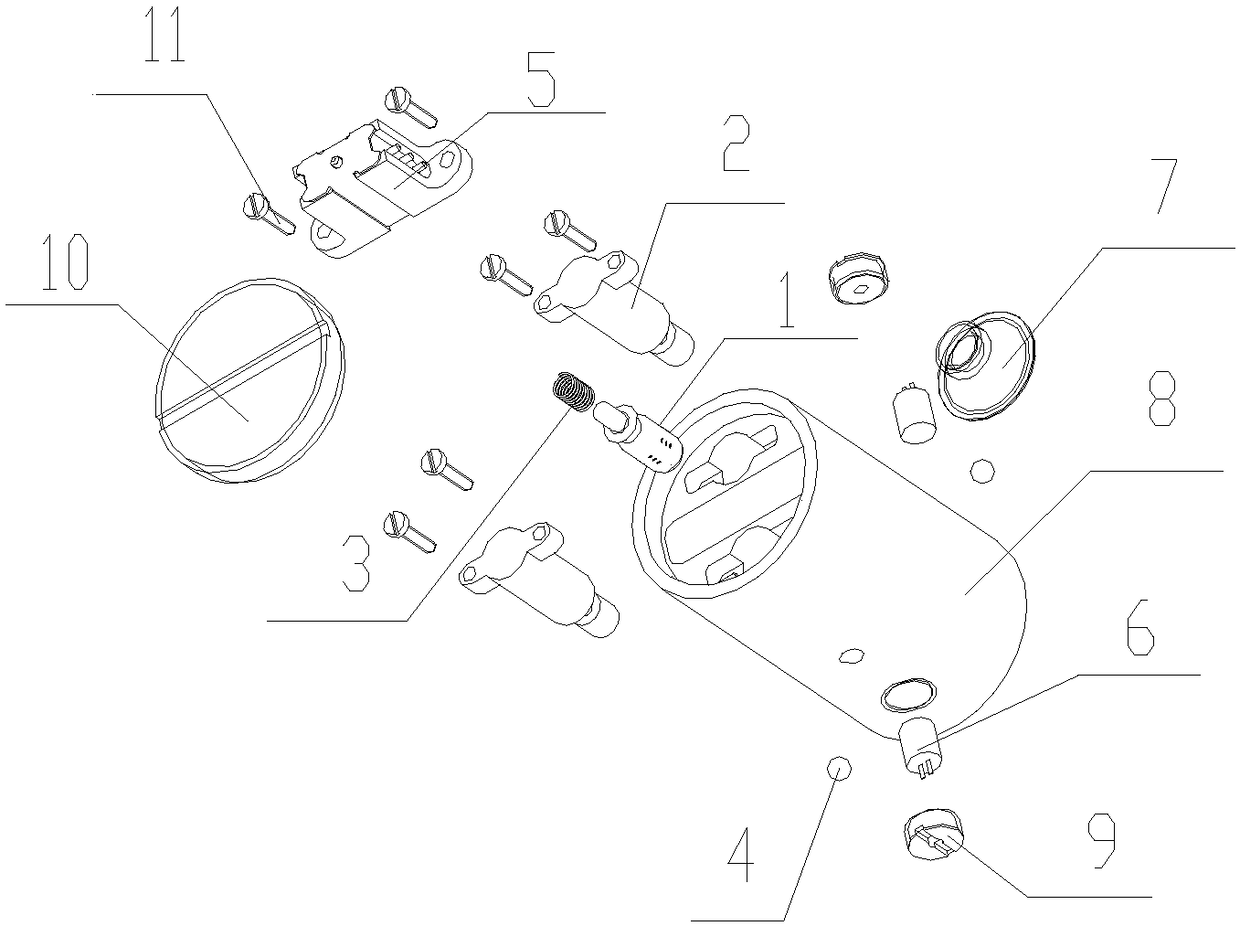

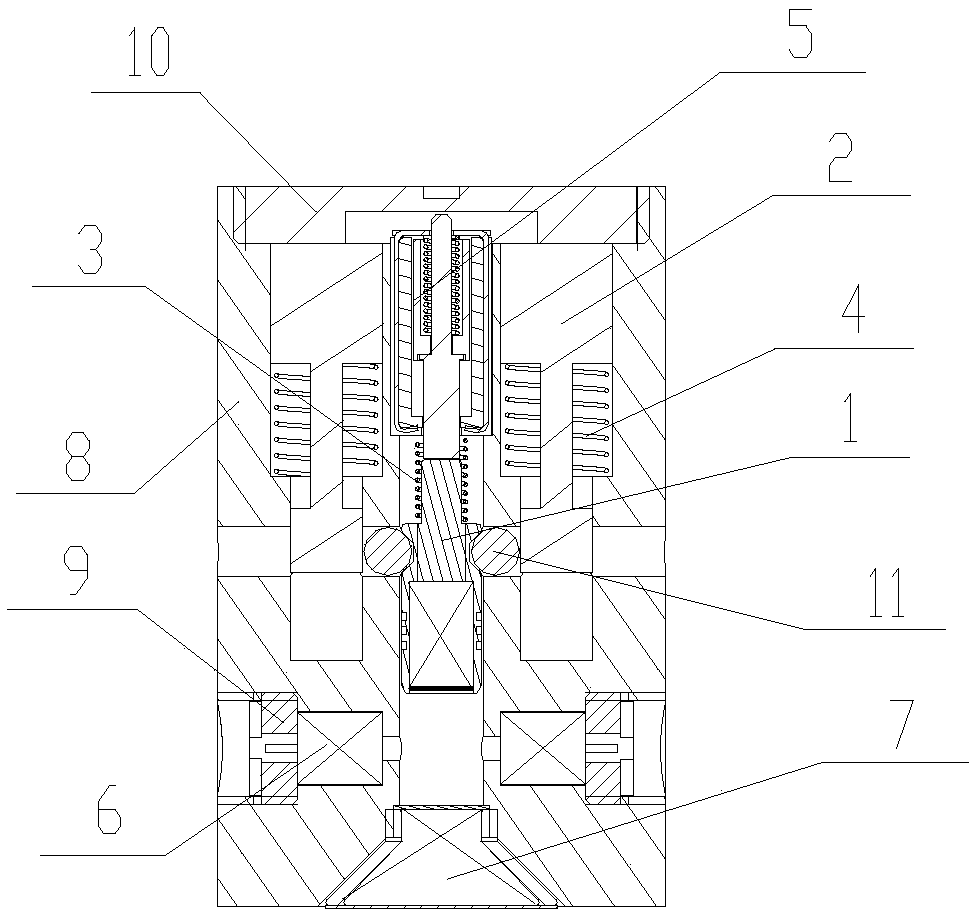

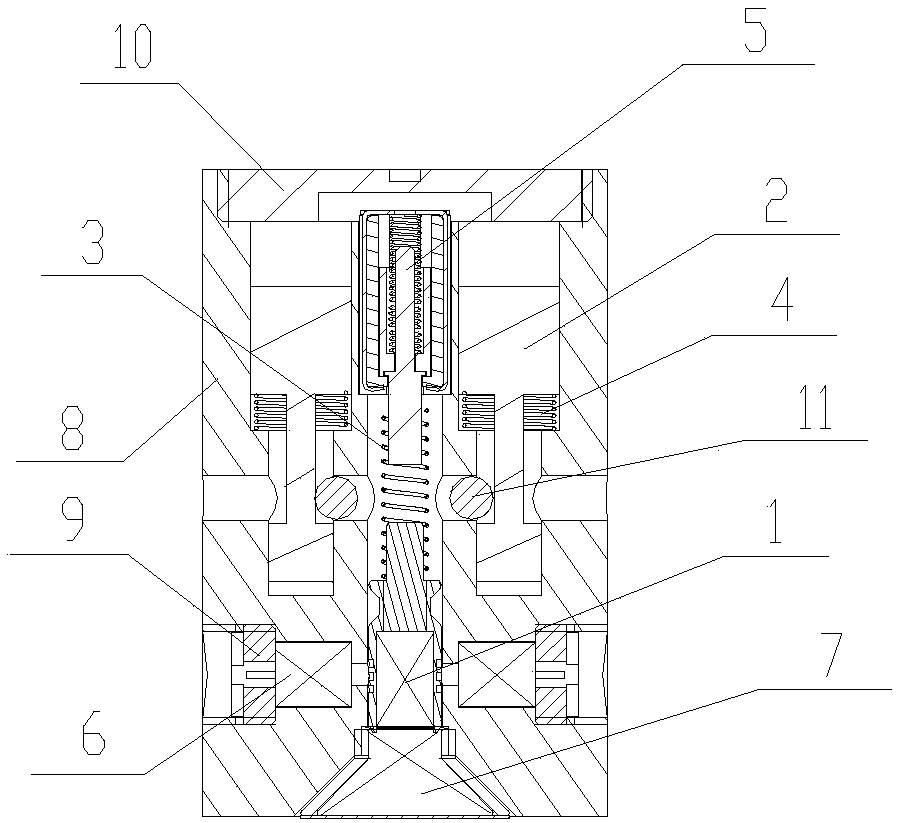

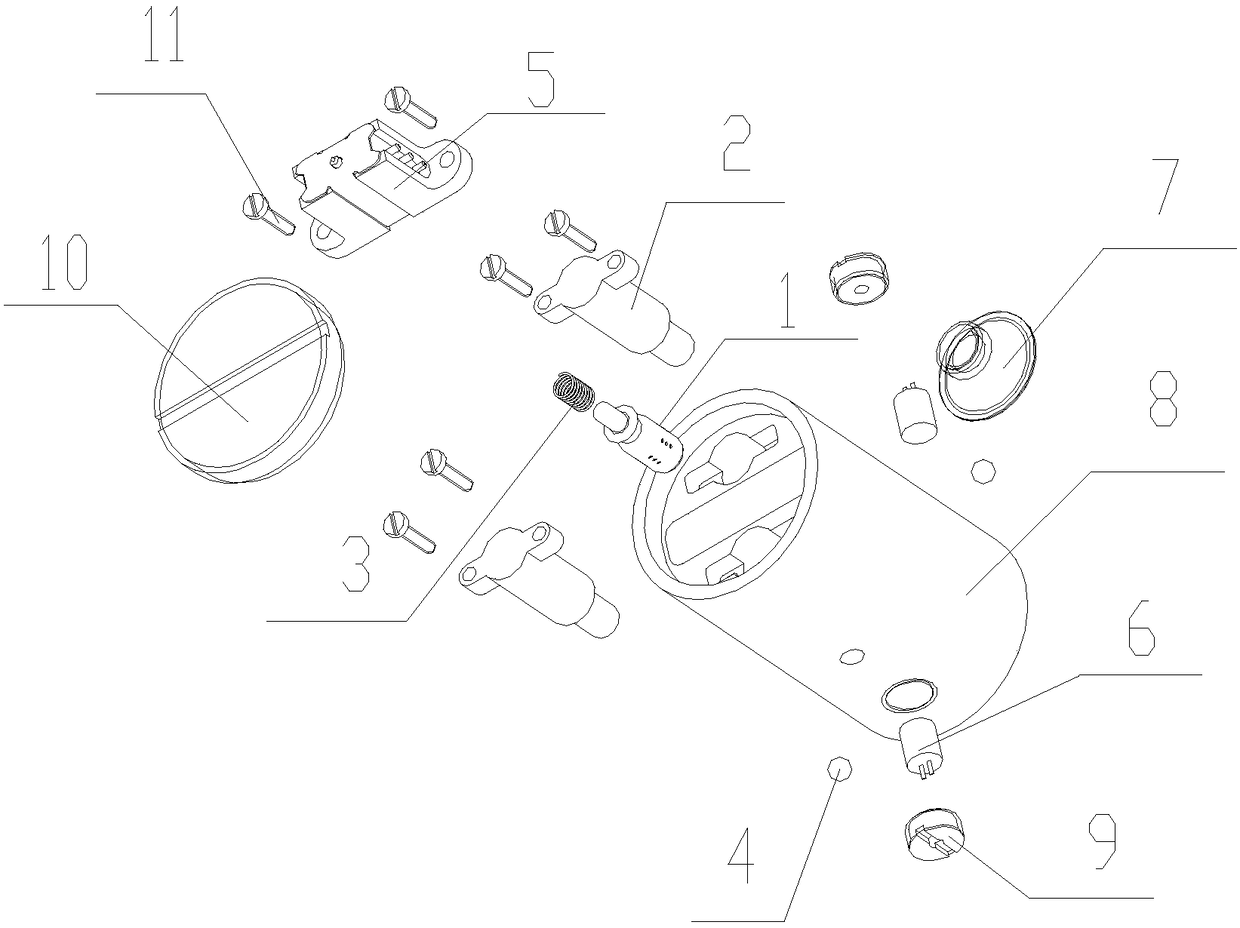

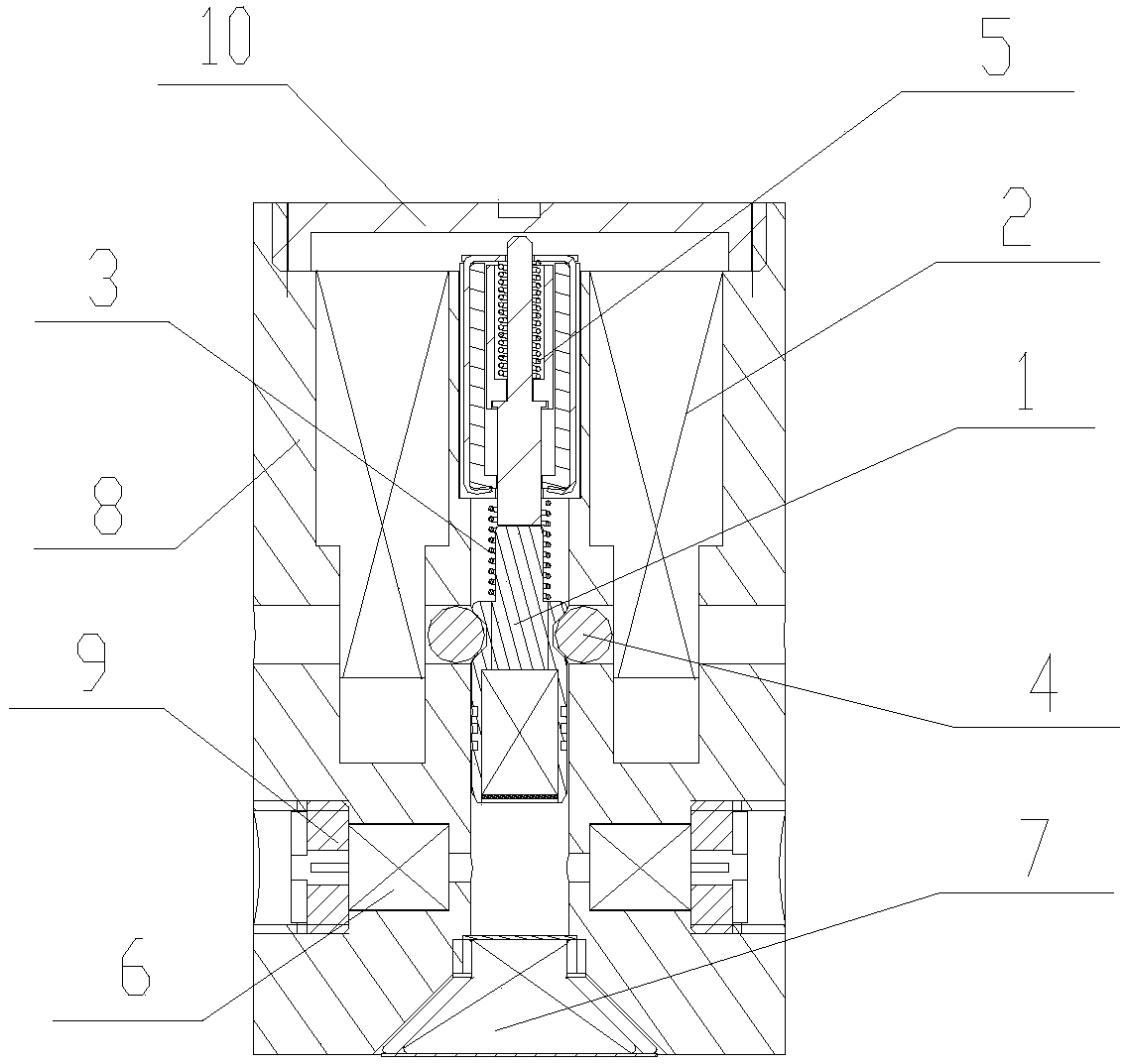

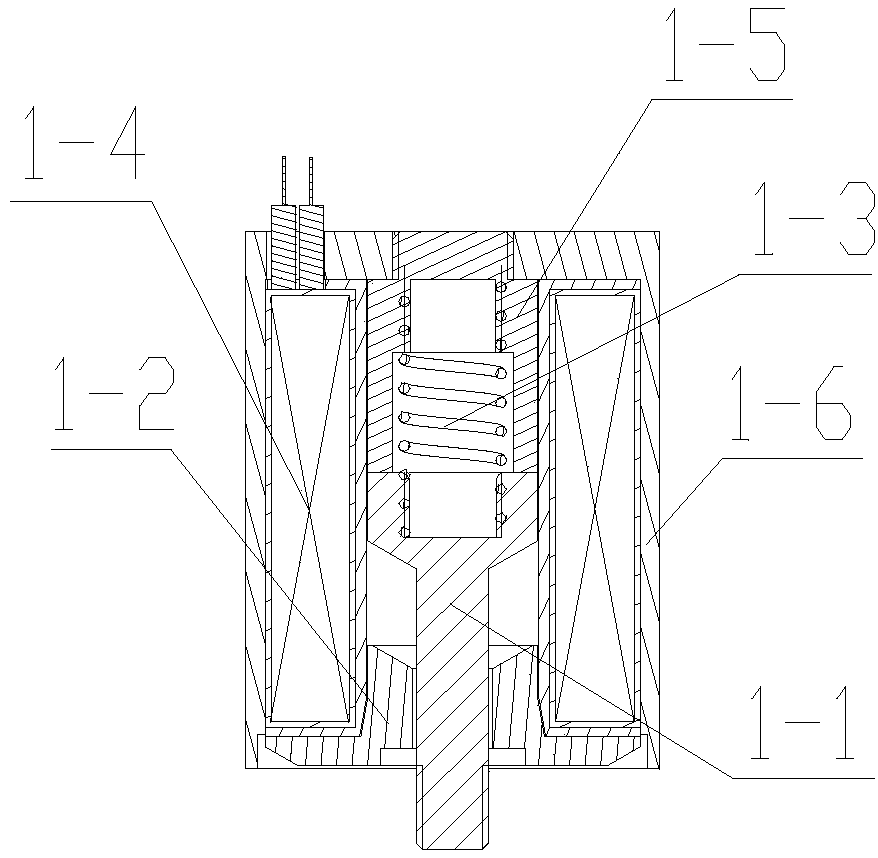

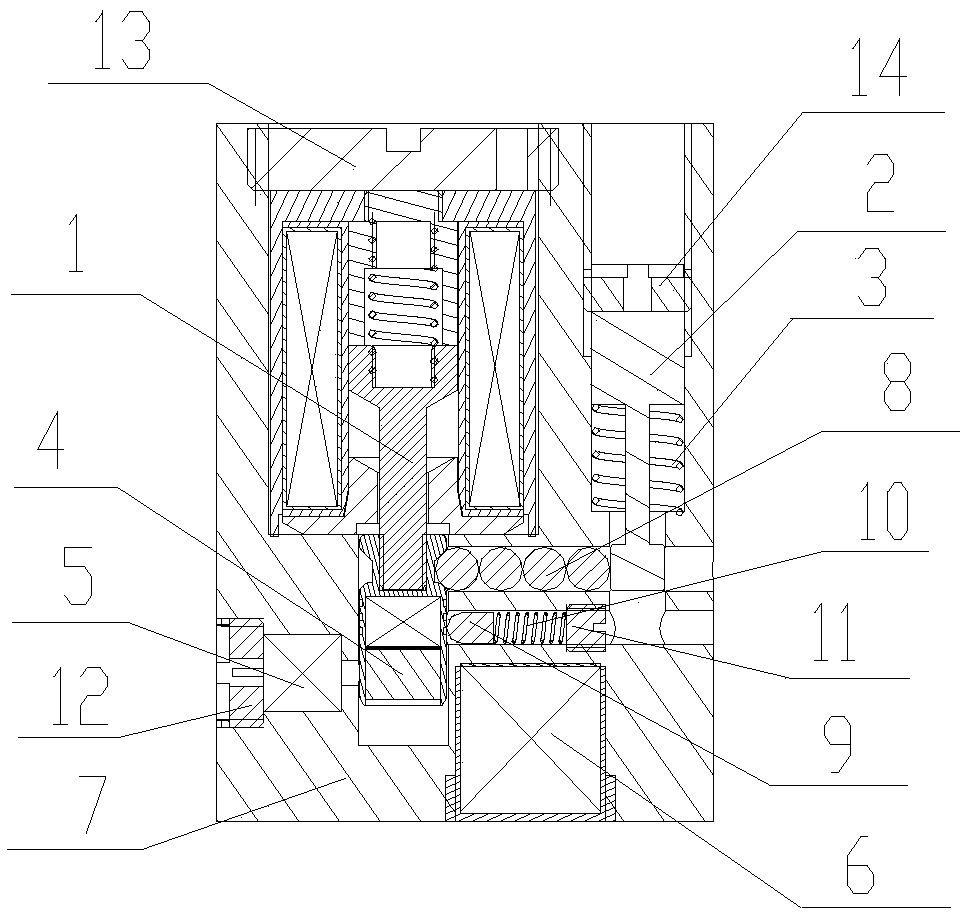

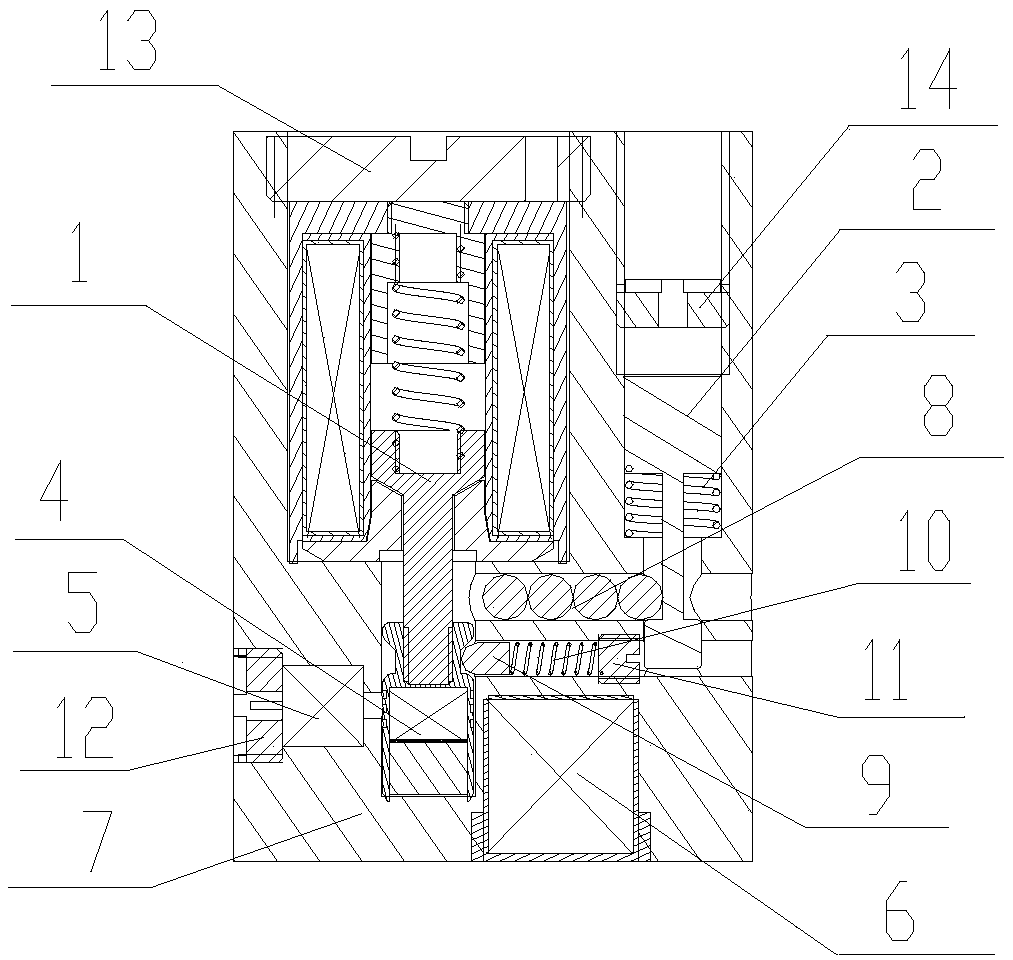

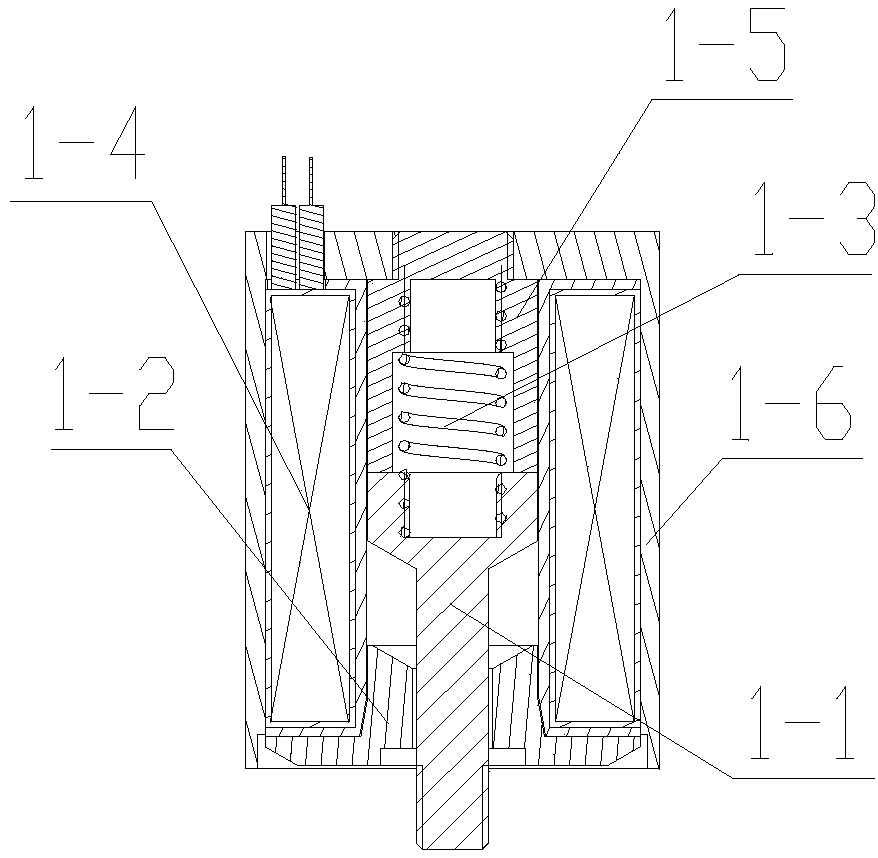

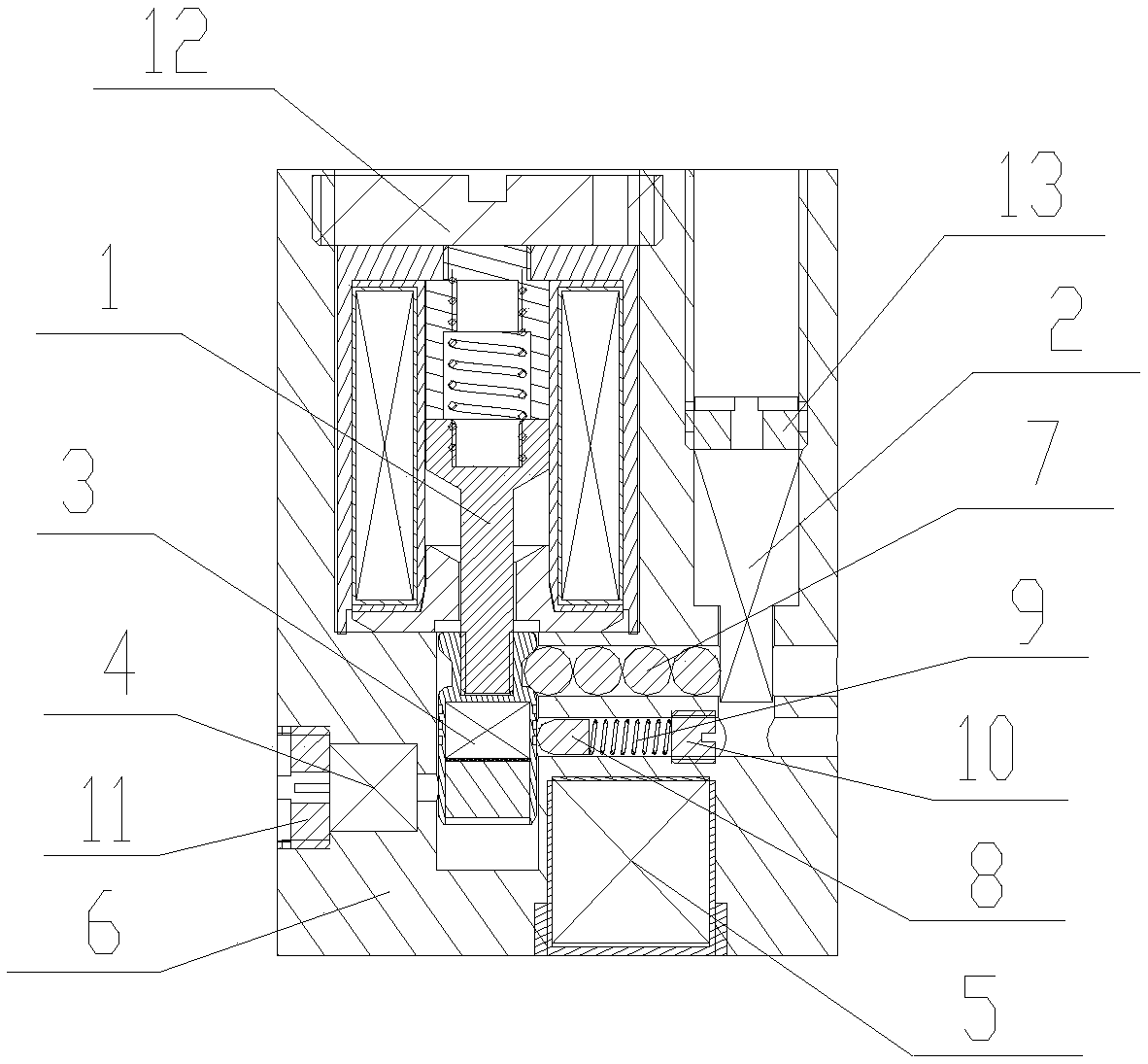

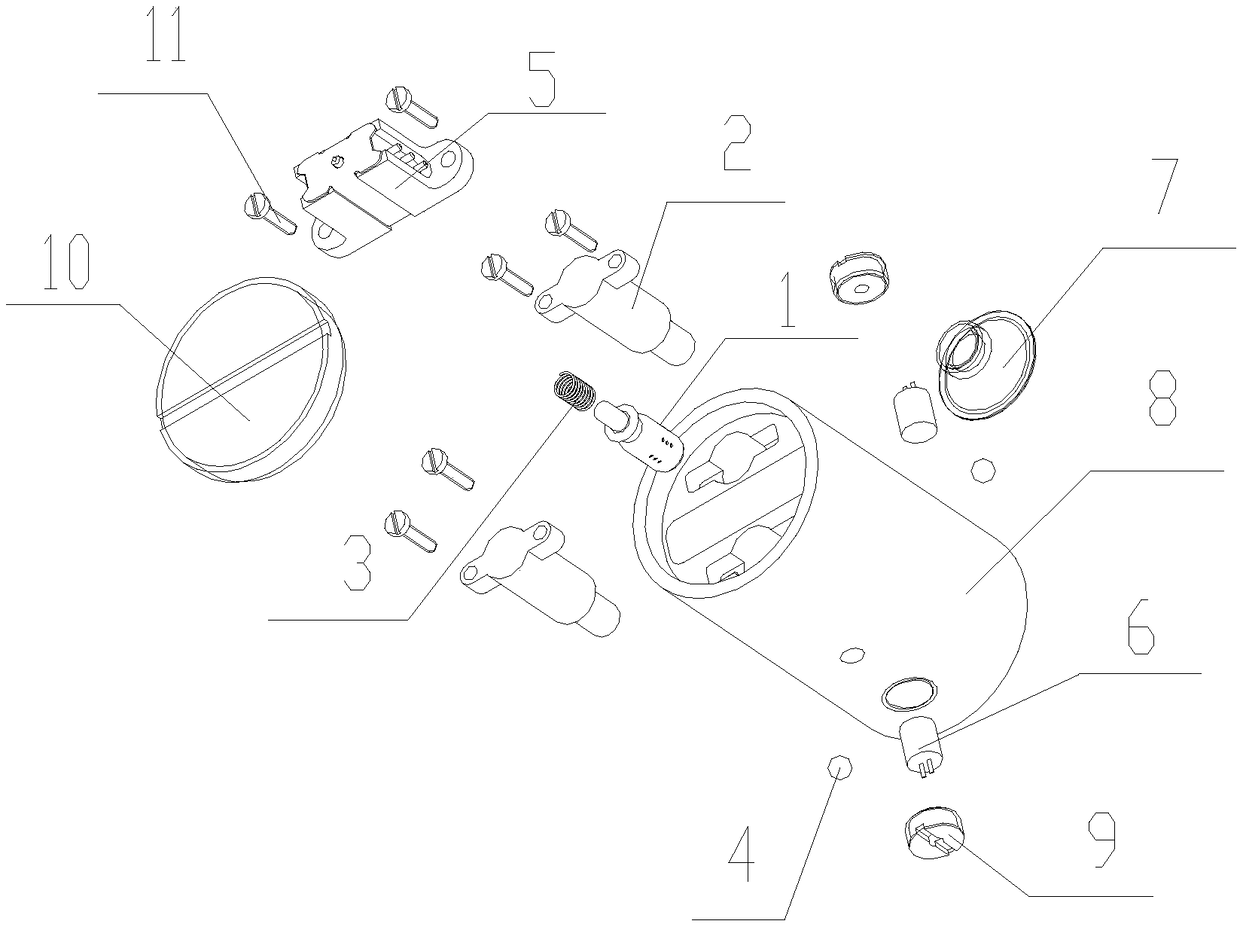

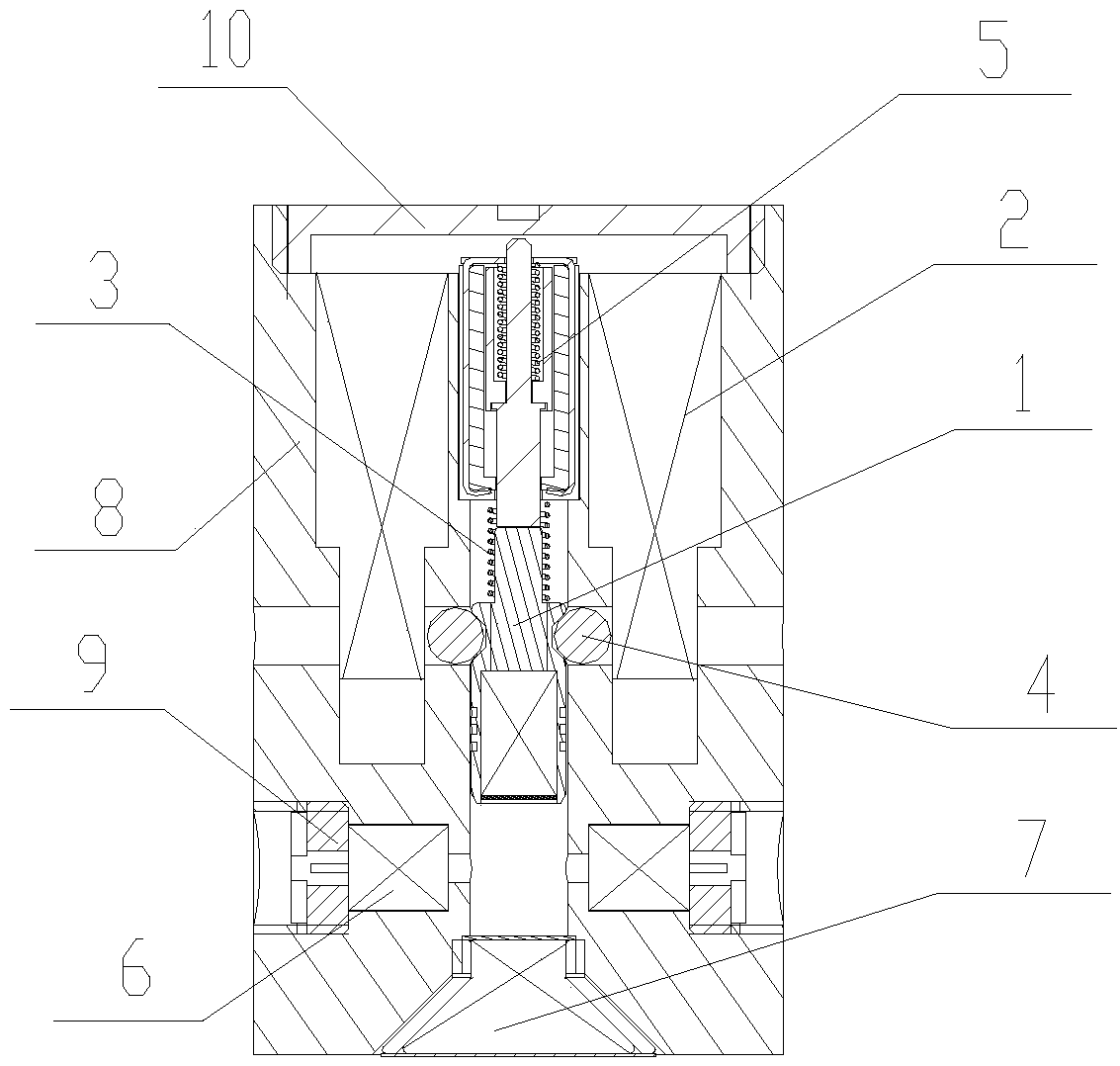

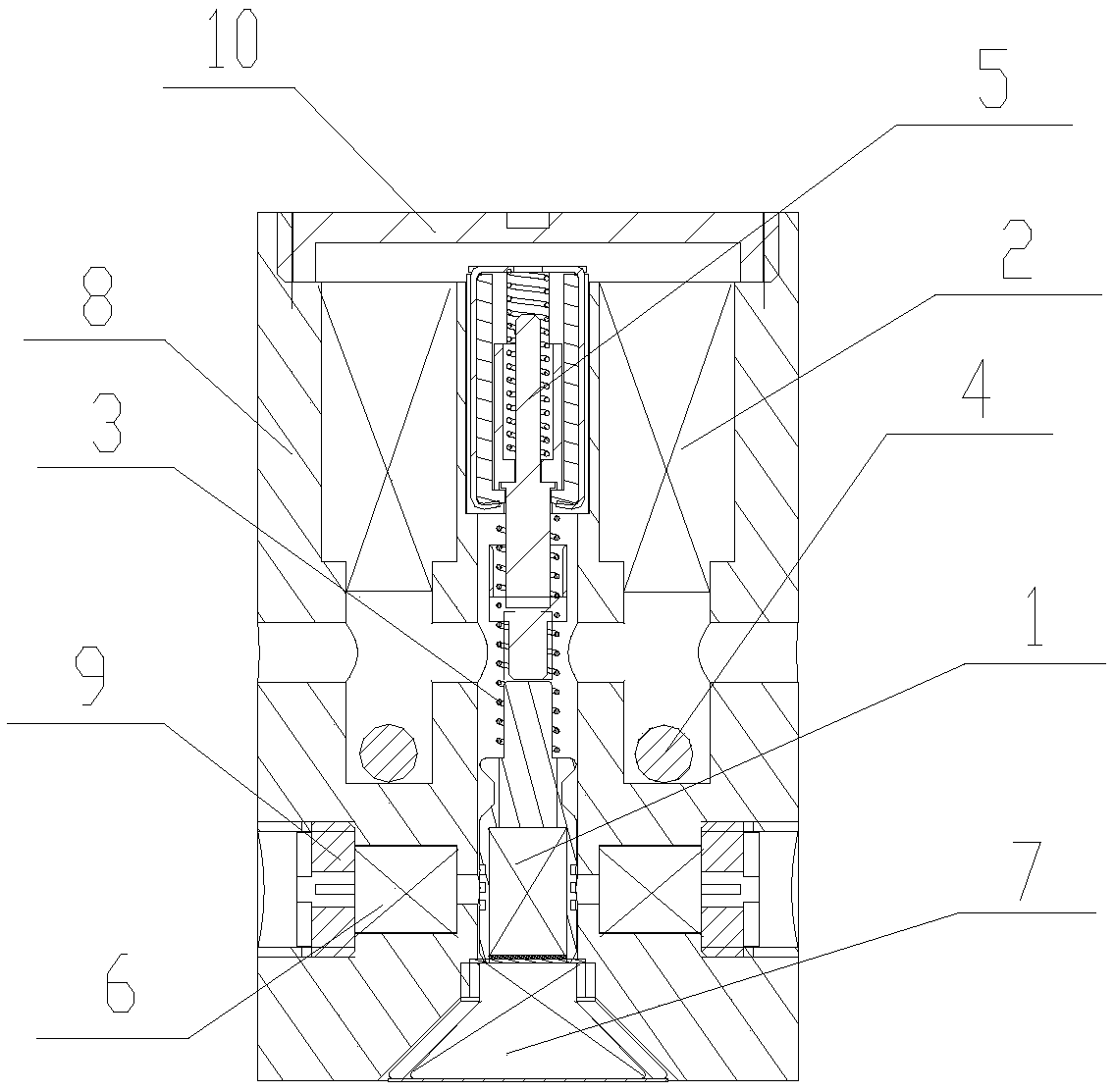

Dual electromagnetic control detonating device

The invention discloses a dual electromagnetic control detonating device, and belongs to the technical field of detonating. The dual electromagnetic control detonating device comprises an electromagnetic pin pushing device, an electromagnetic pin pulling device, an explosion transmission component, an electric detonator, a detonating component, a body, a steel ball, a ball pin, a driving spring, asmall pressure screw, a pressure screw I, a large pressure screw, and a pressure screw II. At ordinary times, the electromagnetic pin pushing device and the electromagnetic pin pulling device lock the explosion transmission component on the position away from the electric detonator, even if the electric detonator accidently acts, the explosion transmission component cannot be detonated, after theelectromagnetic pin pulling device is powered on and acts, the locking on the explosion transmission component is relieved, the electromagnetic pin pushing device is powered on and acts again, the explosion transmission component is pushed to be in the state of being aligned with the electric detonator, the driving spring originally in the compression state pushes the ball pin to lock the explosion transmission component to be in the in-place state, and the dual electromagnetic control detonating device has the advantages of being controlled remotely, being reliable in locking and high in safety, and the like.

