Patents

Literature

34results about How to "Meet the weather resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Weather-resistant coating and solar back plate using same

ActiveCN102315285AImprove adhesionMeet the weather resistanceSynthetic resin layered productsPhotovoltaic energy generationWeather resistanceEngineering

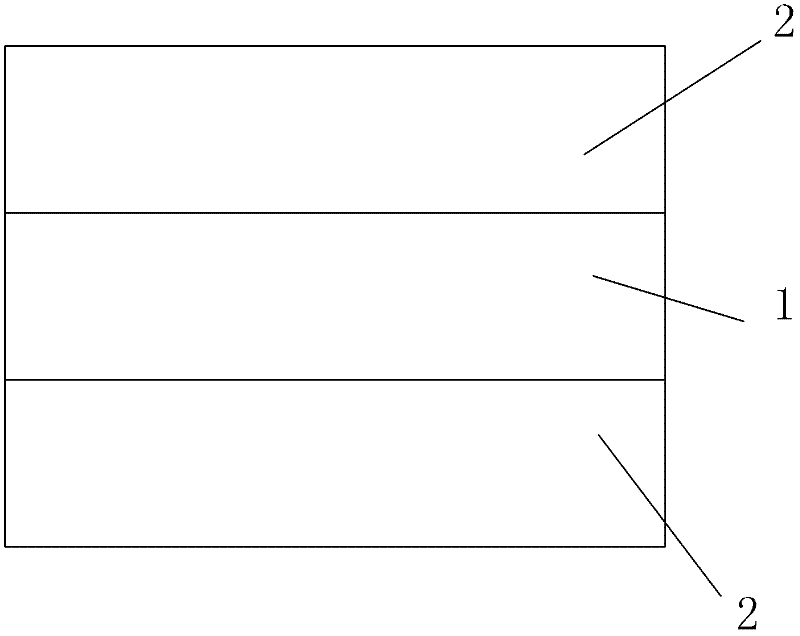

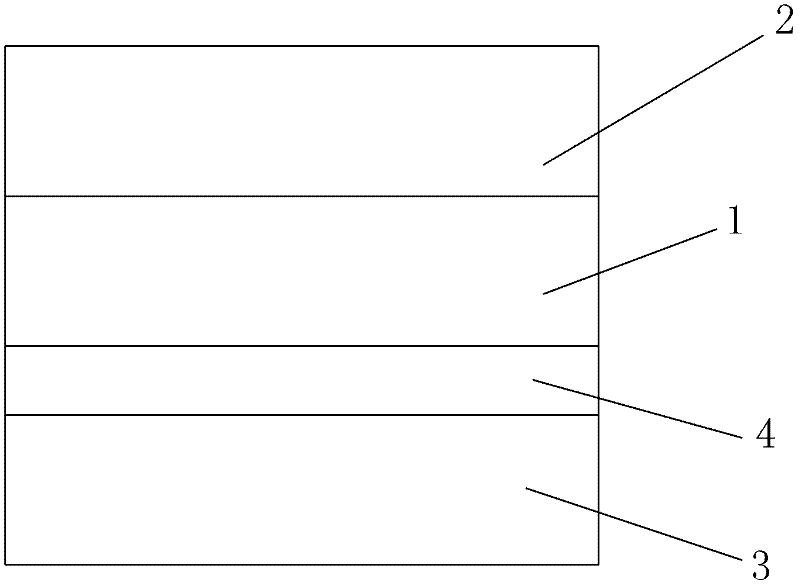

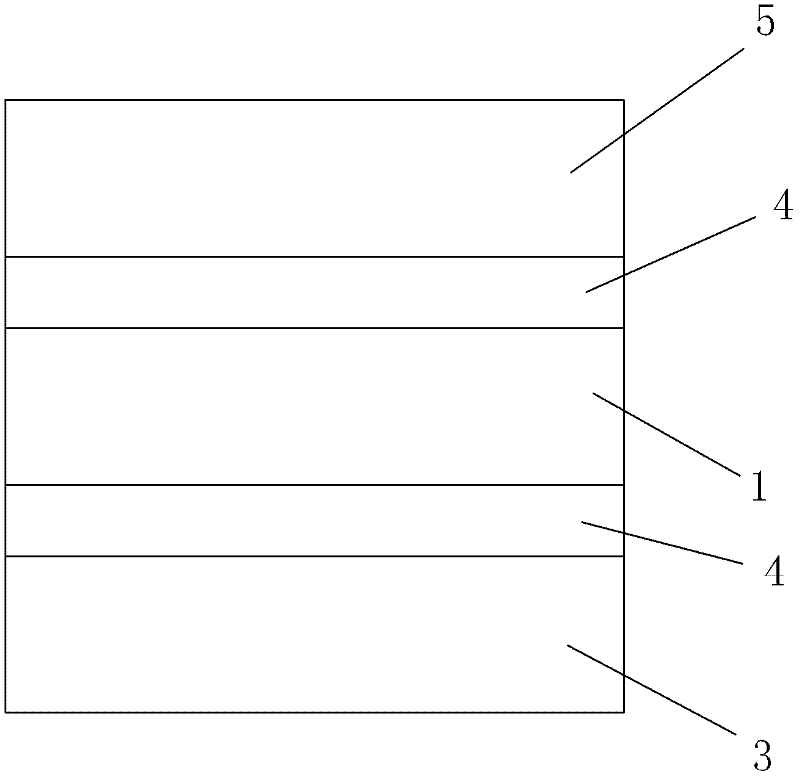

The invention discloses a weather-resistant coating and a solar back plate using the same. The coating comprises the following components calculated according to weight part: 30-90 parts of weather-resistant resin, 1-5 parts of curing agent, 0.1-5 parts of organic filler, 5-60 parts of inorganic filler and 50-100 parts of solvent. The solar back plate is characterized by comprising an insulated base layer, wherein a weather-resistant coating is arranged on at least one surface of the insulating base layer. The invention aims at overcoming the defects in the prior art and provides the weather-resistant coating which can be directly coated on the insulating substrate and has excellent binding power and weather resistance meeting the requirement of service life with more than 25 years of thesolar module; and the invention also has another aim of providing the solar back plate manufactured by adopting the weather-resistant coating.

Owner:ALLSTAE TECH ZHONGSHAN

Low-temperature curing color coiled material paint and method for preparing same

ActiveCN101531860ASuitable for continuous roller coatingMeet the hardness and toughnessPolyester coatingsLow temperature curingSolvent

The invention relates to a paint composition, in particular to a low-temperature curing paint used for manufacturing color steel plates and a method for preparing the same. The method comprises the following steps: adding 45 to 60 weight percent of saturated polyester resin, 3 to 5 weight percent of fully-methylated amino resin and 3 to 5 weight percent of partially-methylated amino resin into a reaction kettle; while stirring, adding 3 to 5 weight percent of propylene glycol ether acetate, 2 to 5 weight percent of binary acid dimethyl ester, 2 to 0.5 weight percent of closed cooling catalyst, 0.2 to 0.5 weight percent of open cooling catalyst, 5 to 10 weight percent of trimethyl benzene solvent to the mixture; after stirring the mixture evenly, adding 0.3 to 0.8 weight percent of dispersant to the mixture, and then adding 20 to 40 weight percent of filling pigment and 0.3 to 0.8 weight percent of wax powder while stirring; and after the mixture is dispersed evenly, performing sanding in a sand mill, and then performing paint and color mixing process to obtain the finished product, namely the low-temperature curing color coiled material paint. The method can solve the problems that the prior high-temperature baking curing paint has high curing temperature to cause energy sources waste.

Owner:JIANGSU LANLING POLYMER MATERIAL CO LTD

Aqueous polyurethane coating with increased limiting film thickness and preparation method of aqueous polyurethane coating

ActiveCN104893527AImprove mechanical propertiesHigh limit film thicknessPolyurea/polyurethane coatingsWater basedComposition B

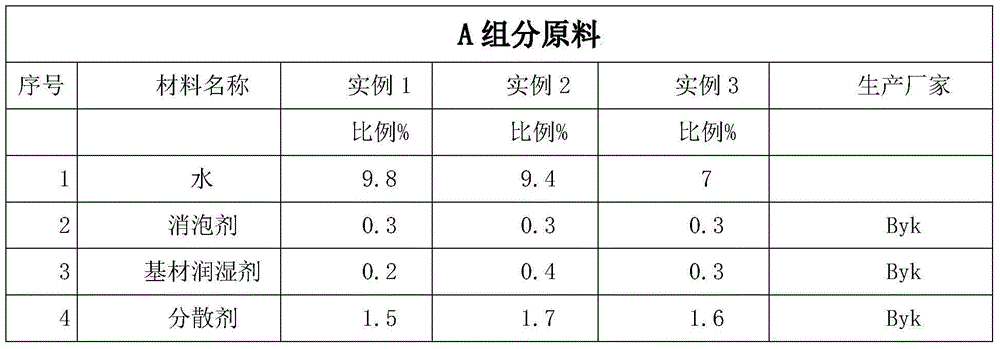

The invention discloses an aqueous polyurethane coating with an increased limiting film thickness and a preparation method of the aqueous polyurethane coating. The aqueous polyurethane coating comprises a composition A and a composition B, wherein the composition A comprises the following components in parts by weight: 35-42 parts of water based hydroxy acrylic acid a, 15-18 parts of water based hydroxy acrylic acid b, 25-30 parts of a filler, 1-3 parts of additives, 4-6 parts of a film-forming additive c and 7-10 parts of water; the composition B comprises the following components in parts by weight: 8-10 parts of water, 80-90 parts of isocyanate and 3-5 parts a film-forming additive d. The preparation method comprises the following steps: uniformly mixing and stirring water and part of the additives; adding the filler; carrying out dispersion in a high-speed state till the preset fineness is reached; then, reducing the dispersion speed, and uniformly stirring water based hydroxy acrylic acid a, water based hydroxy acrylic acid b and part of the additives to obtain the composition A; uniformly mixing and stirring water, isocyanate and the film-forming additive d to obtain the composition B. The aqueous polyurethane coating provided by the invention is extremely low in VOC, high in physical and mechanical performance, high in limiting film thickness, and suitable for the application scenario of environmental-friendly high decorative finishing coating.

Owner:HAOLISEN COATING SHANGHAI

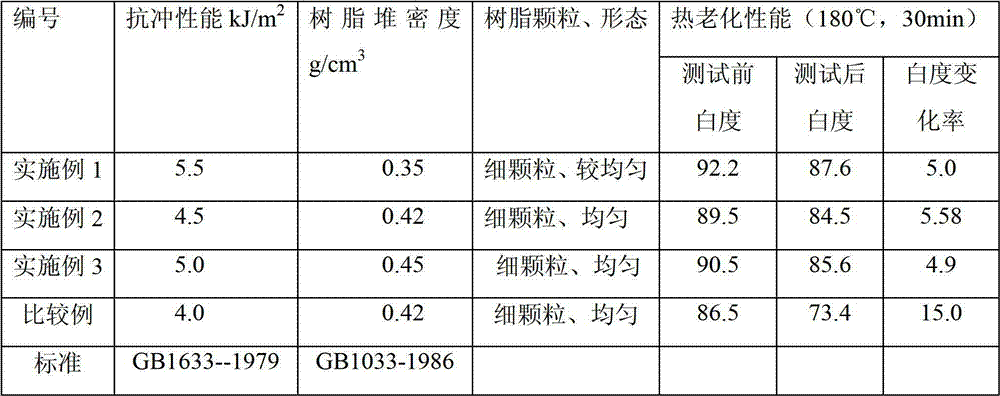

High-tensile-strength impact modifier for PVC (polyvinyl chloride) and preparation technique thereof

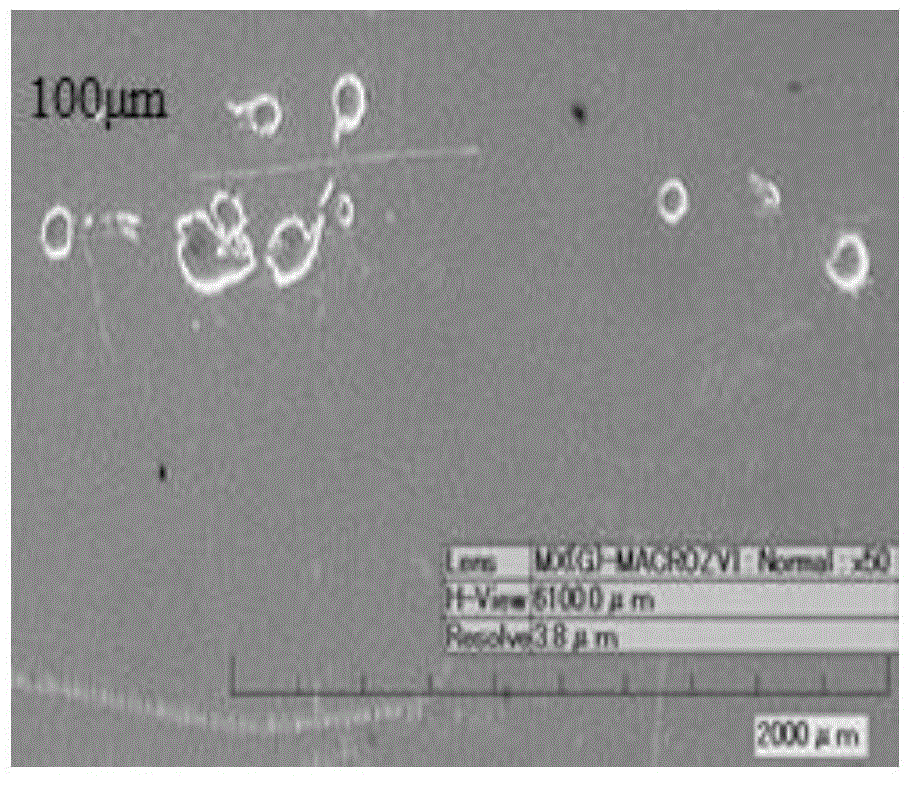

The invention belongs to the technical field of preparation of PVC (polyvinyl chloride) impact modifiers, and particularly relates to a high-tensile-strength impact modifier for PVC and a preparation technique thereof. The preparation technique comprises the following steps: grafting epoxypropyl methacrylate onto a polyethylene main chain in the presence of a grafting assistant, and carrying out chlorination modification by an acid-phase process to obtain the high-tensile-strength impact modifier for PVC. The impact modifier for PVC can be widely used in the fields of PVC profiles, tubes and plates, can be used instead of high-price acrylate impact modifiers in the aspects of shock resistance and tensile property, and greatly enhances the weather resistance and working properties of the PVC product. The invention satisfies the performance requirements for rigidity, weather resistance, dimensional stability and the like, and the production process is green and environment-friendly and is easy to control.

Owner:SHANDONG RUIFENG CHEM

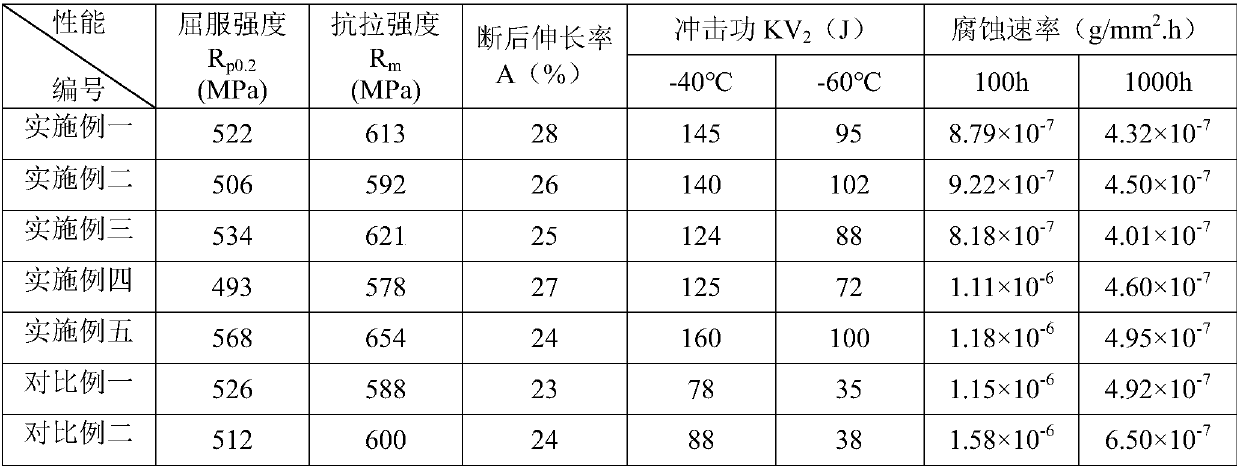

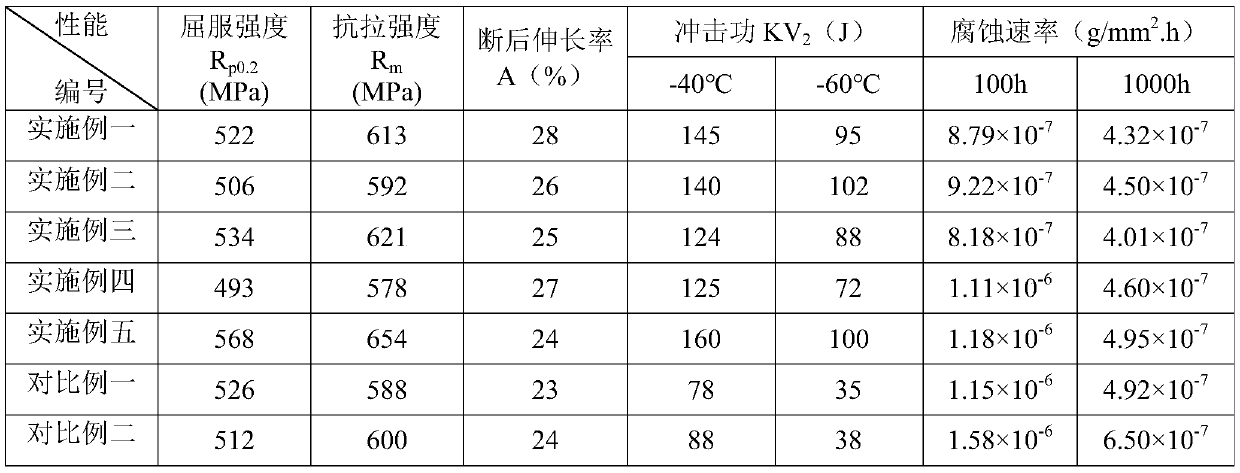

Weathering steel for photovoltaic support and production method of weathering steel

The invention relates to the technical field of steel and iron smelting, discloses weathering steel for a photovoltaic support and a production method of the weathering steel, and provides the following scheme aiming at the problem that when the weathering steel in the prior art is applied to the photovoltaic support, the comprehensive mechanical property is not easily matched with the applicability of the steel for the photovoltaic support. 0.20% to 0.50% of Si; mn: 0.3 to 1.20%; less than or equal to 0.020% of P; s: < = 0.005%; 0.01 to 0.05 percent of Nb; 0.010% to 0.030% of Ti; ni: 0.05 to 0.30%; 0.20% to 0.50% of Cu; 0.4 to 0.8 percent of Cr; n: < = 0.006%; the content of Ca is 0.0010 to 0.0030 percent; and the balance of Fe and inevitable impurity elements. The weathering resistant steel for the photovoltaic support has good weathering resistance, reprocessability, weldability and low-temperature toughness.

