Patents

Literature

43results about How to "Improve vulcanization activity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Operating method for vulcanized hydrogenation catalyst

ActiveCN104593050ANo self-heatingNo flammability issuesMolecular sieve catalystsHydrotreatment operations starting-upHydrogenation reactionReaction temperature

The invention discloses an operating method for a vulcanized hydrogenation catalyst. The method comprises the following steps: impregnating the vulcanized hydrogenation catalyst with an organic complex solution of a group-VIII metal; carrying out heat treatment so as to allow a layer of a protective film to form on the surface of the vulcanized hydrogenation catalyst; carrying out treatment in the presence of inert gas so as to allow the group-VIII metal to be inlaid in the defect of molybdenum disulfide or tungsten disulfide, thereby forming a high-activity hydrogenation active phase; and then carrying out switching into hydrogen, adjusting pressure and temperature to reaction pressure and reaction temperature after air current is steady, feeding raw oil and beginning a hydrogenation reaction. The method provided by the invention can passivate the vulcanized catalyst, facilitates transportation, storage and filling of the catalyst and can improve hydrogenation performance of the catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

Second-active-center-containing catalyst hydrogenation apparatus startup method

ActiveCN106947527AImprove usage activityConvenience and Economic PathwayTreatment with hydrotreatment processesProduct gasChemistry

The present invention discloses a startup sulfurization method of a hydrocracking apparatus. According to the present invention, with the grading use of the ex-situ presulfided catalyst, the hydrogenation catalyst containing the second active center is pre-protected with the hydrogen sulfide gas produced in the heating process while a certain auxiliary gas can be selectively injected according to different preparation methods of the second active center catalysts, such that the wet startup is converted into the dry startup; and the activity of the catalyst can be improved with the method of the present invention, and the method is suitable for the sulfurization startup process of the hydrogenation catalyst containing the second active center.

Owner:CHINA PETROLEUM & CHEM CORP +1

Treating method for vulcanized hydrogenation catalyst

ActiveCN104588043APrevent oxidationEasy to storeMolecular sieve catalystsHydrocarbon oil crackingBiological activationMetal

The invention discloses a treating method for a vulcanized hydrogenation catalyst. The method comprises the following steps: impregnating the vulcanized hydrogenation catalyst with an organic complex solution of a group-VIII metal; and carrying out heat treatment so as to allow a layer of a protective film to form on the surface of the vulcanized hydrogenation catalyst. The method provided by the invention can passivate the vulcanized catalyst, facilitates transportation, storage and filling of the catalyst, enables the catalyst to be directly used without activation during operation and can improve hydrogenation performance of the catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

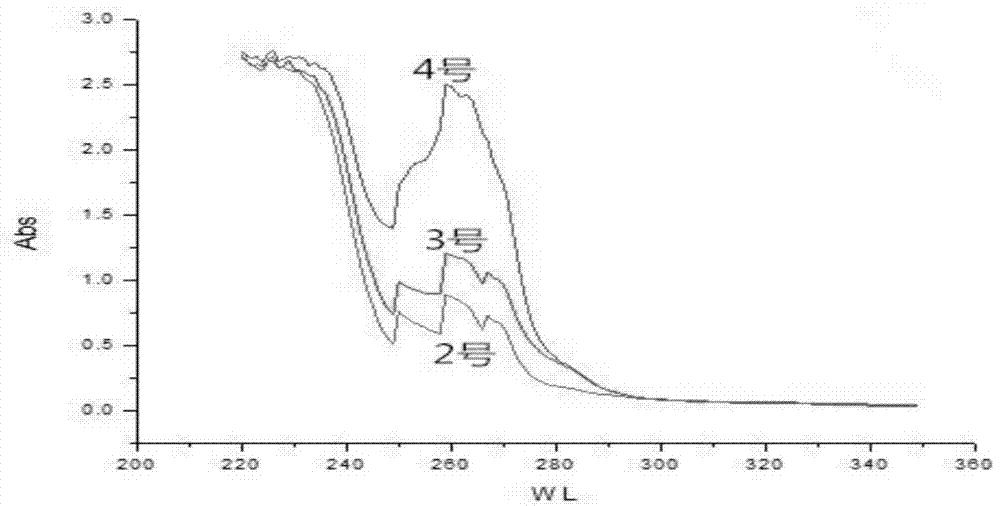

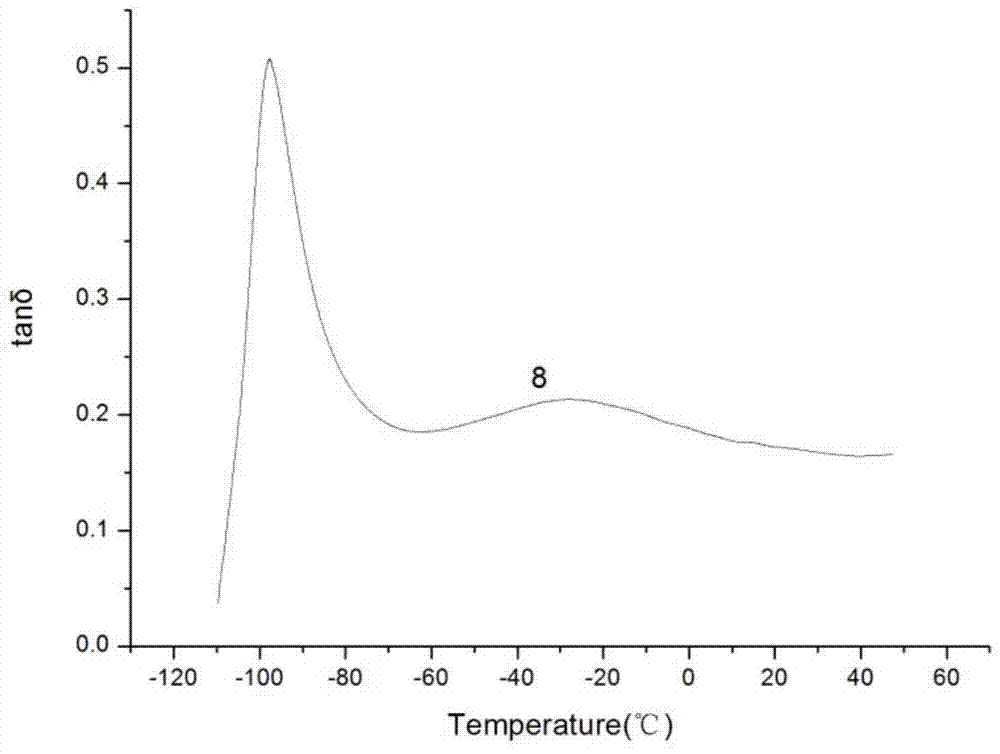

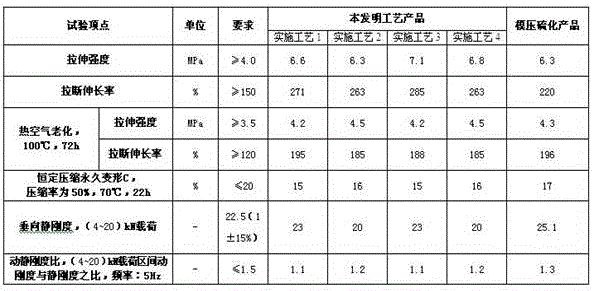

Damping silicon rubber with relatively small temperature effect and preparation method thereof

The invention relates to damping silicon rubber with a relatively small temperature effect and a preparation method thereof. The crude rubber of the damping silicon rubber is characterized in that a main chain of the crude rubber of the silicon rubber consists of methyl phenyl silicone chain elements, diethyl silicone chain elements, dimethyl silicone chain elements and methyl ethylene silicone chain elements with different content; the molecular weight of the crude rubber is more than 400 thousands; the crude rubber is prepared by copolymerizing methyl phenyl cyclosiloxane, diethyl cyclosiloxane, dimethyl cyclosiloxane and methyl ethylene cyclosiloxane in the presence of initiators of polypropylene oxide and the like. The crude rubber with the structure has good damping property in a relatively wide temperature range after being vulcanized, the dynamic loss factor and the modulus hardly change along with temperature changes, and the damping silicon rubber belongs to the field of organic silicon high polymer.

Owner:SHANDONG UNIV

High-performance composite cable jacket material for cables

InactiveCN104610666ALow costDelay agingInsulated cablesInsulated conductorsStearic acidChlorinated paraffins

The invention discloses a high-performance composite cable jacket material for cables. The high-performance composite cable jacket material is prepared from the following raw materials in parts by weight: 35-45 parts of ethylene propylene terpolymer, 30-50 parts of EVA resin, 30-45 parts of modified nanokaolin, 1-2 parts of dibenzothiazyl disulfide, 1.5-2.5 parts of zinc oxide, 1-3 parts of zinc dimethyldithiocarbamate, 1-2 parts of anti-aging agent ODA, 45-55 parts of high abrasion furnace black, 25-35 parts of calcined clay, 20-30 parts of nano calcium carbonate, 1-1.8 parts of dioctyl phthalate, 1-3 parts of stearic acid, 0.5-1.5 parts of chlorinated paraffin, 2-4 parts of solid calcium-zinc stabilizer and 1-2.5 parts of anti-aging agent RD. The high-performance composite cable jacket material for cables disclosed by the invention has good ageing resistance, good mechanical properties and low cost.

