Anti-corrosion alloy sucker rod and manufacturing method thereof

A sucker rod, anti-corrosion technology, applied in anti-corrosion coatings, drill pipes, earth-moving drilling, etc., to achieve the effect of small friction factor and improved wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

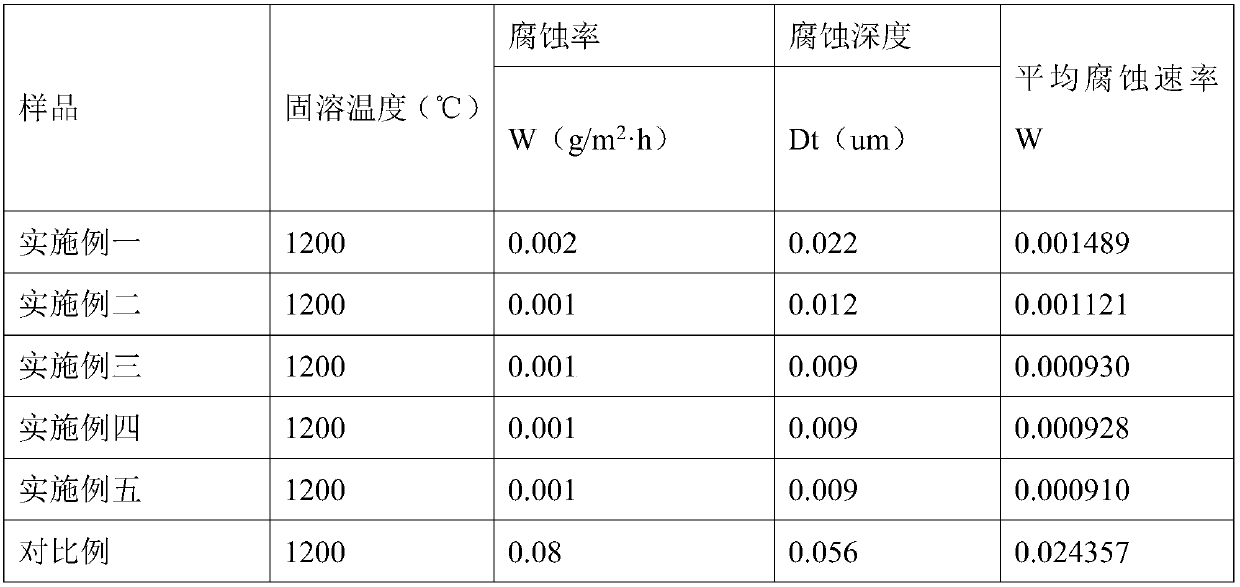

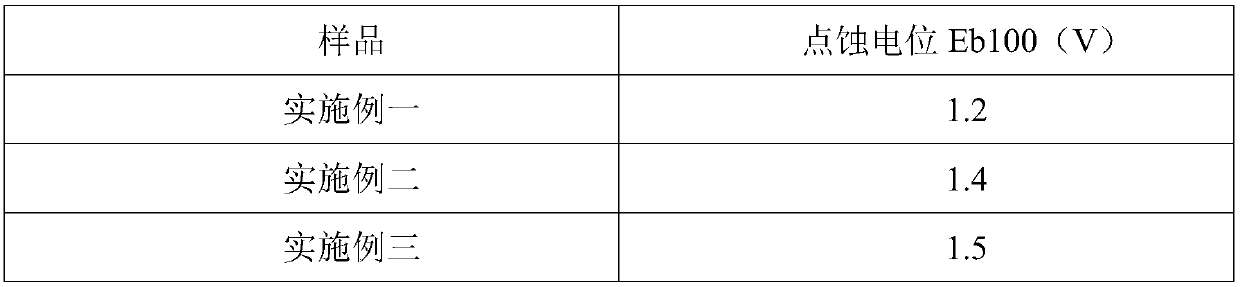

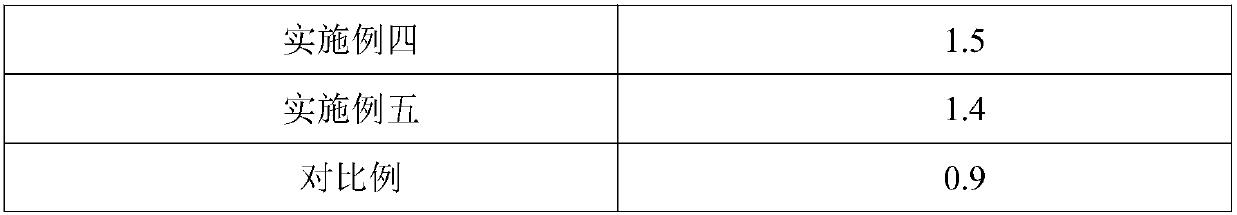

Examples

Embodiment 1

[0045] An anti-corrosion alloy sucker rod is prepared by the following steps:

[0046] (1) Forming of steel matrix;

[0047] (a) Ingredients: 0.015% carbon, 0.6% manganese, 0.009% phosphorus, 0.005% sulfur, 14.0% chromium, 10.0% nickel, 2.15% molybdenum, 0.80% rhenium, 0.4% zinc, Potassium element 0.05%, nitrogen element 0.13%, boron element 0.035%, the rest is iron element;

[0048] (b) Pretreatment of chromium and molybdenum elements: melting the cage silsesquioxane at a high temperature of 400-450°C, and continuously feeding N 2 flow, continue to heat up to 1050-1150 ° C, according to the weight ratio of cage silsesquioxane to chromium element is 1:3, put chromium element and molybdenum element into hot rolling treatment, stir at 180-200r / min for 1.5- 2h, to obtain nano-scale liquid chromium and molybdenum elements;

[0049] (c) During the electric arc furnace smelting process, the furnace temperature is first raised to 760-780°C, and carbon, manganese, phosphorus, sulfu...

Embodiment 2

[0062] An anti-corrosion alloy sucker rod differs from the first embodiment in that the formula of the steel matrix is different. Among them, 0.015% carbon, 0.6% manganese, 14.2% chromium, 9.5% nickel, 2.2% molybdenum, 0.85% rhenium, 0.45% zinc, 0.06% potassium, 0.12% nitrogen, 0.03 boron %, and the rest is iron.

Embodiment 3

[0064] An anti-corrosion alloy sucker rod differs from the first embodiment in that the formula of the steel matrix is different. Among them, carbon element 0.02%, manganese element 0.8%, phosphorus element 0.04%, sulfur element 0.002%, chromium element 14.3%, nickel element 10.0%, molybdenum element 2.3%, rhenium element 0.9%, zinc element 0.5%, potassium element 0.07% %, 0.15% nitrogen, 0.04% boron, and the rest is iron.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com