Owner:ANYANG IRON & STEEL +1

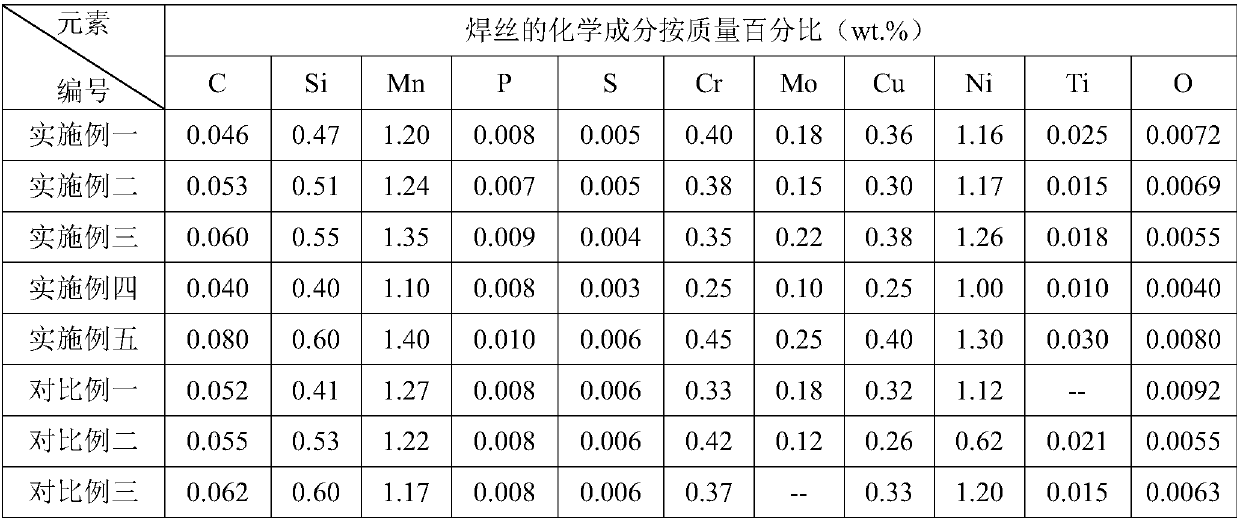

High-toughness gas shielded welding wire for long-life weathering steel structure and preparation method of high-toughness gas shielded welding wire

ActiveCN108015451AWeather resistantMeet the weather resistanceWelding/cutting media/materialsSoldering mediaMechanical propertyImpurity

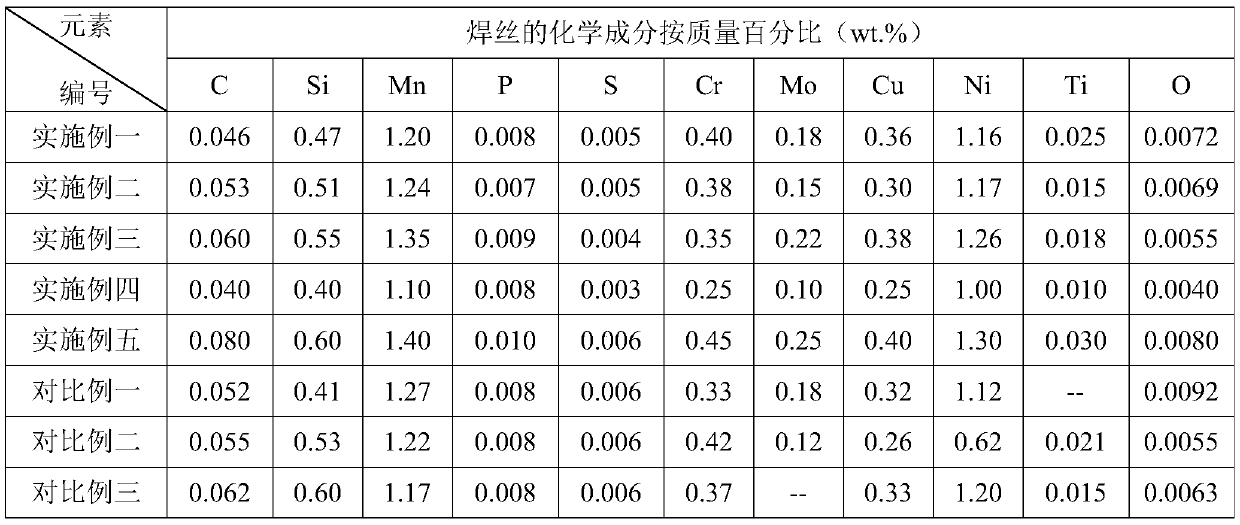

Provided are a high-toughness gas shielded welding wire for a long-life weathering steel structure and a preparation method of the high-toughness gas shielded welding wire. The chemical components ofthe welding wire comprise, by mass percent, 0.04-0.08 % of C, 0.40-0.60 % of Si, 1.10-1.40 % of Mn, being less than or equal to 0.010 % of P, being less than or equal to 0.006 % of S, 0.25-0.45 % of Cr, 0.10-0.25 % of Mo, 0.25-0.40 % of Cu, 1.00-1.30 % of Ni, 0.01-0.03 % of Ti, 0.004-0.008 % of O, being less than or equal to 0.30 % of the sum of unavoidable impurity elements, and the balance Fe. Through the technical scheme of scientific proportioning of the chemical components of the welding wire, the welding performance is stable, and the obtained deposited metal not only has good comprehensive mechanical properties but also has excellent corrosion resistance and low temperature impact toughness. According to the preparation method, the manufacturing process is stable, and the percent ofpass is high.

Owner:SICHUAN XIYE NEW MATERIAL

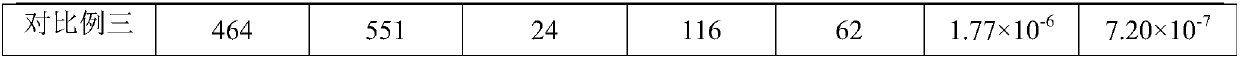

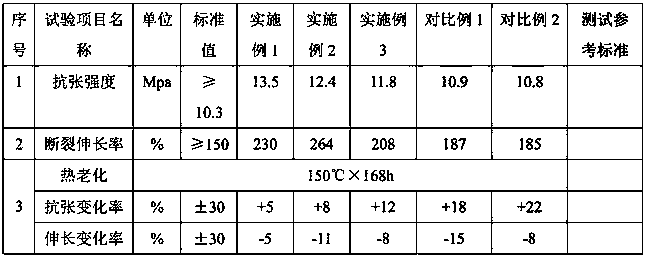

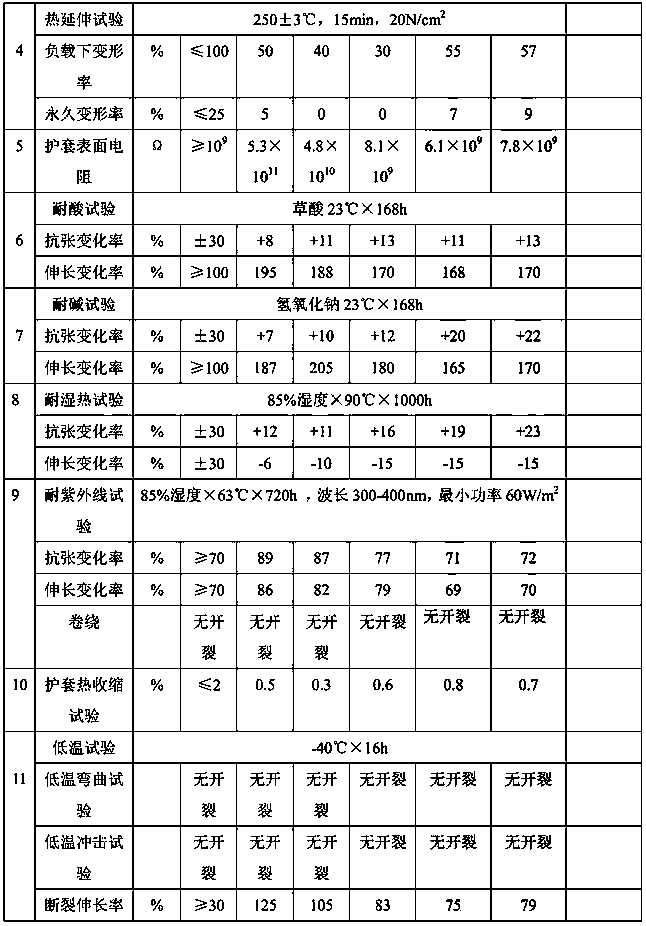

Zero-halogen low-smoke flame-retardant sheath material used for photovoltaic cable and production method and application thereof

InactiveCN109957199AEnhanced interactionImprove flame retardant performanceRubber insulatorsPlastic/resin/waxes insulatorsElastomerPolyolefin

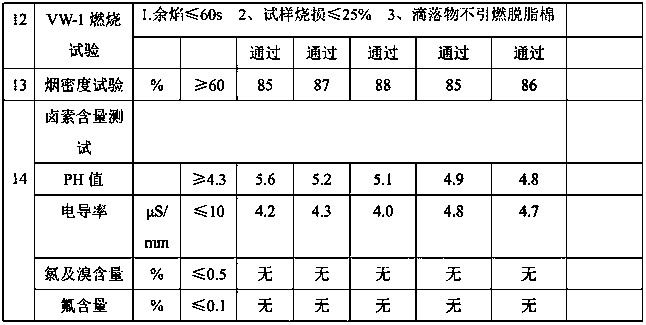

The invention discloses a zero-halogen low-smoke flame-retardant sheath material used for a photovoltaic cable. The zero-halogen low-smoke flame-retardant sheath material used for the photovoltaic cable is composed of the following components of, in parts by weight, 2-10 parts of maleic anhydride-grafted ethylene-vinyl acetate copolymer, 5-20 parts of ethylene-propylene-diene monomer, 2-10 parts of high-density polyethylene, 5-20 parts of polyolefin elastomer, 45-65 parts of fire retardant, 1-5 parts of flame-retardant synergist, 0.5-1.5 parts of surface modifier, 0.5-2 parts of antioxidant, 1-5 parts of lubricant and 0.5-1.5 parts of cross-linking sensitizer. The produced zero-halogen low-smoke flame-retardant sheath material used for the photovoltaic cable not only meets the specification in EN50618 standard of dampness-heat resistance, low temperature resistance, weather resistance, ozone resistance, 250-DEG C thermal elongation, resistance to acid and alkali, light transmittance insmoke, non-halogen and the like, but also meets the specification in UL4703 standard of oil resistance, VW-1 combustion, mechanical performance and the like, and is a cable sheath material which is up to both the EN50618 standard and the UL4703 standard.

Owner:SHANGHAI KAIBO SPECIAL CABLE FACTORY

High appearance effect waterborne topcoat paint composition for bus body and preparation method thereof

InactiveCN107142000AMeet the colorful appearance requirementsGood lookingPolyurea/polyurethane coatingsOrganic solventWeather resistance

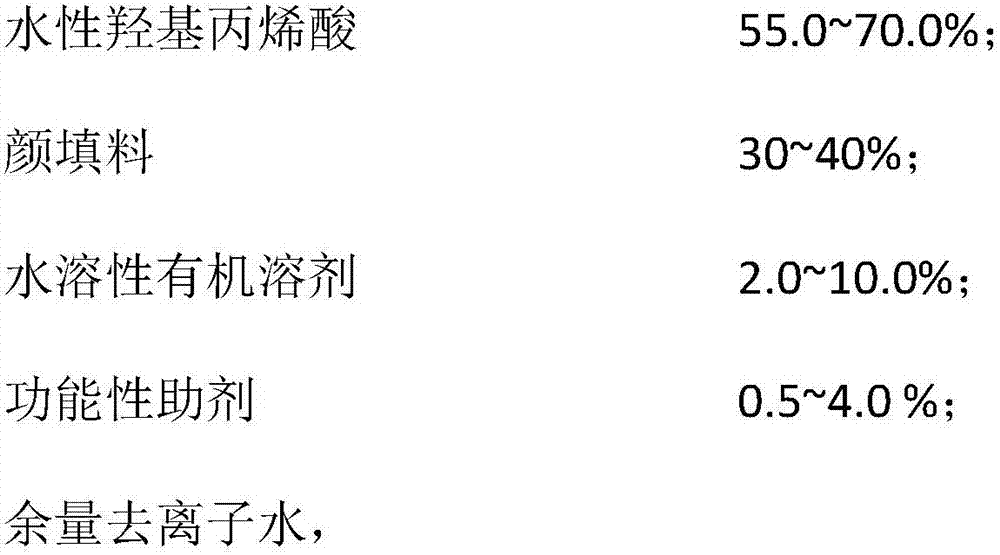

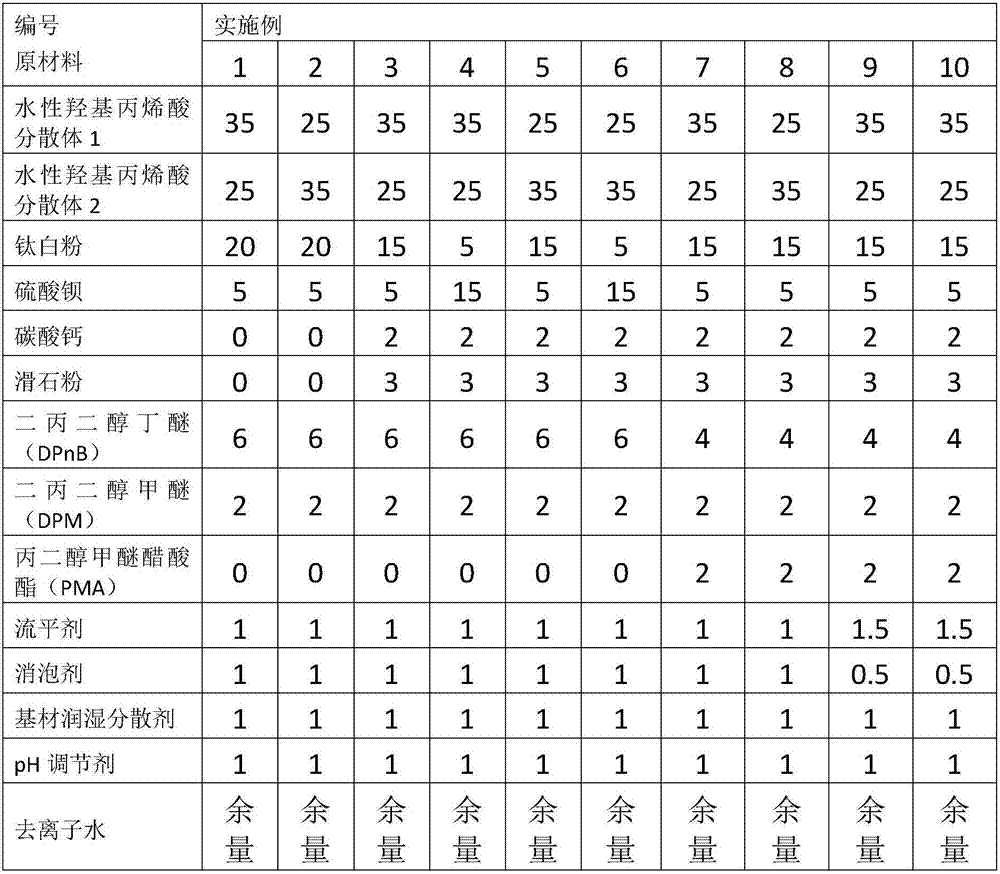

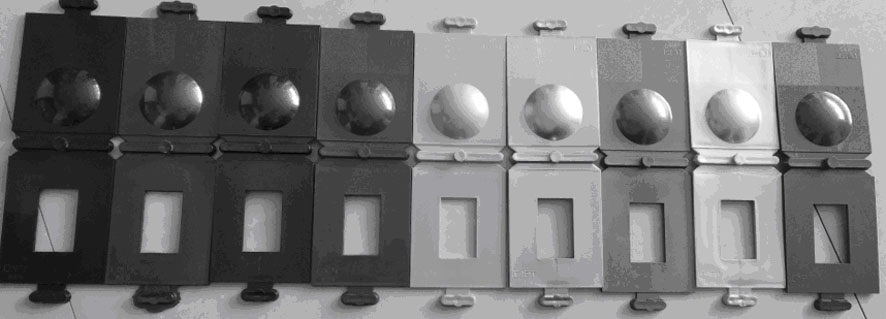

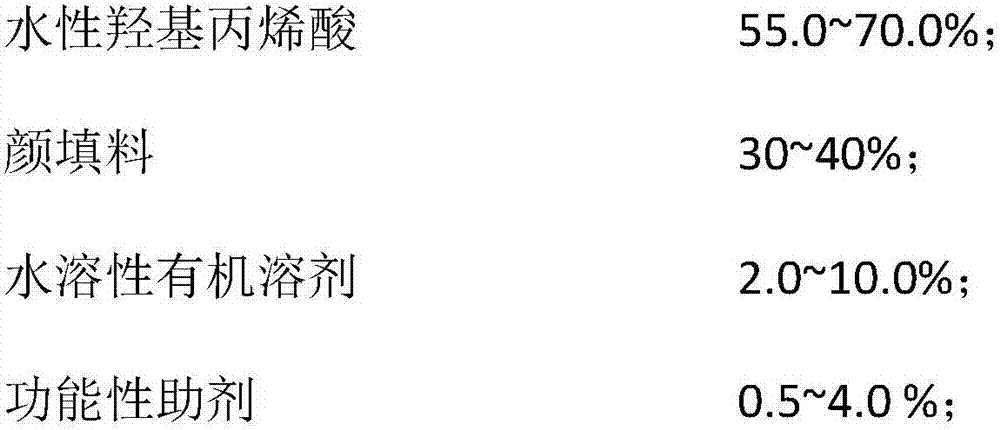

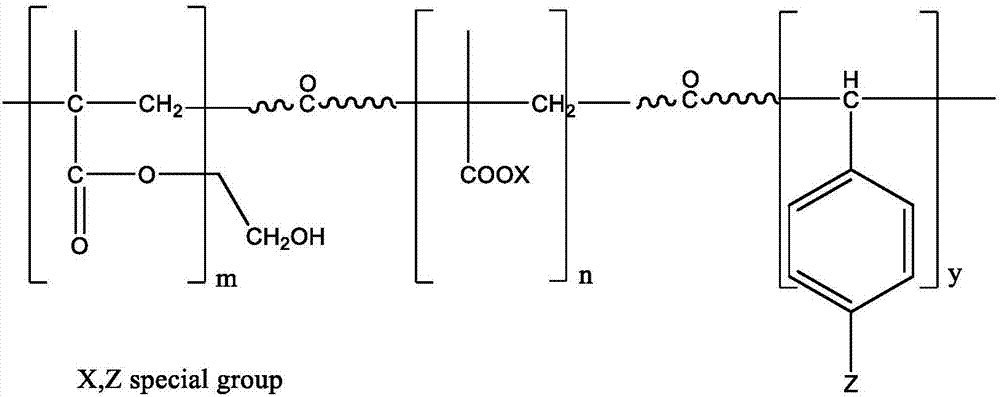

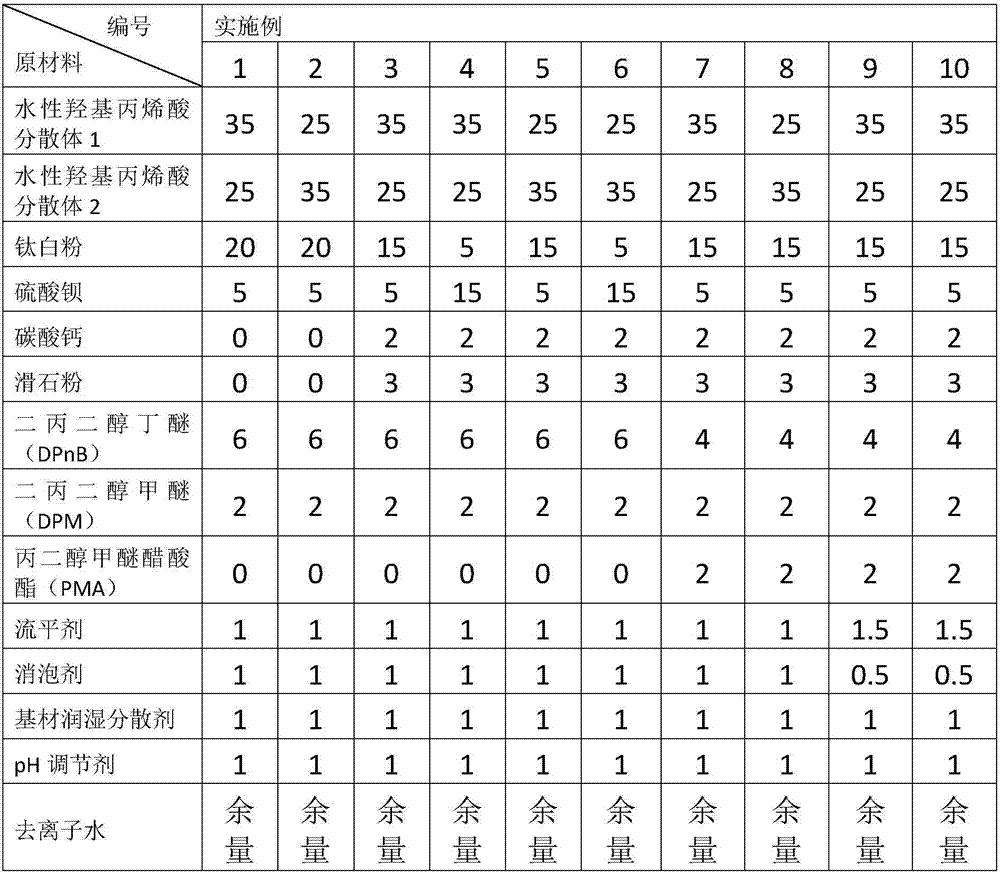

The invention relates to a high appearance effect waterborne topcoat paint composition for a bus body. The waterborne topcoat paint composition comprises a component A and a component B, wherein the component A includes the following ingredients by weight percentage: 55.0-70.0% of waterborne hydroxy acrylic acid; 30-40% of pigment and filler; 2.0-10.0% of a water-soluble organic solvent; 0.5-4.0% of functional additives; and the balance deionized water, and the component B includes the following ingredients by weight percentage: 60.0-80.0% of a waterborne isocyanate curing agent; and 20.0-40.0% of a water-soluble organic solvent. The weight percent of the component A is 75-90.0%, and the weight percent of the component B is 25%-10.0%. The paint composition provided by the invention has very good appearance effect and high gloss, and also meets the hardness, impact, weather resistance and other performance requirements and quick and defect-free construction requirements.