Owner:XIAOGAN RUICHUANG MACHINERY TECH CO LTD

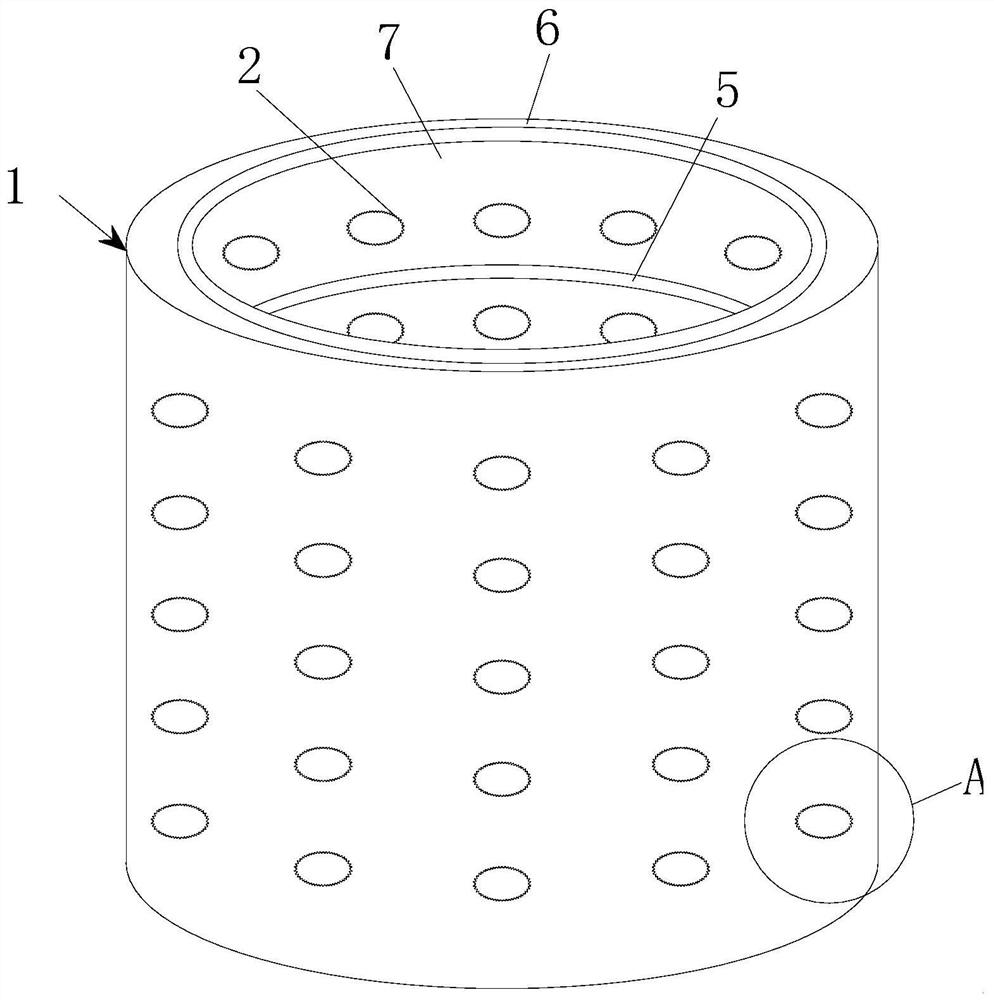

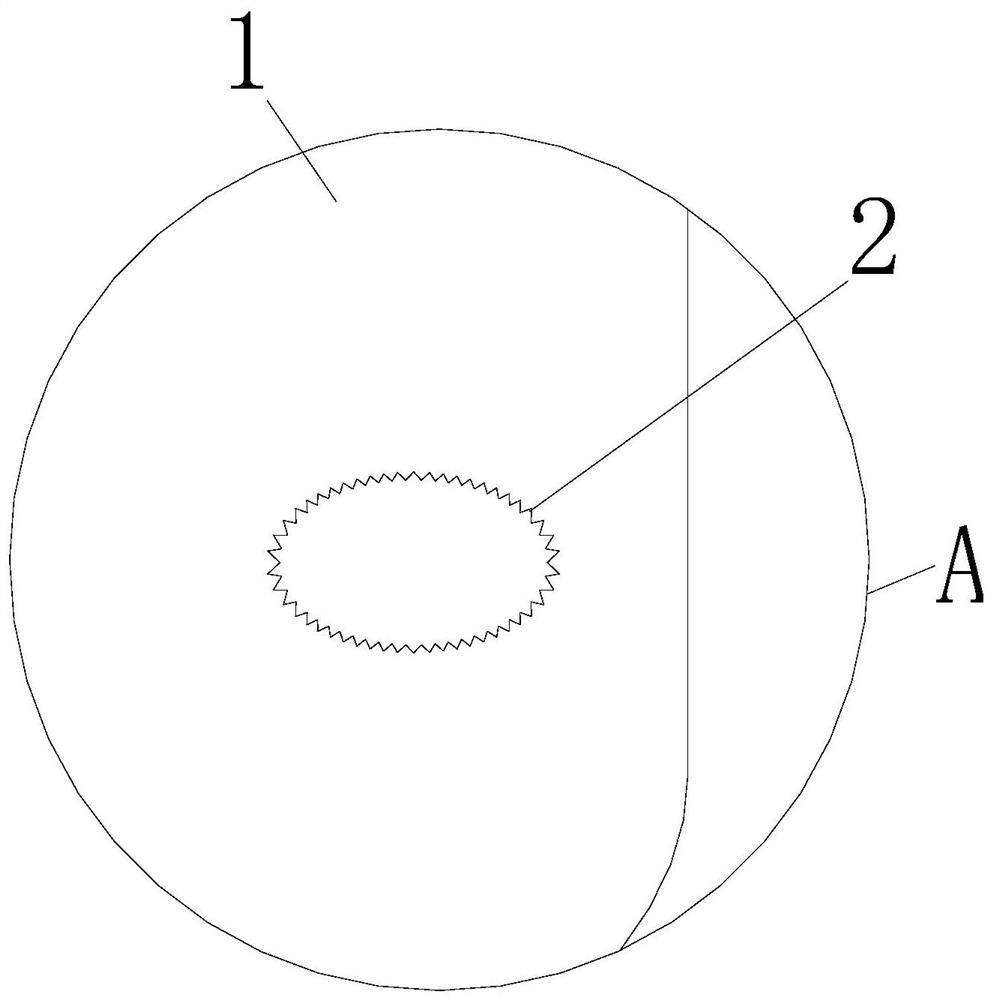

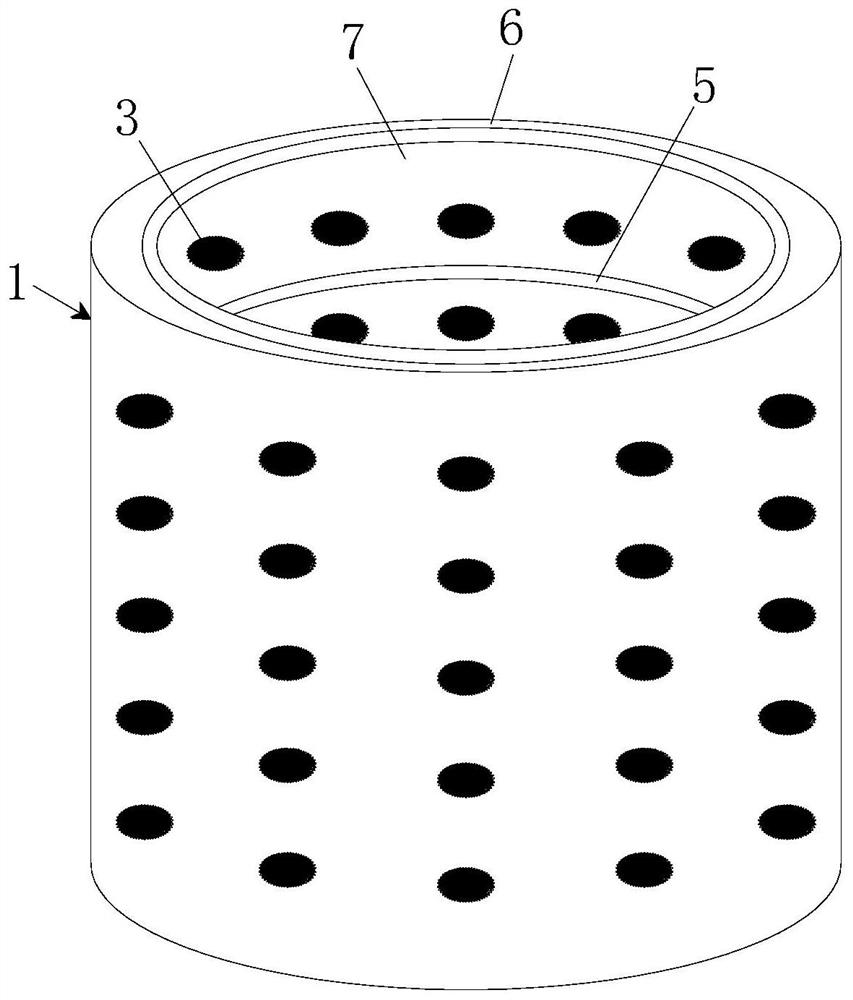

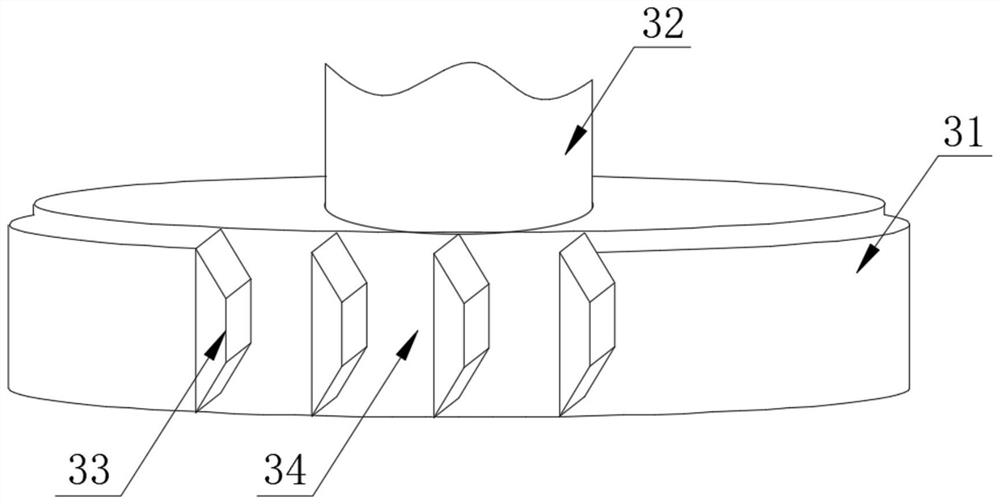

HYB-650 copper-based inlaid solid lubricating bearing and manufacturing process thereof

ActiveCN111795074AIncrease loading capacityGood anti-fatigue propertiesShaftsBearing componentsMetallurgyLubrication

The invention provides an HYB-copper-based inlaid solid lubricating bearing, and relates to the field of bearings. The HYB-650 copper-based inlaid solid lubricating bearing and a manufacturing processthereof comprise a bearing substrate, lace embedded holes and a corrugated solid lubricating column. The bearing substrate comprises a copper-base layer and a sintered layer. The lace embedded holespenetrate through the inner and outer diameters of the bearing substrate. A plurality of lace embedded holes are distributed criss-crossed on the bearing substrate. The HYB-650 copper-based inlaid solid lubricating bearing and the manufacturing process thereof, through special and unique creation of basic mechanism of the solid lubricating bearing, under the premise of not affecting the integrityof the bearing, greatly improves the problem of poor durability of a lubricating oil film of the solid lubrication bearing, and reserves a lubricating strip film which can be used directly for the oilfilm, thereby effectively solves the problem of poor continuous replenishment of a solid lubricant of a general copper-based inlaid solid lubricating bearing, and the problem of the lubrication effect being in a diminishing state when the solid lubricant is not completely consumed.

