High-hardness air-pressure-resistant silicone rubber, preparation method and use method thereof

A high-hardness, silicone rubber technology, applied in the field of silicone rubber, can solve the problems of no practical value, poor air pressure resistance, low strength of silicone rubber, etc., and achieve the effect of improving hardness, good hardness and air pressure resistance, and improving mechanical strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

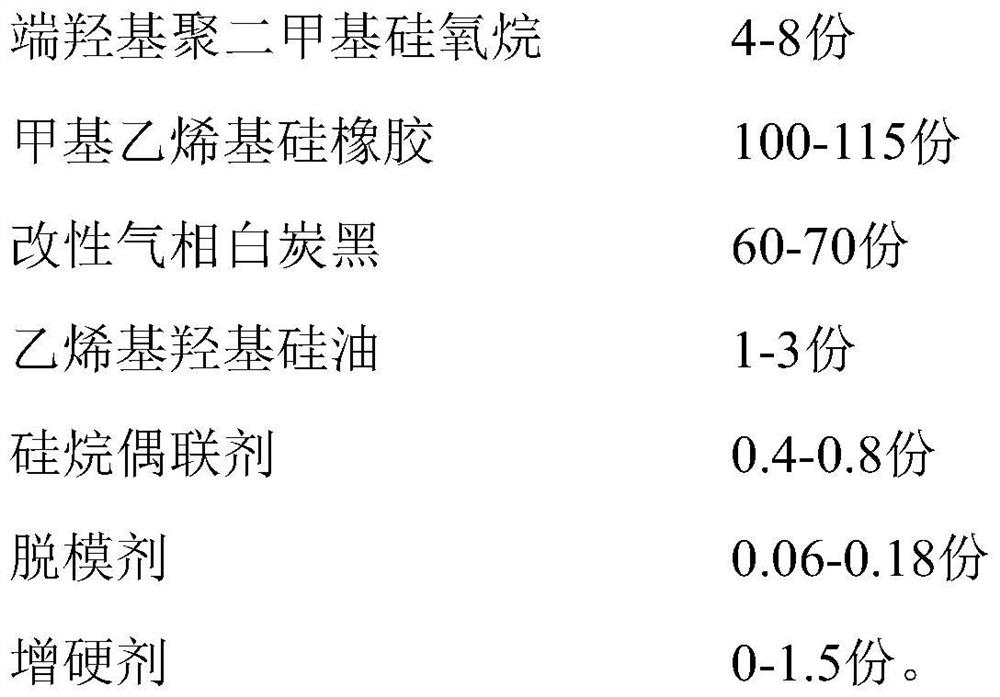

[0039] A high-hardness air pressure-resistant silicone rubber, comprising the following raw materials in parts by weight:

[0040]

[0041] Each part of the methyl vinyl silicone rubber is a mixture of methyl vinyl silicone rubber A, methyl vinyl silicone rubber B and methyl vinyl silicone rubber C in a weight ratio of 3.0:4.5:0.8. The vinyl content of methyl vinyl silicone rubber A is 0.06%, and the molecular weight is 60,000; the vinyl content of the methyl vinyl silicone rubber B is 0.21%, and the molecular weight is 650,000; the methyl vinyl silicone rubber C has a vinyl content of 4.8% and a molecular weight of 500,000.

[0042] Each part of the modified fumed silica includes the raw materials of the following parts by weight:

[0043] Dimethyldiethoxysilane 1 part

[0044] Fumed silica 58 parts

[0045] 0.4 parts of deionized water;

[0046] Each part of the fumed silica is 380 fumed silica.

[0047] Described modified fumed silica is obtained by the following me...

