Rubber composition for upper support of automobile shock absorber

A rubber composition and automobile shock absorber technology, applied in the field of rubber, can solve problems such as waste of rubber and metal materials, abnormal noise of the shock absorber, and gap between rubber and baffle, so as to improve heat resistance and dynamic performance Effect of improving fatigue life and tear strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

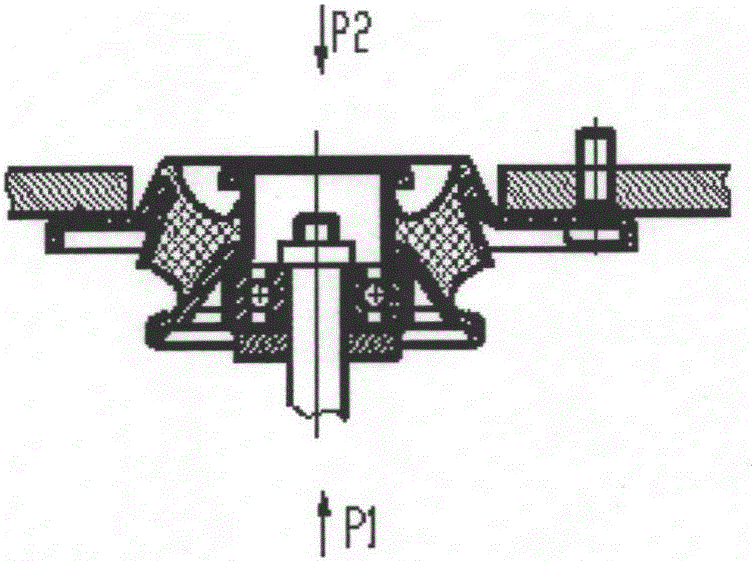

Image

Examples

Embodiment 1

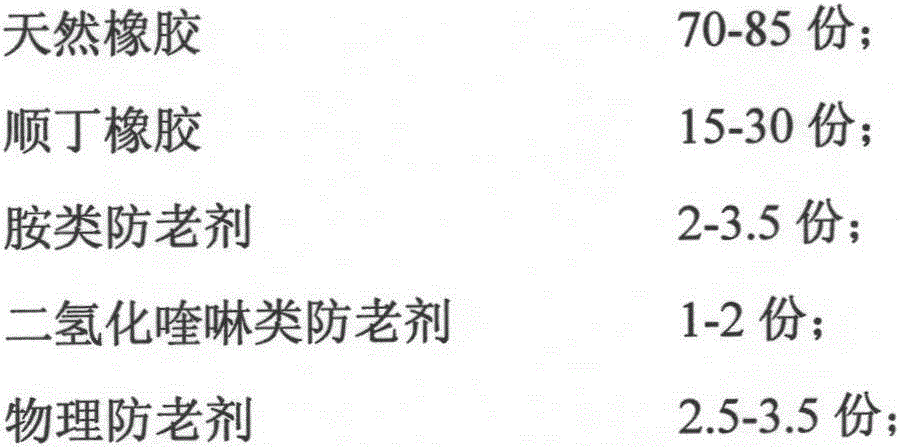

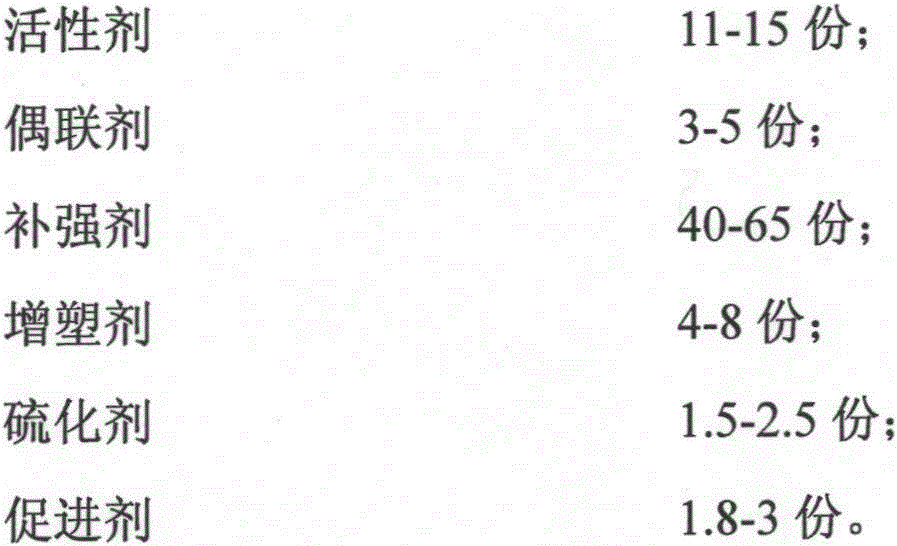

[0026] A support rubber composition on an automobile shock absorber, comprising the following components in parts by weight:

[0027] Table 1

[0028] raw material parts by weight CV60 85 copies BR9000 15 copies WB900 5 copies SA 1 copy Nano ZNO 5 copies Antiaging agent KY405 1 copy Antiaging agent 3100 1 copy Antiaging agent RD 2 copies mixed wax 3.5 servings R50S 3 copies N-550 carbon black 20 copies N-660 carbon black 20 copies Paraffin oil 25110 4 parts OT-90 2.2 parts Accelerator DTDC 1.3 parts accelerator DM 0.7 parts

Embodiment 2

[0030] A support rubber composition on an automobile shock absorber, comprising the following components in parts by weight:

[0031] Table 2

[0032]

[0033]

Embodiment 3

[0035] A support rubber composition on an automobile shock absorber, comprising the following components in parts by weight:

[0036] table 3

[0037]

[0038]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com