A kind of fireproof blocking material and preparation method thereof

A technology for fire blocking materials and raw materials, applied in the field of fire protection products, can solve the problems of high density of fire blocking materials, loose blocking, easy burning and cracking, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

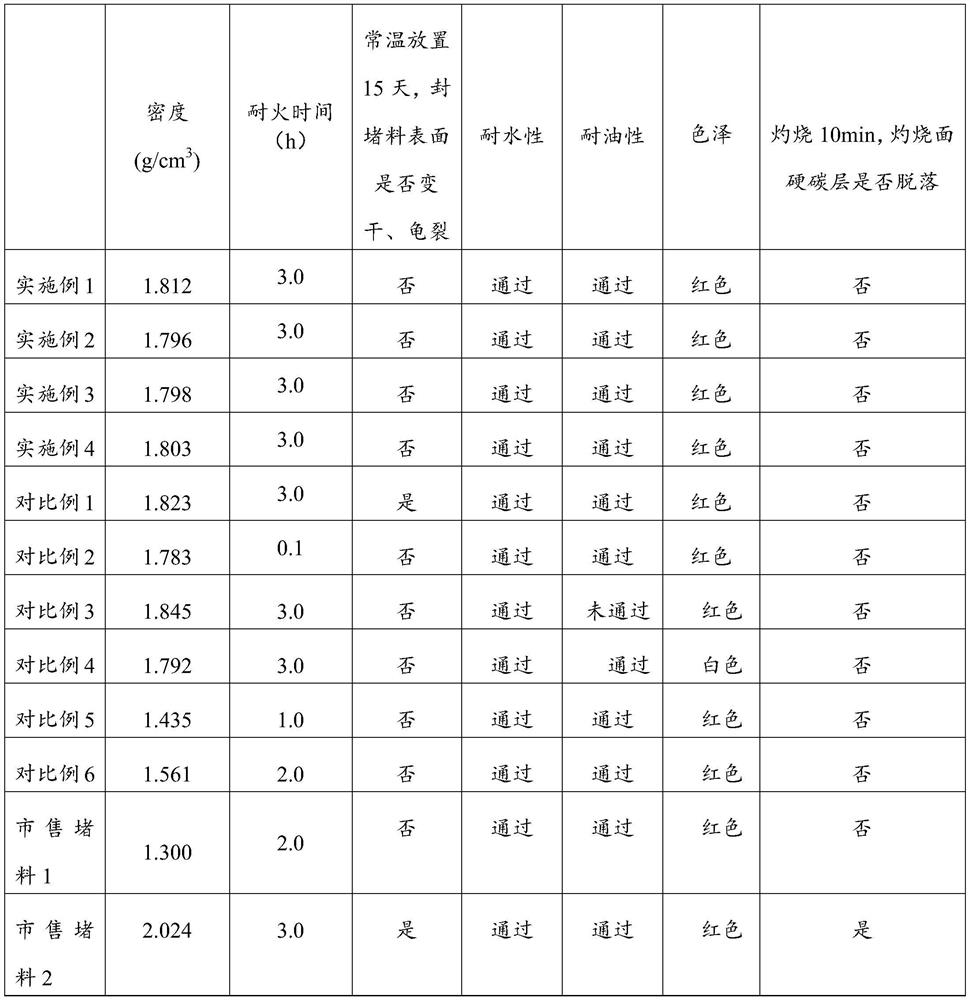

Examples

Embodiment 1

[0037] In this example, a kind of fireproof blocking material is prepared, the specific raw materials and process are as follows:

[0038] S1: Mix 6 parts of SEBS (molecular weight: 70,000, brand YH-501) and 3 parts of CR2442 neoprene in an open mill. Among them, when mixing, the mixed rubber of the organic fireproof blockage should be mixed for 15 minutes in an open mill heated to 120°C, and then rolled into sheets;

[0039] S2: Put the mixed rubber in step S1 into a kneader at a temperature of 130° C., add 4 parts of antioxidant 264 and 26 parts of CP52 chlorinated paraffin and knead for 10 minutes;

[0040] S3: Add 36 parts of dolomite powder, 20 parts of silicon micropowder, and 5 parts of precipitated iron oxide red in sequence, and continue kneading for 30 minutes. After mixing, turn over the kneader hopper to discharge, and lower the fireproof plugging material into strips. After 24 hours of storage, samples were prepared for testing.

Embodiment 2

[0042] In this example, a kind of fireproof blocking material is prepared, the specific raw materials and process are as follows:

[0043] S1: Blend 7 parts of SEBS (molecular weight: 100,000, brand YH-502), 1 part of CR2442 neoprene rubber, and 2 parts of CR2441 neoprene rubber in an open mill. Among them, when mixing, the mixed rubber of the organic fireproof blockage should be mixed for 17 minutes in an open mill heated to 125°C, and then rolled into flakes;

[0044] S2: Put the mixed rubber in step S1 into a kneader at a temperature of 125° C., add 4 parts of antioxidant 264 and 24 parts of CP52 chlorinated paraffin and knead for 10 minutes;

[0045] S3: Add 34 parts of dolomite powder, 24 parts of silicon micropowder, and 4 parts of precipitated iron oxide red in sequence, and continue kneading for 30 minutes. After mixing, turn over the hopper of the kneader to discharge, and lower the fireproof plugging material into strips. After 24 hours of storage, samples were prep...

Embodiment 3

[0047] In this example, a kind of fireproof blocking material is prepared, the specific raw materials and process are as follows:

[0048] S1: Blend 6 parts of SEBS (molecular weight: 220,000, brand YH-503) and 4 parts of CR2441 neoprene in an open mill. Among them, when mixing, the mixed rubber of the organic fireproof blockage should be mixed for 20 minutes in an open mill heated to 125°C, and then rolled into flakes;

[0049] S2: Put the mixed rubber in step S1 into a kneader at a temperature of 120° C., add 3 parts of antioxidant 1010, 1 part of tris(nonylphenyl) phosphite (TNP), and 24 parts of CP42 chlorinated paraffin and knead for 10 minutes;

[0050] S3: Add 34 parts of dolomite powder, 24 parts of silicon micropowder, and 4 parts of precipitated iron oxide red in sequence, and continue kneading for 30 minutes. After mixing, turn over the hopper of the kneader to discharge the material, and lower the fireproof sealing material into strips. After 24 hours of storage,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com