Owner:ANHUI HONGYI CABLE GROUP

Sheathing material for power cables and preparation method thereof

InactiveCN103788517AAvoid premature vulcanizationHigh tensile strengthRubber insulatorsInsulated cablesPotassiumPolyethylene glycol

The invention discloses a sheathing material for power cables. The sheathing material comprises the following raw materials in parts by weight: 12-16 parts of chlorosulfonated polyethylene, 3-6 parts of butadiene-acrylonitrile rubber, 6-9 parts of chlorinated butyl rubber, 0.3-0.5 part of zinc dimethyldithiocarbamate, 0.3-0.7 part of dibenzothiazyl disulfide, 1.2-1.7 parts of an activator zinc oxide, 2-3 parts of stearic acid, 0.6-1 part of N-(cyclohexylthio)phthalimide, 0.5-1 part of chlorinated paraffin, 1-2 parts of a surfactant polyethylene glycol, 1.5-2 parts of potassium chloroplatinate, 1-4 parts of dioctyl phthalate, 4-7 parts of a reinforcing agent carbon black 330, 4-6 parts of a filler ultrafine talcum powder, and 2.5-4 parts of a filler calcium carbonate. The invention also discloses a preparation method of the sheathing material for power cables. According to the invention, the sheathing material for the power cables is good in mechanical properties, high in tensile strength, good in tear strength and wear resistance, excellent in aging resistance, simple in preparation process, and low in production cost.

Owner:ANHUI ZHONGTONG CABLE TECH

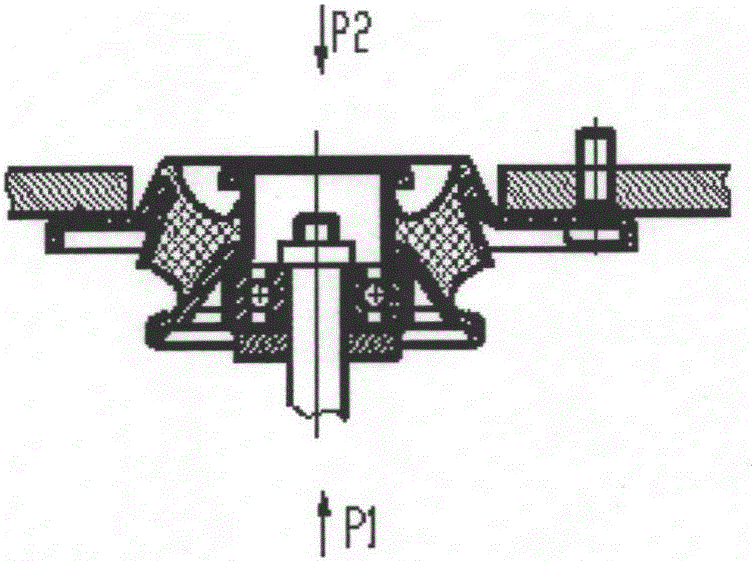

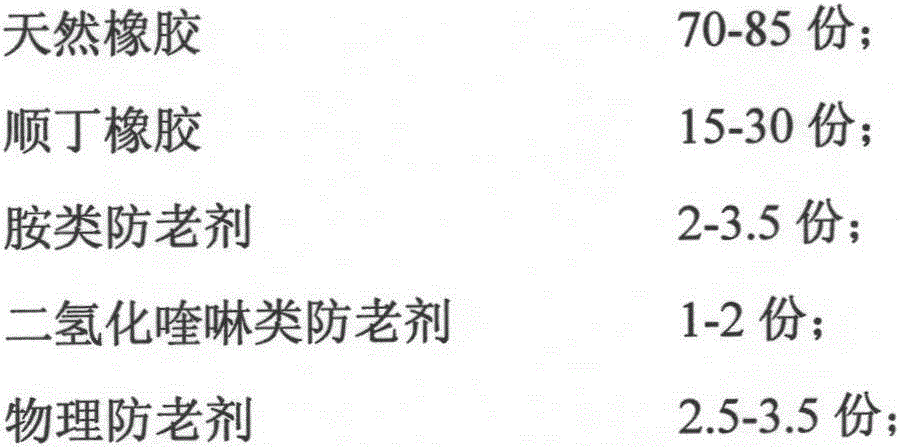

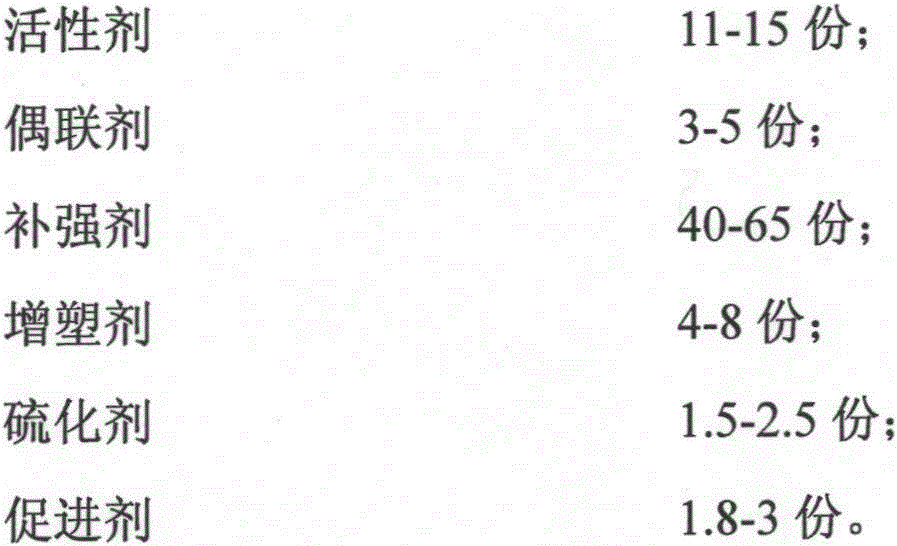

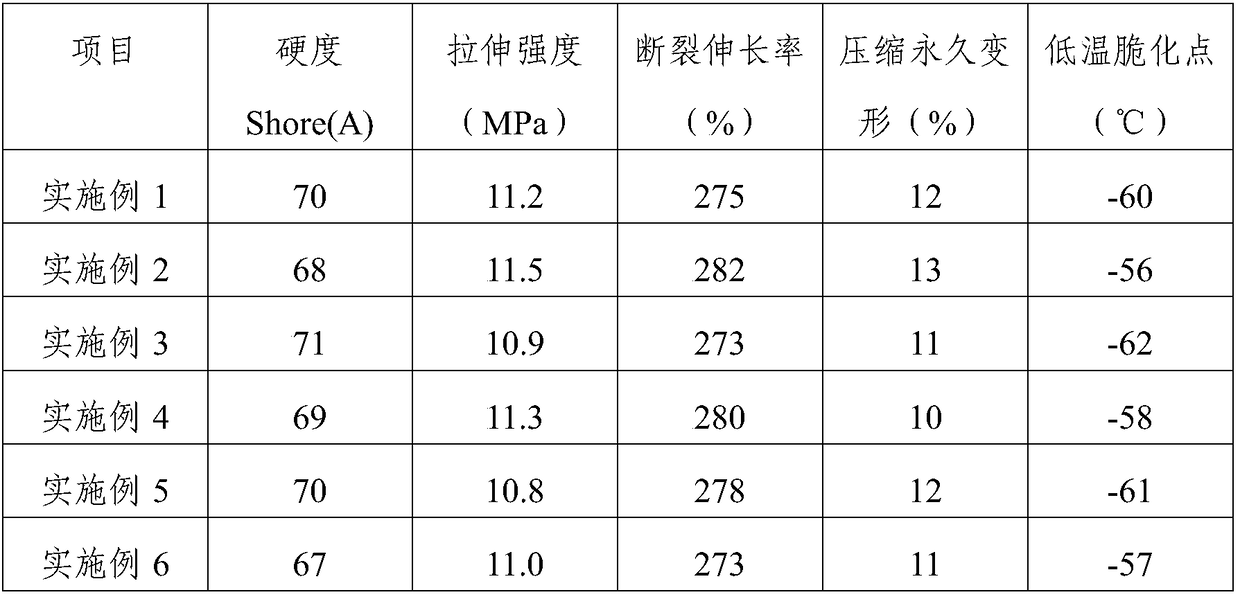

Rubber composition for upper support of automobile shock absorber

The invention discloses a rubber composition for an upper support of an automobile shock absorber. The rubber composition is prepared from the following components: 70 to 85 parts of natural rubber, 15 to 30 parts of butadiene rubber, 2 to 3.5 parts of amine antiagers, 1 to 2 parts of quinoline dihydride antiagers, 2.5 to 3.5 parts of physical antiager, 11 to 15 parts of activating agent, 3 to 5 parts of coupling agent, 40 to 65 parts of reinforcing agent, 4 to 8 parts of plasticizer, 1.5 to 2.5 parts of vulcanizing agent and 1.8 to 3 parts of accelerant. The rubber composition for the upper support of the automobile shock absorber, provided by the invention, has the advantages of excellent properties of high temperature resistance and heat resistance, as well as small physical property change, high strength retaining rate and good high-temperature compression permanent deformation of aged rubber. The produced upper support of the automobile shock absorber has excellent high-temperature creepage and dynamic fatigue property, is in a leading level of the industry, and obtains the approval of domestic and foreign customers.

