Weather-resistant coating and solar back plate using same

A solar backplane and weather resistance technology, applied in the field of solar backplanes, can solve the problems of low bonding strength, complicated processing technology, and high cost

Active Publication Date: 2012-01-11

ALLSTAE TECH ZHONGSHAN

View PDF5 Cites 44 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

For the backsheet produced by the traditional process, if both sides are made of fluoropolymer film, adhesive layers are required on both sides, the processing technology is complicated, and the cost is too high, which is not conducive to the promotion of solar power generation in the civilian market, and the fluoropolymer film and modules The bonding strength of the packaging adhesive film EVA is small; if the fluoropolymer film is attached to one side and the PE film or EVA film is attached to the other side, adhesive layers are required on both sides, and the processing technology is complicated, the cost is too high, and the PE film Film or EVA film has poor aging resistance and cannot meet the requirements of solar modules with a service life of more than 25 years

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0027] The weather-resistant coating of the present invention consists of the following components by weight:

[0028]

Embodiment 2

[0030] The weather-resistant coating of the present invention consists of the following components by weight:

[0031]

Embodiment 3

[0033] The weather-resistant coating of the present invention consists of the following components by weight:

[0034]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

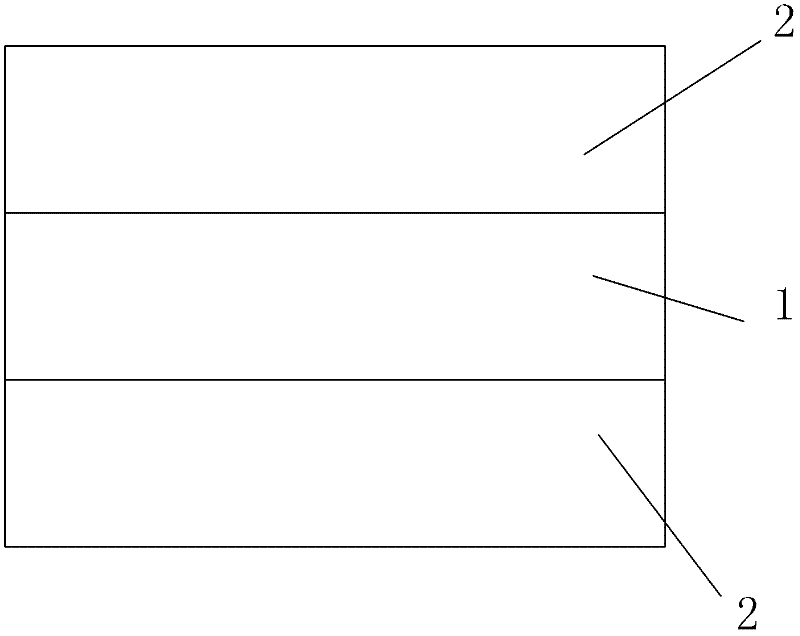

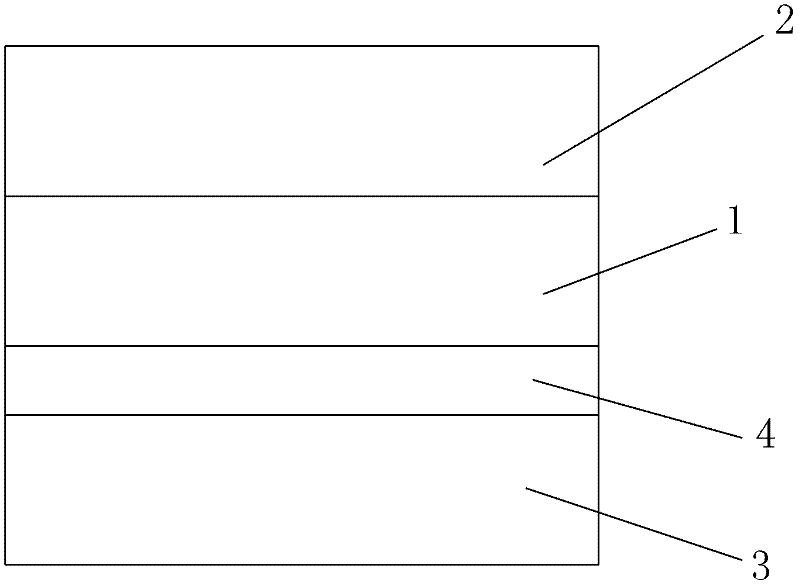

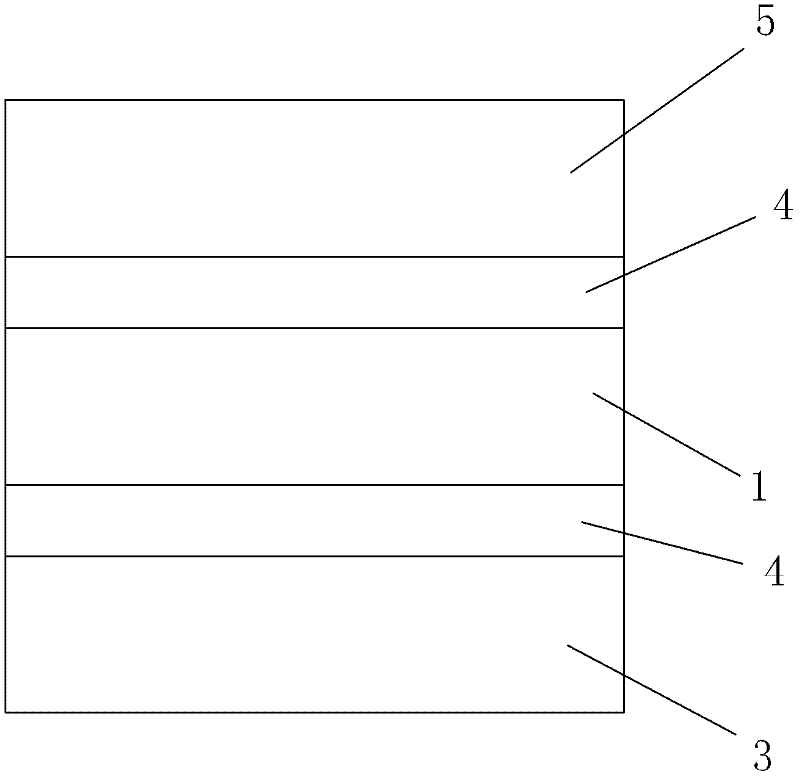