Owner:HAOLISEN COATING SHANGHAI

Spraying-free metal-texture high-gloss high-weather-resistance PMMA/ASA alloy material and preparation method thereof

The invention discloses a spraying-free metal-texture high-gloss high-weather-resistance PMMA / ASA alloy material and a preparation method thereof. AS resin, PMMA resin, ASA rubber powder, glass powder, a pigment and auxiliary agents are mixed and then added into a screw extruder, and the spraying-free metal-texture high-gloss high-weather-resistance PMMA / ASA alloy material is obtained through extrusion. The metal-texture high-gloss high-weather-resistance PMMA / ASA alloy material provided by the invention is a material which can realize a colorful appearance effect without paint spraying treatment, with direct injection molding and without spraying, so that the cost is reduced, the environment is protected, the production process is simple, the product yield is improved, the application prospect is wide, and the PMMA / ASA alloy material has a good use value.

Owner:浙江科普特新材料有限公司

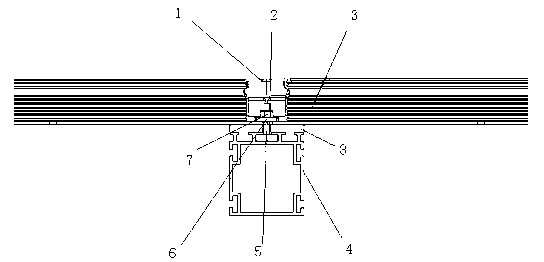

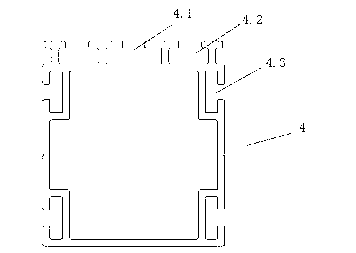

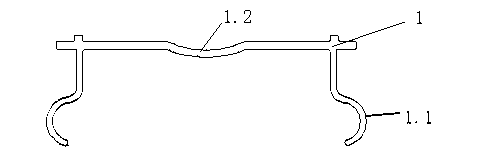

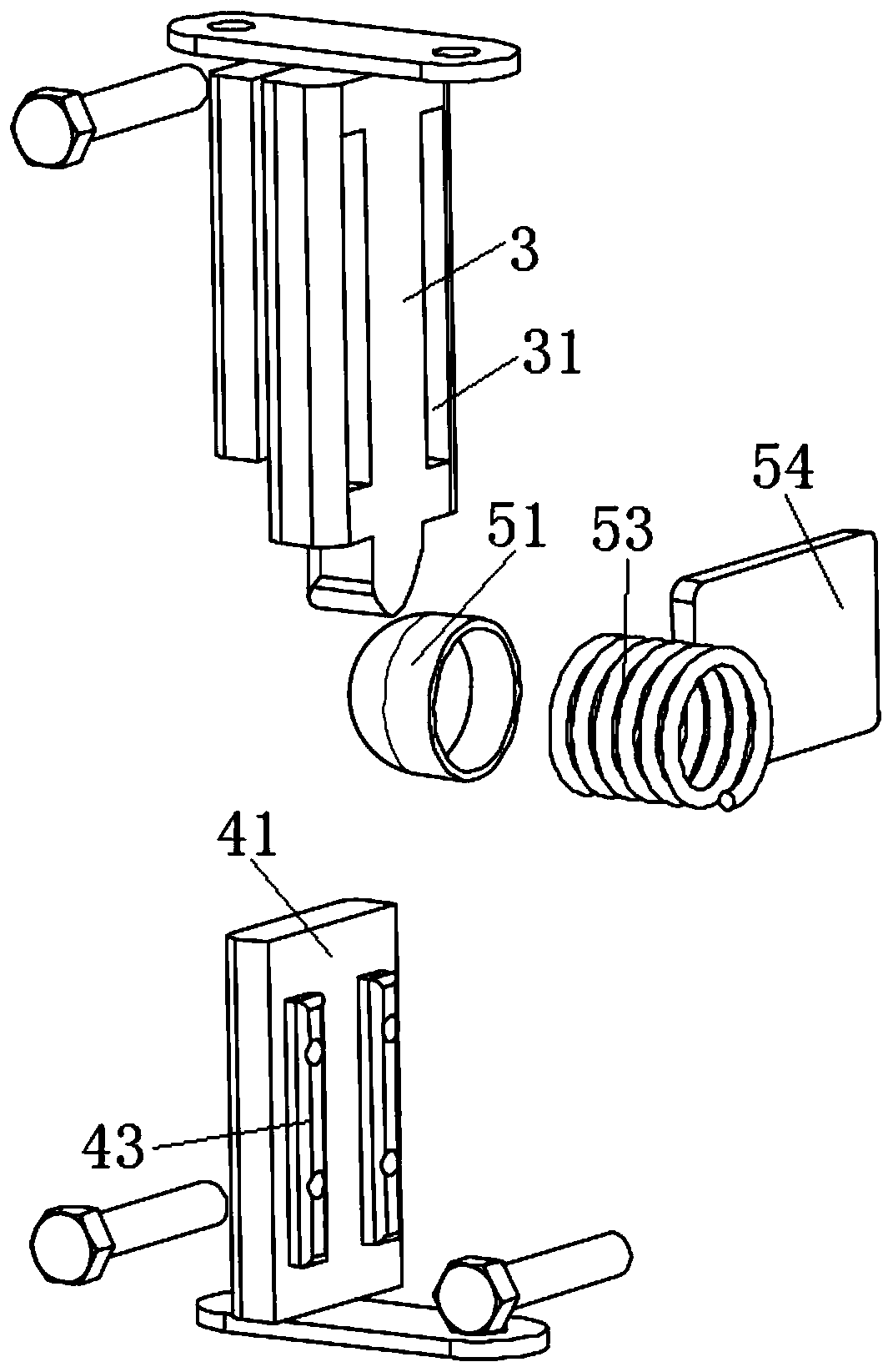

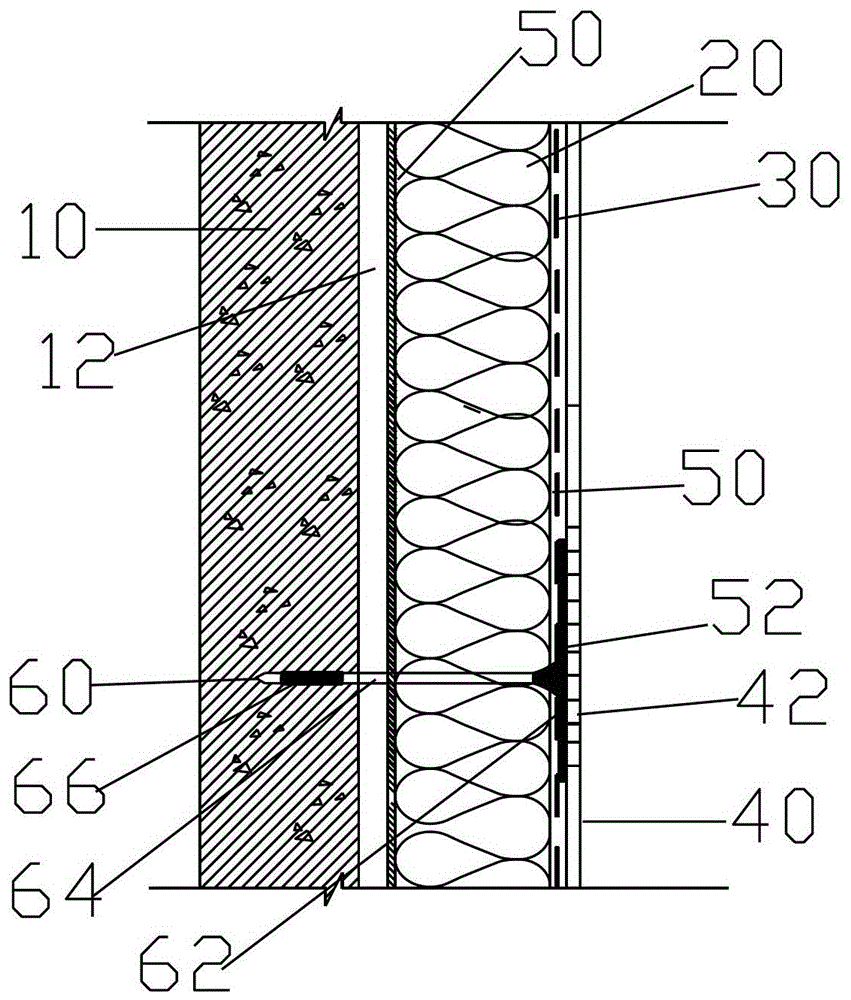

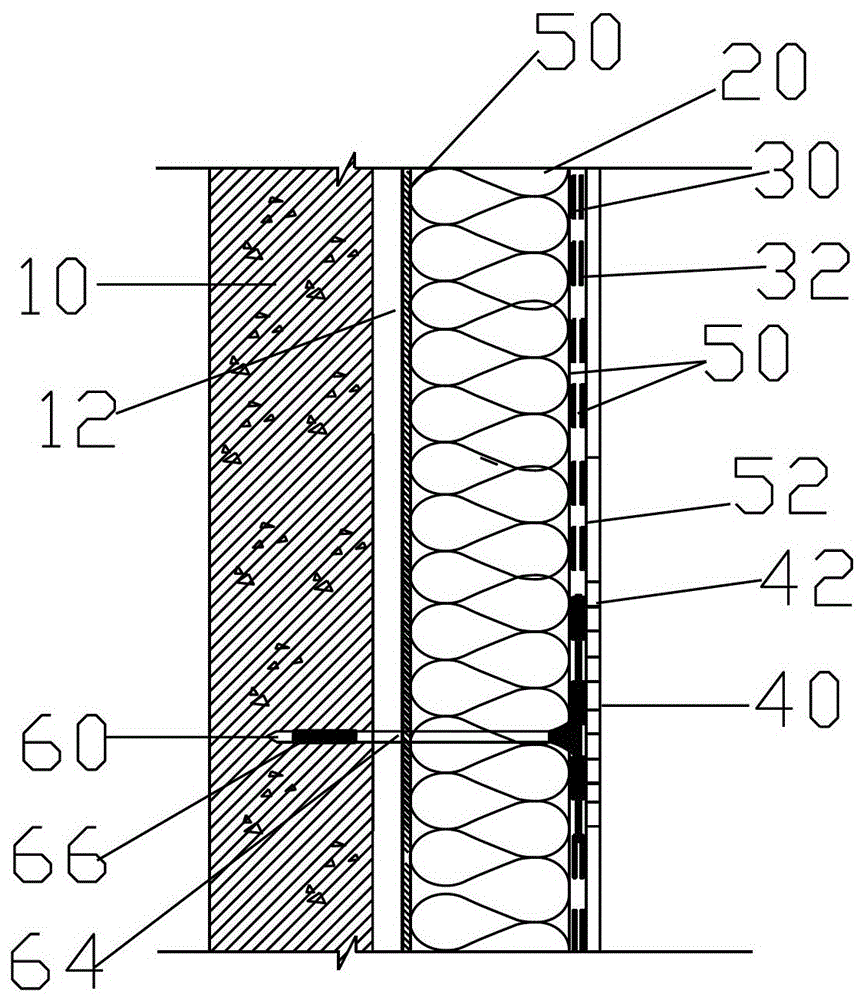

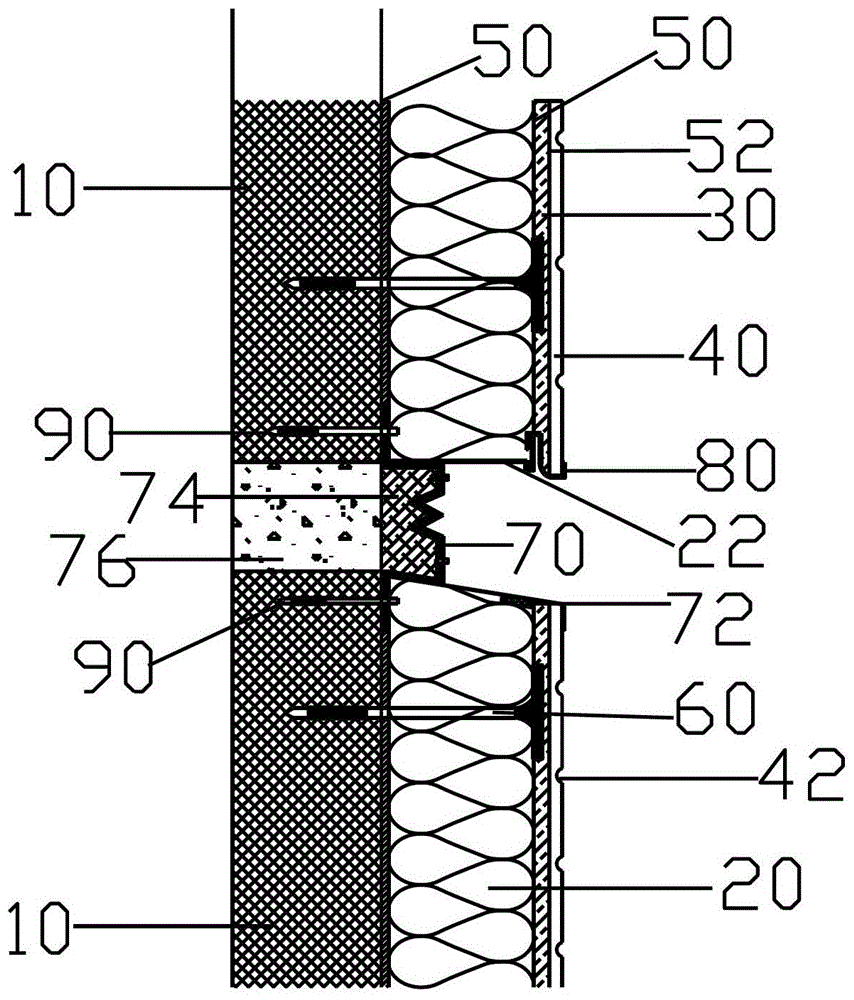

Keel installation assembly used for building photovoltaic components

ActiveCN103343595AMeet structural strengthMeet fire protectionRoof covering using slabs/sheetsRoof covering using tiles/slatesBridge materialWeather resistance

The invention relates to a keel installation assembly based on building based on photovoltaic components. The keel installation assembly comprises a keel and sealing strips, a bolt insertion groove is formed in the keel in the length direction of the center of the upper position, thermal insulation broken bridge insertion grooves are formed in the two sides of the bolt insertion groove, thermal insulation broken bridge materials are arranged in the thermal insulation broken bridge insertion grooves, and frames of the adjacent building photovoltaic components are installed on the keel and fixed through bolts and press block screws, wherein the two thermal insulation broken bridge materials are inserted in the keel. A groove is formed by the frames of the adjacent building photovoltaic components in a splicing installation mode, a sealing gum waterproof layer is arranged in the groove, and the sealing strips are arranged on the sealing gum waterproof layer. The keel installation assembly can meet the requirements of a building for structural strength, fire prevention, weather resistance, heat preservation, heat dissipation, water tightness, gas tightness and the like, is highly compatible with existing construction and installation technologies and methods and also meets relevant standards and specification requirements of the building.