Owner:HUAYI BEARING TECH JIANGSU CO LTD

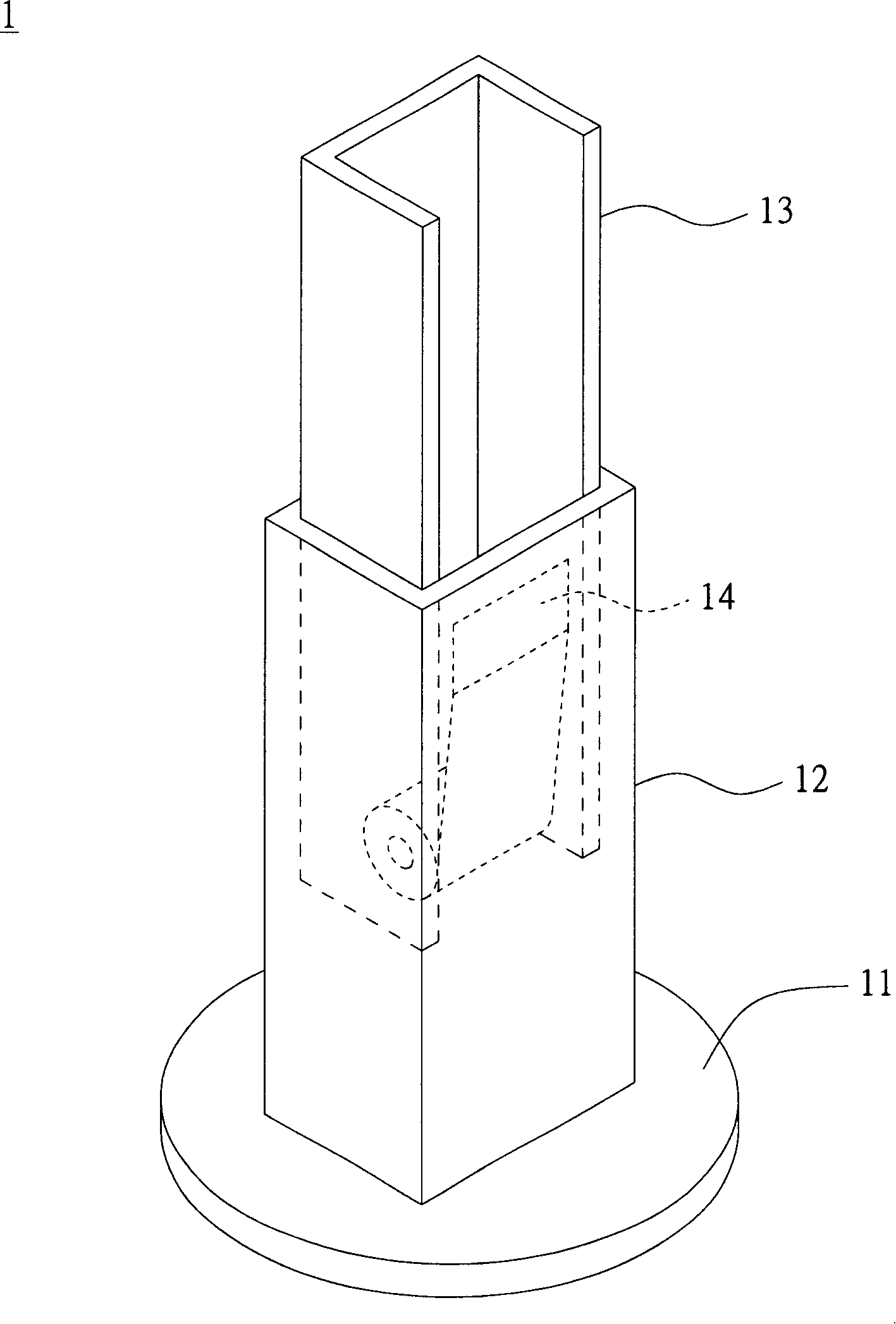

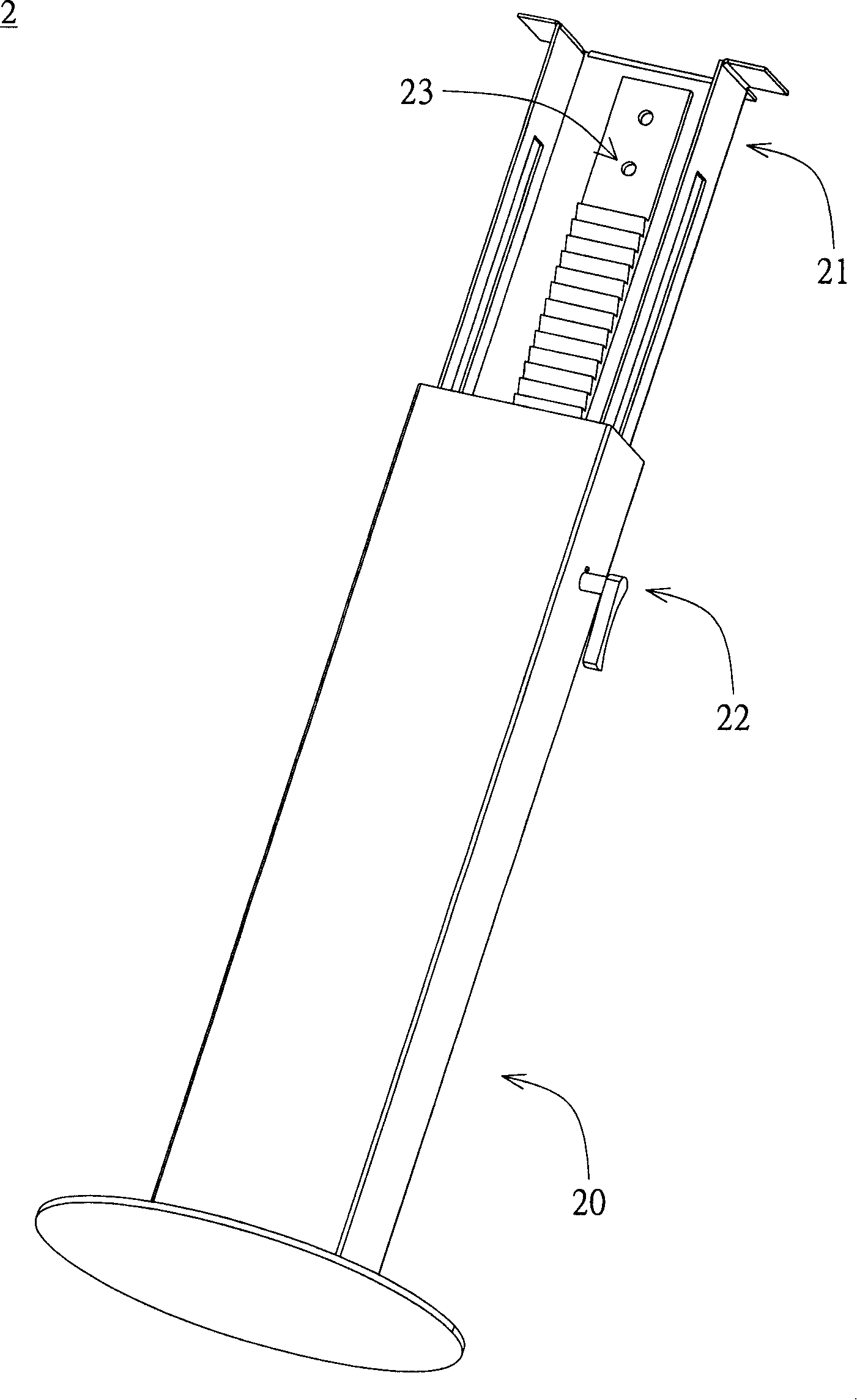

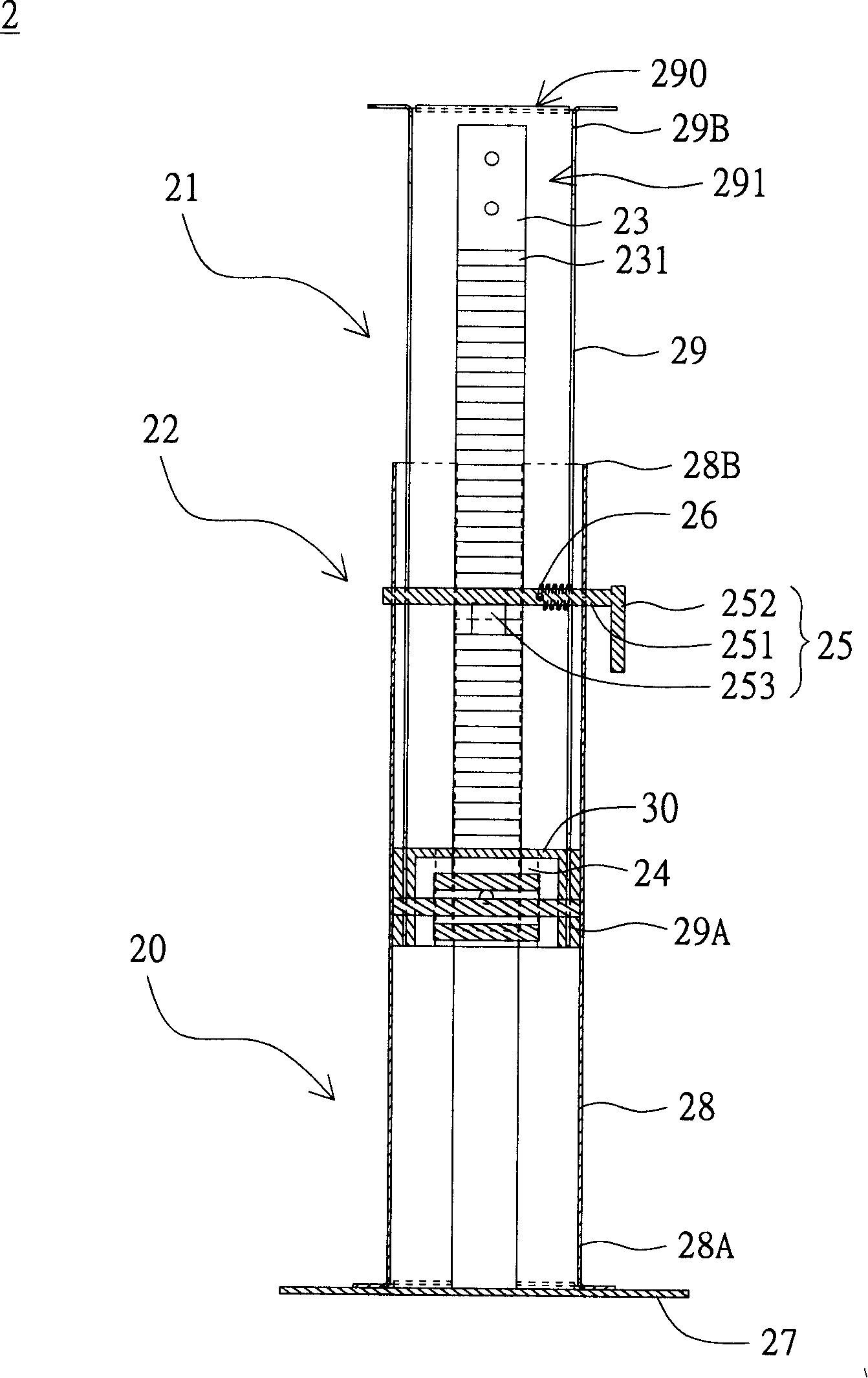

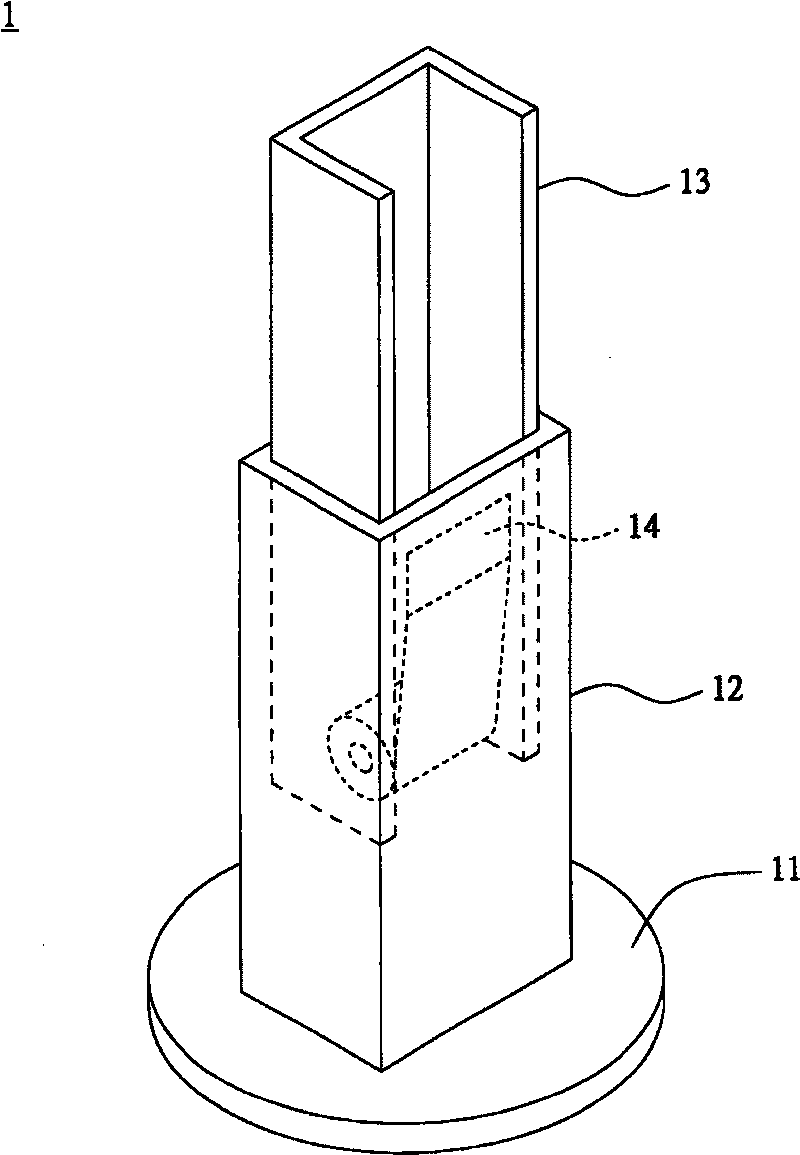

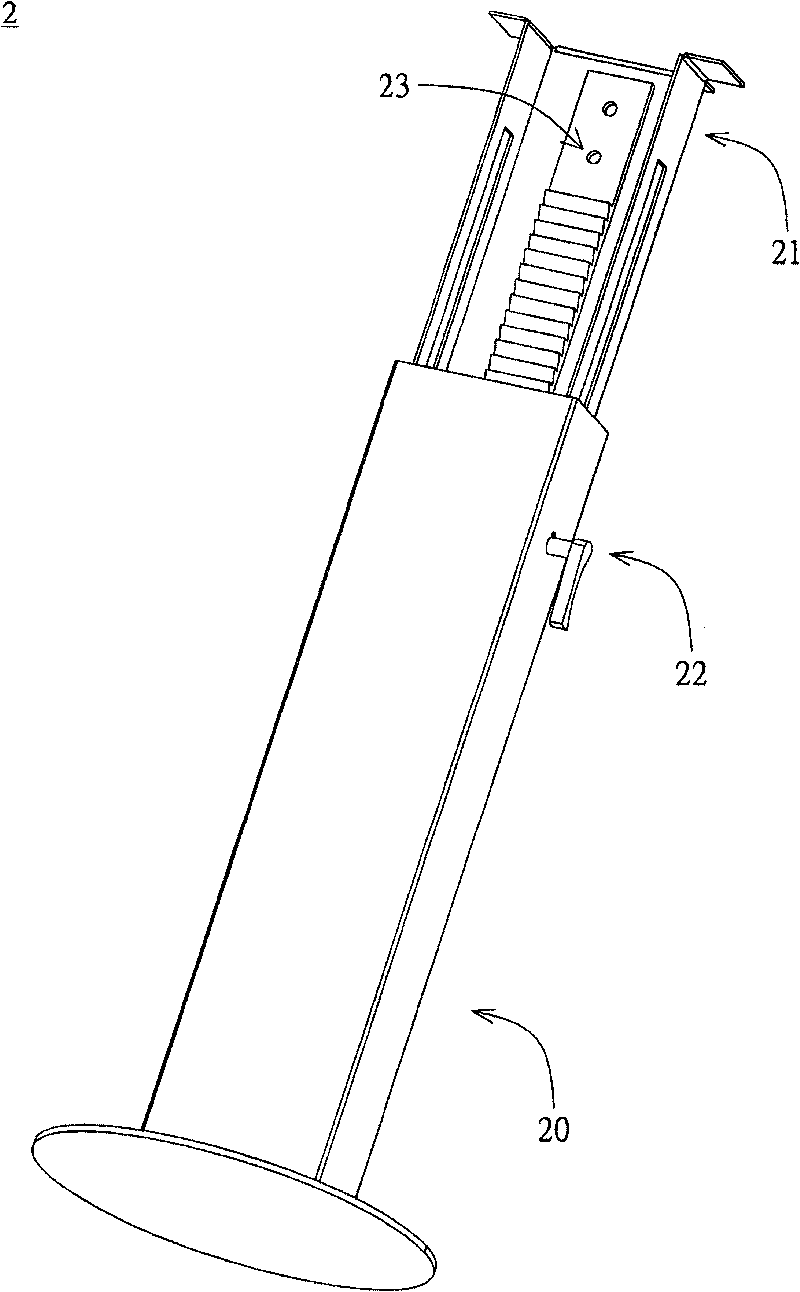

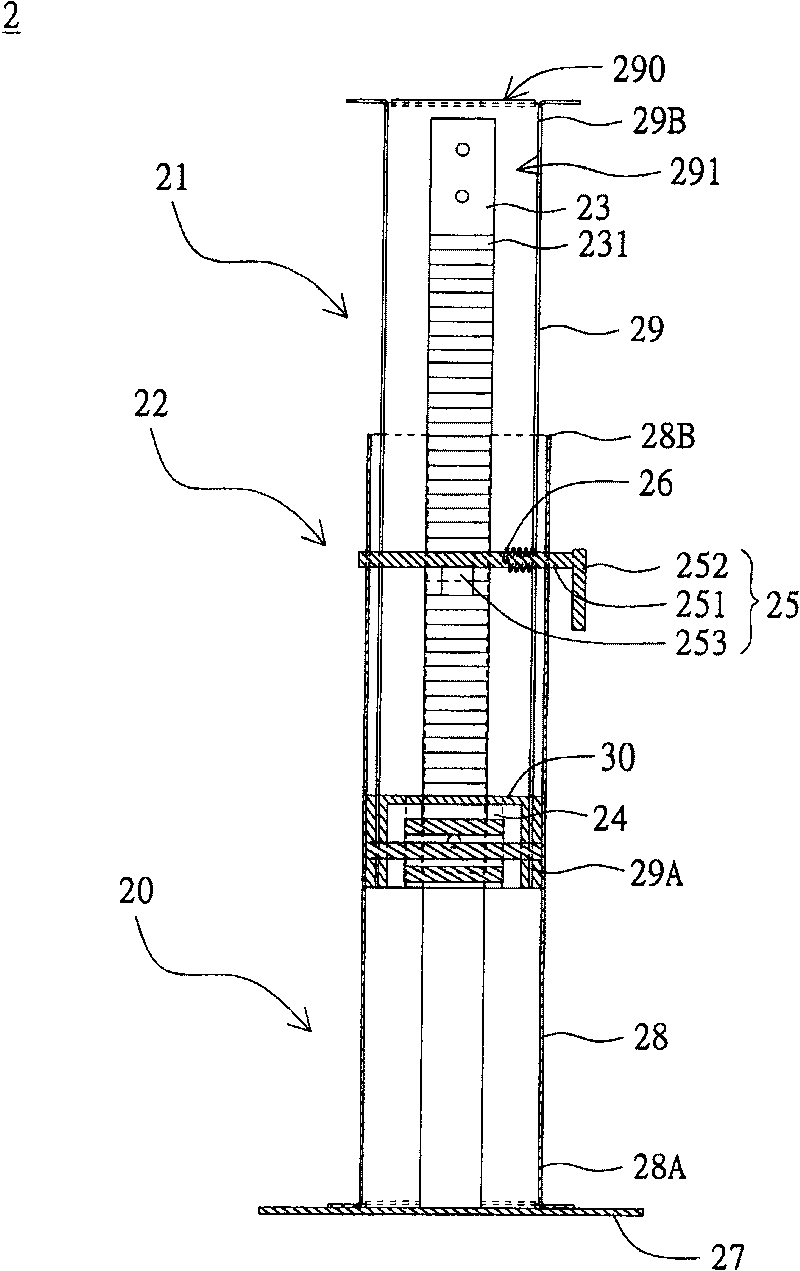

Lifting support device and display device applying same

InactiveCN101211673AReduce friction factorSolving Elasticity ProblemsTelevision system detailsColor television detailsElastic componentDisplay device

The invention relates to a lifting supporting device, which comprises a supporting base, a sliding component and an adjusting component. The sliding component is arranged on the supporting base in a sliding way and is provided with a stopping part. The adjusting component is arranged on the supporting base and is selectively fastened on the stopping part, thus fastening the sliding component on the supporting base. The adjusting component further comprises at least an elastic component to connect the supporting base and the sliding component, wherein, the elastic force of the elastic component allows the sliding component to move corresponding to the supporting base in one direction automatically when the adjusting component is separated from the stopping part. When the sliding component is forced, the sliding component drives the stopping part to push away the adjusting component, thus allowing the sliding component to move corresponding to the supporting base in the reverse direction of the direction.

