A kind of acrylic resin coating with bottom and surface integrated and preparation method thereof

A technology of acrylic resin and paint, which is applied in the direction of anti-corrosion paint, polyurea/polyurethane paint, coating, etc. It can solve the problems of many construction workers, large capital investment, and long construction line, so as to reduce the pressure of VOC investment, Effect of reducing spraying process and satisfying weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

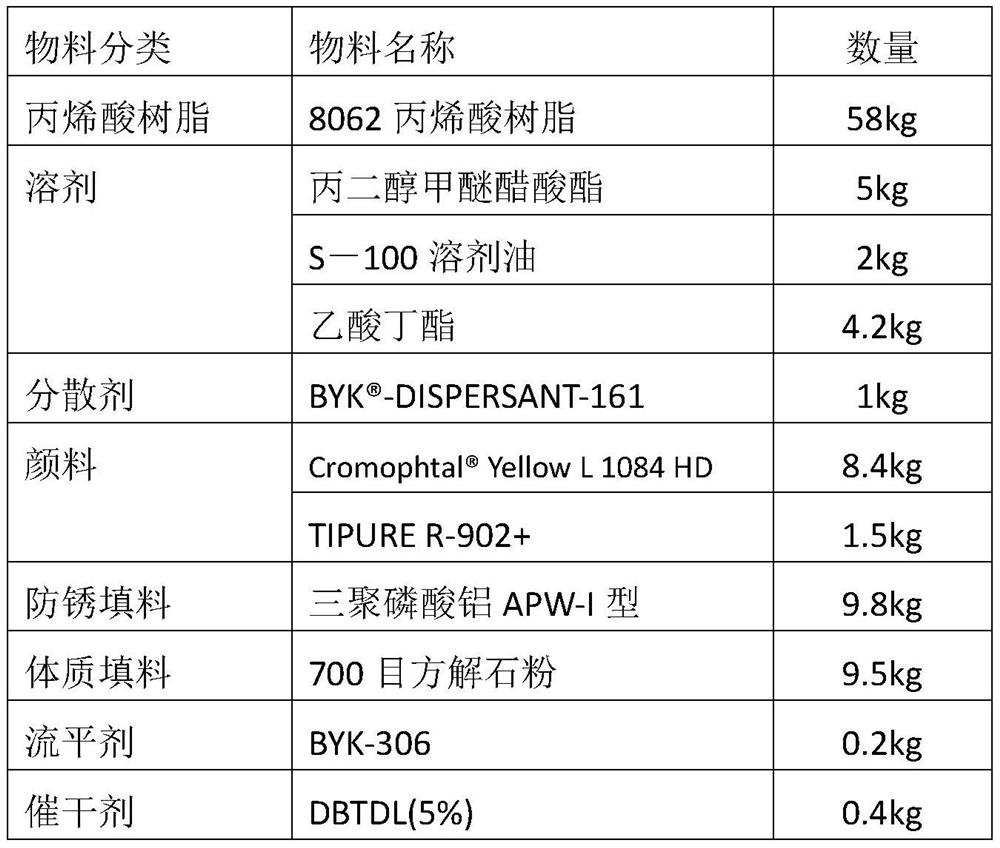

preparation example Construction

[0035] The present invention also provides a preparation method of the acrylic resin coating with the above-mentioned bottom surface integrated, comprising:

[0036] S1: Mix 50-70 parts of acrylic resin, 2-4 parts of dispersant, 1-2 parts of dispersing aid, and 5-11 parts of solvent, stir at 400-600 rpm for 10-15 minutes; then add 20-40 parts of pigment Filler, stir at 600-800rpm for 10-15min; continue to add 1-4 parts of solvent and stir until uniformly mixed, use a sand mill to grind to a suitable fineness; add 0.1-4 parts of other additives, stir until uniformly mixed to obtain Group A Minute;

[0037] S2: Mix 65-75 parts of hexamethylene diisocyanate, 25-35 parts of butyl acetate and 0.1-0.5 parts of water-absorbing agent to obtain component B;

[0038] S3: Mix component A and component B uniformly according to the weight ratio of 5-7:1 to obtain an acrylic resin coating with bottom and surface integrated.