Owner:SHANGHAI ZHONGLI INVESTMENT +1

High-temperature-resistant and wear-resistant fluororubber sealing element and preparation method thereof

InactiveCN108504004AHigh strengthImprove performanceOther chemical processesCalcium silicateWear resistant

The invention provides a high-temperature-resistant and wear-resistant fluororubber sealing element and a preparation method thereof. The high-temperature-resistant and wear-resistant fluororubber seal element is prepared from the following raw materials in parts by weight: 50-70 parts of 26 type fluororubber, 20-45 parts of 23 type fluororubber, 12-20 parts of medium-particle pyrolysis carbon black, 5-8.5 parts of organic modified attapulgite, 1-1.8 parts of calcium silicate, 0.5-1 part of a talc powder, 1.5-2.5 parts of hydroxyl fluorosilicone oil, 1.5-2.5 parts of magnesium oxide, 0.3-0.5 part of a silane coupling agent, 2-3 parts of perfluoromethyl phenyl hydroxyl peroxide, 0.4-0.7 part of triallyl isocyanurate, and 0.5-1 part of a processing aid. The prepared sealing element has excellent high-temperature resistance and wear resistance and high strength, and the service life of the sealing element can be effectively prolonged.

Owner:ANHUI PROPELLENT HEAT TRANSFER TECH CO LTD

Foamed silicone rubber and preparation method thereof

InactiveCN109486203AExpand the scope of selectionImprove heat aging resistancePolymer scienceVulcanization

The invention discloses foamed silicone rubber and a preparation method thereof, and belongs to the technical field of silicone rubber materials. Vinyl silicone rubber containing different amounts ofethylene is taken as a base rubber, the introduction of a small amount of ethylene is beneficial to improving vulcanization activity, increasing the selection range of organic peroxide vulcanizing agents, improving the heat aging resistance, mechanical strength and compression permanent deformation performance of vulcanized rubber; and meanwhile, the foamed silicone rubber is prepared by adoptinga method combining freezing and two-stage vulcanization reaction, and the two-stage vulcanization reaction is beneficial to avoiding the occurrence of over-sulfur, thus improving the mechanical properties and compression permanent deformation properties of a foamed silicone rubber product. Combined with the freezing process, the foaming uniformity and mechanical properties of the prepared productare improved, and the tensile strength of the prepared foamed silicone rubber reaches 0.87 Mpa.

Owner:安徽旭川新材料科技有限公司

Method for improving zinc oxide sulfuration activity

The invention relates to a method for improving zinc oxide sulfuration activity and belongs to the technical field of natural rubber processing. The method comprises adding 0.5-10 parts of rare earth oxide into 100 parts of common zinc oxide and carrying out ball milling and high temperature sintering rare earth doping. According to inherent characteristics of rare earth, zinc oxide particle conformation structure and ion surface chemical properties are changed, sulfuration activity is improved, a use ratio of zinc oxide in the rubber formula is reduced from 5: 100 to 2: 100, sulfuration time is shortened, natural vulcanized rubber crosslinking density and mechanical properties are improved and reasonable utilization and saving of a zinc ore resource are realized.

Owner:AGRI PRODS PROCESSING RES INST CHINESE ACAD OF TROPICAL AGRI SCI

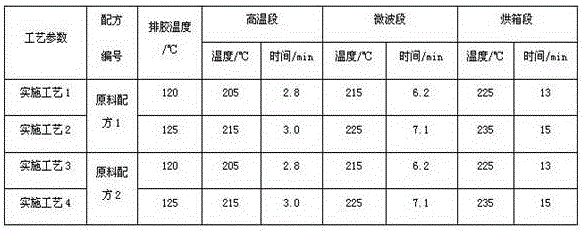

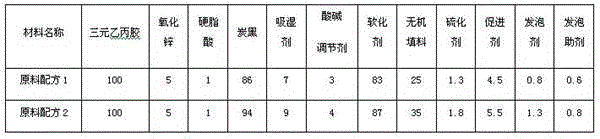

Production process for ethylene propylene diene monomer microporous base plate and product produced by production process

The invention discloses a production process for an ethylene propylene diene monomer microporous base plate. The production process comprises the following steps: adding ethylene propylene diene monomer into a kneading machine to knead, and then adding zinc oxide, stearic acid, carbon black, a moisture absorbent, an acid and alkali regulator, a softening agent and an inorganic filler into the kneading machine to knead, thereby preparing a master batch; adding the prepared master batch into an open mixing machine, adding a vulcanizing agent, a promoter, a foaming agent and a foaming aid, uniformly mixing, regulating roll spacing to 0.8-1.3 millimeters for thin-passing, carrying out triangular packaging for 3-4 times, regulating the roll spacing to 5-6 millimeters for discharging, so as to prepare a rubber compound, and standing the rubber compound for not smaller than 16 hours; putting the rubber compound on a cutter for cutting; feeding prepared rubber strips into a cold feeding extruder to extrude; sequentially feeding the prepared rubber strips into a high-temperature section, a microwave section and an oven section to carry out continuous vulcanizing until complete vulcanizing; and pulling the prepared vulcanized rubber into the cutter through a pulling machine, and cutting the prepared vulcanized rubber into a needed dimension, thereby obtaining a microporous base plate finished product. The invention further provides an ethylene propylene diene monomer microporous base plate.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Modified composite cable sheath material and preparation method thereof

InactiveCN104629200AGood chemical resistanceGood physical and mechanical propertiesPlastic/resin/waxes insulatorsInsulated cablesParaffin waxOxide

The invention discloses a modified composite cable sheath material which is prepared from the following raw materials in parts by weight: 30-40 parts of chlorosulfonated polyethylene, 20-30 parts of crosslinked insulation polyethylene, 15-20 parts of modified nano kaolin, 0.8-1.3 parts of dibenzothiazyl disulfide, 1-3 parts of zinc oxide, 1-2 parts of zinc dimethyldithiocarbamate, 0.8-1.5 parts of anti-aging agent 4010NA, 40-50 parts of high-wear-resistance carbon black, 20-30 parts of calcined argil, 15-25 parts of nano calcium carbonate, 0.5-2 parts of dioctyl phthalate, 1-2 parts of stearic acid, 1-2 parts of chlorinated paraffin wax, 1-3 parts of solid calcium-zinc stabilizing agent and 1-3 parts of phosphite. The modified composite cable sheath material has the advantages of favorable aging resistance, excellent physical and mechanical properties and lower cost.

Owner:ANHUI HONGYI CABLE GROUP

Cable with fluorine-modified polyacrylate sheath layer

InactiveCN105175820AGood adhesionGood waterproof and oil-proofRubber insulatorsInsulated cablesEngineeringStearic acid

The invention discloses a cable with a fluorine-modified polyacrylate sheath layer. The cable comprises a cable core and a sheath layer which coats the cable core. Raw materials of the sheath layer comprise, by weight, 32-35 parts of nitrile rubber 2707, 24-27 parts of fluorine-modified polyacrylate, 23-26 parts of ethylene propylene diene monomer, 13-16 parts of para-aramid fibers, 11-14 parts of furnace black, 17-20 parts of mica, 8-11 parts of sepiolite, 3-5 parts of a mono-alkoxy titanate coupling agent, 2.3-3.5 parts of sulphur, 1.5-1.8 parts of an accelerant TT, 2.2-2.5 parts of an accelerant DM, 1.1-1.4 parts of an anti-aging agent SP, 2.3-2.6 parts of an anti-aging agent RD, 0.7-1.1 parts of stearic acid, 7-11 parts of phenyl petroleum sulfonate and 1-3 parts of castor oil. The cable has good waterproofness and oil-proof performance, and has excellent weather fastness and corrosion resistance. The preparation process is simple and easy to operate, and reaction conditions are mild. The cable is convenient for industrial production.

