A kind of start-up vulcanization method of hydrogenation catalyst

A hydrogenation catalyst and catalyst technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of uneven sulfuration degree of catalyst, damage of catalyst activity, increase of material consumption, etc., to avoid Emissions and environmental pollution, increase the time of intensified vulcanization, and reduce the consumption of reagents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

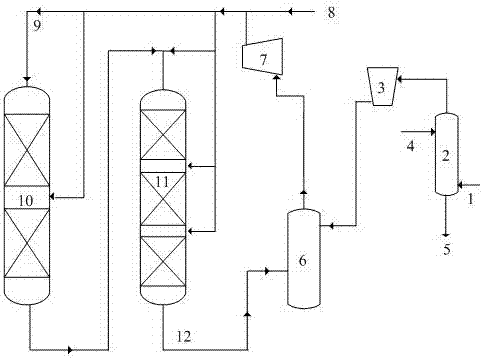

[0040] Such as figure 1 As shown, an embodiment of the hydrogenation catalyst start-up method of the present invention is as follows:

[0041] Raise the inlet temperature of the refining reactor 10 to 120-140°C. Sulfur-containing exhaust gas 1 passes through light hydrocarbon absorption tower 2 for light hydrocarbon recovery, absorbing liquid heavy naphtha 4 is injected into the top of the tower, mixed naphtha 5 is discharged from the bottom of the tower to analyze and stabilize the system, and the absorbed gas is injected into the In high pressure separator 6. Then the obtained high-fraction gas is mixed with the new hydrogen 8 through the circulating hydrogen desulfurization tower 7 to obtain the mixed hydrogen 9, which enters the refining reactor 10 and the cracking reactor 11 in turn, and the cracking reactor effluent 12 enters the high-pressure separator 6, so that the gas circulation process is carried out After the hydrogen sulfide concentration is greater than or equ...

Embodiment 1

[0043] The properties of the catalysts used in Examples 1, 2 and Comparative Examples 1, 2 are listed in Table 1. Among them, Example 1 and Example 2 are the start-up methods of the present invention, Comparative Example 1 is a conventional wet start-up process, and Comparative Example 2 is a conventional gas phase (dry method) start-up process, wherein hydrogen sulfide gas is not used for protection.

[0044] Table 1 The main physicochemical properties of the catalysts.

[0045]

[0046] Example 1

[0047] After the hydrogen airtightness of the hydrocracking unit is qualified, adjust the inlet pressure of the reaction system to 14.0MPa, start to raise the temperature at 20°C / h, and when it reaches 140°C, pass the mixed exhaust gas into the light hydrocarbon absorption system for absorption, and then start the compression The machine injects the gas after absorbing light hydrocarbons into the high fraction, and then enters the reaction system through the compressor. After...

Embodiment 2

[0049] After the hydrogen airtightness of the hydrocracking unit is qualified, adjust the inlet pressure of the reaction system to 14.0MPa, start to raise the temperature at 20°C / h, and when it reaches 140°C, collect the exhaust gas of the hydrogenation unit containing hydrogen sulfide gas, and then start The compressor injects the collected exhaust gas into the high fraction, and then enters the reaction system through the compressor. After the concentration of hydrogen sulfide at the outlet of the hydrocracking reactor reaches 0.01v%, it is considered that hydrogen sulfide has played a protective role. Then cut off the injection channel of the sulfur-containing gas, adjust the reactor inlet temperature to 180°C, start injecting the vulcanizing agent DMDS, and adjust the catalyst bed temperature to 230°C after the hydrogen sulfide concentration at the outlet of the hydrocracking reactor reaches 0.1v%. Constant temperature for 8 hours, this process maintains the concentration ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com