[0039] In the preparation process, the organic solvent is added...

Embodiment 1

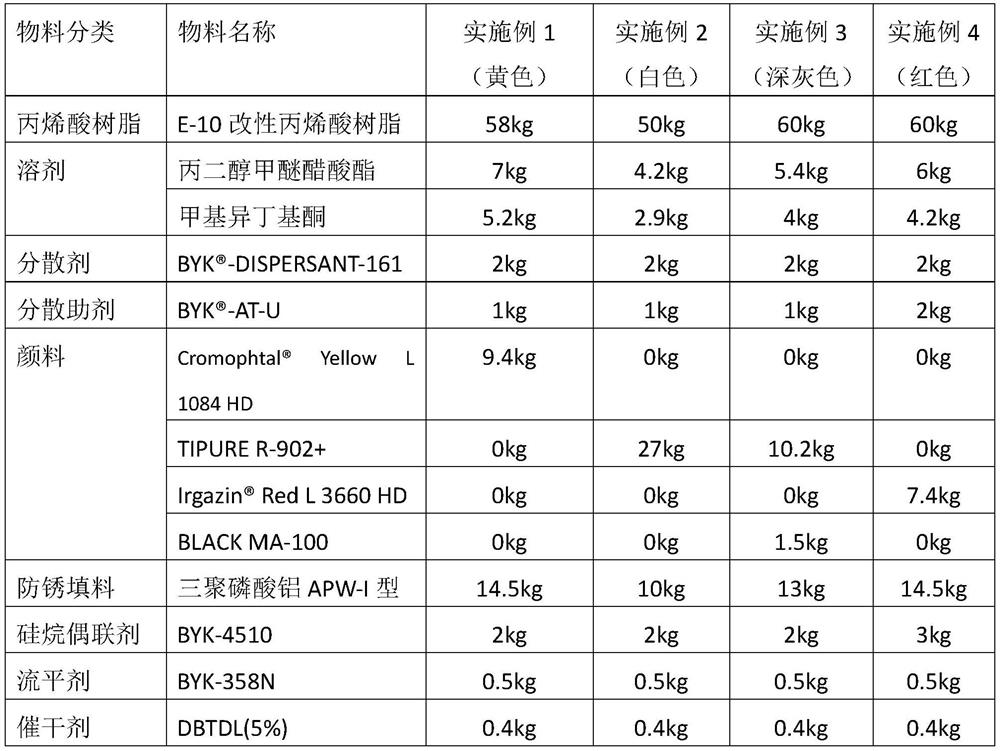

[0047] Preparation of yellow base-surface-in-one acrylic paint

[0048] S1: Add 58kg of acrylic resin, 5.2kg of propylene glycol methyl ether acetate, 5.2kg of methyl isobutyl ketone, 2kg of dispersant, and 1kg of dispersing aid into a suitable container, and stir (400-600rpm) for 10-15 minutes;

[0049] Add 9.4kg of yellow pigment and 14.5kg of anti-rust pigment while stirring. After adding, stir (600-800rpm) for 10-15 minutes;

[0050] Add 1.8kg propylene glycol methyl ether acetate along the container wall while stirring, and continue to stir for 15 minutes until uniform; start grinding and dispersing on the designated sand mill until the fineness meets the requirements;

[0051] During stirring (400-600rpm), add 2kg of silane coupling agent, 0.5kg of leveling agent, and 0.4kg of drier, and then stir (400-600rpm) for 15 minutes until completely uniform to obtain component A.

[0052] S2: 70kg of hexamethylene diisocyanate, 29.5kg of butyl acetate and 0.5kg of water-absorbi...

Embodiment 2-3

[0056] The raw material composition table of the coating prepared in Example 2-3 is shown in Table 1, and its preparation process is basically the same as that of Example 1.

[0057] The molecular weight of the E-10 modified acrylic resin in Example 2-3 is 1800, the solid content is 75%, the viscosity is 6 Pa.S, and the hydroxyl value is 120 mgKOH / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com