Processing method of coating microstructured bionic surface type diamond cutter

A diamond tool and microstructuring technology, which is applied in the field of tool metal processing, can solve the problems of poor cutting performance and short service life, and achieve the effect of improving lubrication ability, high thermal conductivity and good use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

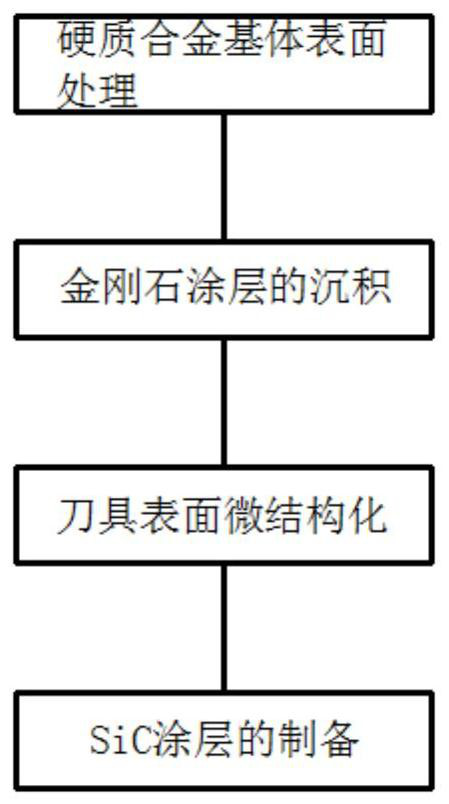

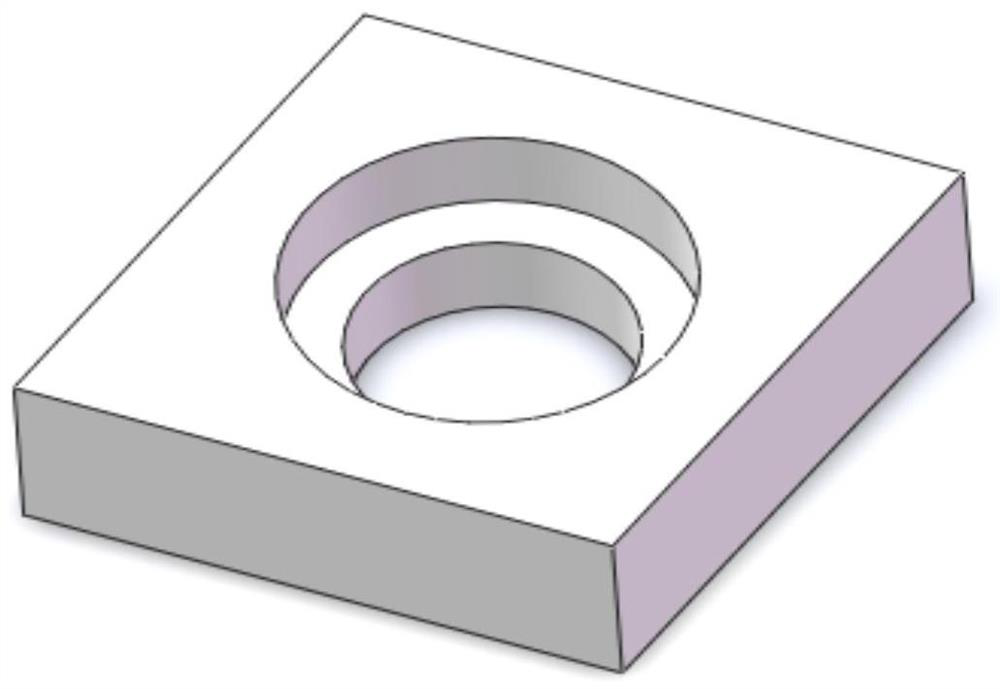

[0020] Embodiment 1: as attached figure 1 Shown, a kind of processing method of coated microstructured biomimetic surface diamond tool, described method comprises the following steps: one, cemented carbide substrate surface treatment; Two, the deposition of diamond coating; Three, tool surface microstructure Processing; Fourth, the preparation of silicon carbide coating.

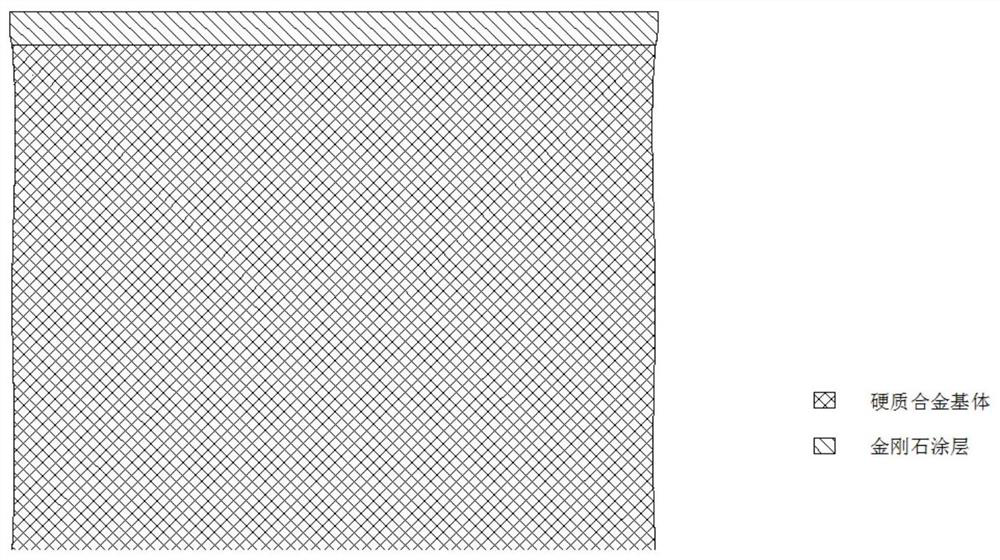

[0021] In step 1, the two-step method of acid and alkali is adopted, that is, the cemented carbide substrate is first placed in an alkaline solution of sodium hydroxide with a concentration of 50%-80%, and the grease and tungsten carbide covered on the surface of the substrate are removed, and then ultrasonic cleaning is performed. ; Then place the cleaned substrate in an acidic solution of hydrochloric acid with a concentration of 20%-40% to remove Co, and then perform ultrasonic cleaning and drying. as attached figure 2 shown.

[0022] The removal of Co and carbide treatment of cemented carbide, its fu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com