High-temperature-resistant and wear-resistant fluororubber sealing element and preparation method thereof

A technology of fluorine rubber and seals, which is applied in the field of high temperature and wear-resistant fluorine rubber seals and its preparation, can solve the problems of temperature resistance, wear resistance, and strength to be improved, and achieve the improvement of comprehensive performance, increase of vulcanization density, The effect of improving high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

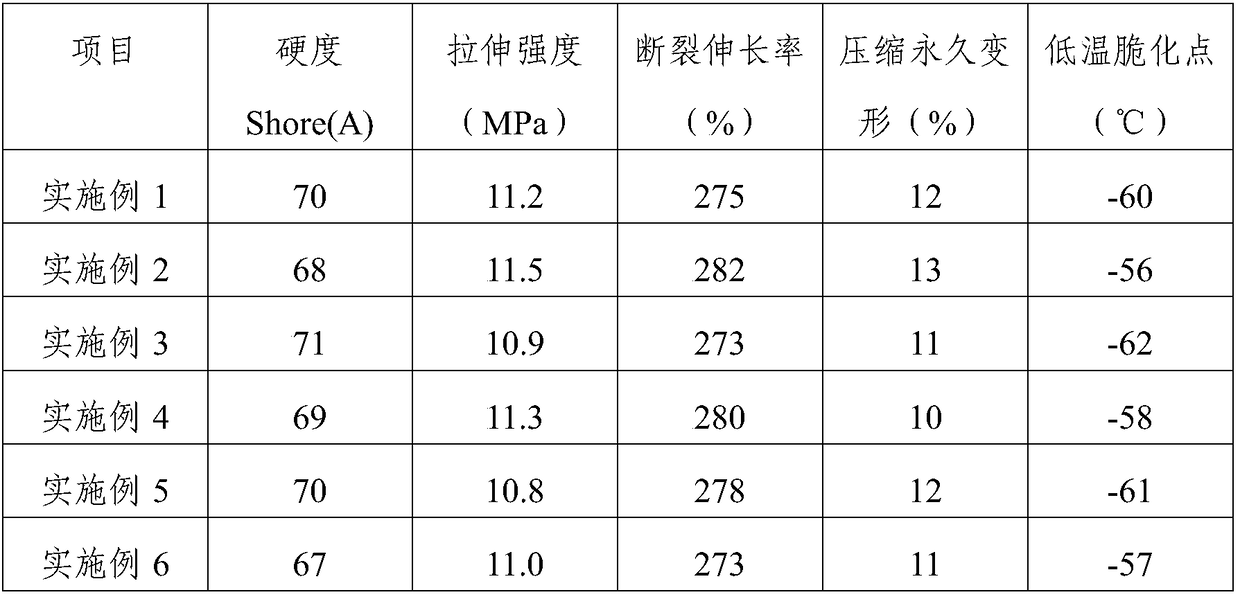

Examples

Embodiment 1

[0022] A heat-resistant and wear-resistant fluororubber seal, made of the following raw materials in parts by weight: 55 parts of 26-type fluororubber, 35 parts of 23-type fluororubber, 18 parts of medium-particle pyrolysis carbon black, and organically modified concave-convex clay 8 parts, 1 part of calcium silicate, 1 part of talcum powder, 2 parts of hydroxyfluorosilicone oil, 2.5 parts of magnesium oxide, 0.45 parts of silane coupling agent KH-460, 3 parts of perfluoromethylphenyl hydroxyperoxide, triene 0.4 parts of propyl isocyanurate, 0.5 parts of zinc stearate, and 0.3 parts of carnauba wax.

[0023] The preparation method of organically modified attapulgite is as follows: add 0.05 parts of octadecyltrimethylammonium bromide to 60 parts of water and stir, after completely dissolving, add 1 part of attapulgite, stir for 5 hours; then suction filter to obtain The filter cake is vacuum-dried and crushed to obtain the organically modified attapulgite.

[0024] The prepara...

Embodiment 2

[0030] A heat-resistant and wear-resistant fluororubber seal, made of the following raw materials in parts by weight: 60 parts of 26-type fluororubber, 20 parts of 23-type fluororubber, 12 parts of medium-particle pyrolysis carbon black, and organically modified concave-convex clay 6 parts, 1.8 parts of calcium silicate, 0.5 parts of talc, 2 parts of hydroxyfluorosilicone oil, 2 parts of magnesium oxide, 0.4 parts of silane coupling agent KH-550, 2.5 parts of perfluoromethylphenyl hydroxyperoxide, triene 0.7 parts of propyl isocyanurate, 0.2 parts of zinc stearate, and 0.5 parts of carnauba wax.

[0031] The preparation method of organic modified attapulgite is as follows: add 0.05 part of dodecyl dimethyl ammonium chloride to 60 parts of water and stir, after completely dissolving, add 1 part of attapulgite, stir and react for 3 hours; then suction filter to obtain The filter cake is vacuum-dried and crushed to obtain the organically modified attapulgite.

[0032] The prepar...

Embodiment 3

[0038] A heat-resistant and wear-resistant fluororubber seal, made of the following raw materials in parts by weight: 70 parts of 26-type fluororubber, 25 parts of 23-type fluororubber, 20 parts of medium-particle pyrolysis carbon black, and organically modified concave-convex clay 8.5 parts, 1 part of calcium silicate, 0.8 parts of talc, 2.5 parts of hydroxyfluorosilicone oil, 2.5 parts of magnesium oxide, 0.5 parts of silane coupling agent KH-560, 3 parts of perfluoromethylphenyl hydroxyperoxide, triene 0.5 parts of propyl isocyanurate, 0.3 parts of zinc stearate, and 0.2 parts of carnauba wax.

[0039] The preparation method of organically modified attapulgite is as follows: add 0.01 part of octadecyltrimethylammonium bromide to 40 parts of water and stir, after completely dissolving, add 1 part of attapulgite, stir for 4 hours; then suction filter to obtain The filter cake is vacuum-dried and crushed to obtain the organically modified attapulgite.

[0040] The preparation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com