Steel roller support used rubber cushion block and preparation method thereof

A technology of rubber pads and steel rollers, applied in the field of steel roller support spare parts, can solve the problems of low processing efficiency of the pads, poor operability, low material hardness, etc., to achieve high vulcanization activity, improve service life and ensure physical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

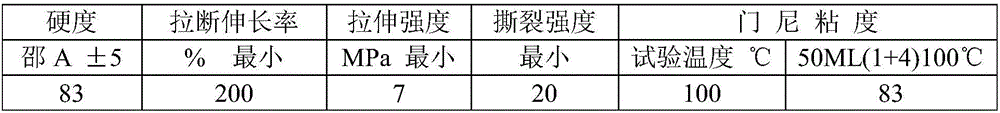

[0039] In this example, the rubber pads used for steel roller support, the mass parts of each material are as shown in Table 1:

[0040] Table 1

[0041] Raw material name

parts by mass

SBR

100

High wear-resistant carbon black

65

Universal carbon black

45

Rubber powder for elastic materials

85

40

Clay

75

Aromatic oil

45

Accelerator D

1.8

accelerator DM

1.5

12

[0042] Wherein, the elastic material rubber powder is a mixture including natural rubber powder, styrene-butadiene rubber powder, nitrile rubber powder, and ethylene-propylene rubber powder, and the mesh number is 50 mesh;

[0043] The preparation method of the steel roller supporting rubber block of the present embodiment is as follows:

[0044] A. Masterbatch mixing

[0045] Put styrene-butadiene rubber raw rubber and elastic material rubber powder in a high-temperat...

Embodiment 2

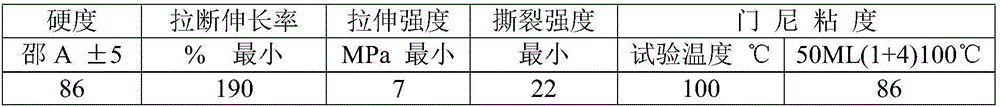

[0056] The steel roller supporting rubber block of the present embodiment, the mass parts of each material are as shown in table 3:

[0057] table 3

[0058] Raw material name

parts by mass

SBR

100

60

Universal carbon black

40

Rubber powder for elastic materials

80

40

Clay

70

Aromatic oil

45

Accelerator D

2

accelerator DM

1.2

15

[0059] Wherein, the elastic material rubber powder is a mixture including styrene-butadiene rubber powder, nitrile rubber powder, and ethylene-propylene rubber powder, and the mesh number is 70 mesh;

[0060] The preparation method of the steel roller supporting rubber block of the present embodiment is as follows:

[0061] A. Master batch mixing

[0062] Put styrene-butadiene rubber raw rubber and elastic material rubber powder in a high-temperature internal mixer for 50 second...

Embodiment 3

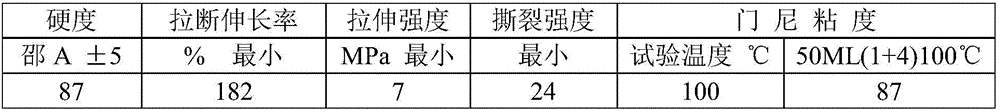

[0072] The steel roller supporting rubber block of the present embodiment, the mass parts of each material are as shown in table 4:

[0073] Raw material name

parts by mass

SBR

100

55

Universal carbon black

40

Rubber powder for elastic materials

95

50

Clay

70

Aromatic oil

45

Accelerator D

1.5

accelerator DM

1.5

20

[0074] Among them, the elastic material rubber powder is a mixture of styrene-butadiene rubber powder, nitrile rubber powder, and ethylene-propylene rubber powder, and the mesh number is 90 mesh;

[0075] The preparation method of the steel roller supporting rubber block of the present embodiment is as follows:

[0076] A. Master batch mixing

[0077] Put styrene-butadiene rubber raw rubber and elastic material rubber powder in a high-temperature internal mixer for 65 seconds at a temperature o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com