Owner:ANHUI HONGHAI CABLE

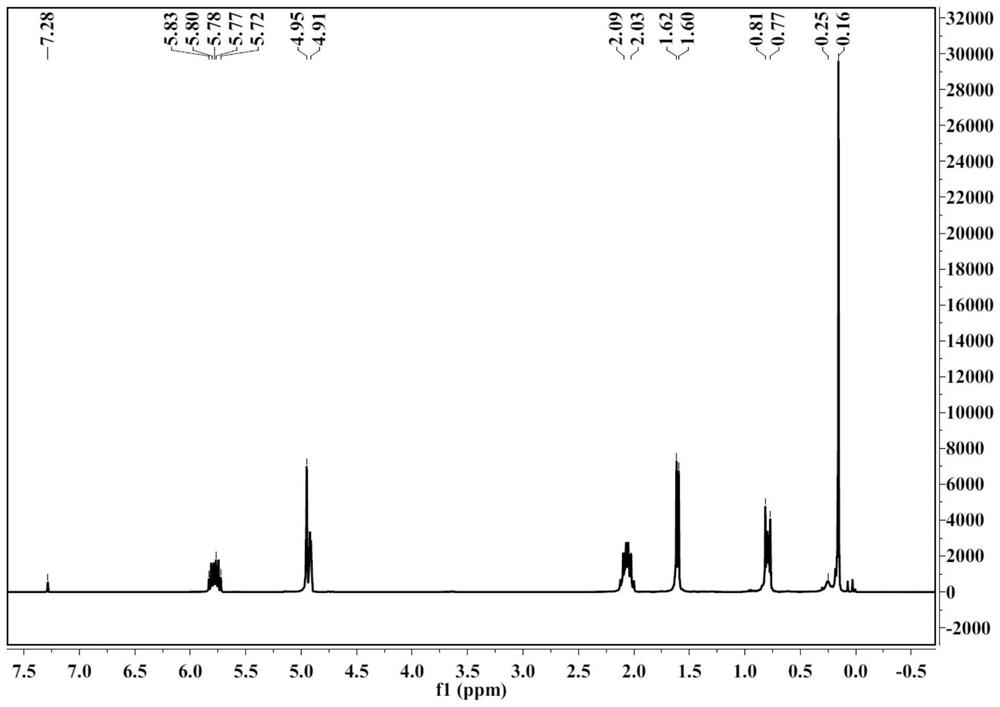

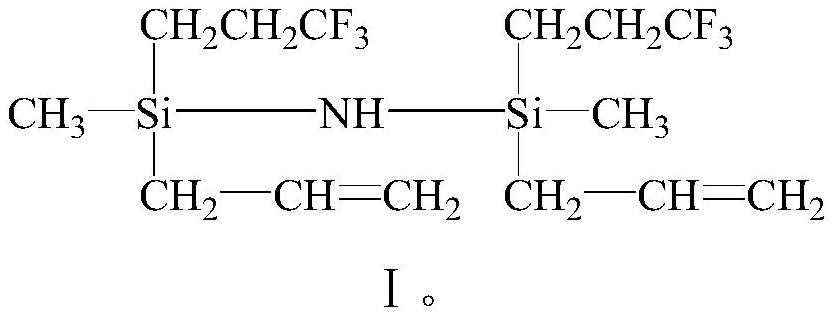

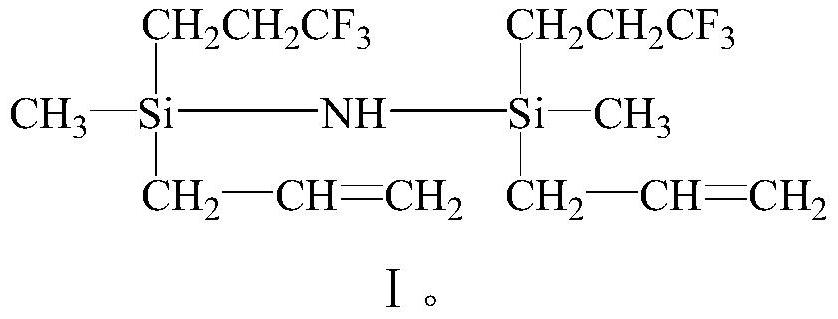

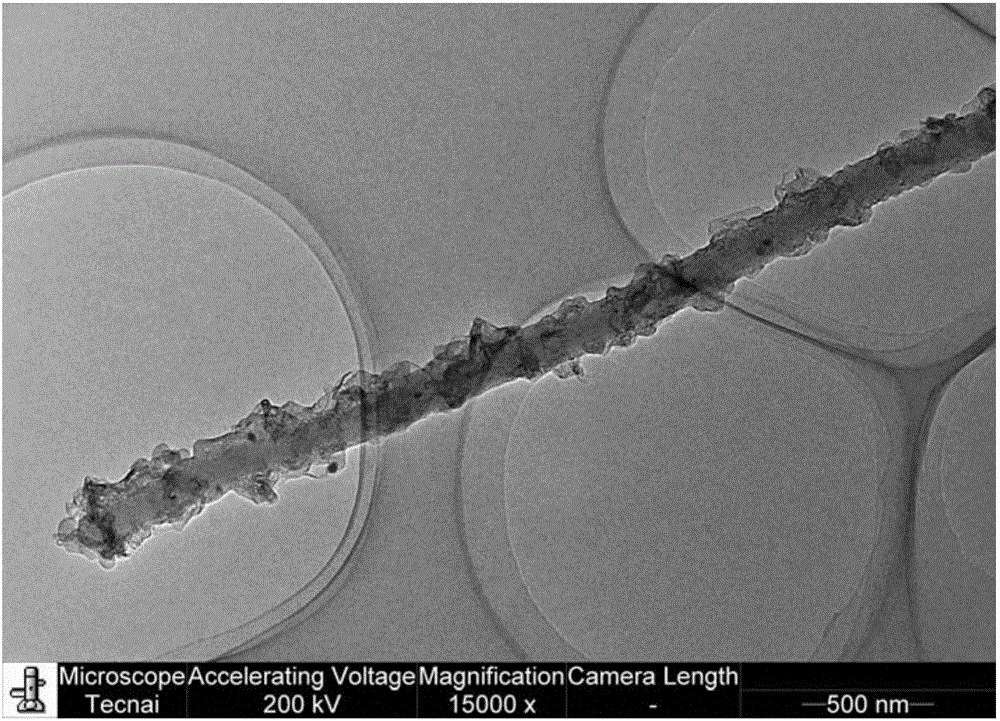

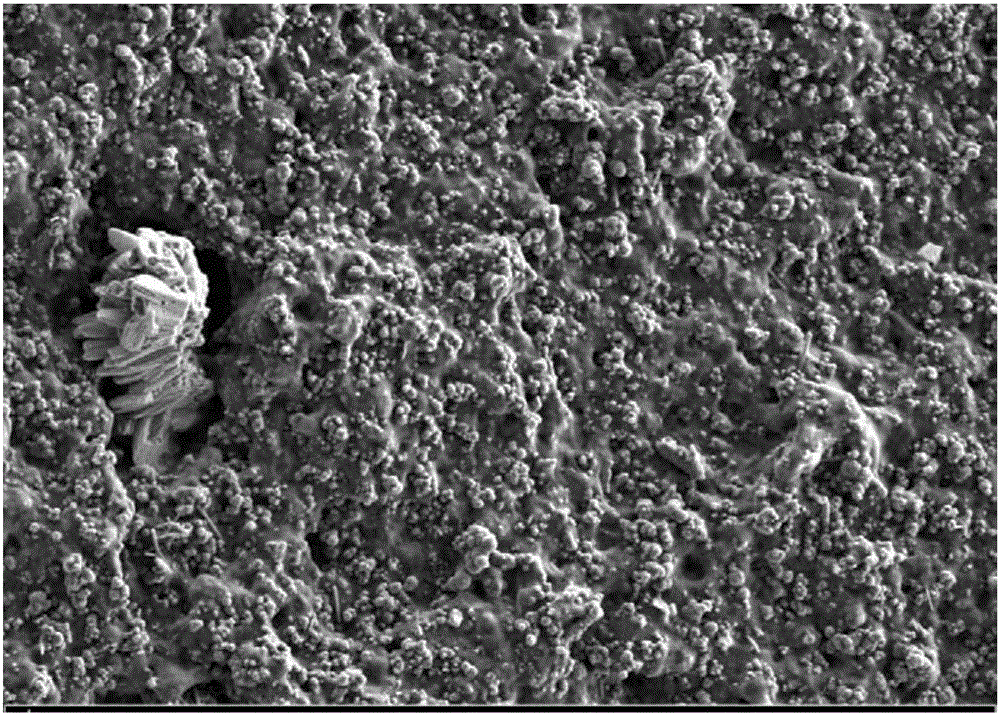

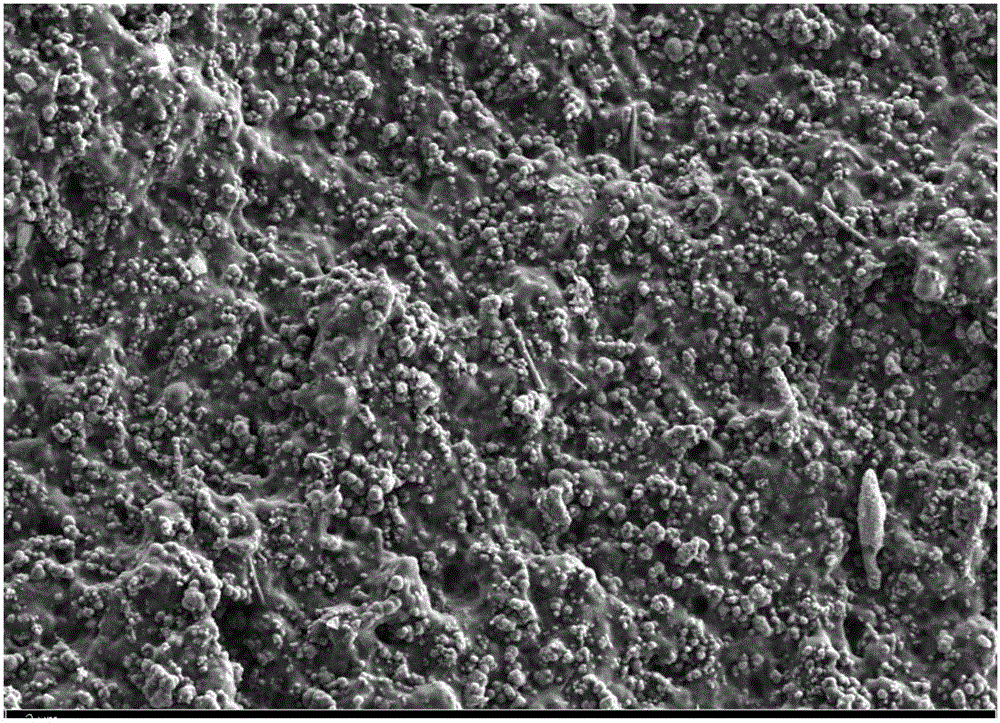

Novel fluorinated silicone rubber additive as well as preparation method and application thereof

ActiveCN111606941AHigh resilienceImprove oil resistance volume change rateSilicon organic compoundsPolymer scienceSilazane

The invention provides a novel fluorinated silicone rubber additive as well as a preparation method and application thereof, and the preparation method comprises the following steps: in the presence of a solvent, reacting trifluoropropyl methyl dichlorosilane, magnesium chips and halopropene, adding a complex breaker after the reaction is finished, filtering, and rectifying to obtain trifluoropropyl allyl methyl chlorosilane; mixing trifluoropropyl allyl methyl chlorosilane with a non-polar solvent, introducing ammonia gas to react, and finally filtering and carrying out reduced pressure distillation to obtain di (trifluoropropyl) di (allyl) dimethyl disilazane. The novel fluorinated silicone rubber additive disclosed by the invention has the advantages that the effect of a structured control agent can be achieved; meanwhile, the compatibility of the white carbon black and the fluorosilicone raw rubber can be improved, a cross-linking reaction with a cross-linking point on the fluorosilicone raw rubber is easier to occur, chemical bond connection is formed between the white carbon black and the fluorosilicone raw rubber, and the elasticity and oil resistance of the fluorosilicone rubber are improved under the condition that the use amount is very small.