Owner:合肥微纳电工有限公司

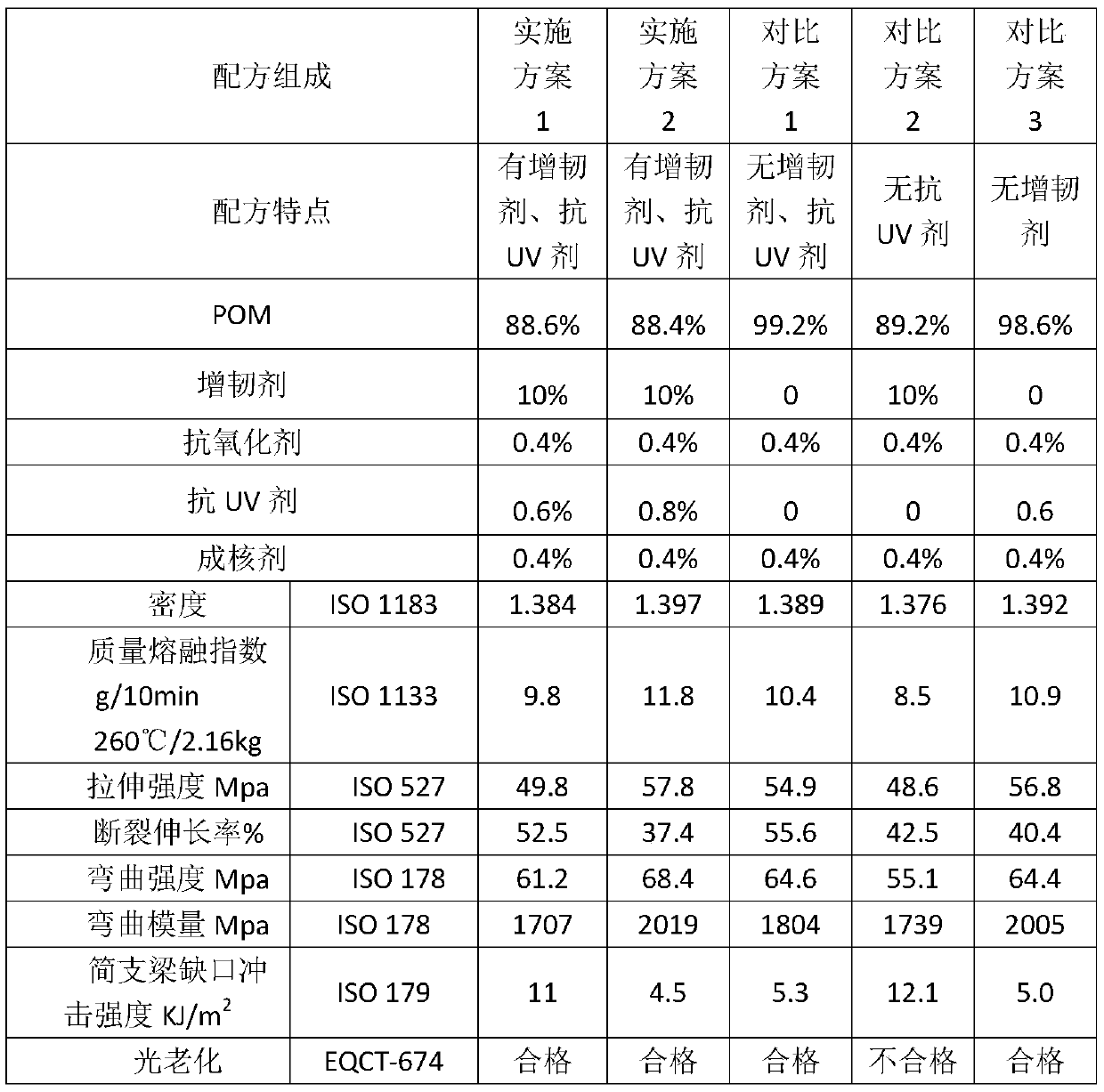

Anti-aging high-toughness polyformaldehyde material and preparation method thereof

The invention discloses an aging-resistant high-toughness polyformaldehyde material and a preparation method thereof, and relates to the technical field of high polymer materials, the aging-resistanthigh-toughness polyformaldehyde material comprises the following components by mass: 80-95% of polyformaldehyde resin (POM); 1%-20% of a toughening agent; 0.2-1% of an antioxidant; 0.1%-2% of an anti-UV agent; and 0.2%-1% of a nucleating agent. The aging-resistant high-toughness polyformaldehyde resin material has the advantages of high toughness, excellent aging resistance and favorable mechanical properties, can satisfy the requirements of outdoor products for external environment resistance, and is suitable for manufacturing antifriction wear-resistant parts, transmission parts, chemical engineering, instruments and other parts.

Owner:湖北合聚高分子材料有限公司

Water-based finish coating composition for appearance effect of bus body and its preparation method

InactiveCN107418414AMeet the colorful appearance requirementsGood lookingPolyurea/polyurethane coatingsEmulsion paintsWater basedOrganic solvent

The invention relates to a water-based finish coating composition for appearance effect of bus body, which comprises the A component and the B component, wherein the A component is prepared from, by weight percent, 55.0-70.0% of water-based hydroxy acrylic acid, 30-40% of pigment filler, 2.0-10.0% of water-soluble organic solvent, 0.5-4.0% of functional assistant, and allowance of deionized water. The B component is prepared from, by weight percent, 60.0-80.0% of water-based isocyanate curing agent, 20.0-40.0% of water-soluble organic solvent; according to the weight percent, the A component is 75-90.0%, and the B component is 25-10.0%. The coating composition is featured by very good appearance effect and high gloss; the water-based finish coating composition can meet performance requirements such as hardness, impact and weather fastness, and the construction requirement of rapid and no-mistake.

Owner:HAOLISEN COATING SHANGHAI

Single-component polyurethane adhesive and preparation method thereof

InactiveCN110483726AHigh bond strengthMeet water resistancePolyureas/polyurethane adhesivesSolventWeather resistance

The invention discloses a single-component polyurethane adhesive and a preparation method thereof. The raw materials comprise the following components in parts by weight: 40 to 50 parts of HDI monomers, 10 to 15 parts of hydroxyl-terminated silicone oil, 10 to 20 parts of polycarbonate diol, 30 to 40 parts of trifunctional polyether polyol, 5 to 10 parts of chain extender and 0.015 to 0.03 part ofcatalyst. The trifunctional polyether polyol is a reaction product of polyol and polyisocyanate, the polyol contains trifunctional polyether polyol with more than one ethyleneoxy group in one molecule and the number average molecular weight of more than 3000, and the invention relates to the technical field of preparation of polyurethane adhesives. According to the invention, in specific practical application, the adhesive strength between glue and stones can be improved, outdoor water resistance, weather resistance, ultraviolet resistance, yellowing resistance and aging resistance are met, the service life of the water-permeable adhesive stone is prolonged, and by means of low viscosity of hydroxyl silicone oil, the polyurethane adhesive is solvent-free, more environmentally friendly inuse and capable of meeting the requirements of time development.

Owner:无锡庄周新材料科技有限公司

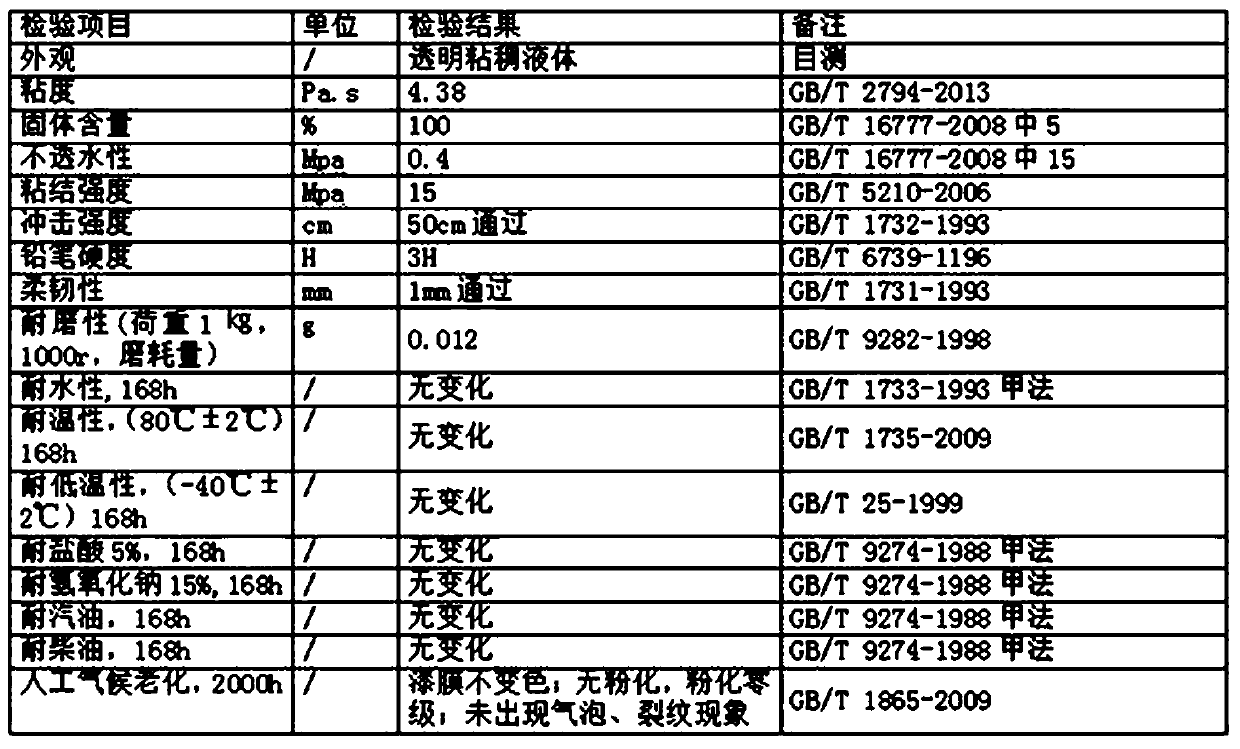

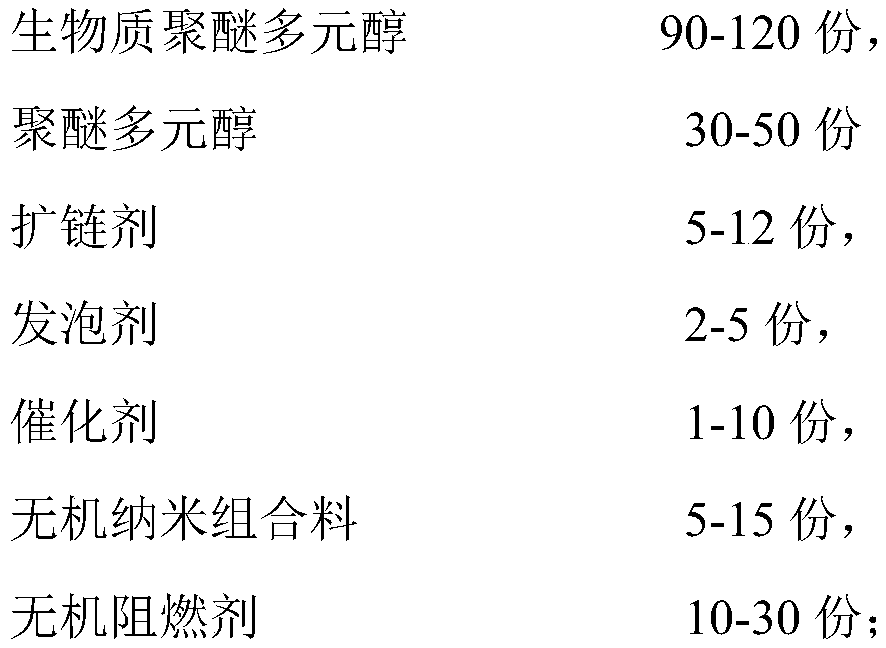

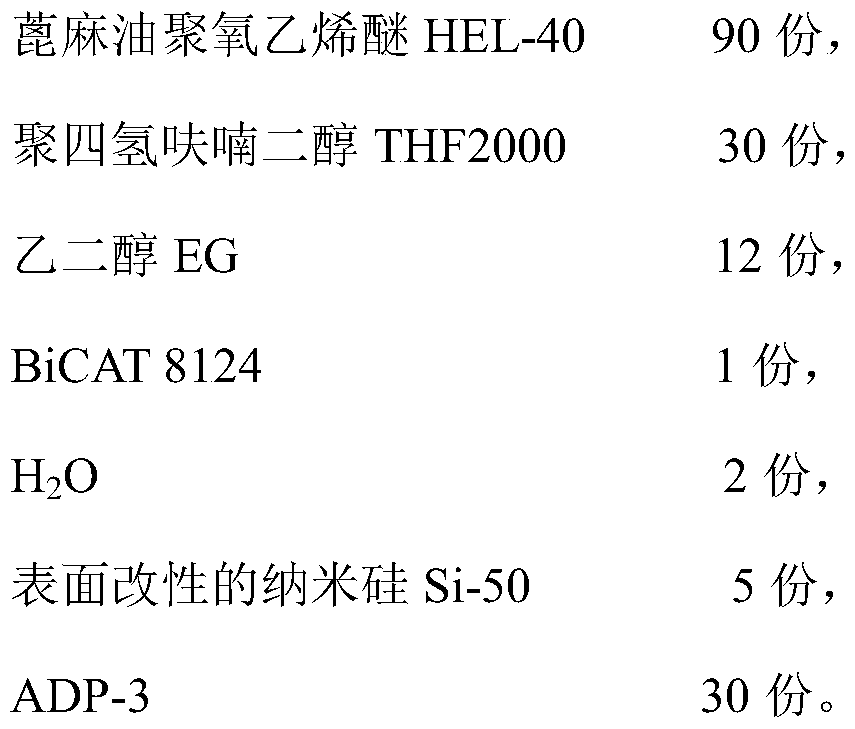

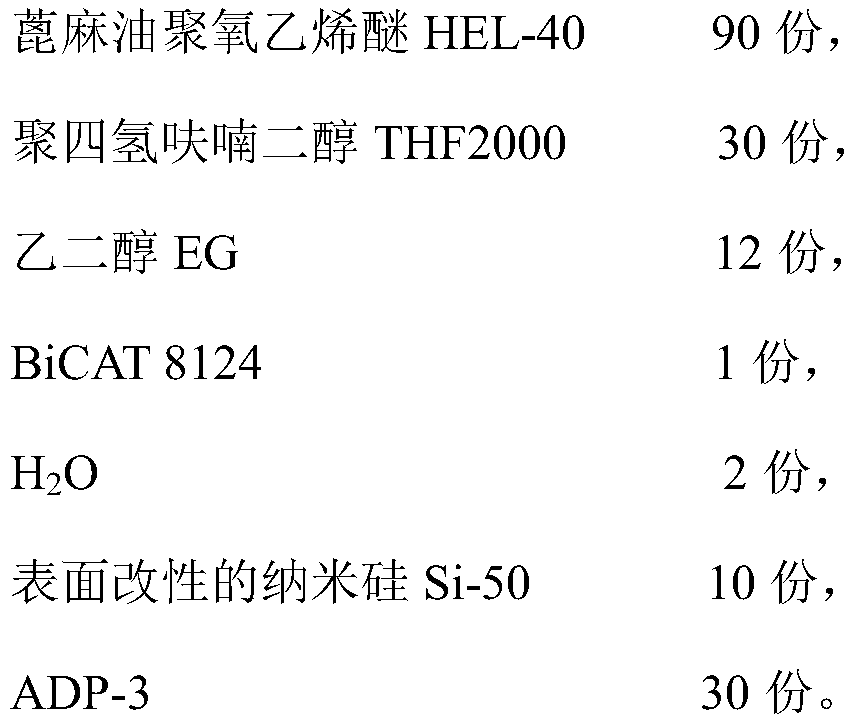

Inorganic particle composite polyurethane synthetic leather and preparation method and application thereof

InactiveCN110656506ASolve the problem of high VOC contentSatisfy flame retardancyVehicle componentsRoad vehiclesPtru catalystPolyol

The invention discloses inorganic particle composite polyurethane synthetic leather and a preparation method and application thereof. The inorganic particle composite polyurethane synthetic leather isprepared from a composite material A and a composite material B according to a mass ratio of 100:(40-80) through solvent-free reaction. The composite material A is prepared from, by mass, 90-120 parts of biomass polyether polyol, 30-50 parts of polyether polyol, 5-12 parts of a chain extender, 2-5 parts of a foaming agent, 1-10 parts of a catalyst, 5-15 parts of an inorganic nano composite material and 10-30 parts of an inorganic flame retardant. The composite material B refers to cyanate ester organics. Organic solvent consumption is avoided in a manufacturing process, and the prepared inorganic particle composite polyurethane synthetic leather has excellent flame retardation and mechanical properties, high resistance to light and heat and long service life and has evident economic and environment-friendly advantages in application to automotive interior decorative materials.