The invention discloses a weather-resistant coating and a solar back plate using the same. The coating comprises the following components calculated according to weight part: 30-90 parts of weather-resistant resin, 1-5 parts of curing agent, 0.1-5 parts of organic filler, 5-60 parts of inorganic filler and 50-100 parts of solvent. The solar back plate is characterized by comprising an insulated base layer, wherein a weather-resistant coating is arranged on at least one surface of the insulating base layer. The invention aims at overcoming the defects in the prior art and provides the weather-resistant coating which can be directly coated on the insulating substrate and has excellent binding power and weather resistance meeting the requirement of service life with more than 25 years of thesolar module; and the invention also has another aim of providing the solar back plate manufactured by adopting the weather-resistant coating.

Description

technical field [0001] The invention relates to a weather-resistant coating, and also relates to a solar backboard made of the weather-resistant coating. Background technique [0002] As a green alternative to traditional methods of electricity production, photovoltaic cell modules are used to generate electricity from sunlight. Photovoltaic cell modules are assembled from various semiconductor component systems and must be protected to mitigate the impact and damage of environmental effects such as moisture, oxygen and ultraviolet rays. Photovoltaic cell modules usually adopt a structure in which glass or plastic film protection layers are laminated on both sides of the silicon wafer. The plastic film protective layer is a composite material composed of an insulating film and a weather-resistant film or a weather-resistant coating, also known as a solar backplane. [0003] The traditional backsheet production method is to paste the pre-manufactured fluoropolymer film, PE ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01L31/0216H01L31/048B32B27/08B32B27/18

CPCY02E10/50

Inventor 张家骥刘沛然黄素锦卢会敏

Owner ALLSTAE TECH ZHONGSHAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com