Reclaimed rubber prepared from oil field oil sludge and production method thereof

A technology of reclaimed rubber and oil sludge, which is applied in the field of reclaimed rubber, can solve the problems of small amount of oilfield sludge used, high production cost of reclaimed rubber, and large amount of miscellaneous rubber powder, so as to reduce solid waste discharge, improve the quality of reclaimed rubber, and reduce consumption. The effect of dosage increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

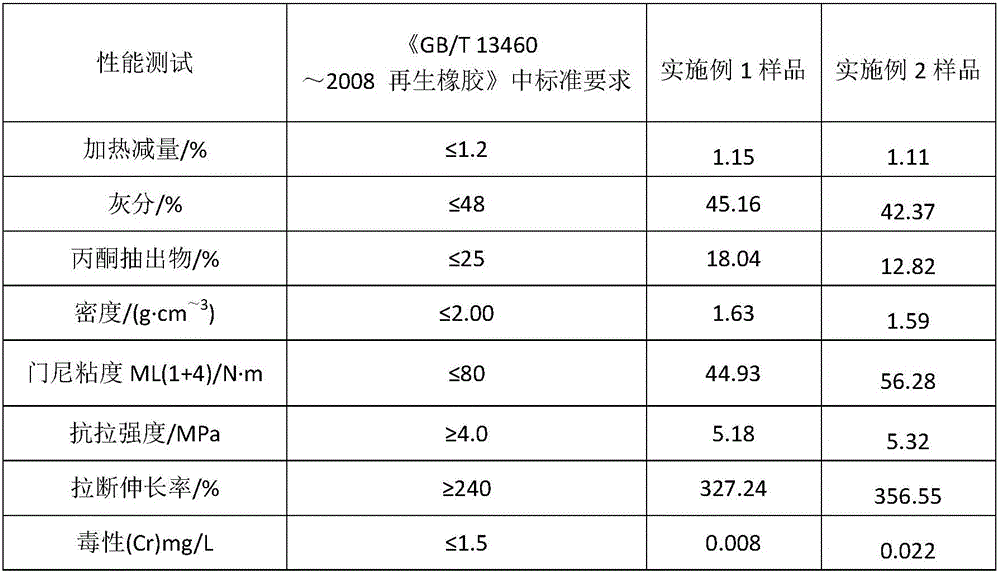

Embodiment 1

[0044] For the reclaimed rubber prepared from oilfield oil sludge provided in this example, the mass percent composition of the raw material formula is:

[0045] Oily sludge: 63.1%;

[0046] Waste tire rubber powder: 15.1%;

[0047] Clay: 21.1%;

[0048] Activator 420: 0.2%;

[0050] Alkylphenol disulfides: 0.2%.

[0051] The production method of the reclaimed rubber prepared from the oilfield oil sludge comprises the steps of:

[0052] S1: Oilfield sludge pretreatment

[0053] Remove the gravel impurities in oilfield oil sludge to obtain oily sludge;

[0054] S2: Preparation of reclaimed rubber by reaction

[0055] The reaction kettle is preheated in advance to 220°C, and the raw material oily sludge, waste tire rubber powder, and clay are first added to the reaction kettle, and mixed evenly, and then the activator 420, ethylene tar, and alkylphenol disulfide are put into the reaction kettle After mixing evenly, close the reactor, and react ...

Embodiment 2

[0059] For the reclaimed rubber prepared from oilfield oil sludge provided in this example, the mass percent composition of the raw material formula is:

[0060] Oily sludge: 57.6%;

[0061] Waste tire rubber powder: 8.5%;

[0062] Clay: 33.5%;

[0063] Activator 420: 0.12%;

[0064] Ethylene tar: 0.17%;

[0065] Alkylphenol disulfides: 0.11%.

[0066] The production method of the reclaimed rubber prepared from the oilfield oil sludge comprises the steps of:

[0067] S1: Oilfield sludge pretreatment

[0068] Remove the gravel impurities in oilfield oil sludge to obtain oily sludge;

[0069] S2: Preparation of reclaimed rubber by reaction

[0070] The reaction kettle is preheated in advance to 220°C, and the raw material oily sludge, waste tire rubber powder, and clay are first added to the reaction kettle, and mixed evenly, and then the activator 420, ethylene tar, and alkylphenol disulfide are put into the reaction kettle After mixing evenly, close the reactor, and re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com