Owner:ANHUI ANLI MATERIAL TECH

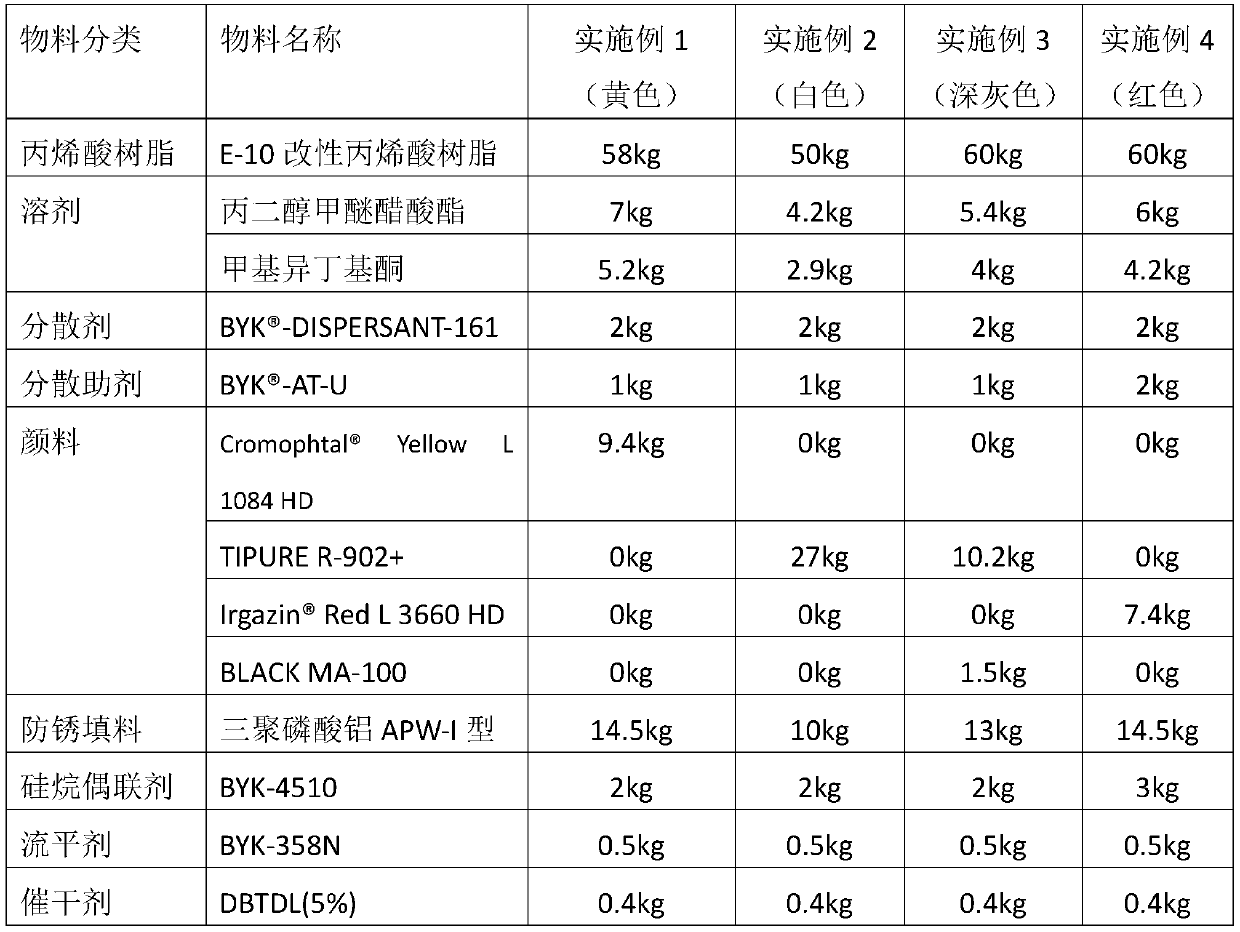

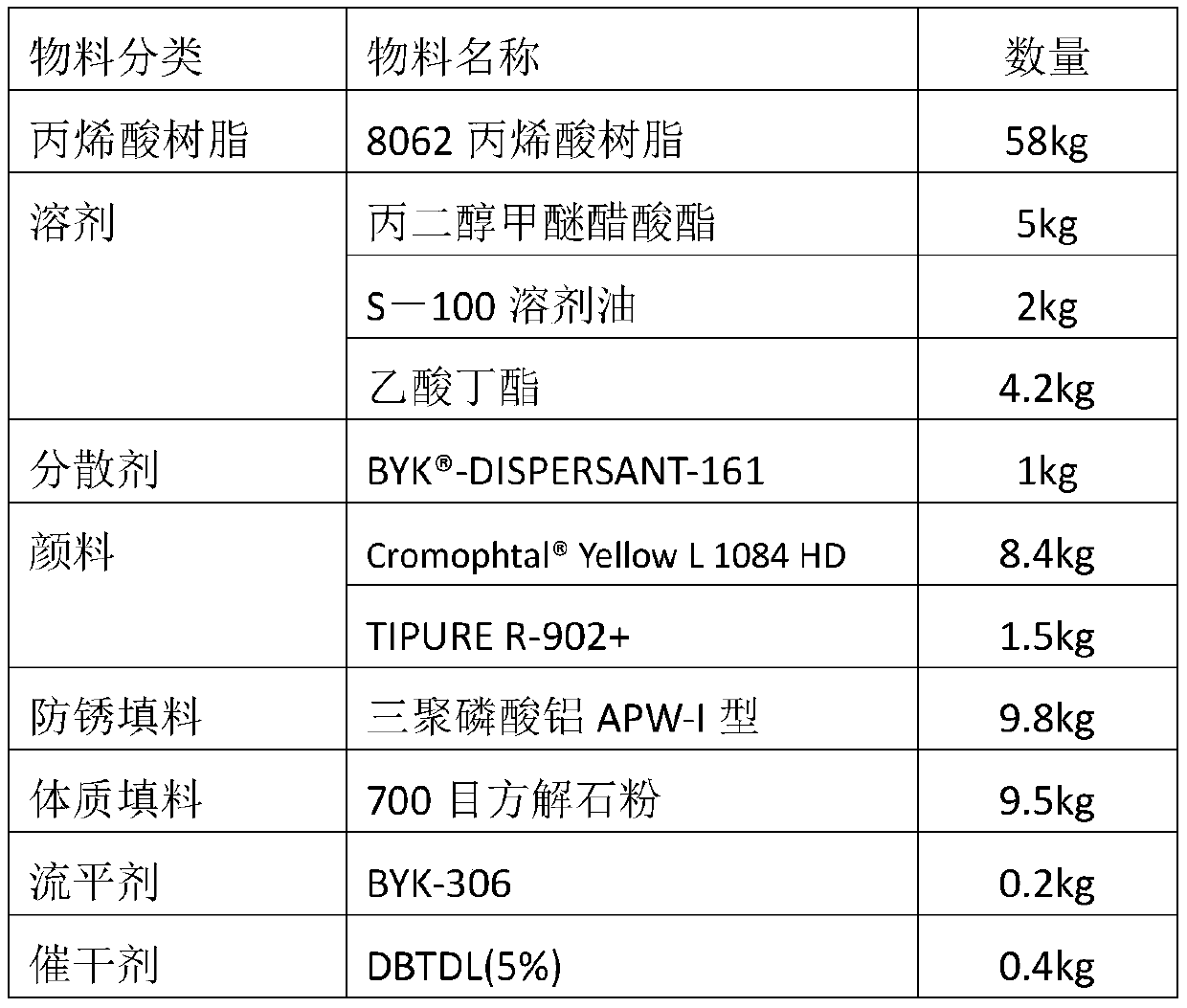

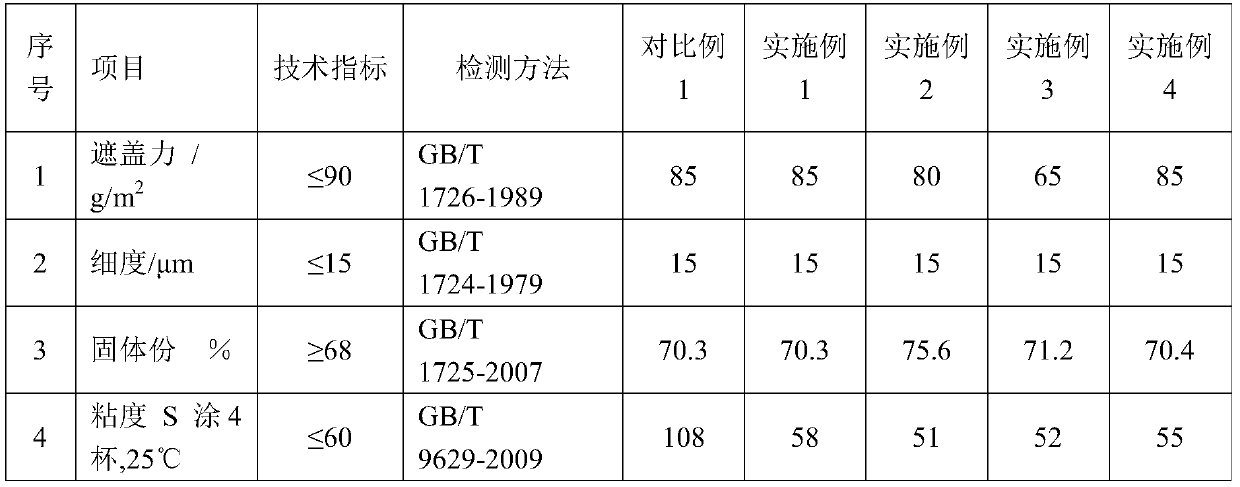

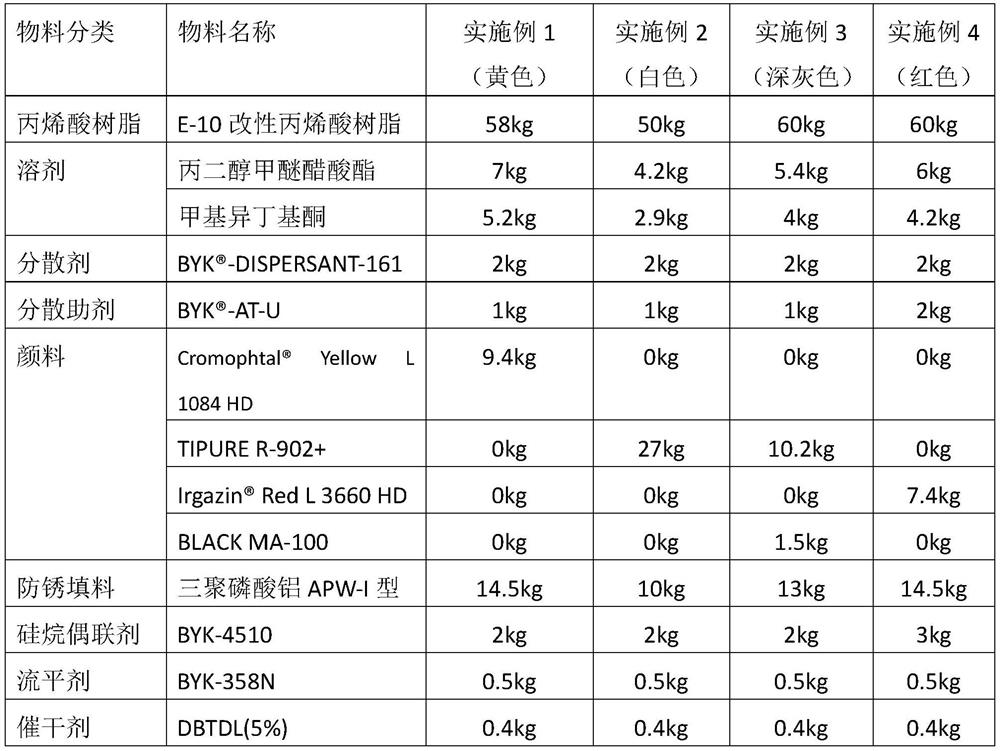

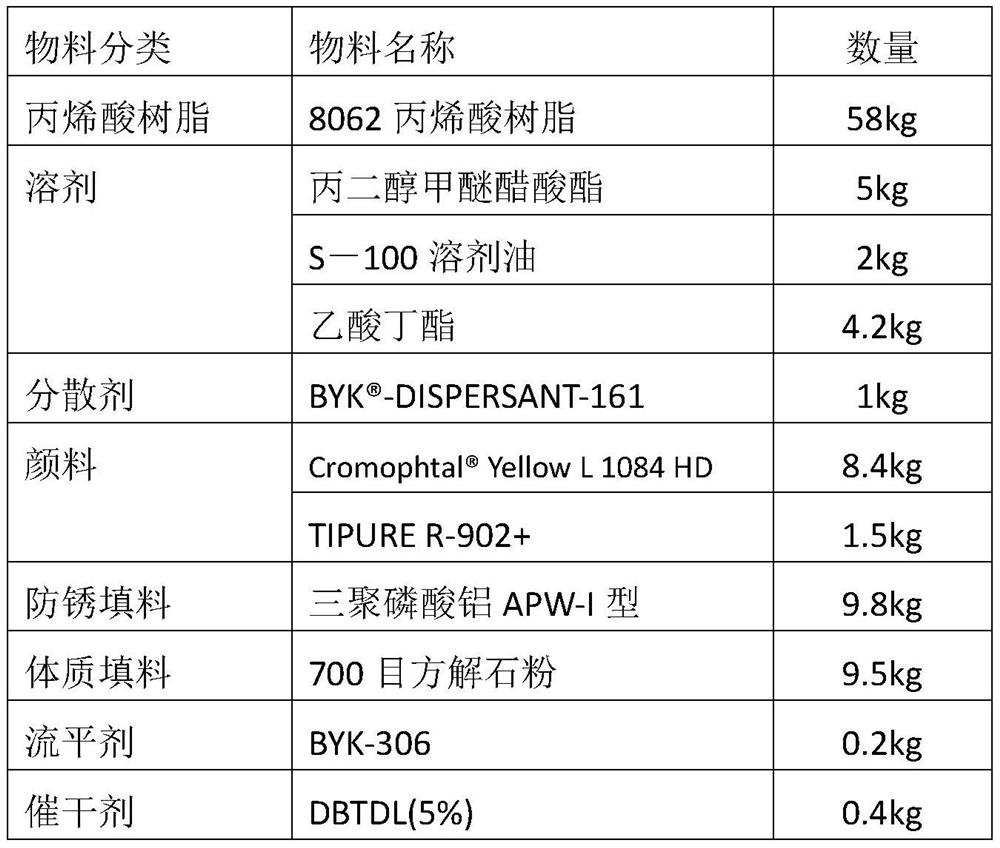

Primer-topcoat acrylic resin coating and preparation method thereof

ActiveCN111286241AReduce the pressure of inputReduce spraying processAnti-corrosive paintsPolyurea/polyurethane coatingsPolymer scienceMeth-

The invention discloses a primer-topcoat acrylic resin coating. The primer-topcoat acrylic resin coating comprises a component A and a component B in a weight ratio of (5-7):1, wherein the component Acomprises the components in parts by weight: 50-70 parts of acrylic resin, 2-4 parts of a dispersing agent, 1-2 parts of a dispersing aid, 20-40 parts of a pigment filler, 0.1-4 parts of other aids and 5-15 parts of a solvent; the component B comprises the components in parts by weight: 65-75 parts of hexamethylene diisocyanate, 25-35 parts of butyl acetate and 0.1-0.5 part of a water absorbent.According to the coating, glycidyl tertiary carbonate modified acrylic resin with specific solid content, viscosity, hydroxyl value and molecular weight of 1600-2000 is used as matrix resin, and hexamethylene diisocyanate and an antirust pigment are matched, so that weather resistance, appearance requirements, hardness, flexibility and the like are met, and low VOC is realized. Meanwhile, one spraying procedure can be omitted in the construction process of the primer-topcoat coating, and no special requirement is needed for construction equipment.

Owner:NIPPON PAINT IND COATINGS SHANGHAI

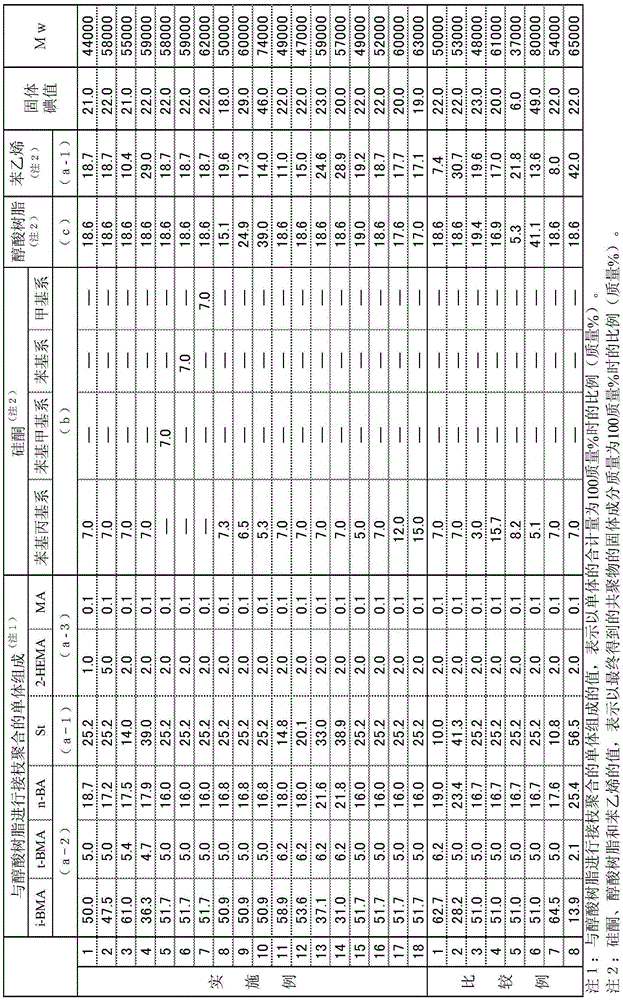

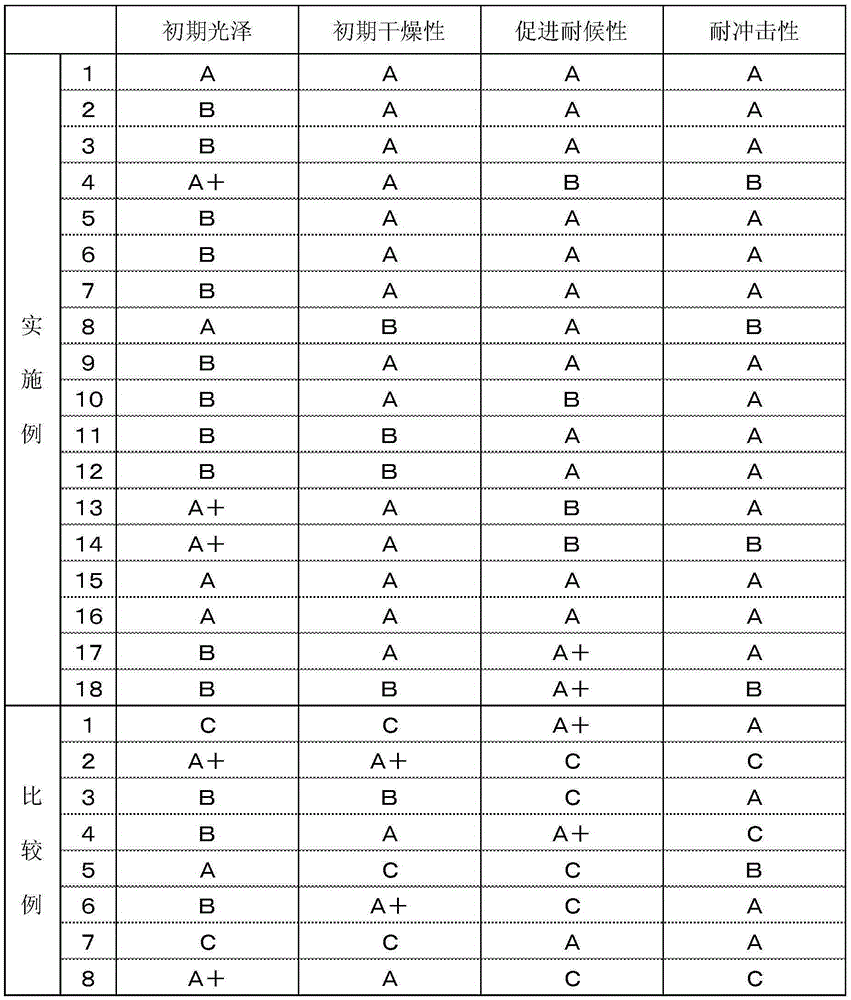

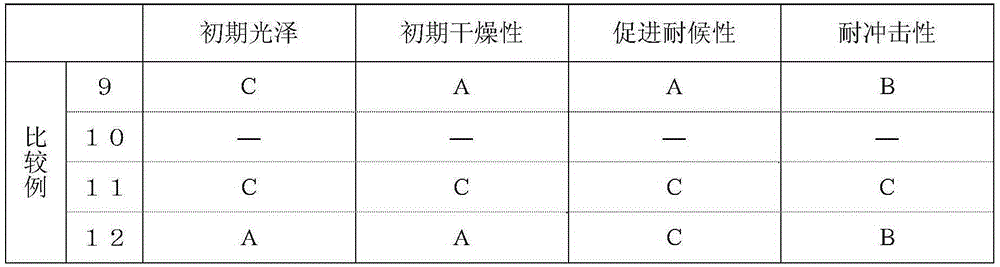

Oxidative curing, alkyd-modified silicone acrylic copolymer

ActiveCN105358607AHigh initial glossMeet the weather resistanceCoatingsAlkoxy groupPolymer chemistry

This oxidative curing, alkyd-modified silicone acrylic copolymer is obtained by reacting (a) an oxidative curing acrylic copolymer, and (b) a silicone having at least a hydroxyl group and / or an alkoxy group. The oxidative curing acrylic copolymer (a) is a copolymer obtained through graft polymerization of a monomer indicated by (a-1) styrenes, (a-2) (meth)acrylic acid esters, and (a-3) predetermined polymerizable unsaturated monomers, to an alkyd resin (c) having an oxidative polymerizable group.