Owner:QISDA SUZHOU

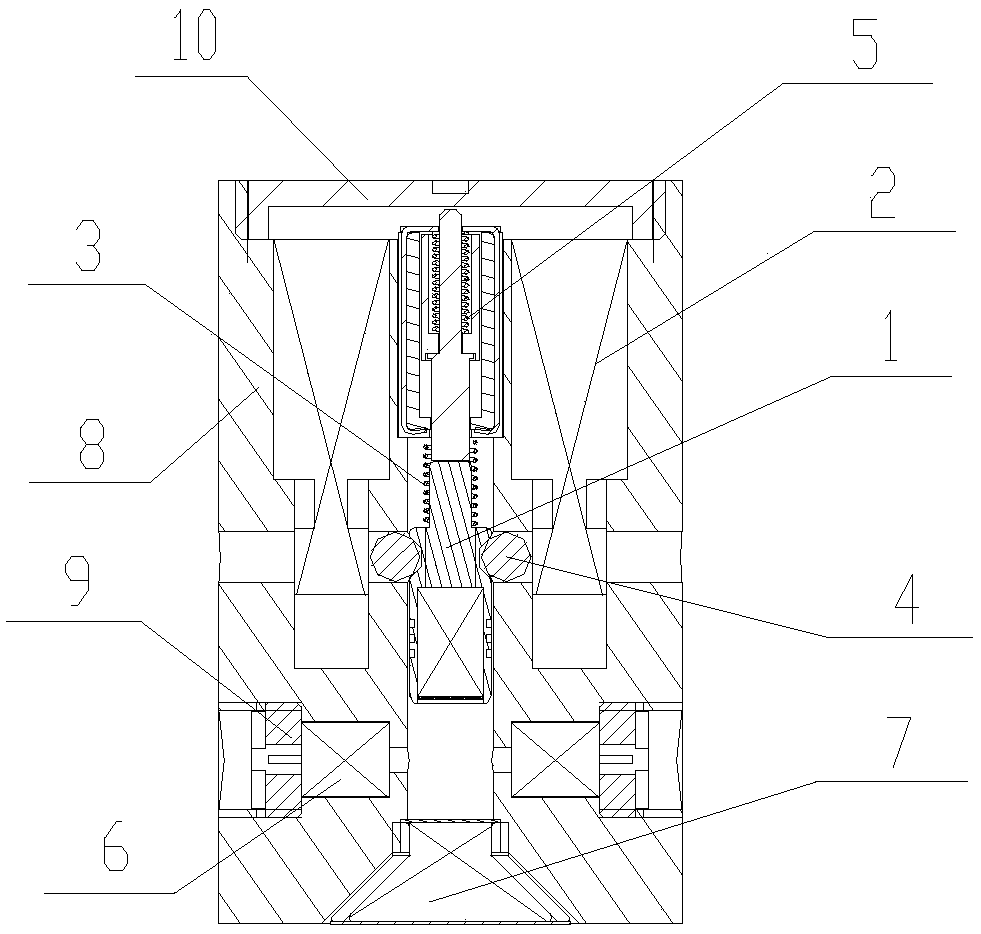

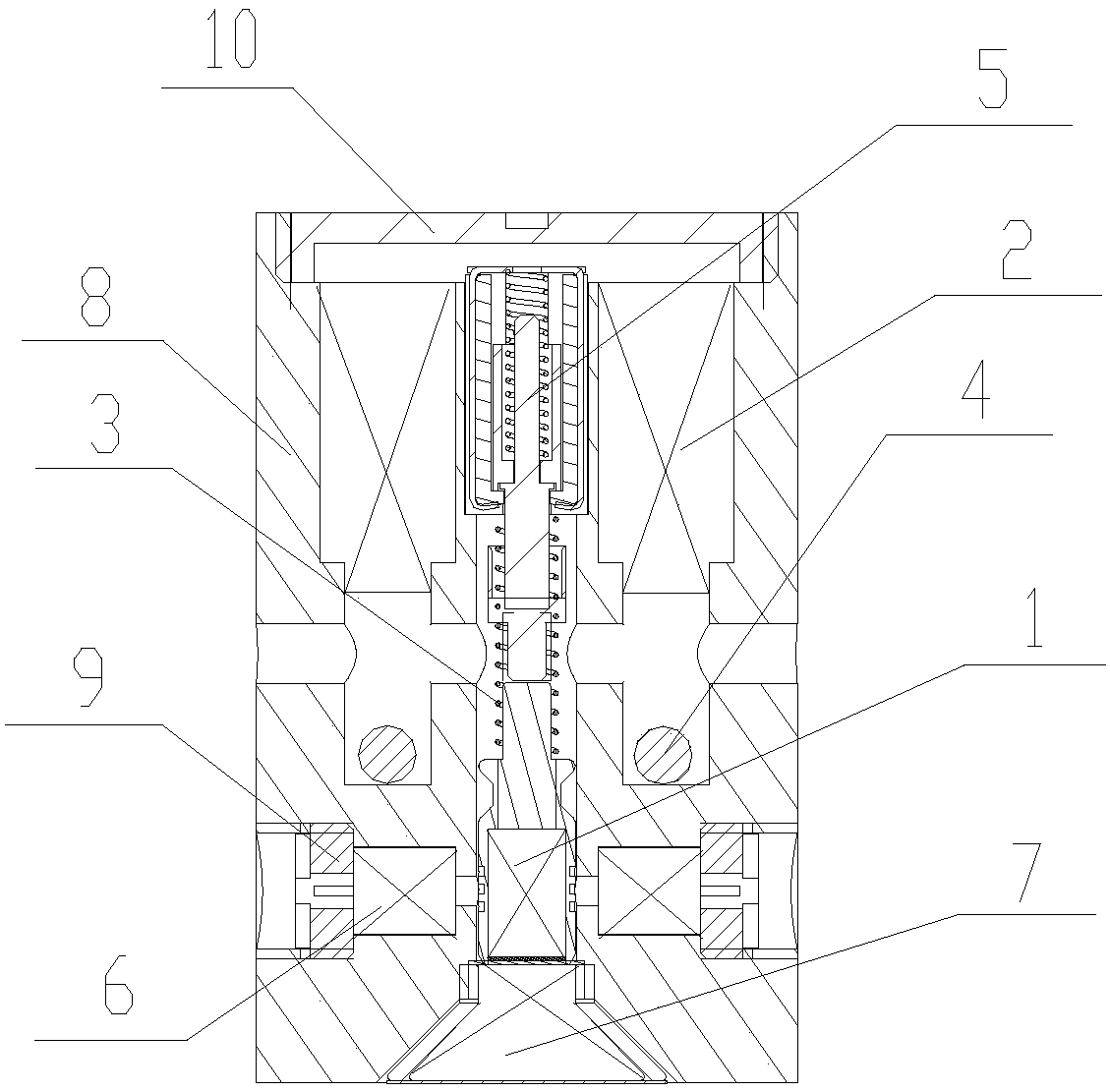

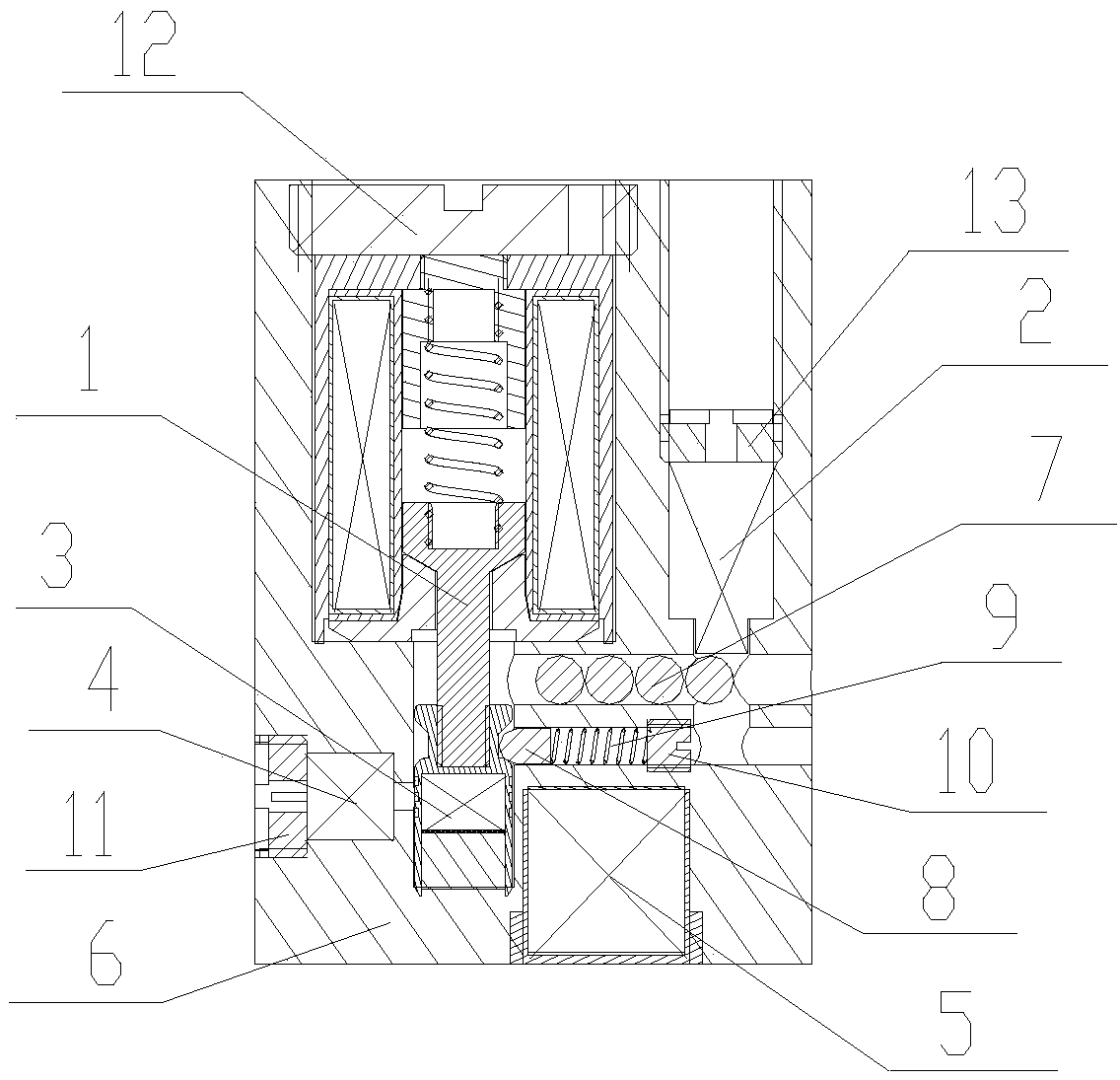

Electromagnetic-constraint-type detonating device

InactiveCN108444339AImprove securityFunction as a status indicatorBlasting cartridgesElectricityDetonator

The invention discloses an electromagnetic-constraint-type detonating device and belongs to the technical field of detonation. The electromagnetic-constraint-type detonating device comprises an explosion transmission component, electromagnetic actuators, a driving spring, steel balls, a state switch, an electric detonator, a detonating component, a body, press nuts, a big press nut, and screws. Atordinary times, the explosion transmission component is locked at the position, far away from the electric detonator, by the two electromagnetic actuators; meanwhile, the state switch provides shortcircuit protection for the electric detonator and has a state indication function, and the explosion transmission component is not detonated, even though the electric detonator acts accidentally; after the electromagnetic actuators are energized to act, the explosion transmission component is unlocked, the driving spring drives the explosion transmission component to move to the alignment state with the electric detonator, the state switch is switched and the short circuit protection for the electric detonator is relieved; the explosion transmission component can be detonated by action of anyway of the electric detonator, and further, the detonating component is detonated by the explosion transmission component. The electromagnetic-constraint-type detonating device has the advantages of remote control, high safety, reliable function, state indication and the like.

Owner:XIAOGAN RUICHUANG MACHINERY TECH CO LTD

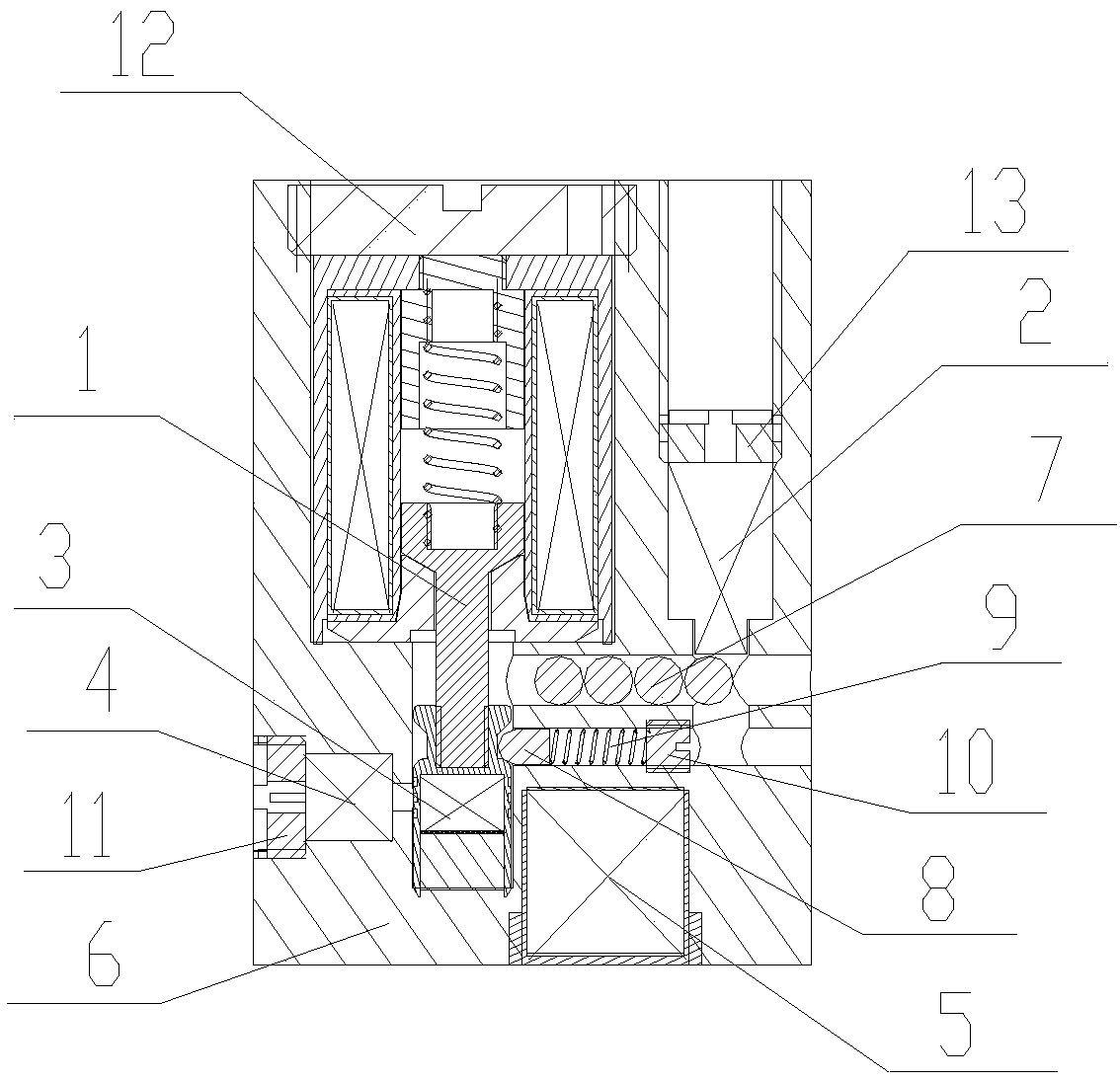

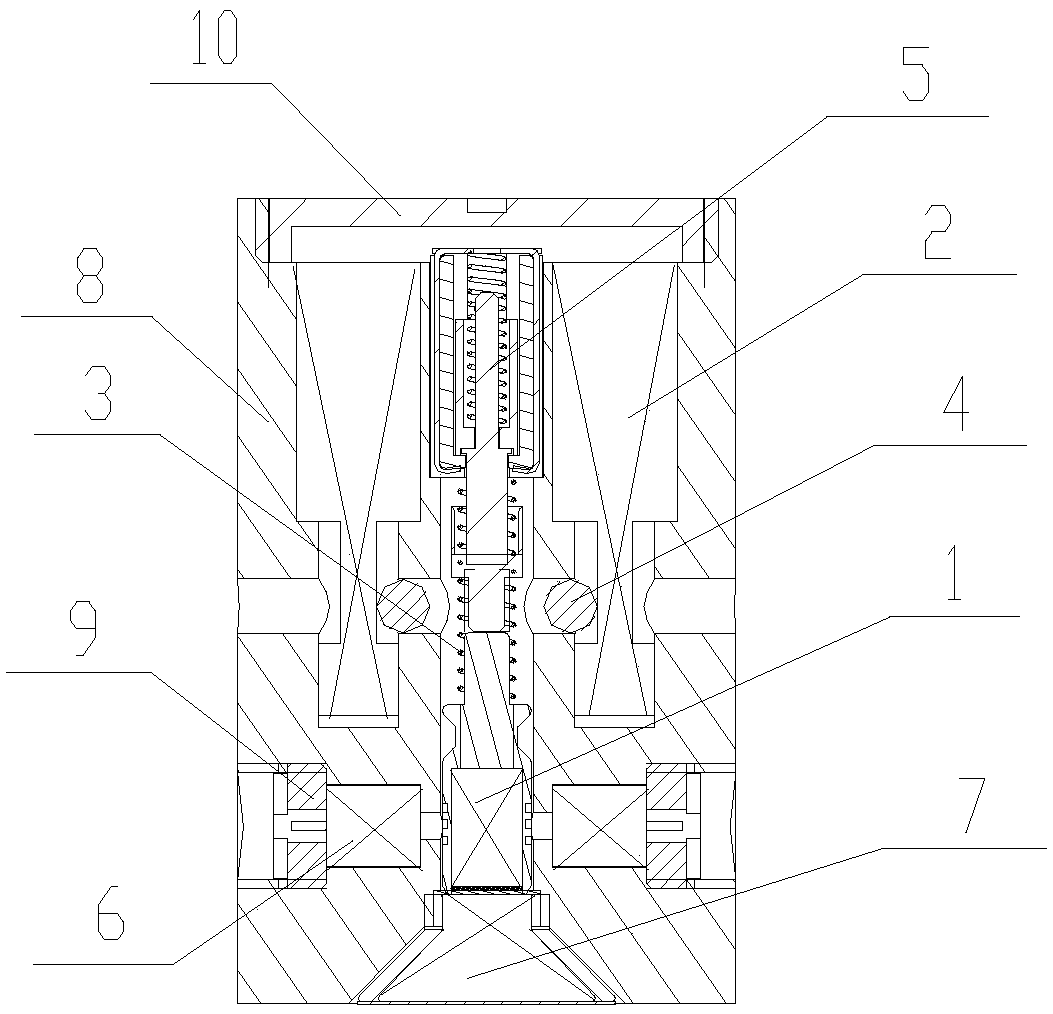

Inertia-start-type detonating device

The invention discloses an inertia-start-type detonating device and belongs to the technical field of detonation. The inertia-start-type detonating device comprises an explosion transmission component, inertia cylinders, a driving spring, inertia springs, a state switch, an electric detonator, a detonating component, a body, a press nut, a big press nut, steel balls and screws. At ordinary times,the explosion transmission component is locked at the position, far away from the electric detonator by the two waysof the inertia cylinders and the inertia springs; meanwhile, the state switch provides short circuit protection for the electric detonator and has a state indication function, the explosion transmission component cannot be detonated, even though the electric detonator acts accidentally; after the two ways of the inertia cylinders and the inertia springs move in place under continuous inertia overload action, the transmission component is unlocked, the driving spring drives the explosion transmission component to move to the alignment state with the electric detonator, the state switch is switched and the short circuit protection for the electric detonator is relieved; the explosion transmission component can be detonated by action of any way of the electric detonator, and further, the detonating component is detonated. The inertia-start-type detonating device has the advantages of being capable of not relying on external power sources or electric orders, simple in system, high in safety, reliable in function, capable of achieving state feedback and the like.

Owner:XIAOGAN RUICHUANG MACHINERY TECH CO LTD

Micron weighted drilling fluid

InactiveCN105273697AEasy tuning of rheological propertiesImprove suspension stabilityDrilling compositionCelluloseVegetable oil

The invention discloses micron weighted drilling fluid, which relates to the technical field of oil field drilling, in particular to the technical field of drilling fluid preparation. In addition to water, the micron weighted drilling fluid also comprises bentonite powder, Na2CO3, NaOH, polyanionic cellulose salt, composite metal ion polymer, polyacrylonitrile ammonium salt, sulfomethal phenolaldehy resin, sulfonated lignite, sulfonated bitumen, vegetable oil lubricant, diluent and activated barite powder. The rheological property of the micron weighted drilling fluid is easy in regulation, the quality of a filter cake is improved, and the suspension stability of weighting materials becomes better. The micron weighted drilling fluid has low-plasticity viscosity, low shearing force and excellent barite suspension property. In a drilling process, the drilling fluid is adopted, and therefore, a barite cuttings bed can be prevented from forming underground, dynamic and static filter loss is small, and solid-phase separation efficiency can be improved. The micron weighted drilling fluid is one of the basic technologies necessary for supporting high pressure formation drilling construction.

Owner:中石化石油工程技术服务有限公司 +1

A kind of manufacturing method of ptfe fabric self-lubricating joint bearing

ActiveCN104149364BGuaranteed StrengthGuaranteed wear resistanceBearing componentsCouplingEngineering

The invention discloses a manufacturing method of a PTFE (polytetrafluoroethylene) fabric self-lubricating spherical plain bearing. The manufacturing method comprises the following steps: one surface of a PTFE fabric liner is coated with glue A which is irreversible after curing; the fabric coated with the glue A is subjected to rolling treatment; the fabric liner is cured by adopting a panel hot-pressing technology; the cured fabric liner is cut into a size suitable for an inner spherical surface of an outer ring of the spherical plain bearing; the inner spherical surface of the outer ring or the other surface of the fabric liner is coated with glue B; then the fabric liner is adhered to the inner spherical surface of the outer ring through the glue B; an inner ring of the spherical plain bearing is sleeved into the outer ring of the spherical plain bearing, which is adhered to the fabric liner; the cured surface of the fabric liner faces to an outer spherical surface of the inner ring for mutual coupling and contact; the periphery of the outer ring is sleeved with a curing lantern ring; and the bearing is put into an oven for oven heating. The curing method not only can ensure the strength and abrasion resistance of the fabric liner, but also avoids the step of coating the outer spherical surface of the inner ring with a mold release agent.