Owner:新元化学(山东)股份有限公司 +1

Reclaimed rubber prepared from oil field oil sludge and production method thereof

InactiveCN106188613AImprove qualityImprove vulcanization activityPlastic recyclingTarTherapeutic effect

The invention belongs to the field of oil field oil sludge resourceful treatment, especially discloses reclaimed rubber prepared from oil field oil sludge as a main raw material, and also discloses a production method. The reclaimed rubber prepared from the oil field oil sludge is composed of the raw materials by the mass percentage: 50%-65% of oily sludge, 5%-20% of a waste tire rubber powder, 20%-40% of clay, 0.1%-0.4% of an activator 420, 0.1%-0.3% of ethylene tar, and 0.1%-0.3% of alkyl phenol disulfide. According to the reclaimed rubber prepared with oil field oil sludge, through formula optimization design, the content of the oily sludge is increased significantly, the consumption of the oil field sludge is increased, and the oil field oil sludge resourceful treatment effect is increased by 20% or more; with use of the waste tire rubber powder, the use amount is only 5%-20% and is significantly reduced, and the production cost is saved; the reclaimed rubber has relatively short reclaiming reaction time and has high degree of desulfurization, and the reclaimed rubber properties all reach national corresponding reclaimed rubber standards.

Owner:青岛三聚猫环保能源科技有限公司

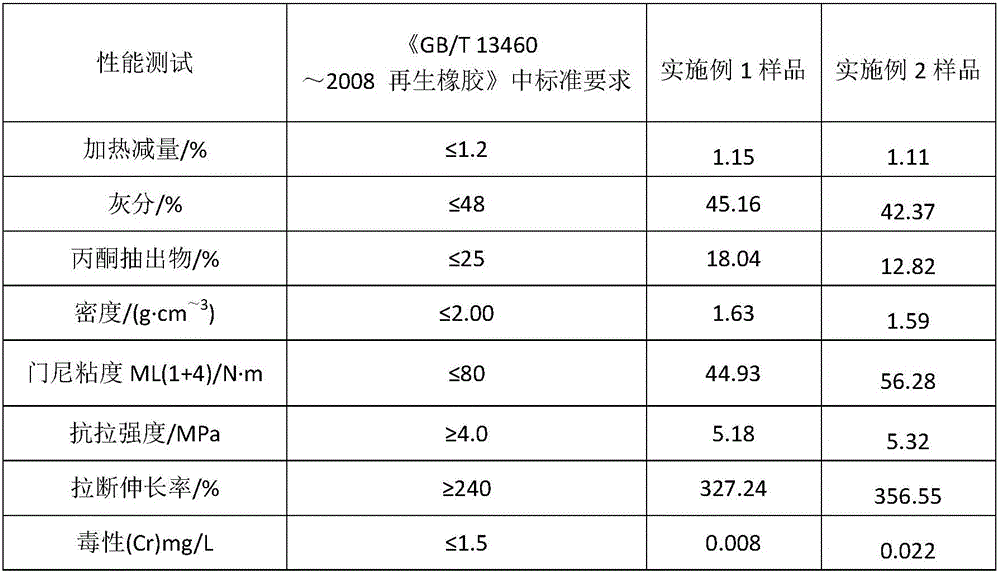

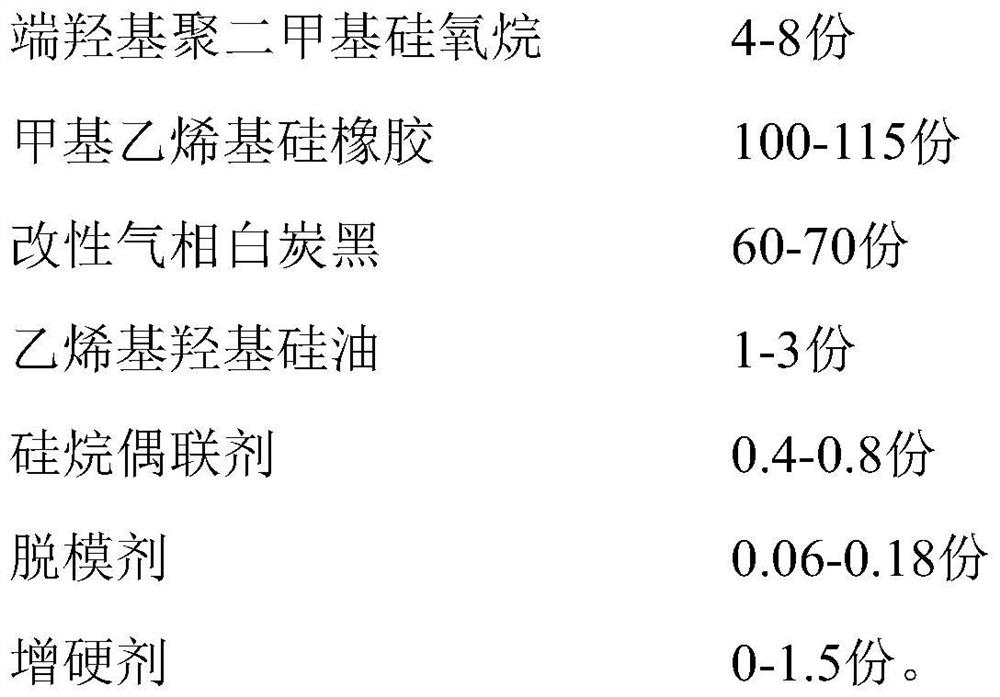

High-hardness air-pressure-resistant silicone rubber, preparation method and use method thereof