Owner:HARIMA CHEM INC

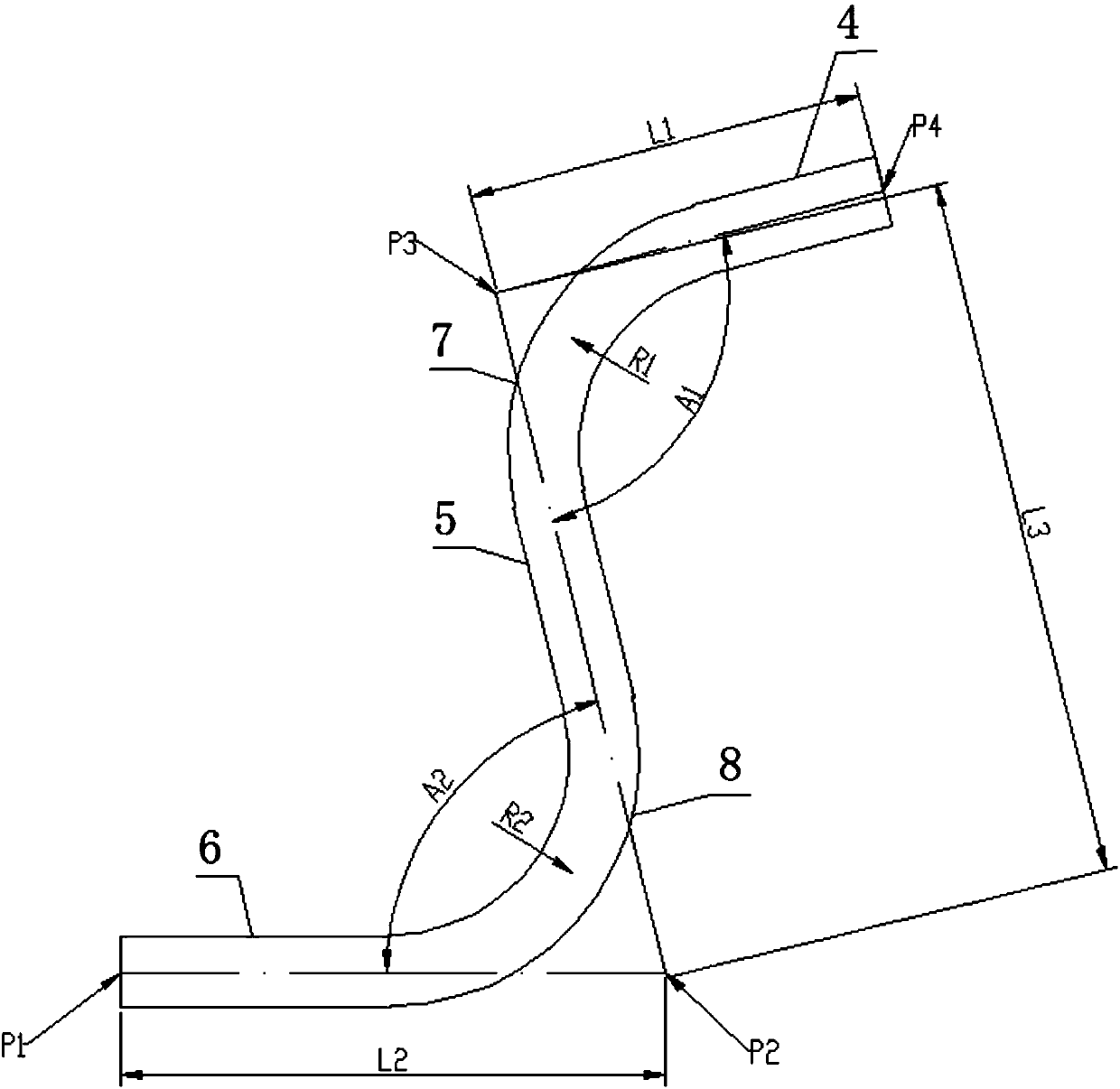

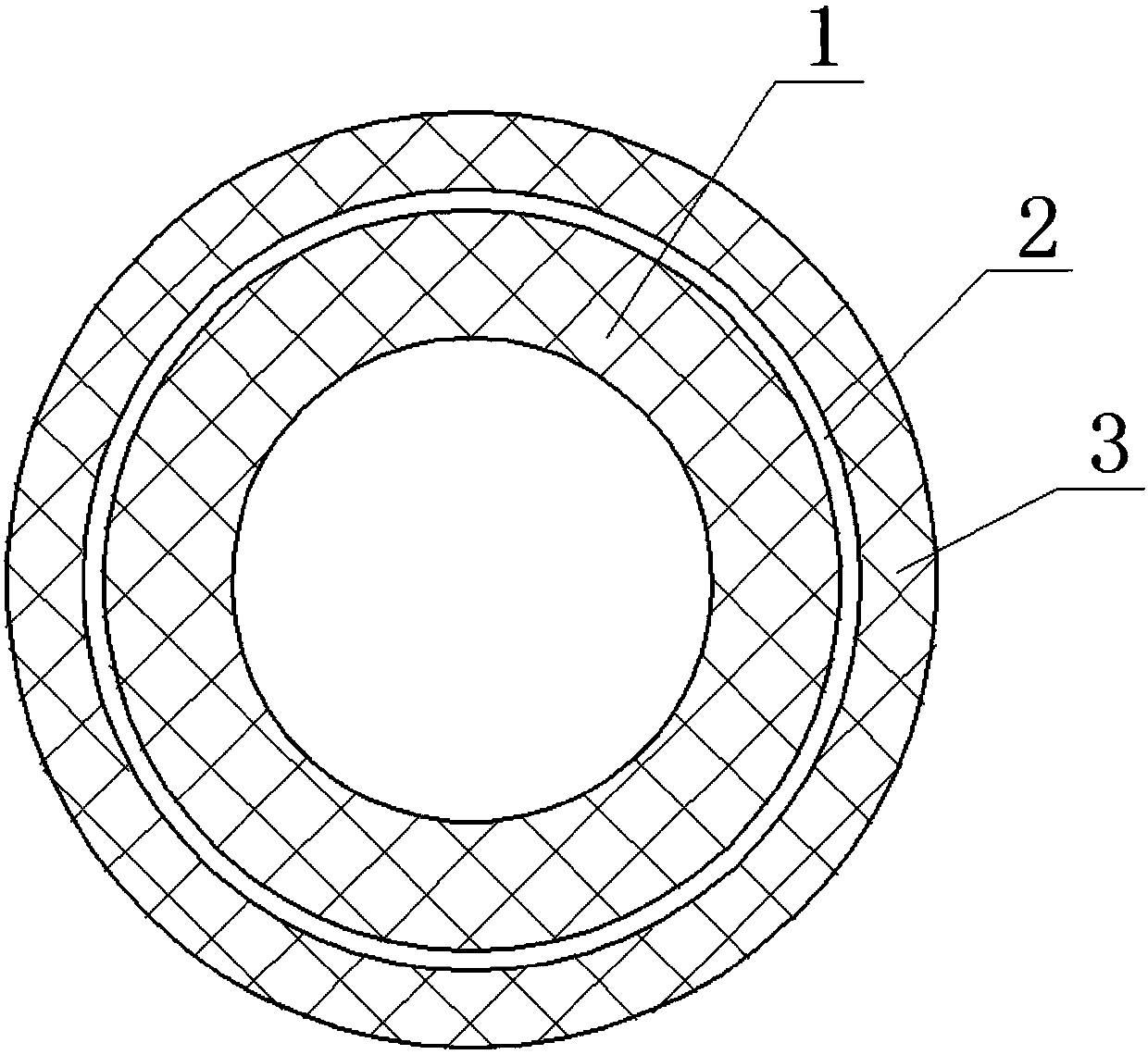

Special-shaped insulation wear-resistant sand spraying rubber flexible pipe

PendingCN107859794AAvoid Axial Twist ProblemsMeet insulationFlexible pipesPipe protection against damage/wearPolyesterWeather resistance

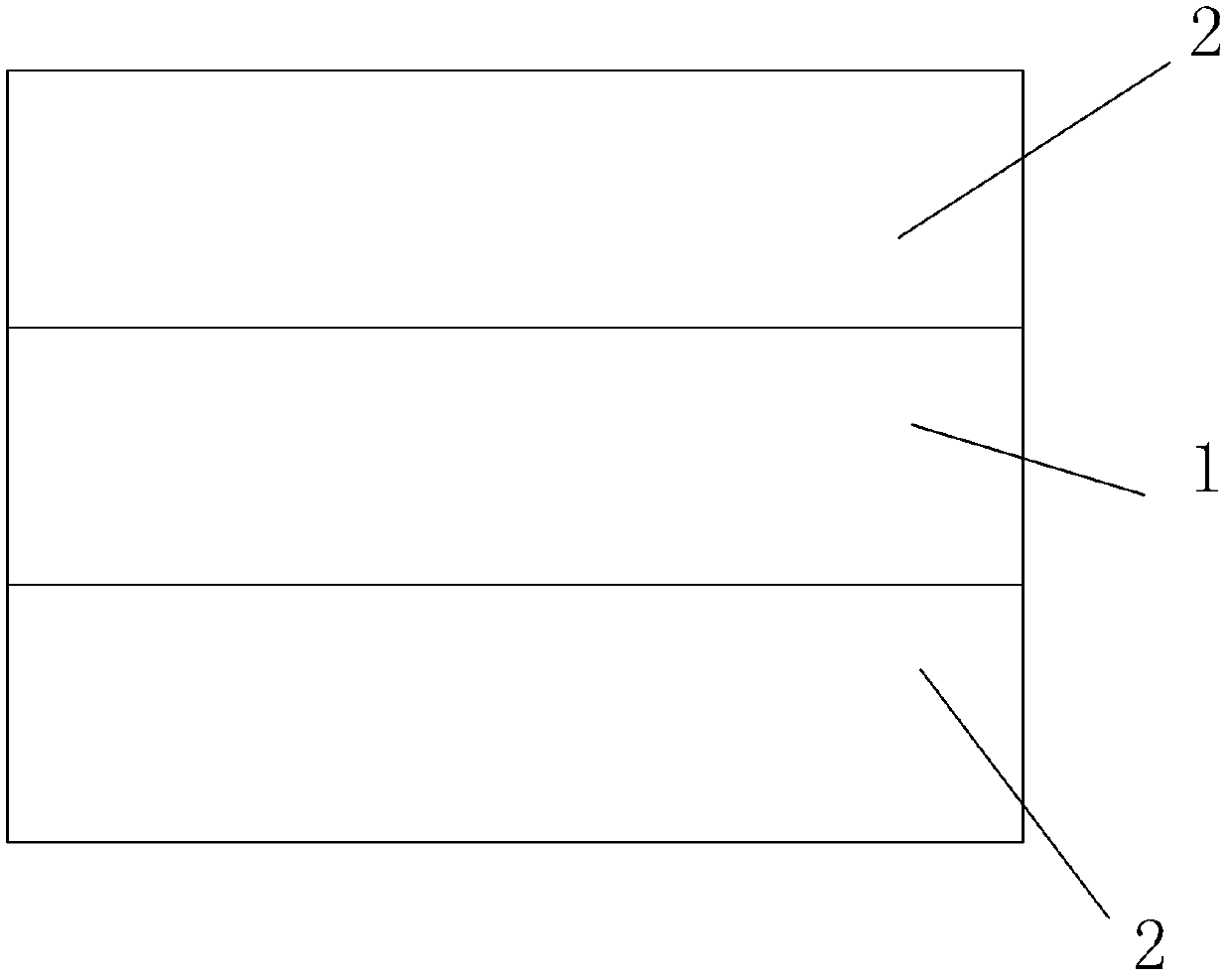

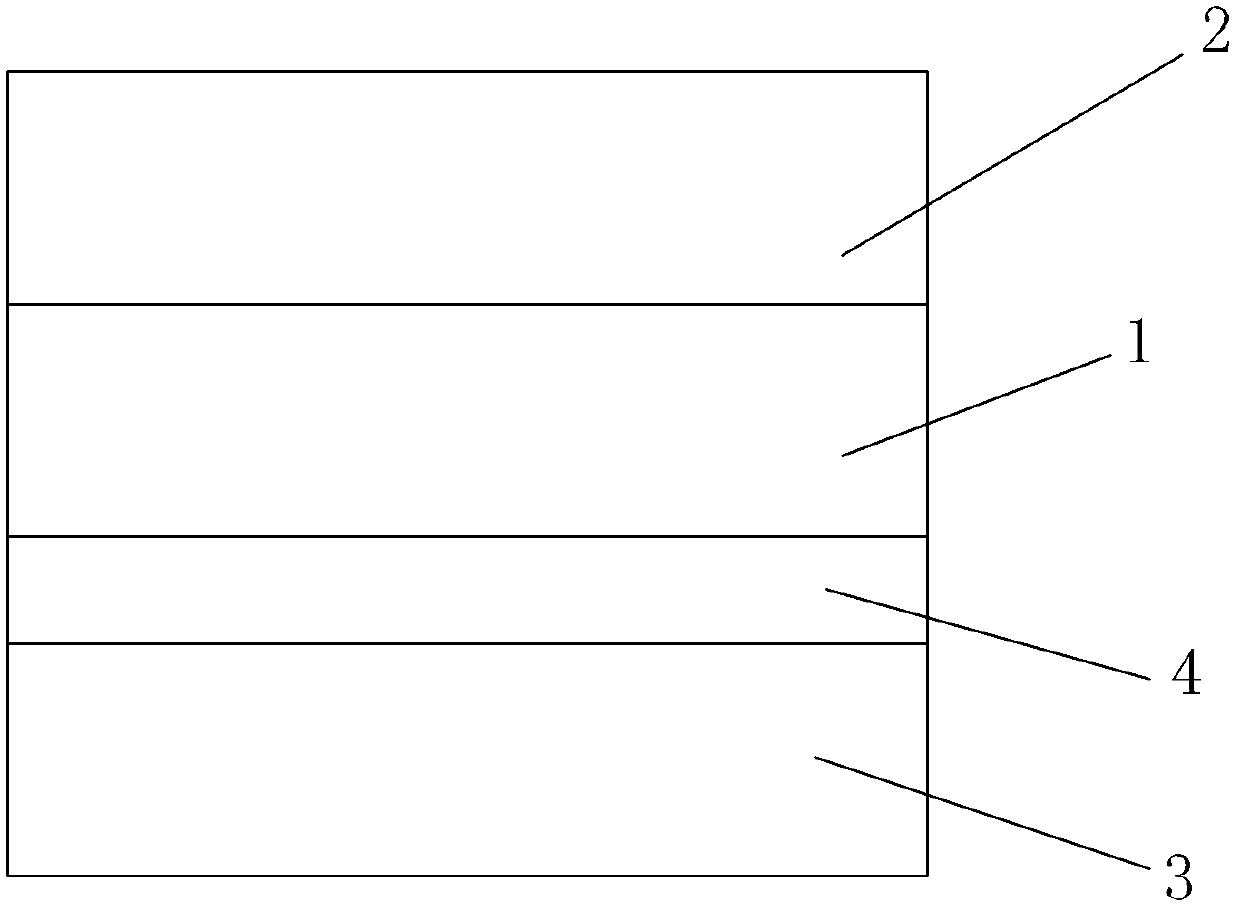

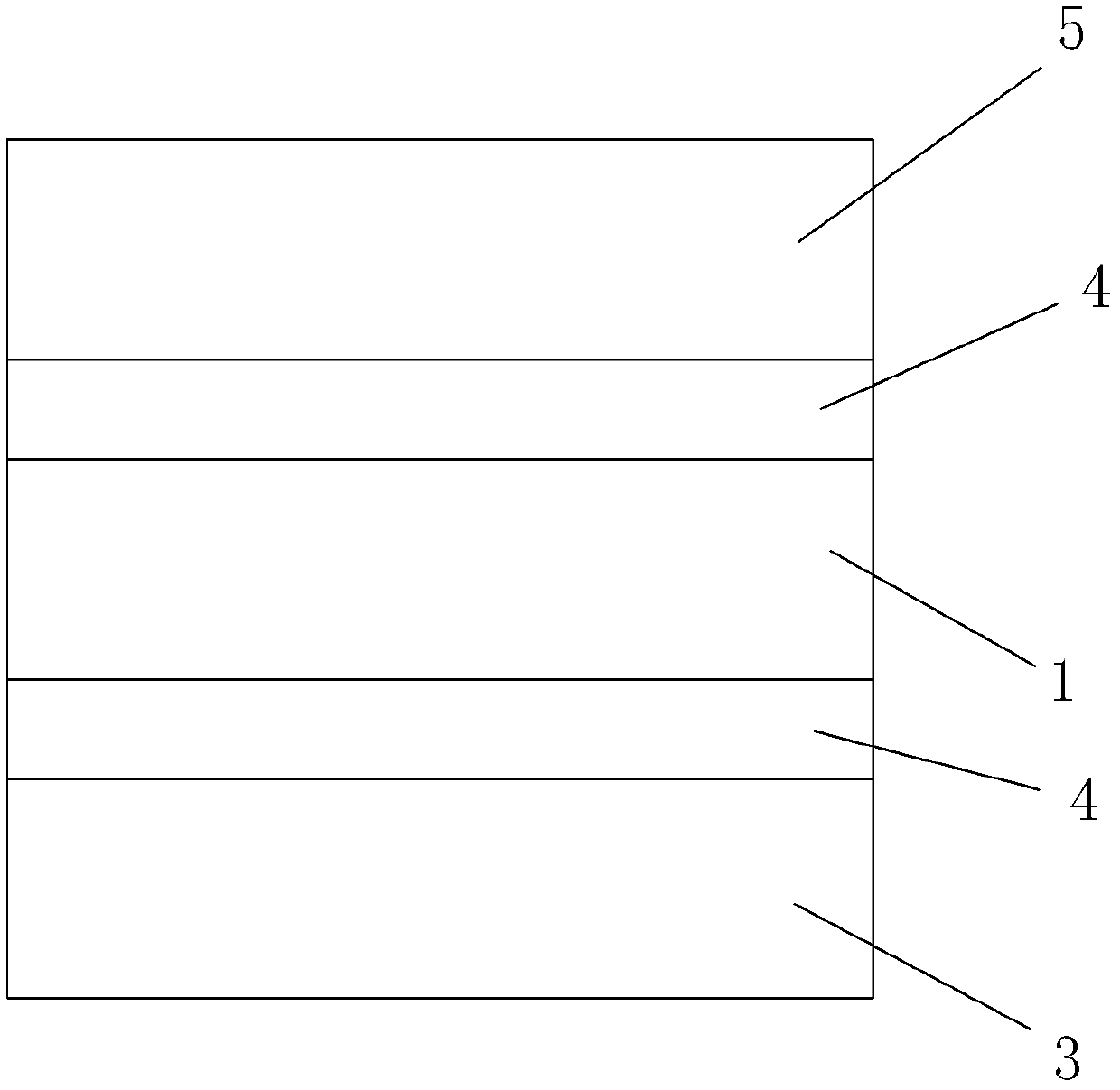

The invention discloses a special-shaped insulation wear-resistant sand spraying rubber flexible pipe. The flexible pipe is composed of an inner rubber layer, a reinforcing layer and an outer rubber layer; the inner rubber layer and the outer rubber layer are made of rubber with good insulation, wear resistance, weather resistance and low-temperature soft performance; the reinforcing layer is madeof fiber materials such as aramid fibers, polyester and vinylon by using winding, knitting or weaving process; the special-shaped sand spraying rubber flexible pipe comprises a first straight pipe section, a second straight pipe section, a third straight pipe section, a first arc section which connects the first straight pipe section and the second straight pipe section and a second arc section which connects the second straight pipe section and the third straight pipe section; the first straight pipe section and the second straight pipe section are correspondingly tangent to the first arc section; and the second straight pipe section and the third straight pipe section are correspondingly tangent to the second arc section. According to the special-shaped insulation wear-resistant sand spraying rubber flexible pipe, the axial twisting force caused by the straight pipe state is effectively avoided, and the rigid pulling force of a rubber pipe and a joint is relieved; and meanwhile, theinstallation direction of the rubber pipe is identified, the installation operation is standardized, and the operation failure rate is effectively reduced.