Owner:FUJIAN LONGXI BEARING (GROUP) CO LTD

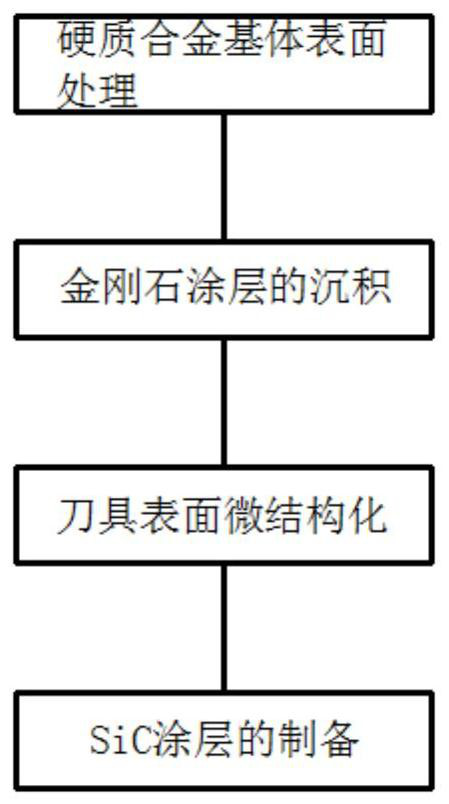

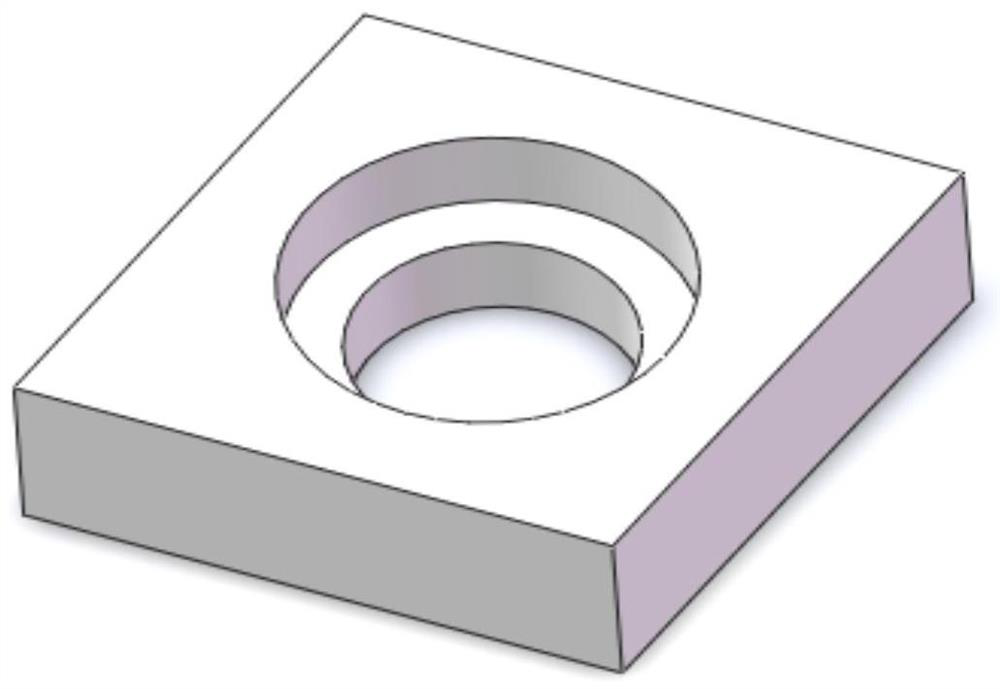

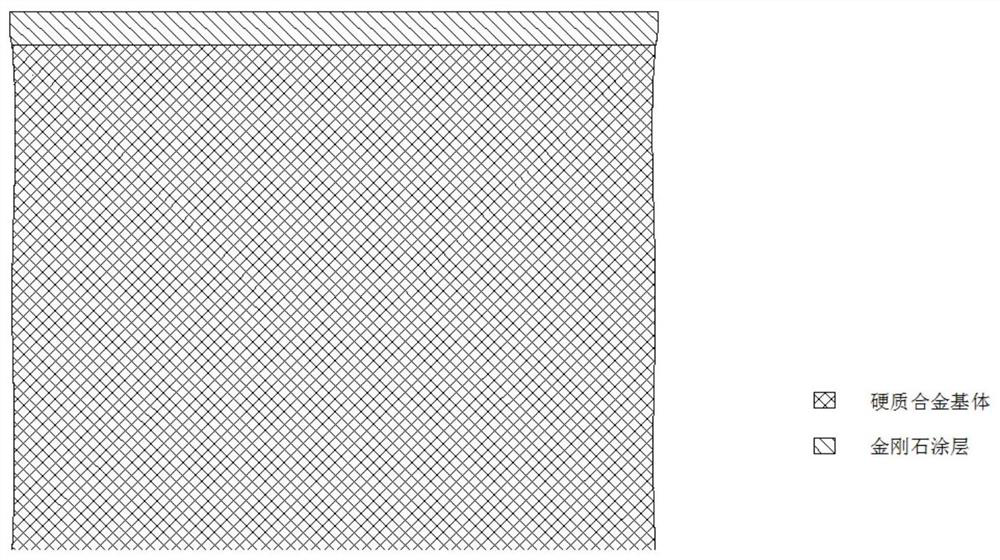

Processing method of coating microstructured bionic surface type diamond cutter

PendingCN112538612AImprove the lubrication effectReduce wearChemical vapor deposition coatingLaser beam welding apparatusCarbide siliconOxidation resistant

The invention discloses a machining method of a coating microstructured bionic surface type diamond cutter. The method comprises the following steps of 1, surface treatment of a hard alloy base body;2, deposition of a diamond coating; 3, microstructural treatment of the surface of a cutter; and 4, preparation of a silicon carbide coating. By the adoption of the technical scheme, the lubricating capacity of the cutter can be improved through cutter surface microstructuring, friction among the cutter, scraps and the surface of a workpiece in the machining process of the cutter is reduced, and therefore the cutting force, the cutting temperature, friction factors, cutter abrasion and other aspects in the cutting process are reduced, the cutting mechanism is achieved; the microstructure shapeis a vein stem shape; researches show that vein stems have a heat transfer effect, so that the heat transfer of the cutter surface is more uniform, and the heat dissipation effect of the cutter is better; and the silicon carbide coating has excellent properties such as high hardness, high strength, high thermal conductivity, corrosion resistance and low expansion coefficient, and after coating, the cutter has higher hardness, strength, wear resistance, oxidation resistance and the like in performance.

Owner:GUIZHOU UNIV

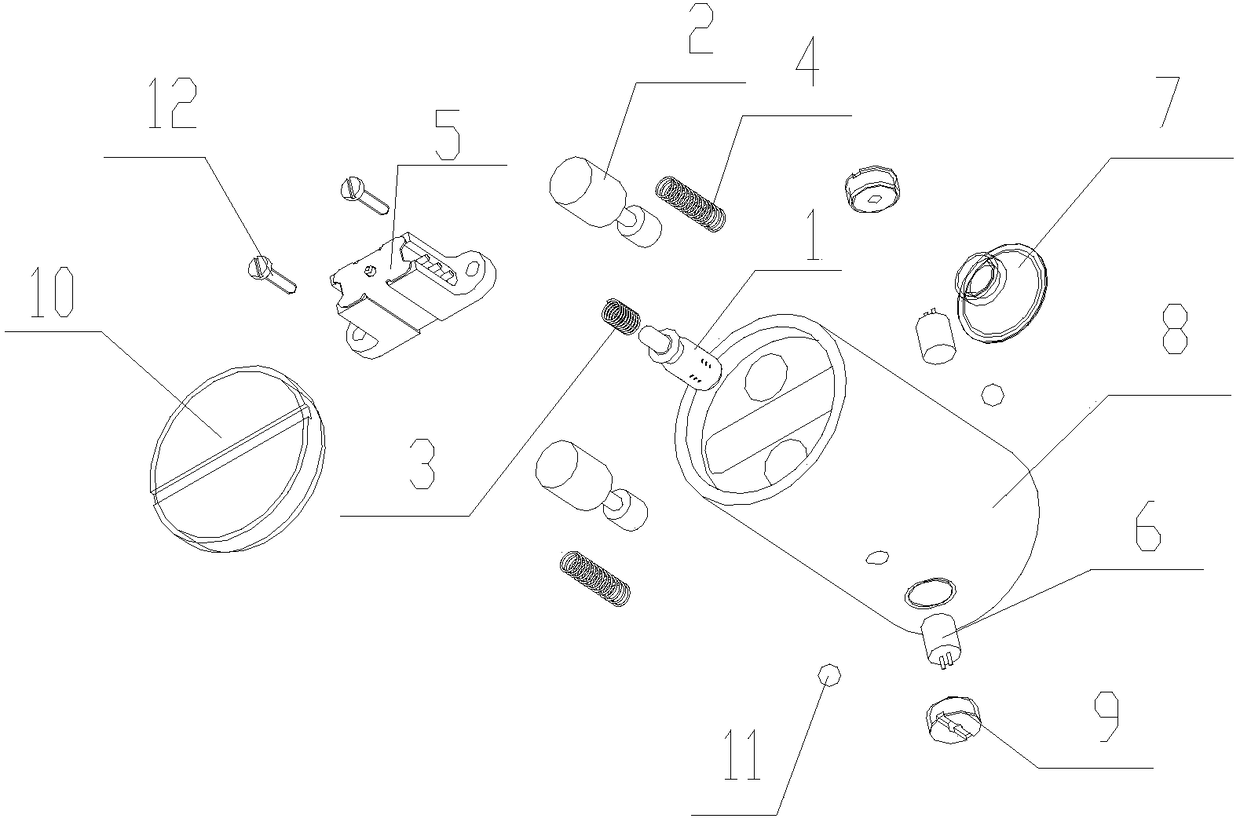

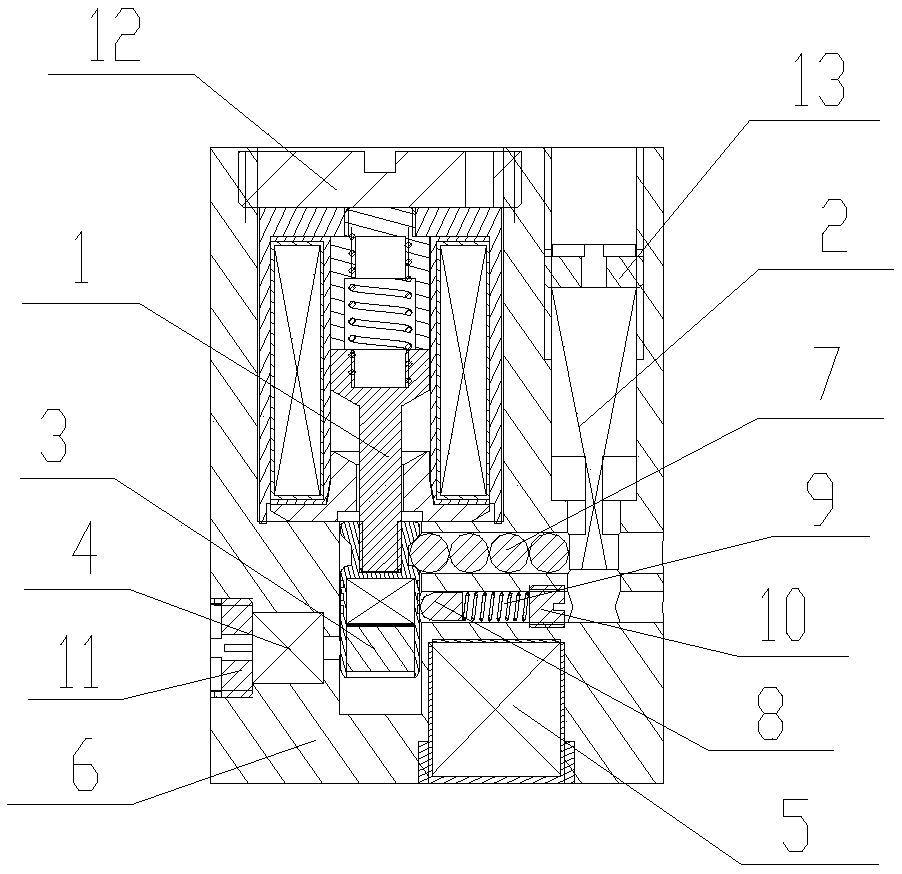

Memory alloy constrained detonation device

The invention provides a memory alloy constrained detonation device, and belongs to the technical field of detonation. The memory alloy constrained detonation device comprises a detonation transmission part, memory alloy actuators, a driving spring, a steel ball, a status switch, an electric detonator, a detonating part, a body, a pressing screw, a large pressing screw and a bolt. At ordinary times, the two memory alloy actuators are used for locking the detonation transmission part at a position far away from the electric detonator, meanwhile, the status switch provides short-circuit protection for the electric detonator and plays a part in status indication, and even if the electric detonator accidentally works, the detonation transmission part is not detonated; after the memory alloy actuators are electrified and work, the locking of the detonation transmission part is relieved, the driving spring drives the detonation transmission part to move till the detonation transmission partis aligned with the electric detonator, and the status switch switches and disconnects short-circuit protection for the electric detonator; and after any electric detonator works, the detonation transmission part can be detonated, and then detonates the detonating part. The memory alloy constrained detonation device has the advantages of long-range control, high safety, reliable working, status indication and the like.

Owner:XIAOGAN RUICHUANG MACHINERY TECH CO LTD

Double-control blasting device

The invention discloses a double-control blasting device, and belongs to the technical field of blasting. The device comprises an electromagnetic pin pushing device, a dielectric elastomer pin pushingdevice, an explosion transmission component, an electric detonator, a detonating component, a body, a steel ball, a ball pin, a drive spring, a small pressure screw, a pressure screw I, a large pressure screw and a pressure screw II. At ordinary, the electromagnetic pin pushing device and the dielectric elastomer pin pushing device lock the explosion transmission component on the position away from the electric detonator, and even if the electric detonator accidently acts, the explosion transmission component cannot be detonated. When the dielectric elastomer pin pushing device is powered on,the locking of the explosion transmission component is relieved, the electromagnetic pin pushing device is powered on, the explosion transmission component is pushed to be in the state of directly facing the electric detonator, and the drive spring originally in the compression state pushes the ball pin to lock the explosion transmission component to be in in-place state. The device has the beneficial effects of being capable of being remotely controlled, reliable in locking, high in safety and the like.

