Rubber fixing block composition used for automobile hose limiting

A fixed block and composition technology, which is applied in the field of automobile manufacturing, can solve problems such as clamp installation position is not fixed or not in the designated area, connection parts or system leakage, leakage, etc., to achieve excellent heat resistance and low temperature performance , good elongation at break and abrasion resistance, high tensile strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

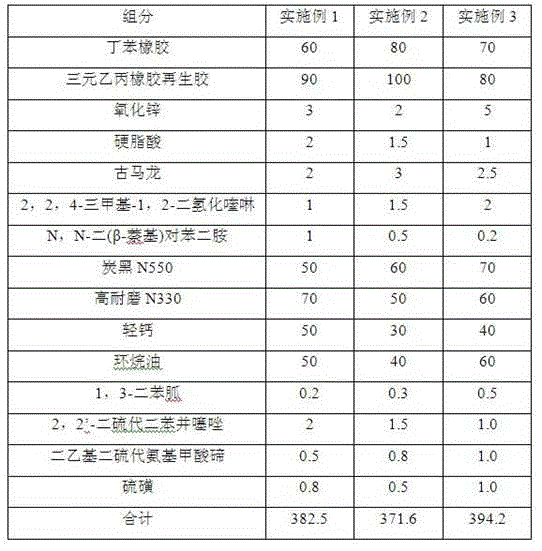

[0024] The content of the present invention will be described in detail below through specific examples. Following is the consumption of each component in embodiment 1~3

[0025] Unit:kg

[0026]

[0027] According to the raw material in the formula listed in the embodiment, the film is made into a film for testing and detection, and the performance comparison of each embodiment is as follows:

[0028]

[0029] From the data in the above table, it can be concluded that the rubber fixing block composition used for the limit of automobile hoses has better original performance, better resistance to hot air aging, excellent low-temperature brittleness, and excellent cooling resistance, which can meet the requirements of different conditions in winter. It is used in the low temperature environment of the region, and the performance of wear resistance and flex crack resistance is also very good, which improves the service life of the product. The rubber fixing block composit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com