Owner:NANJING ORIENTLEADER TECH CO LTD

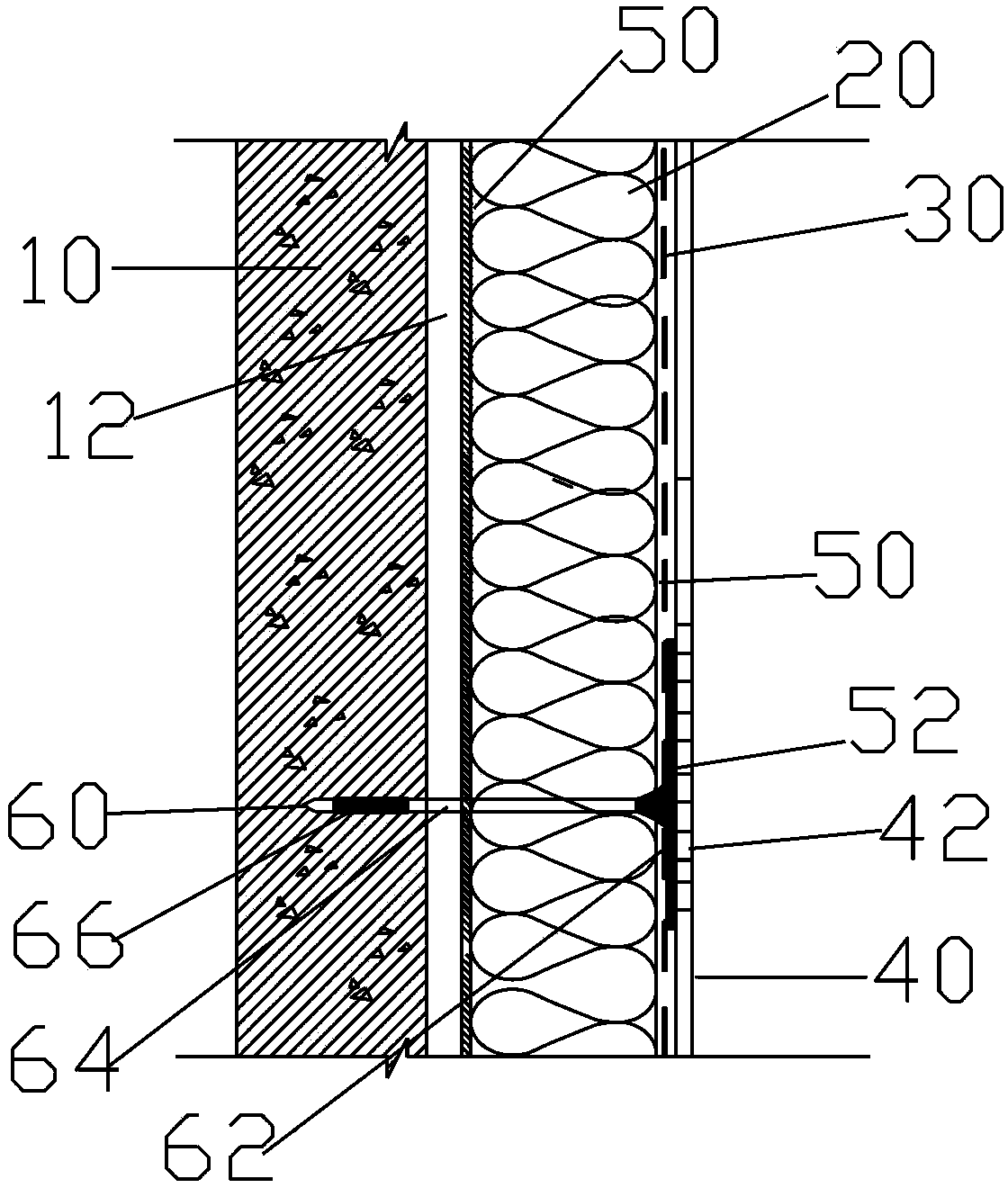

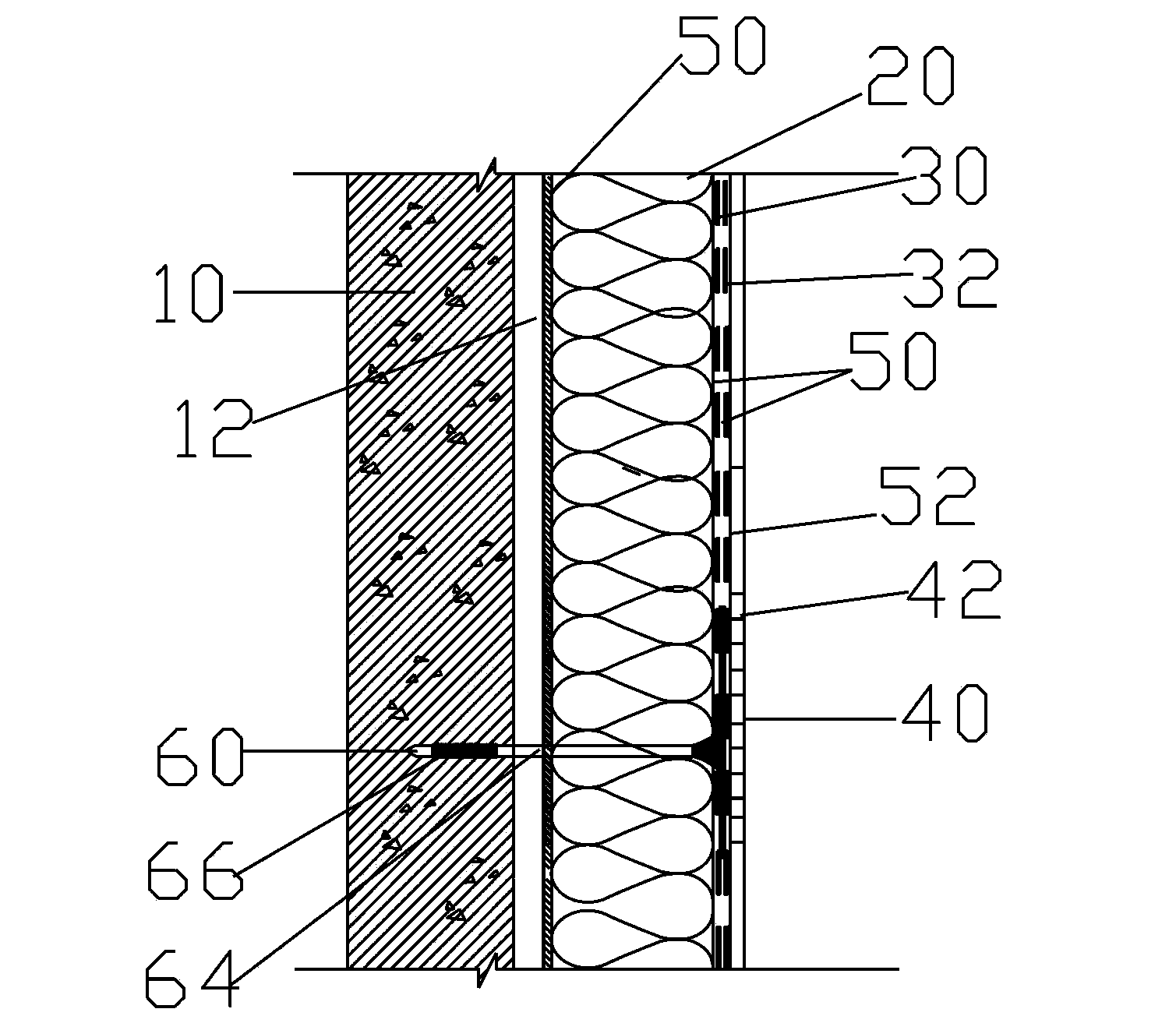

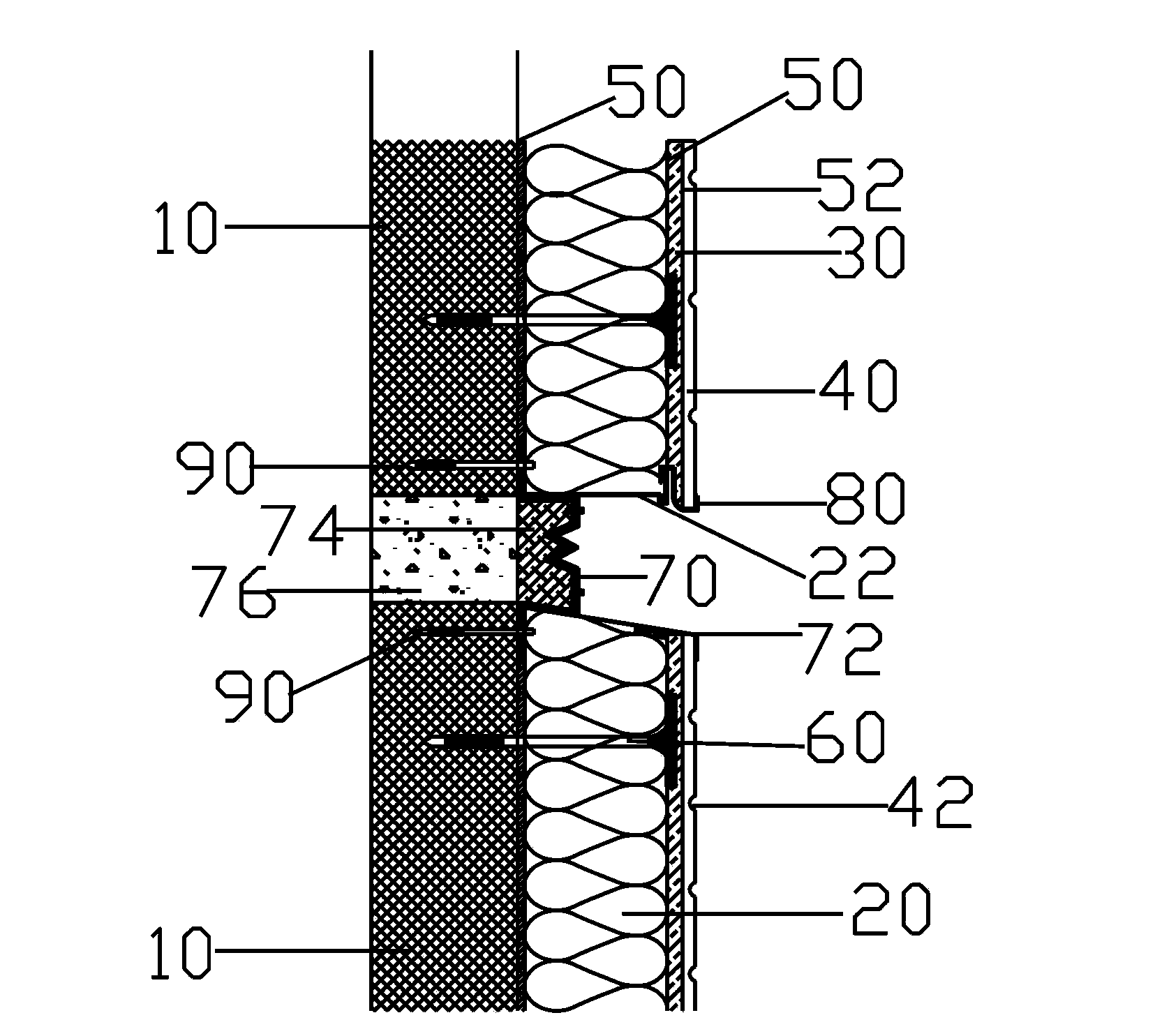

Outer wall system with insulation structure and manufacturing method thereof

InactiveCN103806571AWith thermal insulationWith fire and explosion-proofWallsClimate change adaptationNoise controlInsulation layer

The invention discloses an outer wall system with an insulation structure and a manufacturing method thereof. The system is arranged on the outer side of a substratum wall body, and comprises a plurality of outer wall modules which are separated from one another, wherein each outer wall module comprises rock wool adhered to the substratum wall body, a protection net adhered to the rock wool and a finish coat arranged on the protection net. The two wall body materials, namely the rock wool and the large-mass finish coat are compounded and are matched with special sub-materials for construction, so that the ordinary substratum wall body can have the performance of heat insulation, fire-prevention and explosion proofing, noise control and sound insulation and water-prevention and air permeability. Meanwhile the weather resistance of the insulation layer of the wall body of a building can be guaranteed, the decorating effect of the finish coat of the building can be enriched, and the using range is wide.

Owner:王旭 +2

Forming technology of outdoor epoxy resin composite material product

PendingCN113858539AGood weather resistanceEasy to operateEncapsulation/impregnationEpoxyWeather resistance

The invention discloses a forming technology of an outdoor epoxy resin composite material product. The forming technology comprises the steps that S1, an inner mold is installed, specifically, an iron core and a winding which need to be subjected to insulation packaging are installed in the inner mold to serve as a semi-finished inner container product; S2, curing and forming are conducted on the semi-finished inner container product,inner mold vacuum pouring and automatic pressure gel injection are conducted by adopting an epoxy resin composite material, and curing and forming are conducted in a drying oven to prepare an inner container; S3, the surface of the semi-finished product is cleaned, and a surface release agent is cleaned away; S4, the surface of the semi-finished product is coated with a coupling agent; S5, an outer mold is installed, and the outdoor epoxy resin composite material semi-finished product coated with the coupling agent is installed in the outer mold; and S6, silicone rubber filling and curing forming are conducted. According to the forming technology, the cost is greatly reduced in the industry, the reliability is high, the weather resistance is excellent, the technology efficiency is high, no connection position exists, the electrical property, the waterproofness, the mechanical strength and the like are more reliable, a plurality of molds of a plurality of silicone rubber sheets with different shapes do not need to be manufactured, and only one outer mold is needed.

Owner:GUANGDONG SIHUI INSTR TRANSFORMER WORKS

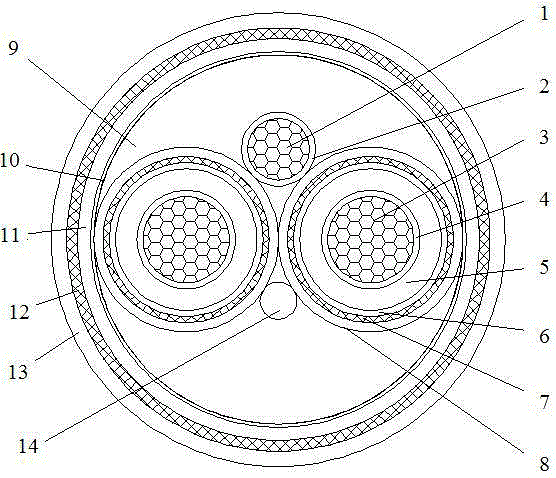

Positive and negative electrodes syncretic optical fiber composite flexible DC medium voltage cable for urban distribution network system

InactiveCN105405497AReduce investmentMeet the weather resistancePlastic/resin/waxes insulatorsFlexible cablesEngineeringFiber-optic communication

The invention discloses a positive and negative electrodes syncretic optical fiber composite flexible DC medium voltage cable for an urban distribution network system. The positive and negative electrodes syncretic optical fiber composite flexible DC medium voltage cable comprises a return cable unit, a polar cable unit and an optical fiber unit, and after the return cable unit, the polar cable unit and the optical fiber unit are formed into the cable, a filling layer, a taped covering, a plastic inner protection layer, a metal armored layer and a plastic outer protection layer are sequentially arranged on an outer layer from inside to outside. The positive and negative electrodes syncretic optical fiber composite flexible DC medium voltage cable disclosed by the invention is safe and reliable in operation, meanwhile can realize power transmission and optical fiber communication and can meet the requirements of relevant regulations, thereby capable of being widely used in novel urban distribution network systems.

Owner:ZHONGTIAN TECH SUBMARINE CABLE CO LTD

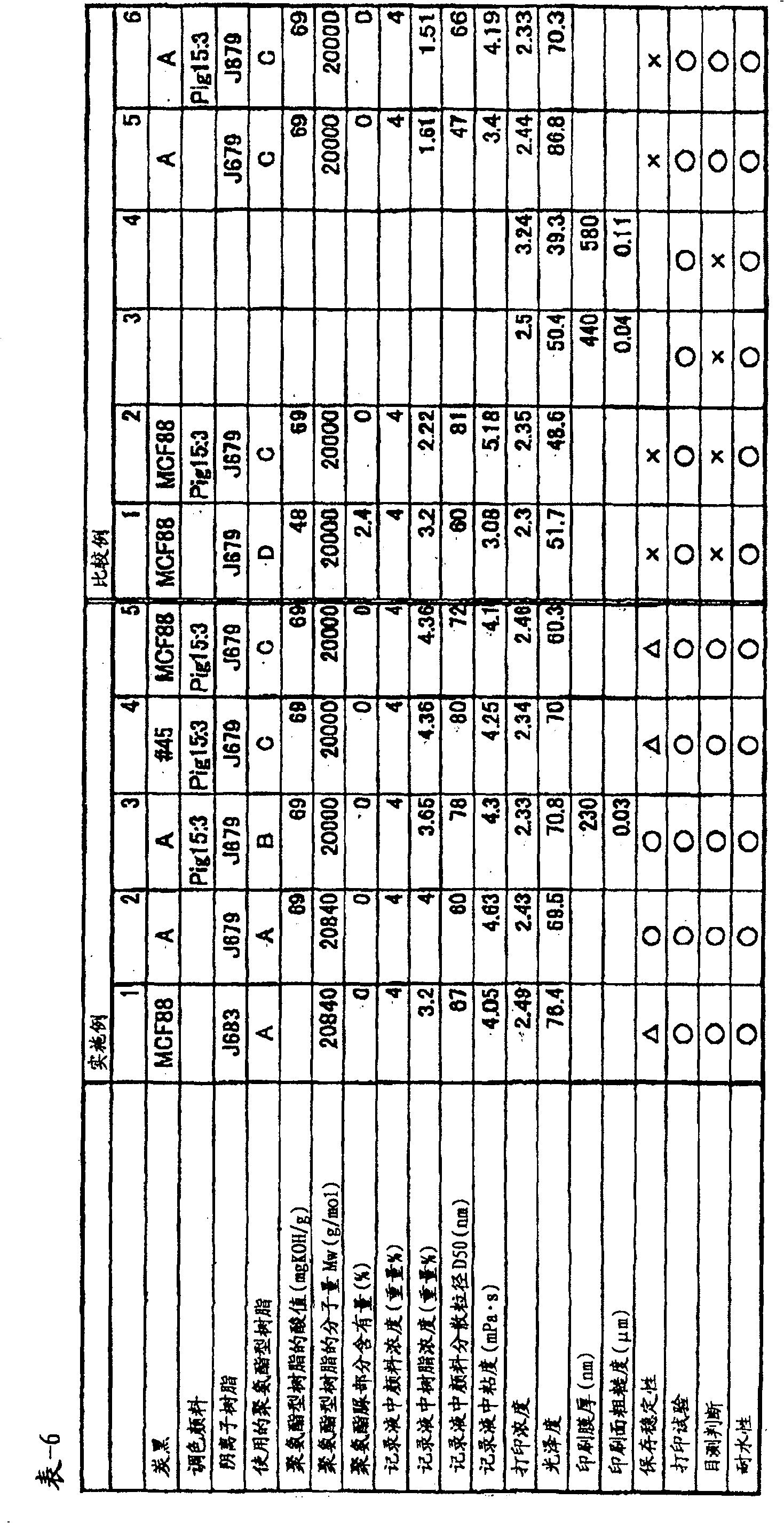

Pigment disperse aqueous recording liquid and printed matter

InactiveCN100562546CHas storage stabilitySatisfy waterproof performanceInksPrintingPolymer sciencePigment dispersion

A pigment-dispersed aqueous recording liquid containing at least a pigment and a resin, characterized in that it contains 60 to 200 parts by weight of a resin relative to 100 parts by weight of a pigment, and at least one of the resins is a water-dispersible polyurethane resin, and the polyurethane The weight proportion of the polyurethane urea part in the type resin is 2.0% by weight or less relative to the polyurethane resin, and the dispersed particle size D50 of the pigment in the recording liquid is 40 to 100 nm.

Owner:SEIKO EPSON CORP +2

Anti-fog solar cell panel back film and preparation method thereof

InactiveCN104385741AInhibition formationReduce the effect of refractionSynthetic resin layered productsLaminationFiberPolyester

The invention discloses an anti-fog solar cell panel back film and a preparation method thereof, and relates to the technical field of solar cell panel back films. The back film is a five-layer structure composite film, and orderly comprises a weather-proof layer, an adhesive layer, a middle layer, an adhesive layer and an easy bonding layer from top to bottom, wherein the weather-proof layer is composed of the following components in parts by mass: 35-55 parts of acrylic monomer, 10-22 parts of acrylic and ether copolymer, 1-3 parts of butyl oleate, 1-3 parts of alkyl calcium salicylate, 1-2 parts of polyoxyethylene ether, 5-9 parts of titanium dioxide, 6-12 parts of polyester fiber, 3-8 parts of a coupling agent and 15-26 parts of solvent. The anti-fog solar cell panel back film disclosed by the invention is good in anti-fog performance, and capable of preventing water drops from forming, thereby reducing the influence of light ray refraction on the solar cell module; and meanwhile, the back film is excellent in weather-proof resistance and barrier property so as to effectively reduce the influence of water on the film layer and the module.