Owner:XIAOGAN RUICHUANG MACHINERY TECH CO LTD

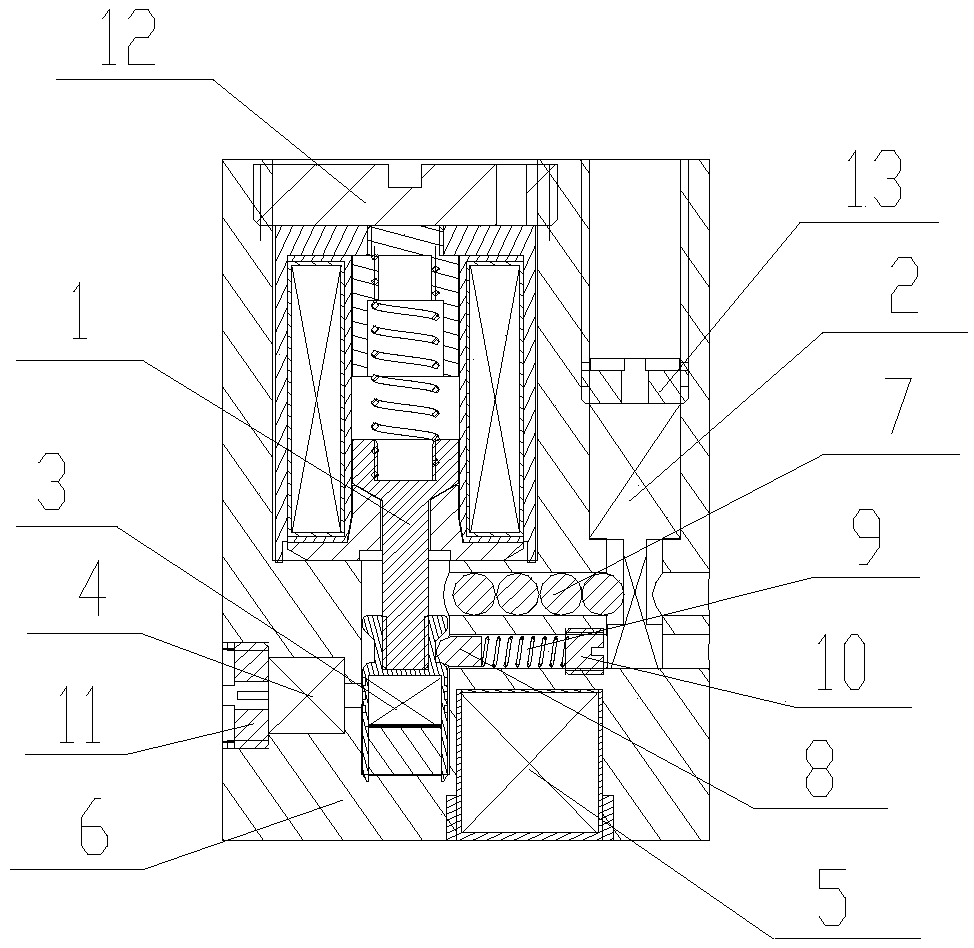

Electromagnetic inertia dual control detonating device

InactiveCN108645294AQuality improvementHigh movement reliabilityAmmunition fuzesElectricityDetonator

The invention relates to an electromagnetic inertia dual control detonating device, and belongs to the technical field of detonating. The electromagnetic inertia dual control detonating device comprises an electromagnetic pin pushing device, an inertia barrel, an inertia spring, a detonating transferring component, an electric detonator, a detonating component, a body, a steel ball, a ball pin, adriving spring, a small pressing screw, a pressing screw I, a large pressing screw and a pressing screw II. At ordinary times, the electromagnetic pin pushing device and the inertia barrel lock the detonating transferring component at the position far away from the electric detonator, and the detonating transferring component cannot be detonated even though the electric detonator acts accidentally; when the inertia barrel feels the overload and moves in place by overcoming the inertia spring, locking of the detonating transferring component is relieved, the electromagnetic pin pushing device is powered to act, the detonating transferring component is pushed to be in the state aligning at the electric detonator, and the driving spring originally in the compression state pushes the ball pinto lock the detonating transferring component in the in-place state. The electromagnetic inertia dual control detonating device has the advantages of achieving in-place locking, being high in safety and reliable in action and the like.

Owner:XIAOGAN RUICHUANG MACHINERY TECH CO LTD

Electromagnetic memory alloy dual control detonating device

The invention relates to an electromagnetic memory alloy dual control detonating device, and belongs to the technical field of detonating. The electromagnetic memory alloy dual control detonating device comprises an electromagnetic pin pushing device, a memory alloy pin pulling device, a detonating transferring component, an electric detonator, a detonating component, a body, a steel ball, a ballpin, a driving spring, a small pressing screw, a pressing screw I, a large pressing screw and a pressing screw II. At ordinary times, the electromagnetic pin pushing device and the memory alloy pin pulling device lock the detonating transferring component at the position far away from the electric detonator, and the detonating transferring component cannot be detonated even though the electric detonator has the accident effect; after the memory alloy pin pulling device is powered to act, locking of the detonating transferring component is relieved, then the electromagnetic pin pushing device is powered on to act, the detonating transferring component is pushed to be in the state aligning at the electric detonator, and the driving spring originally in the compression state pushes the ball pin to lock the detonating transferring component in the in-place state. The electromagnetic memory alloy dual control detonating device has the advantages of achieving remote control, being reliable in locking and high in safety and the like.

Owner:XIAOGAN RUICHUANG MACHINERY TECH CO LTD

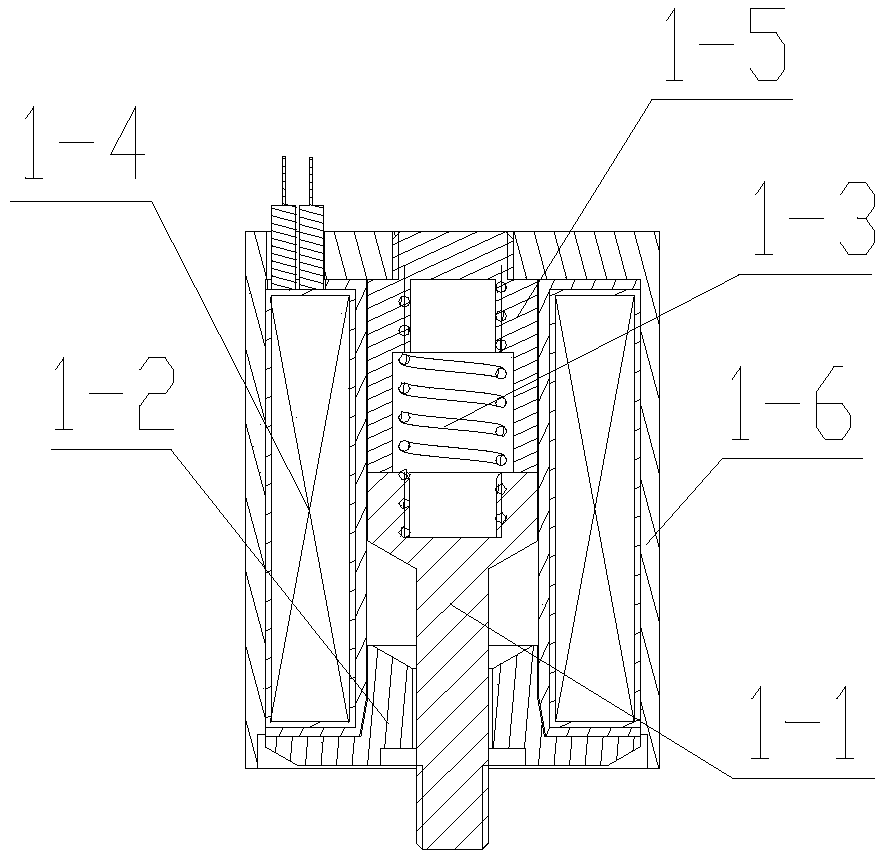

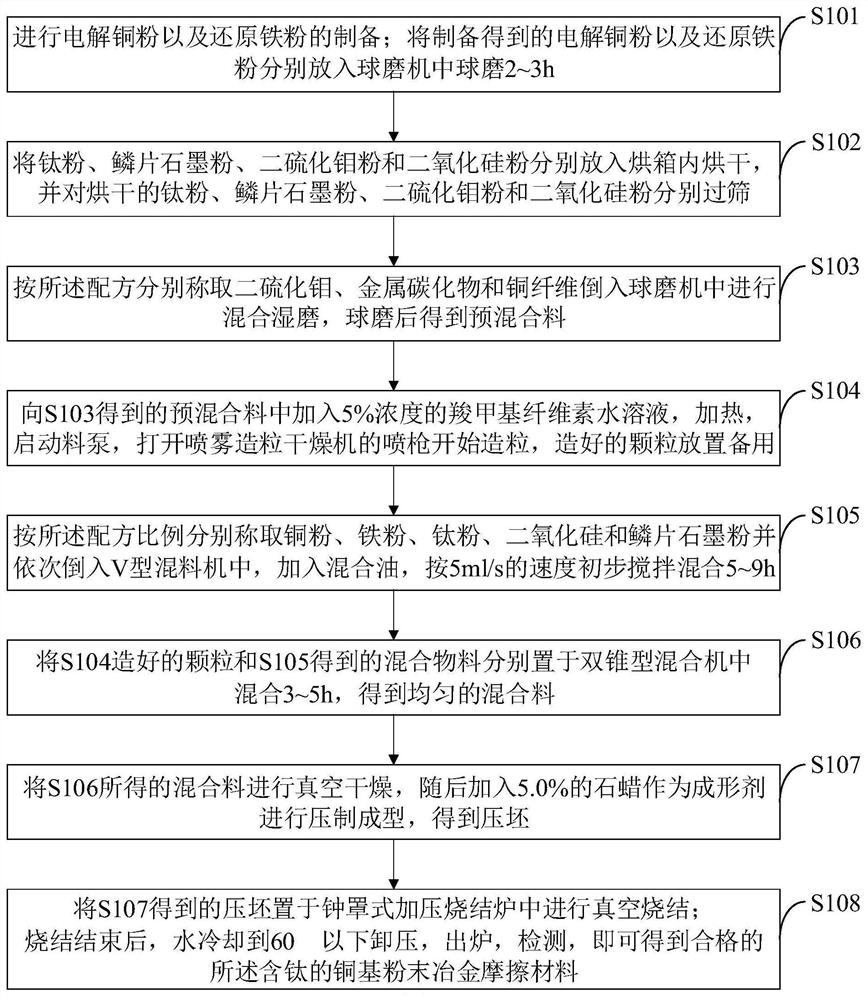

Titanium-containing copper-based powder metallurgy friction material and preparation method thereof

The invention belongs to the technical field of powder metallurgy friction materials, and discloses a titanium-containing copper-based powder metallurgy friction material and a preparation method of the titanium-containing copper-based powder metallurgy friction material comprises, by mass part, 30-45 parts of electrolytic copper powder, 20-35 parts of reduced iron powder, 15-25 parts of titanium powder, 10-22 parts of molybdenum disulfide, 8-15 parts of silicon dioxide, 6-14 parts of crystalline flake graphite powder, 5-8 parts of metal carbide and 3-5 parts of copper fiber. According to the titanium-containing copper-based powder metallurgy friction material and the preparation method thereof, the copper powder, iron powder and titanium powder are adopted as raw materials, various components and proportions of the material are scientifically designed, and the titanium-containing copper-based powder metallurgy friction material with excellent mechanical properties is successfully prepared through the processes of burdening, ball milling, drying, granulating, forming, sintering and the like. Meanwhile, metal carbide is reasonably selected to be matched with other raw materials according to actual working condition requirements, the advantages of the ceramic friction component are exerted, and the comprehensive friction and abrasion performance of the material is improved.

Owner:ANYANG INST OF TECH

Anti-corrosion alloy sucker rod and manufacturing method thereof

PendingCN111118385AHigh thermodynamic stabilitySpread evenlyDrilling rodsVacuum evaporation coatingThin membraneAlloy

The invention relates to an anti-corrosion alloy sucker rod and a manufacturing method thereof. The anti-corrosion alloy sucker rod comprises a rod body and a joint, and the rod body includes a steelsubstrate, a TiCrN hard thin film, a TiCrSiN anti-corrosion thin film and a polyetheretherketone anti-corrosion coating in sequence from inside to outside. The anti-corrosion properties of the steel substrate are relatively high. The TiCrN hard thin film has relatively high hardness, relatively high working stability and oxidation resistance. The TiCrSiN anti-corrosion thin film has excellent abrasive wear resistance, corrosion resistance and oxidation resistance. The corrosion resistance of the polyetheretherketone anti-corrosion coating is similar to that of nickel steel. In summary, the rodbody of the anti-corrosion alloy sucker rod has excellent anti-corrosion and high-strength performance and a long service life.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hot melting alloy constrained type blasting device

The invention discloses a hot melting alloy constrained type blasting device, and belongs to the technical field of blasting. The device comprises a blasting propagation component, hot melting alloy actuators, a drive spring, a steel ball, a state switch, an electric detonator, a blasting component, a body, a pressure screw, a large pressure screw and a screw; at ordinary, two hot melting alloy actuators lock the blasting propagation component on the position away from the electric detonator, meanwhile, the state switch carries out short-circuit protection on the electric detonator and achieves the state indication function, even if the electric detonator plays an unexpected action, the blasting component cannot be detonated, after the hot melting alloy actuators are powered on and act, the locking on the blasting propagation component is relieved, the drive spring drives the blasting propagation component to move to be in the state aligned with the electric detonator, the state switchconverts and relieves the short-circuit protection on the electric detonator, and when any electric detonator acts, the blasting propagation component can be blasted, and the blasting propagation component blasts the blasting component. The device has the beneficial effects of being capable of being controlled remotely, high in safety, reliable in action, capable of achieving state indication andthe like.

Owner:XIAOGAN RUICHUANG MACHINERY TECH CO LTD

Method for preparing high-density iron-base powder metallurgy parts

The invention provides a method for preparing high-density iron-base powder metallurgy parts, and belongs to the technical field of powder metallurgy molding. The compaction density of iron-base powder can be increased by utilizing the special stratified structure, the low friction factor and the good lubricating property of MoS2 (molybdenum disulfide). The method comprises the following steps: uniformly mixing the iron powder with MoS2 powder, carrying out annealing treatment, and causing MoS2 to be uniformly distributed on the surface of the iron powder; and uniformly mixing annealed mixed powder with a certain amount of metal powder, graphite powder and the like, and pressing and sintering to obtain the high-density iron-base parts. In the pressing process, the friction force among powder particles is reduced and the friction state among the powder particles is improved through the MoS2, the pressing performance is increased, and the iron-base powder metallurgy parts with the density of 7.2g / cm3-7.5g / cm3 can be obtained. The method has the advantages that the pressing performance of the iron-base powder is improved; the high-density iron-base powder metallurgy parts is obtained on the premise of cost reducing; the friction factor is reduced, the loss of abrasive tools is decreased, and meanwhile, the adverse influence of sulphur on the iron-base parts does not exist; and the process is simple and suitable for industrial production.

Owner:UNIV OF SCI & TECH BEIJING

Lifting support device and display device applying same

InactiveCN101211673BReduce friction factorSolving Elasticity ProblemsTelevision system detailsColor television detailsElastic componentDisplay device

The invention relates to a lifting supporting device, which comprises a supporting base, a sliding component and an adjusting component. The sliding component is arranged on the supporting base in a sliding way and is provided with a stopping part. The adjusting component is arranged on the supporting base and is selectively fastened on the stopping part, thus fastening the sliding component on the supporting base. The adjusting component further comprises at least an elastic component to connect the supporting base and the sliding component, wherein, the elastic force of the elastic componentallows the sliding component to move corresponding to the supporting base in one direction automatically when the adjusting component is separated from the stopping part. When the sliding component is forced, the sliding component drives the stopping part to push away the adjusting component, thus allowing the sliding component to move corresponding to the supporting base in the reverse directionof the direction.

Owner:QISDA SUZHOU

Winding device for textile processing

ActiveCN112897243ARelieve tensionAvoid breakingFilament handlingStructural engineeringManufacturing engineering

The invention discloses a winding device for textile processing. The winding device for the textile processing comprises a winding limiting assembly; a reciprocating transmission assembly is movably mounted on one side of the winding limiting assembly in a sleeving manner; a rotating tooth-missing piece is movably connected to the top of the reciprocating transmission assembly in a sleeving manner; a limiting and fixing assembly is movably mounted on the other side of the rotating tooth-missing piece in a sleeving manner; locking nuts are movably mounted on the upper side and lower side of the outer surface of the winding limiting assembly in a sleeving manner; a locking screw is movably clamped to the middle of each locking nut; and first transmission buffer rollers are movably mounted on the upper side and lower side of the outer surface of the other side of the winding limiting assembly in a sleeving manner. According to the winding device for the textile processing, by arranging the assemblies of the winding limiting assembly, the first transmission buffer rollers, a second transmission buffer roller and the like, the first transmission buffer rollers and the second transmission buffer roller are driven to rotate through the pulling of a spinning thread, the redundant spinning thread can be reserved in advance through a triangular stretching structure, the tensioning state of the spinning thread can be greatly relieved through the triangular stretching structure, the large pulling force is relieved, and the spinning thread is effectively prevented from being snapped by the pulling force.

Owner:浙江金紫利新材料科技有限公司

A kind of preparation method of tpu and pvc blending improved composite fabric

ActiveCN102729559BGood weather resistanceImprove wear resistanceSynthetic resin layered productsLaminationEngineeringImproved method

The invention discloses a preparation method of TPU and PVC blended improved composite fabrics. According to the method, TPU and PVC are blended to fully perform respective characteristics of TPU and PVC, so as to achieve the purpose of complementary advantages; calendaring molding is carried out by a four roll calender method to obtain a TPU and PVC blended film; and on-line lamination is carried out on the TPU and PVC blended film and glued base cloth on a calendar so as to obtain the TPU and PVC blended improved composite fabrics. The composite fabrics have characteristics of excellent mechanical property, wear resistance, environmental protection and the like. The coating of the composite fabrics is uniform and thickness error is less than 0.015mm. The composite fabrics has advantages of firm adhesion, wear resistance and flexing resistance, and can be widely used in application fields of inflatable life jacket, chemical splash suit, water pot, oil tank, sphygmomanometer, medical bed, oxygen bag, inflatable cushion, airbed, inflatable tent, air bag, air cushion ship, waterproof moisture permeable high-grade costuming and the like.

Owner:无锡翔隆高分子面料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com