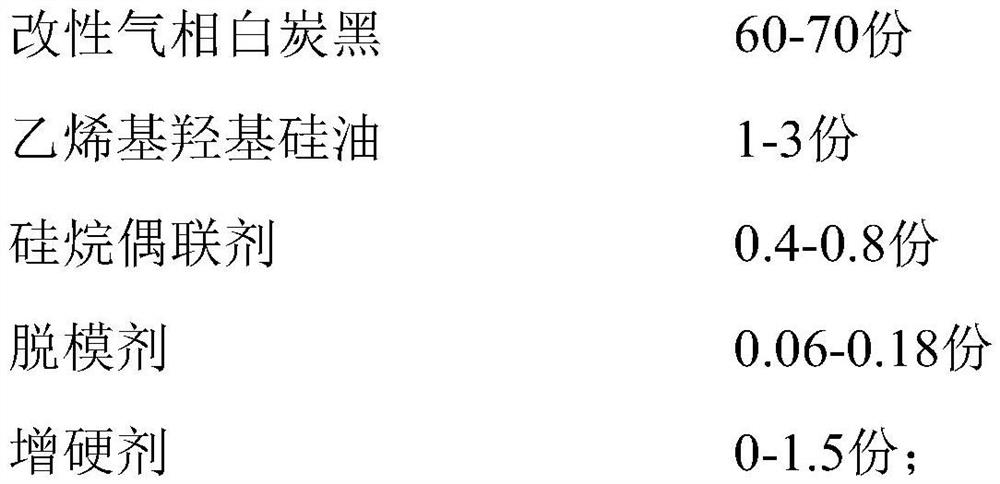

The invention relates to the technical field of silicone rubber, particularly to high-hardness air-pressure-resistant silicone rubber, a preparation method and a use method thereof. The high-hardnessair-pressure-resistant silicone rubber is prepared from the following raw materials in parts by weight: 4-8 parts of hydroxyl-terminated polydimethylsiloxane, 100-115 parts of methyl vinyl silicone rubber, 60-70 parts of modified fumed silica, 1-3 parts of vinyl hydroxyl silicone oil, 0.4-0.8 part of a silane coupling agent, 0.06-0.18 part of a release agent and 0-1.5 parts of a hardening agent. According to the invention, the high-hardness air-pressure-resistant silicone rubber disclosed by the invention has very good hardness and air pressure resistance, has relatively good comprehensive properties such as viscosity, tensile strength and shrinkage rate, and can well meet the requirements of special industrial production on hardness; and the preparation method is simple, convenient to operate and control and high in production efficiency, large-scale industrial production can be achieved, the using method of the high-hardness air-pressure-resistant silicone rubber is convenient to operate and control and stable in quality, and the prepared silicone rubber product is stable in performance.

Owner:东莞市朗晟材料科技有限公司

SBS modified asphalt waterproof coiled material capable of realizing self-adhesion construction and preparation method of SBS modified asphalt waterproof coiled material

PendingCN114635297AGood compatibilitySolve the phenomenon of separationTextiles and paperArticle deliveryPolymer scienceBituminous waterproofing

The invention belongs to the technical field of waterproof coiled materials, and particularly relates to an SBS modified asphalt waterproof coiled material capable of achieving self-adhesion construction and a preparation method thereof.The SBS modified asphalt waterproof coiled material is prepared from 80-100 parts of ethylene-vinyl acetate copolymer, 20-30 parts of halogenated butyl rubber, 15-25 parts of tackifying resin, 3-5 parts of styrene-isoprene-styrene block copolymer and 50-100 parts of polyisobutene. According to the non-asphalt-based self-adhesive material disclosed by the invention, a non-asphalt-based rubber component and an SBS modified asphalt rubber component are embedded together through vulcanization, and the problem of poor compatibility of a non-asphalt-based self-adhesive material and an SBS coating material is mainly solved.

Owner:河南蓝翎环科防水材料有限公司

Preparation method of high-performance rubber

The invention relates to the field of material synthesis, and provides a preparation method of a high-performance rubber product. Zinc oxide and organic zinc are uniformly deposited onto the rubber main reinforcing material by a physical or chemical process to form the zinc-oxide / organic-zinc-coated reinforced composite material. The composite material is directly added in the rubber compounding link; and the zinc oxide implements nano dispersion in the rubber master batch by the aid of the reinforcing material, thereby effectively avoiding the quality problems of gelling, scorching and the like caused by zinc oxide aggregation, and reducing the consumption of the zinc oxide in the rubber product.

Owner:赛福纳米科技(徐州)有限公司

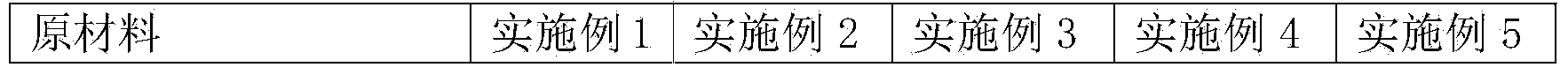

All-steel radial giant engineering tire sidewall filling rubber

The invention discloses an all-steel radial giant engineering tire sidewall filling rubber which is composed of the following components in parts by weight: 100 parts of natural rubber, 10-25 parts of white carbon black, 20-50 parts of hard carbon black, 6-15 parts of softening agent, 2-4 parts of resorcinol, 6-15 parts of zinc oxide, 1-3 parts of stearic acid, 2-7 parts of anti-aging system, 1.3-3.5 parts of vulcanization system, 0.8-1.5 parts of accelerator and 0.1-0.5 part of anti-scorching agent. The sidewall filling rubber prepared according to the formula has the advantages of low heat generation, excellent bending resistance, moderate hardness and moderate stress at definite elongation, and can obtain favorable balance between Mooney viscosity and tire adhesiveness.

Owner:HAOHUA SOUTH CHINAGUILIN RUBBER

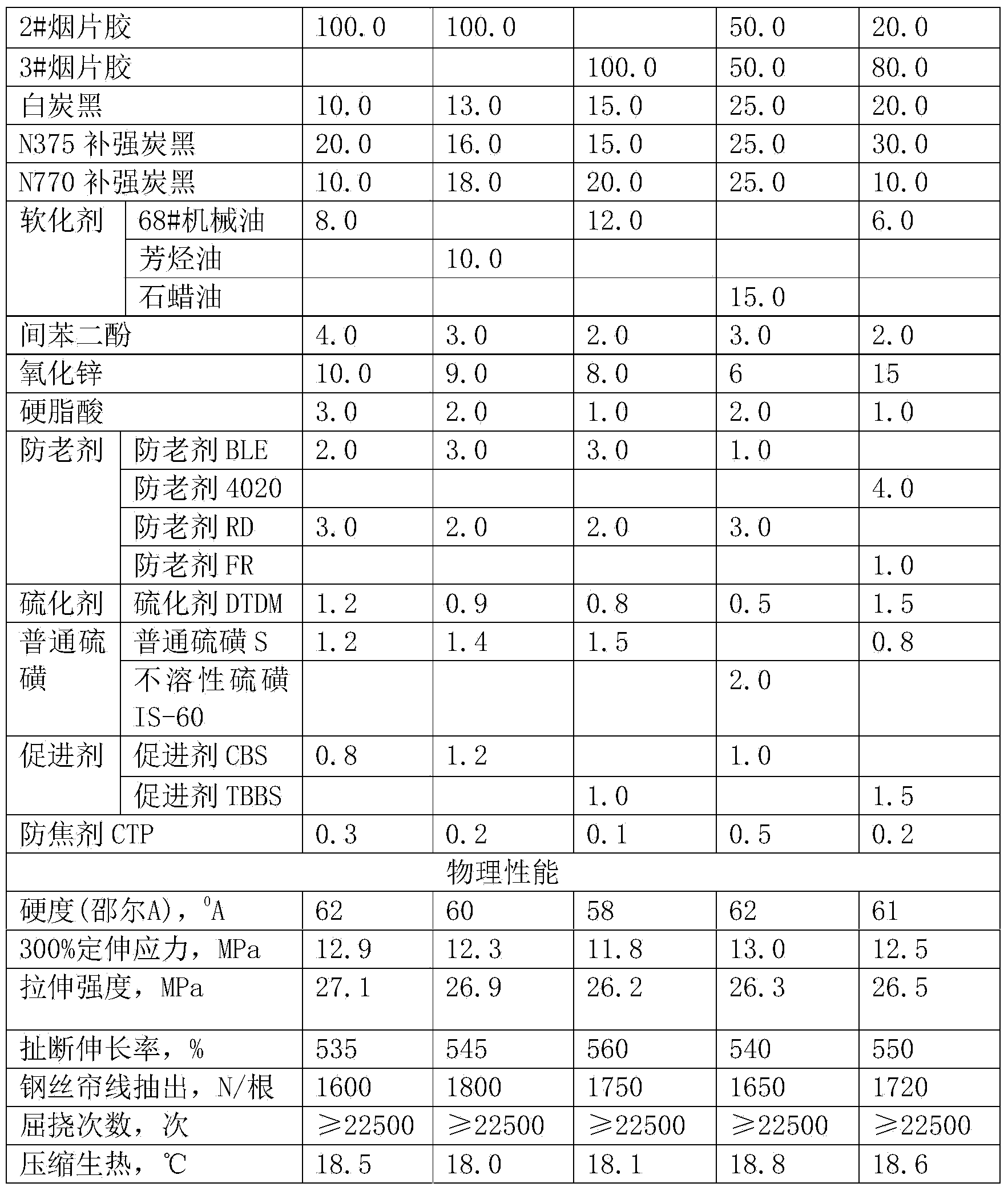

Rubber fixing block composition used for automobile hose limiting

The invention relates to a rubber fixing block composition used for automobile hose limiting. The rubber fixing block consists of the following components in parts by weight: 60-80 parts of butadiene styrene rubber, 80-100 parts of ethylene propylene diene monomer rubber reclaimed rubber, 2-5 parts of zinc oxide, 1-2.0 parts of stearic acid, 2-3 parts of coumarone, 1-2.0 parts of 2,2,4-trimethyl-1,2-dihydroquinoline, 0.2-1 part of N,N-di(beta-naphthyl)ursol, 50-70 parts of carbon black N550, 50-70 parts of high wear-resistant N330, 30-50 parts of light calcium, 40-60 parts of naphthenic oil, 0.2-0.5 part of 1,3-melaniline, 1-2.0 part of 2,2'-disulfbenzothiazole, 0.5-1.0 part of tetrakis(diethyldithiocarbamato-S,S')tellurium and 0.5-1.0 part of sulphur. The rubber fixing block composition has the characteristics of good heat resistance, low temperature resistance, abrasion resistance, weather resistance, ozone resistance, cracking resistance and the like.

