Composite vulcanization activator and rubber capable of not releasing nitrosoamine

A vulcanization activator and nitrosamine technology, which is applied in the field of rubber additives, can solve the problems of limited use of CLD, poor vulcanization effect, and long vulcanization time, and achieve the goal of improving physical and mechanical properties, vulcanization effect, and physical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

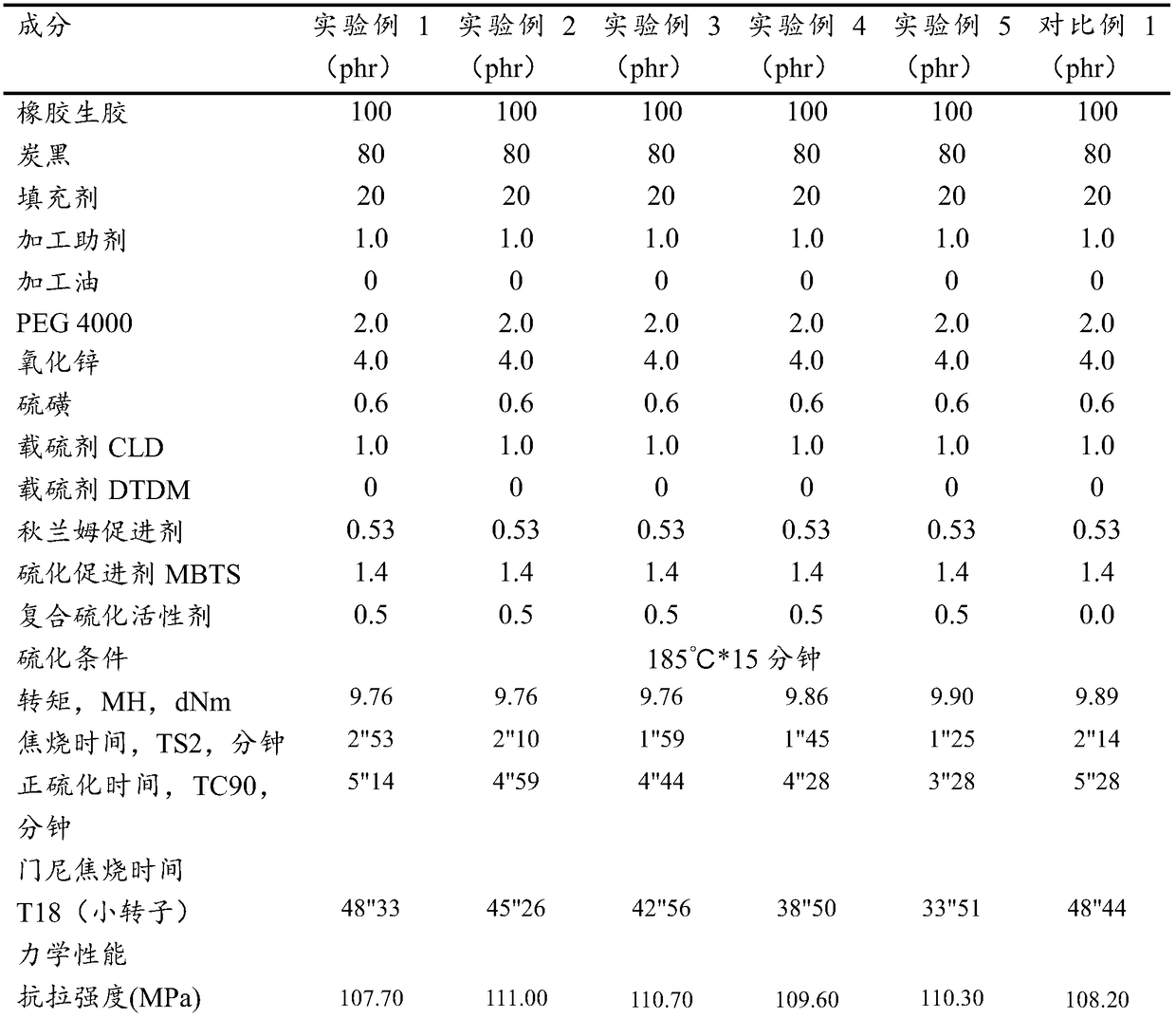

Examples

Embodiment 1

[0028] A compound vulcanization activator comprises the following components: 9.0% of rubber carrier, 75.0% of urea grease, 13.5% of processing oil and 2.5% of processing aid. In the above formula, the rubber carrier is EPDM rubber, the processing oil is a lipid rubber plasticizer, and the processing aid is aliphatic amine. The preparation method is as follows: the rubber carrier, processing aid, processing oil, and urea grease are industrially mixed, filtered, and granulated according to the above ratio to obtain a composite vulcanization active agent. The industrial mixing refers to general rubber mixing process, including but not limited to internal mixing process or open mixing process.

[0029] A kind of rubber without nitrosamine release, including the following components: raw rubber 100phr, carbon black 80phr, filler 20phr, processing aid 1.0phr, PEG 4000 2.0phr, zinc oxide 4.0phr, sulfur 2.5phr, autumn blue Mu accelerator 0.67phr, vulcanization accelerator MBTS1.25ph...

Embodiment 2

[0031] A compound vulcanization activator comprises the following components: 10.0% of rubber carrier, 70.0% of urea grease, 15.0% of processing oil and 5% of processing aid. In the above formula, the rubber carrier is binary ethylene-propylene rubber, the processing oil is aromatic rubber plasticizer, and the processing aid is fatty acid soap. The preparation method is as follows: the rubber carrier, processing aid, processing oil, and urea grease are industrially mixed, filtered, and granulated according to the above ratio to obtain a composite vulcanization active agent. The industrial mixing refers to general rubber mixing process, including but not limited to internal mixing process or open mixing process.

[0032] A kind of rubber without nitrosamine release, including the following components: raw rubber 100phr, carbon black 80phr, filler 20phr, processing aid 1.0phr, PEG 4000 2.0phr, zinc oxide 4.0phr, sulfur 0.6phr, sulfur loaded agent 1.0phr, thiuram accelerator 0.5...

Embodiment 3

[0034] A compound vulcanization activator comprises the following components: 6.0% of rubber carrier, 80.0% of urea grease, 11.0% of processing oil, and 3% of processing aid. In the above formula, the rubber carrier is EPDM rubber, the processing oil is aromatic rubber plasticizer, and the processing aid is vegetable oil. The preparation method is as follows: the rubber carrier, processing aid, processing oil, and urea grease are industrially mixed, filtered, and granulated according to the above ratio to obtain a composite vulcanization active agent. The industrial mixing refers to general rubber mixing process, including but not limited to internal mixing process or open mixing process.

[0035] A kind of rubber without nitrosamine release, including the following components: raw rubber 100phr, carbon black 60phr, filler 15phr, processing aid 2.0phr, processing oil 5.0phr, PEG 4000 1.0phr, zinc oxide 3.0phr, sulfur 1.0phr, sulfur carrier 2.0phr, thiuram accelerator 1.0phr, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com