Owner:WUXI SUNOCEAN

Low-temperature curing color coiled material paint and method for preparing same

ActiveCN101531860BSuitable for continuous roller coatingMeet the hardness and toughnessPolyester coatingsLow temperature curingSolvent

Owner:JIANGSU LANLING POLYMER MATERIAL CO LTD

A kind of acrylic resin coating with bottom and surface integrated and preparation method thereof

ActiveCN111286241BMeet the weather resistanceMeet appearance requirementsAnti-corrosive paintsPolyurea/polyurethane coatingsPolymer scienceMeth-

The invention discloses an acrylic resin paint with bottom and surface integrated. The raw material includes component A and component B with a weight ratio of 5-7:1; component A includes 50-70 parts of acrylic resin in parts by weight , 2 to 4 parts of dispersant, 1 to 2 parts of dispersing aid, 20 to 40 parts of pigment and filler, 0.1 to 4 parts of other additives and 5 to 15 parts of solvent; component B includes 65 to 75 parts of hexamethylene Diisocyanate, 25-35 parts of butyl acetate and 0.1-0.5 parts of water-absorbing agent. The coating is based on acrylic resin modified with glycidyl ester of tertiary carbonic acid with specific solid content, viscosity, hydroxyl value and molecular weight of 1600-2000 as the main resin. Requirements, hardness, flexibility, etc., while also achieving lower VOC. At the same time, the bottom-surface-in-one coating can save one spraying process in the construction process, and has no special requirements for construction equipment.

Owner:NIPPON PAINT IND COATINGS SHANGHAI

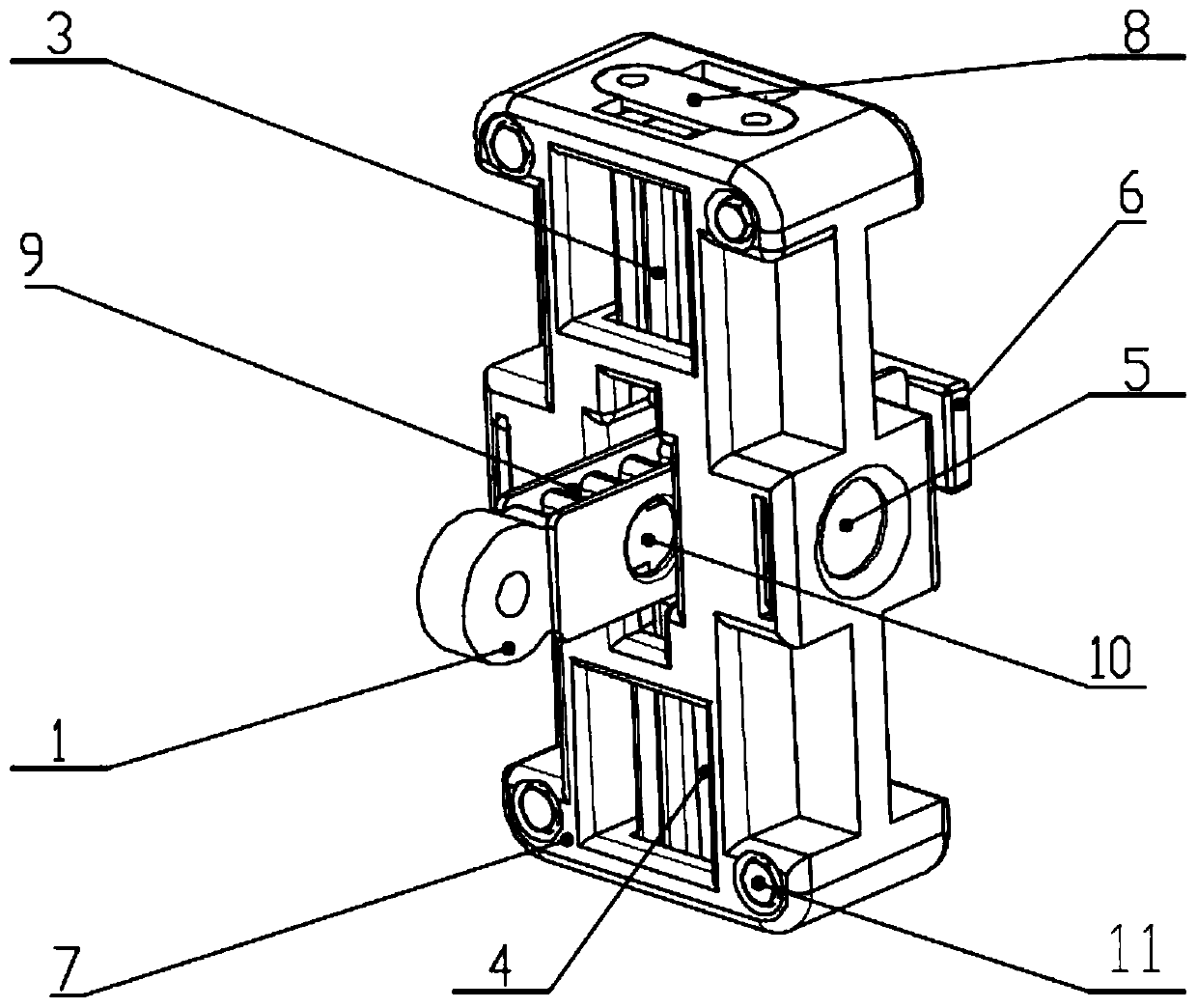

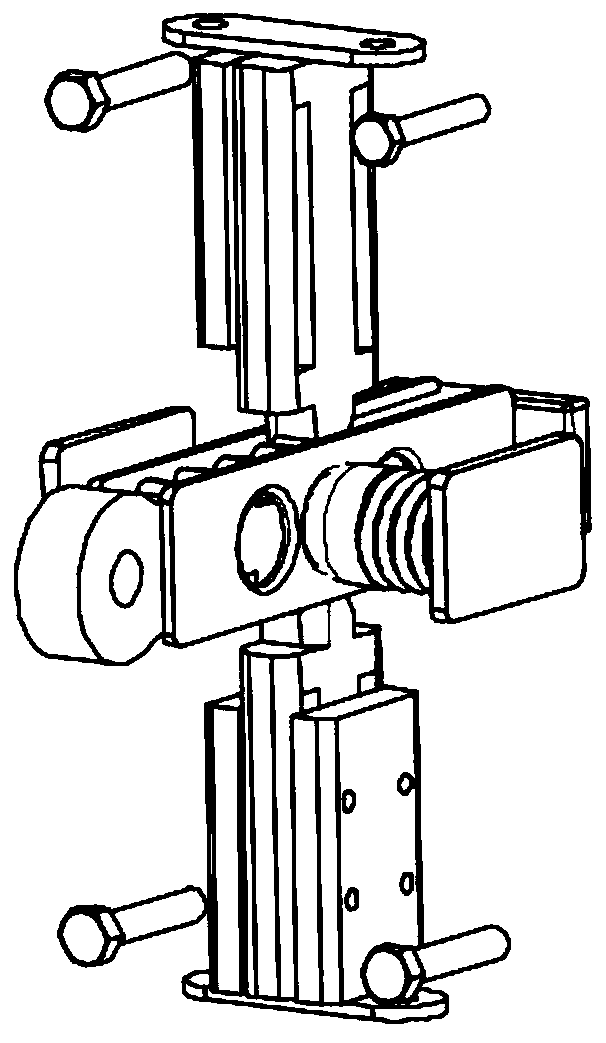

Automobile door limiting device

The invention discloses an automobile door limiting device which comprises a shell, a limiting rod, limiting locks and speed reduction assemblies. The shell is connected with an automobile door through a bolt. The limiting rod penetrates in the shell, one end of the limiting rod is connected with an automobile door pillar, limiting grooves are symmetrically formed in the upper side face and the lower side face of the limiting rod in a concave manner, and speed reduction grooves are symmetrically inwards formed in the left side face and the right side face of the limiting rod in a concave manner. The limiting locks are symmetrically arranged at the positions, on the upper side and the lower side of the limiting rod, in the shell and are matched and connected with the limiting grooves in theupper side face and the lower side face of the limiting rod to limit the limiting rod. The speed reduction assemblies are symmetrically arranged at the positions, on the left side and the right sideof the limiting rod, in the shell and are matched and connected with the speed reduction grooves formed in the left side face and the right side face of the limiting rod to limit the limiting rod. Theproblem that after an automobile driver conducts parking on the roadside, a person in an automobile suddenly opens the door, and if pedestrians or automobiles pass through the opening side in the close range at the moment, colliding is likely to happen is solved.

Owner:ZHEJIANG SCI-TECH UNIV

Exterior wall system with thermal insulation structure and manufacturing method thereof

InactiveCN103806571BWith thermal insulationWith fire and explosion-proofWallsClimate change adaptationNoise controlInsulation layer

The invention discloses an outer wall system with an insulation structure and a manufacturing method thereof. The system is arranged on the outer side of a substratum wall body, and comprises a plurality of outer wall modules which are separated from one another, wherein each outer wall module comprises rock wool adhered to the substratum wall body, a protection net adhered to the rock wool and a finish coat arranged on the protection net. The two wall body materials, namely the rock wool and the large-mass finish coat are compounded and are matched with special sub-materials for construction, so that the ordinary substratum wall body can have the performance of heat insulation, fire-prevention and explosion proofing, noise control and sound insulation and water-prevention and air permeability. Meanwhile the weather resistance of the insulation layer of the wall body of a building can be guaranteed, the decorating effect of the finish coat of the building can be enriched, and the using range is wide.

Owner:王旭 +2

Weather-resistant coating and solar back plate using same

ActiveCN102315285BImprove adhesionMeet the weather resistanceSynthetic resin layered productsPhotovoltaic energy generationThermodynamicsWeather resistance

The invention discloses a weather-resistant coating and a solar back plate using the same. The coating comprises the following components calculated according to weight part: 30-90 parts of weather-resistant resin, 1-5 parts of curing agent, 0.1-5 parts of organic filler, 5-60 parts of inorganic filler and 50-100 parts of solvent. The solar back plate is characterized by comprising an insulated base layer, wherein a weather-resistant coating is arranged on at least one surface of the insulating base layer. The invention aims at overcoming the defects in the prior art and provides the weather-resistant coating which can be directly coated on the insulating substrate and has excellent binding power and weather resistance meeting the requirement of service life with more than 25 years of thesolar module; and the invention also has another aim of providing the solar back plate manufactured by adopting the weather-resistant coating.

Owner:ALLSTAE TECH ZHONGSHAN

High-toughness gas-shielded welding wire for long-life weathering steel structure and preparation method thereof

ActiveCN108015451BWeather resistantMeet the weather resistanceWelding/cutting media/materialsSoldering mediaMechanical propertyWeathering steel

Provided are a high-toughness gas shielded welding wire for a long-life weathering steel structure and a preparation method of the high-toughness gas shielded welding wire. The chemical components ofthe welding wire comprise, by mass percent, 0.04-0.08 % of C, 0.40-0.60 % of Si, 1.10-1.40 % of Mn, being less than or equal to 0.010 % of P, being less than or equal to 0.006 % of S, 0.25-0.45 % of Cr, 0.10-0.25 % of Mo, 0.25-0.40 % of Cu, 1.00-1.30 % of Ni, 0.01-0.03 % of Ti, 0.004-0.008 % of O, being less than or equal to 0.30 % of the sum of unavoidable impurity elements, and the balance Fe. Through the technical scheme of scientific proportioning of the chemical components of the welding wire, the welding performance is stable, and the obtained deposited metal not only has good comprehensive mechanical properties but also has excellent corrosion resistance and low temperature impact toughness. According to the preparation method, the manufacturing process is stable, and the percent ofpass is high.

Owner:SICHUAN XIYE NEW MATERIAL

Wear-resistant and low-cracking possibility football fabric and preparation method thereof

The invention discloses a wear-resistant and low-cracking possibility football fabric. The football fabric is prepared from thermoplastic urethane elastomer rubber, neoprene, polyisoprene rubber, benzoyl peroxide, dicumyl peroxide, butyl epoxyoctadecanoate, calcium lignosulfonate, sodium lauryl sulfate phenol, mica powder, modified basalt fibers, nanometer aluminum hydroxide, benzophenone, polyethersulfone, white carbon black, perchlorocyclopentane, melamine polyphosphate, an antioxidant, zinc borate and an antiager. The invention discloses a preparation method of the wear-resistant and low-cracking possibility football fabric. The wear-resistant and low-cracking possibility football fabric can satisfy football material requirements on weatherability, flame retardancy, thermal stability and corrosion resistance, has good abrasion resistance and toughness, is not easy to crack during use, prolongs a service life of a football and has a wide market prospect.

Owner:丁燕飞

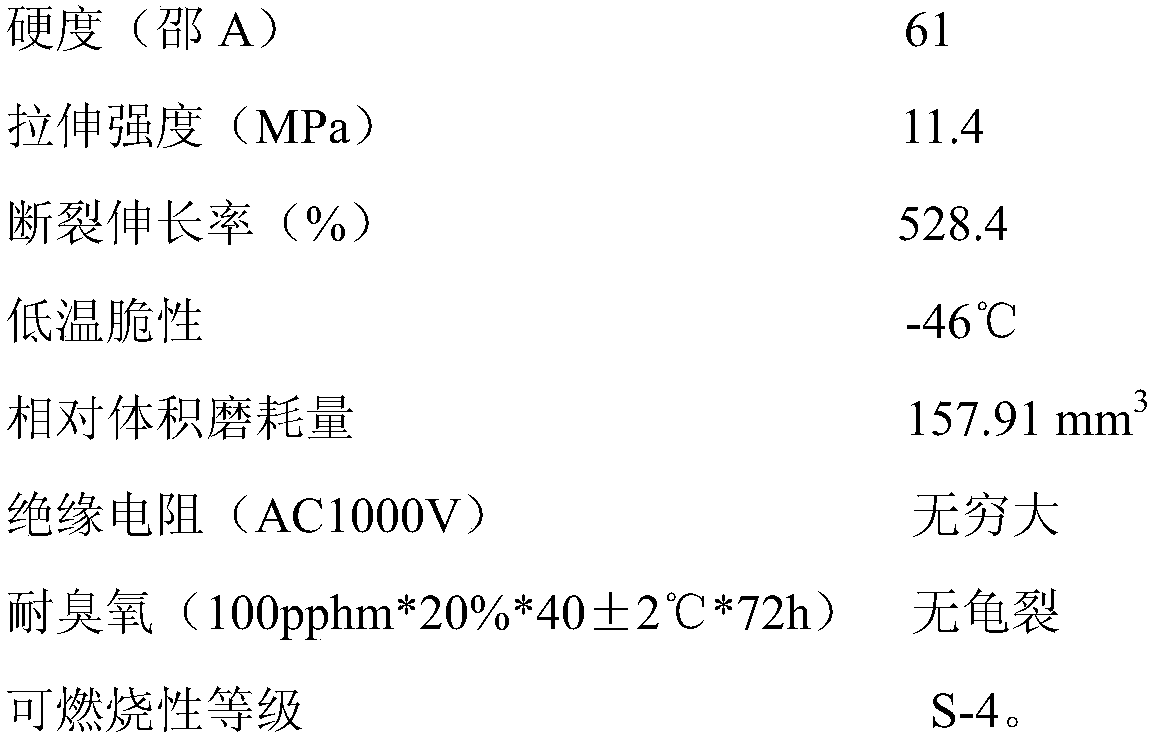

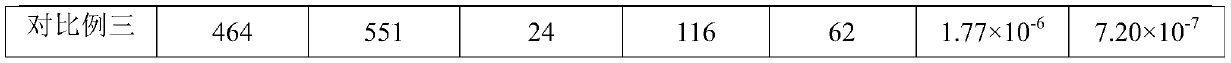

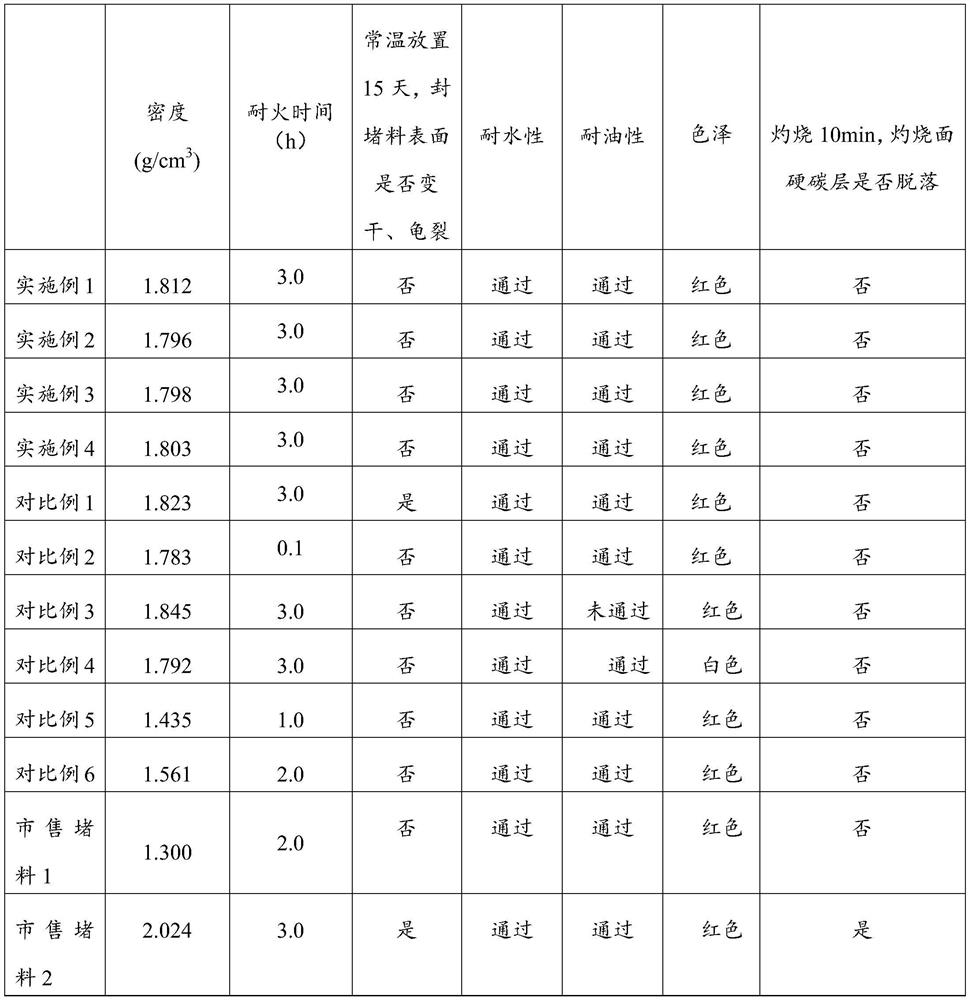

A kind of fireproof blocking material and preparation method thereof

The invention provides a fireproof blocking material and a preparation method thereof. The raw materials for the preparation of the fireproof blockage include styrene-ethylene-butadiene-styrene block copolymer, chloroprene rubber, chlorinated paraffin, dolomite powder, silicon micropowder, antioxidant and iron oxide red. The fireproof blockage provided by the invention improves the fire resistance of the fireproof blockage and at the same time does not fall off when burning, maintains the durability of fire resistance and reduces the cost of the fireproof blockage. Good moisture and heat resistance, long fire-resistant time. The density is light, the viscosity is better, no heating is needed during use, and it can be directly kneaded for sealing. Meet high fire resistance (≥3.00h). Meet the weather resistance performance, which is embodied in the water resistance (≥3d) and oil resistance (≥3d) of the organic fireproof blockage.

Owner:长沙长缆电工绝缘材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com