Owner:BRILLIANCE AUTO

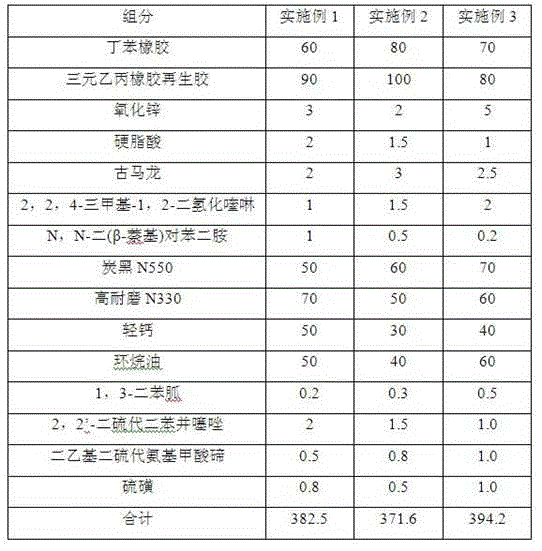

Antistatic and wear-resistant rubber material for rubber covered roller

InactiveCN107337824AImprove wear resistanceImprove antistatic performanceRubber materialPolymer science

The invention discloses a rubber material for wear-resistant and antistatic rubber rollers. The raw materials include, by weight, 50-70 parts of carboxylated nitrile rubber, 30-50 parts of EPDM rubber, and 5-25 parts of naphthenic oil , 15-30 parts of reinforcing agent, 3-6 parts of modified nano-zinc oxide, 6-10 parts of plasticizer, 2-3 parts of vulcanizing agent, 1-3 parts of accelerator, 1-5 parts of auxiliary agent; wherein, The weight percent content of propylene units in the EPDM rubber is 40-50%, the weight percentage content of ethylene units is 45-55%, and the weight percentage content of ethylidene norbornene units is 4-6%. The invention adopts the blending of EPDM rubber obtained by polymerization of ethylene, propylene and ethylidene norbornene with a specific ratio and carboxylated nitrile rubber, which reduces the hardness of EPDM rubber and improves the tensile strength and wear resistance Performance, adding modified nano zinc oxide, improves the wear resistance and antistatic performance of the rubber roller, and at the same time improves the rubber vulcanization activity, shortens the vulcanization time and reduces the production cost.

Owner:薛念念

Rubber vulcanization activator, preparation method and application thereof

The invention provides a rubber vulcanization activator, and a preparation method and application thereof, and relates to the technical field of rubber vulcanization. The rubber vulcanization activator provided by the invention comprises calcium terephthalate and zinc oxide loaded on the surface of the calcium terephthalate; the mass ratio of the zinc oxide to the calcium terephthalate is (1-6): (9-4). According to the rubber vulcanization activator of the invention, the calcium terephthalate can be used as a matrix for loading the zinc oxide, so that the dispersibility of the zinc oxide can be improved; the zinc oxide can be uniformly dispersed in a rubber matrix, and therefore, on the basis of ensuring the vulcanization activity of the zinc oxide, the dosage of the zinc oxide is effectively reduced, production cost is reduced, and meanwhile, the pollution of the zinc oxide to the environment is reduced. The calcium terephthalate is a non-polar material and is used as the matrix for loading the zinc oxide, so that the contact area of the zinc oxide and rubber molecules is increased, and therefore, the compatibility of the zinc oxide and a rubber molecular chain is enhanced, and the tensile strength of vulcanized rubber is improved.

Owner:江西宝弘纳米科技有限公司

Steel roller support used rubber cushion block and preparation method thereof

InactiveCN106009117AImprove vulcanization activityIncrease the amount of sulfurCalcium carbonateButadiene-styrene rubber

The invention discloses a rubber cushion block for steel roll support and a preparation method thereof, belonging to the technical field of steel roll support spare parts. The rubber block for steel roller support of the present invention is made of the following raw materials in parts by mass: styrene-butadiene rubber: 100 parts; carbon black: 90-115 parts; rubber powder: 80-105 parts; calcium carbonate: 35-50 parts Clay: 70-80; Aromatic oil: 40-50 parts; Accelerator D: 1-2 parts; Accelerator DM: 1-1.5 parts; Sulfur 12-20 parts. In the preparation method of the present invention, the rubber cushion blocks for steel roller support are prepared through the steps of master batch rubber mixing→second stage mixing→master batch rubber kneading machine vulcanization→molding vulcanization. The rubber cushion block for steel roll support of the present invention has the advantages of low production cost, high processing efficiency, light volume, convenient use and operation, no damage to the surface of the steel roll, and long service life.

Owner:南京金三力橡塑有限公司

Composite vulcanization activator and rubber capable of not releasing nitrosoamine