Embodiment 2

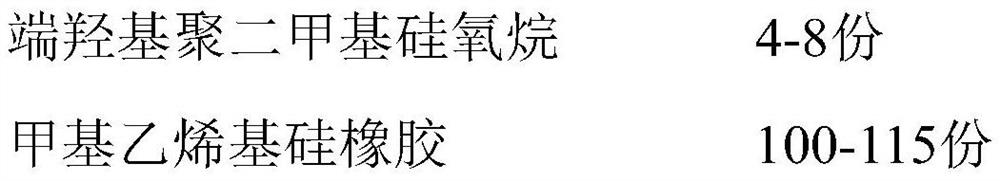

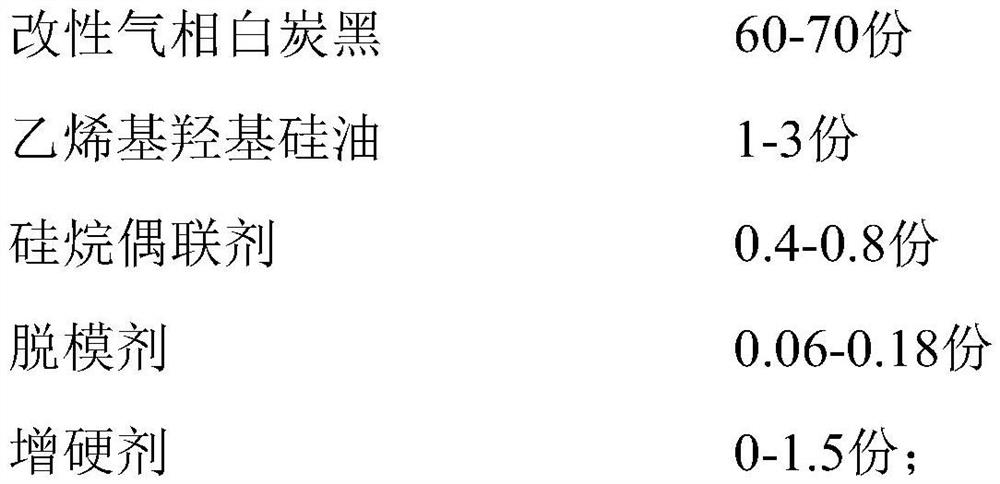

[0061] A high-hardness air pressure-resistant silicone rubber, comprising the following raw materials in parts by weight:

[0062]

[0063]

[0064] Each part of the methyl vinyl silicone rubber is a mixture of methyl vinyl silicone rubber A, methyl vinyl silicone rubber B and methyl vinyl silicone rubber C in a weight ratio of 3.3:4.9:0.9. The vinyl content of the methyl vinyl silicone rubber A is 0.07%, and the molecular weight is 680,000; the vinyl content of the methyl vinyl silicone rubber B is 0.215%, and the molecular weight is 680,000; the methyl vinyl silicone rubber C has a vinyl content of 4.9% and a molecular weight of 530,000.

[0065] Each part of the modified fumed silica includes the raw materials of the following parts by weight:

[0066] Dimethyldiethoxysilane 2 parts

[0067] Fumed silica 59 parts

[0068] 0.5 parts of deionized water;

[0069] Each part of the fumed silica is 300 fumed silica.

[0070] Described modified fumed silica is obtained ...

Embodiment 3

[0084] A high-hardness air pressure-resistant silicone rubber, comprising the following raw materials in parts by weight:

[0085]

[0086] Each part of the methyl vinyl silicone rubber is a mixture of methyl vinyl silicone rubber A, methyl vinyl silicone rubber B and methyl vinyl silicone rubber C in a weight ratio of 3.7:5.3:1.0, the said The vinyl content of methyl vinyl silicone rubber A is 0.08%, and the molecular weight is 700,000; the vinyl content of the methyl vinyl silicone rubber B is 0.22%, and the molecular weight is 700,000; the methyl vinyl silicone rubber C has a vinyl content of 5.0% and a molecular weight of 550,000.

[0087] Each part of the modified fumed silica includes the raw materials of the following parts by weight:

[0088] Dimethyldiethoxysilane 3 parts

[0089] Fumed silica 61 parts

[0090] 0.6 parts of deionized water;

[0091] The fumed silica per part is 3200 fumed silica.

[0092] Described modified fumed silica is obtained by the foll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com