A kind of thermally conductive vulcanization bladder and preparation method thereof

A technology of vulcanization bladders and heat-conducting fillers, applied in chemical instruments and methods, heat exchange materials, etc., can solve problems affecting the service life of vulcanization bladders, achieve good comprehensive performance, high thermal conductivity, and improve dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

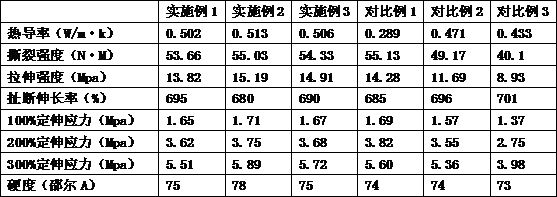

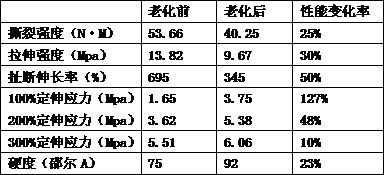

Examples

preparation example Construction

[0053] An embodiment of the present invention provides a preparation method of a thermally conductive vulcanization bladder, comprising the following steps:

[0054] Step S100. According to the mass ratio of rubber main material: carbon black: thermal conductive filler: fiber filler: processing aid=100: (40-50): (10-20): (1-5): (3-6.5) A section of mixed rubber is prepared by refining;

[0055] Step S200. Add a coordination aid and a vulcanization aid to the first-stage mixed rubber in the step S100 and knead to prepare a second-stage mixed rubber;

[0056] Step S300. curing the second-stage rubber compound in the step S200 after filtering and tableting;

[0057] Step S400. injecting and vulcanizing the second-stage rubber compound after curing in the step S300;

[0058] Step S500. Obtain the thermally conductive vulcanization bladder;

[0059] The coordination aid described in the step S200 is at least one of zinc stearate and zinc acrylate;

[0060] In the step S200, the...

Embodiment 1

[0094] The present embodiment provides a preparation method of a thermally conductive vulcanization bladder, comprising the following steps:

[0095] Step S1. According to the mass ratio of phenol: lignin: hydrogen bromide solution = 100:10:2, mix phenol, lignin and hydrogen bromide solution with a mass fraction of 45%, and react in microwave at 80~120℃ for 1~4h , after the reaction is completed, add water to dilute and adjust pH value=2, and obtain demethyl lignin after centrifugation, washing and drying;

[0096] Step S2. Mix the demethylated lignin of Step S1 with bromobutyl rubber at a mass ratio of 1:100, and knead at 70-110° C. for 5-20 minutes to obtain modified bromobutyl rubber;

[0097] Step S3. In the modified bromobutyl rubber of step S2, add butyl rubber in a mass ratio of 10:90, and mix at 130~150°C to obtain the main rubber material;

[0098] Step S4. Mix acetylene carbon black and carbon black N330 at a mass ratio of acetylene carbon black:carbon black N330=2:...

Embodiment 2

[0110] The present embodiment provides a preparation method of a thermally conductive vulcanized bladder, and its implementation conditions and steps are the same as those in Example 1, but the formula is adjusted as follows:

[0111] In step S1, mix according to the mass ratio of phenol: lignin: hydrogen bromide solution=100: 50: 10;

[0112] In step S2, demethyl lignin is mixed with bromobutyl rubber in a mass ratio of 4:100;

[0113] In step S3, the modified bromobutyl rubber is added to the butyl rubber in a mass ratio of 50:50;

[0114] In step S5, the boron-nitrogen polymer is added in the sodium hydroxide solution with a mass fraction of 20% at a mass ratio of 100:5;

[0115] In step S6, the silane coupling agent is added to the ethanol solution with a mass fraction greater than 95% in a mass ratio of 100:0.15, and the boron-nitrogen polymer is added to the mixed solution in a mass ratio of 100:10 for one treatment;

[0116] In step S7, the secondary treatment boron n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com