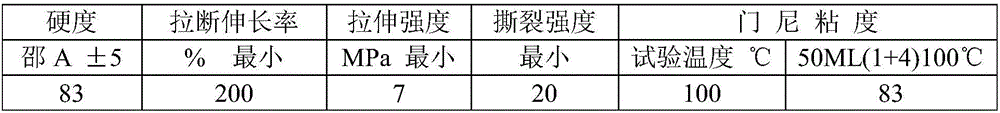

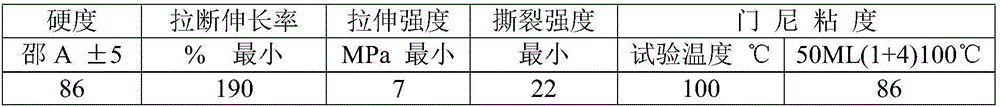

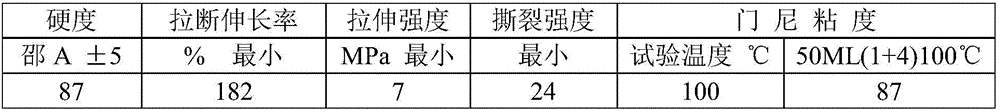

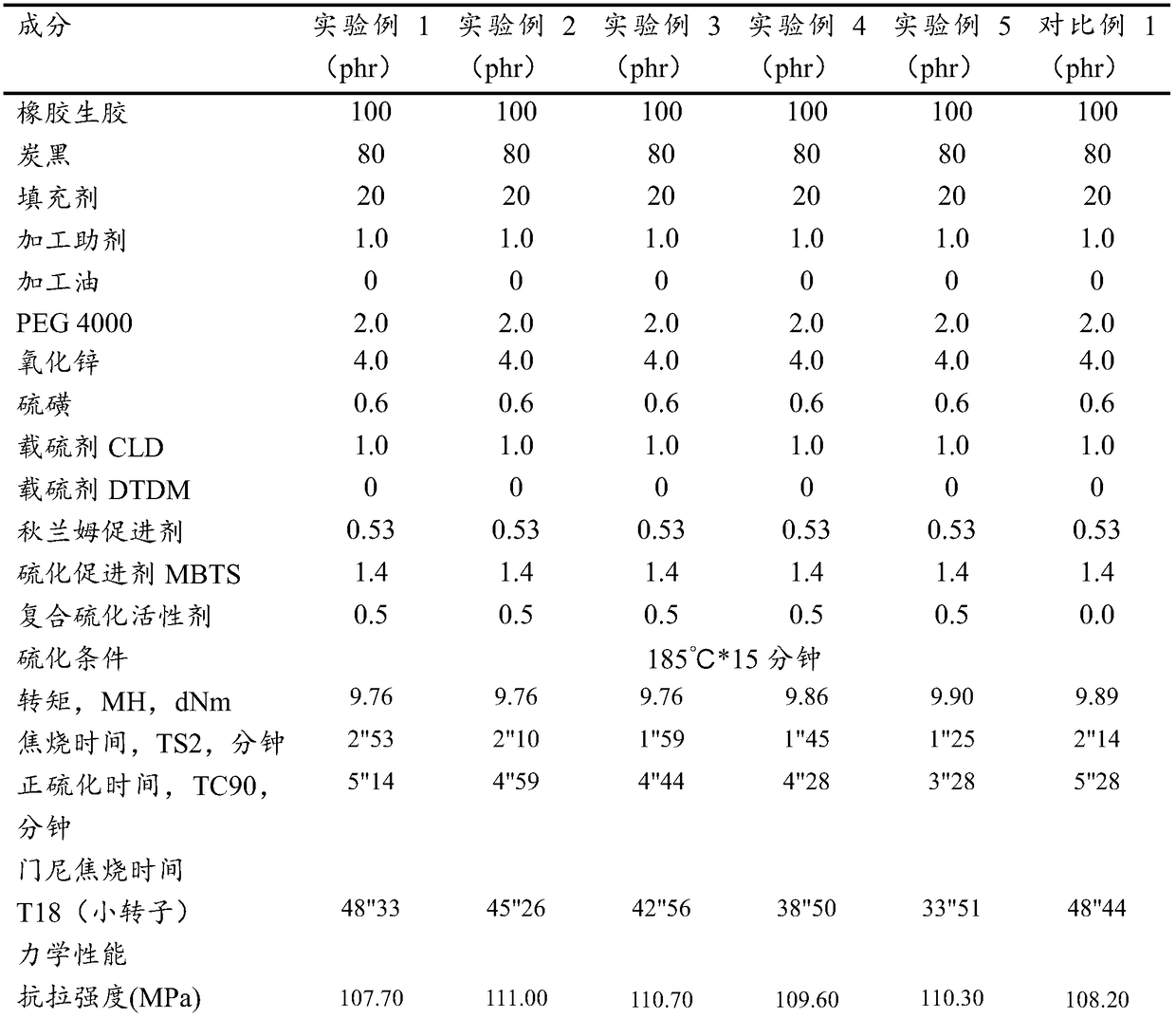

The invention discloses a composite vulcanization activator and rubber capable of not releasing nitrosoamine, and belongs to the technical field of rubber auxiliaries. The composite vulcanization activator is prepared from the components in percentage by mass: 6.0%-10.0% of a rubber carrier, 70.0%-80.0% of urea resin, 7.0%-15.0% of processing oil and 0-5.0% of a processing agent which are mixed evenly and then are blended. The rubber is prepared from the following components: raw rubber, carbon black, a filling agent, a processing agent, processing oil, PEG 4000, zinc oxides, sulfur, a sulfurdonor, a thiuram accelerant, a vulcanizing accelerator MBTS and the composite vulcanization activator. The composite vulcanization activator can improve the vulcanization rate and vulcanization effectand also greatly reduces the dosage of CLD. The rubber prepared through the composite vulcanization activator is short in vulcanization time, good in scorching safety and capable of not releasing nitrosoamine.

Owner:濮阳科茂威新材料有限公司

Method for preparing zinc oxide for sealing ring

InactiveCN109133151AImprove vulcanization activityIncrease vulcanization rateZinc oxides/hydroxidesVulcanizationPolymer science

The invention discloses a method for preparing zinc oxide for a sealing ring. The method comprises the following steps: weighing the following components in parts by weight: mixing polyethylene and aplasticizer and performing plasticizing treatment for 10 to 15 minutes to obtain a mixture A; mixing the common zinc oxide, chitosan, nanometer titanium dioxide and nanometer white carbon black, throwing the mixture into a muffle furnace, sintering for 1 to 2 hours, transferring into a ball mill and grinding a mixture B; mixing the mixture B, the mixture A and a phthalic ester coupling agent, throwing the mixture into a ball mill,and stirring at the speed of 120 to 180 rpm to obtain a material A; and transferring the material A into a calcining furnace and calcining to obtain the needed zinc oxide. The method capable of improving the vulcanization activity of the common zinc oxide is simple to operate, the effect is obvious, and the vulcanization speed of natural rubber can be obviously improved and the use amount of the zinc oxide in a formula can be reduced under the condition of guaranteeing the crosslinking density of vulcanized rubber; in addition, the nanometer white carbon blackis added in the formula, and the obtained zinc oxide has high lubricating property and high wear resistance.

Owner:江苏伊顿航天材料股份有限公司

A kind of start-up vulcanization method of hydrogenation catalyst

ActiveCN105754637BImprove distributionAvoid cokingCatalyst activation/preparationRefining to eliminate hetero atomsForming gasVulcanization

A gaseous starting method for a hydrocracker containing a hydrogenation catalyst with second type active centers is provided. The method utilizes a plurality of hydrogen sulfide containing gases in industrial equipment to pre-protect the catalyst before sulfuration, and a formed gas protective film can completely avoid decomposition of auxiliary agents in the catalyst, thus avoiding problems which are activity loss and increased material consumption in a starting process, saving energy and greatly improving using activity of the catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of pre-dispersed masterbatch carrier and the predispersed masterbatch used therein and its preparation method and application

The invention discloses a pre-dispersed masterbatch particle carrier. The pre-dispersed masterbatch particle carrier comprises the following raw materials in parts by mass: 5-90 parts of rubber, 1-10 parts of stearic acid, 1-10 parts of pentaerythritol aliphatic ester, 2-10 parts of an ethylene vinyl acetate copolymer EVA and / or EVM and 0.1-10 parts of a polar plasticizer. The components are cooperatively used to form a heat softening carrier system with high compatibility and can be mixed with liquid active components, powdery active components and granular active components at the temperature of not more than 55 DEG C, and the active components can achieve excellent dispersion and distribution effects. The problems of sublimation, volatilization, reaction and failure of the active components caused by over-high pre-dispersion mixing temperature are avoided; the active components are uniformly dispersed in masterbatch particles in the absence of aggregates, so that the active components can be uniformly dispersed in a rubber system in the production process of followed rubber products to form high-performance rubber products.

Owner:RACHEM CHINA CO LTD +1

A method for improving zinc oxide vulcanization activity

The invention relates to a method for improving zinc oxide sulfuration activity and belongs to the technical field of natural rubber processing. The method comprises adding 0.5-10 parts of rare earth oxide into 100 parts of common zinc oxide and carrying out ball milling and high temperature sintering rare earth doping. According to inherent characteristics of rare earth, zinc oxide particle conformation structure and ion surface chemical properties are changed, sulfuration activity is improved, a use ratio of zinc oxide in the rubber formula is reduced from 5: 100 to 2: 100, sulfuration time is shortened, natural vulcanized rubber crosslinking density and mechanical properties are improved and reasonable utilization and saving of a zinc ore resource are realized.

Owner:AGRI PRODS PROCESSING RES INST CHINESE ACAD OF TROPICAL AGRI SCI

A kind of thermally conductive vulcanization bladder and preparation method thereof

ActiveCN112724544BGood dispersionImprove mechanical propertiesHeat-exchange elementsFiberPolymer science

The invention relates to the technical field of vulcanization bladders, in particular to a thermally conductive vulcanization bladder and a preparation method thereof, comprising the following steps: Step S100. According to rubber main materials: carbon black: thermally conductive filler: fiber filler: processing aid=100: (40~ 50): (10-20): (1-5): (3-6.5) mass ratios to prepare a first-stage mixed rubber; step S200. Add coordination to the first-stage mixed rubber in the step S200 The auxiliary agent and the vulcanization auxiliary are mixed to prepare the second-stage mixed rubber; Step S300. The second-stage mixed rubber in the step S200 is filtered and pressed into tablets and then matured; Step S400. After the curing in the step S300 The second-stage rubber compound is injected and vulcanized; step S400. Obtain the thermally conductive vulcanization bladder. The thermally conductive vulcanization bladder provided by the invention has high thermal conductivity, good mechanical properties, fast vulcanization speed and good comprehensive use performance.

Owner:YONGYI RUBBER CO LTD

Sizing material for spiral spring supporting seat, preparation method of sizing material and automobile spiral spring supporting seat

The invention provides a sizing material for a spiral spring supporting seat, a preparation method of the sizing material and an automobile spiral spring supporting seat, and the sizing material for the spiral spring supporting seat is prepared from the following components in parts by weight: 60-80 parts of star branched butyl rubber, 20-40 parts of cis-1, 4-polybutadiene rubber, 3-5 parts of zinc oxide, 1-2 parts of stearic acid, 3-6 parts of Sumilink100 and 5-15 parts of thermal isoprene rubber. The composition is prepared from the following components in parts by weight: 20 to 30 parts of carbon black N330, 10 to 15 parts of white carbon black 7000 GR, 1 to 1.5 parts of POLYVEST, 10 to 20 parts of paraffin oil, 5 to 8 parts of an anti-aging agent, 0.75 to 0.85 part of sulfur and 3.70 to 4.35 parts of an accelerant. The rubber material for the spiral spring supporting seat has the characteristics of high damping, high durability, high wear resistance, weather resistance, low temperature resistance and the like, so that the comprehensive performance of the spiral spring supporting seat can be improved.

Owner:NUOBO RUBBER PRODION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com