High-toughness gas shielded welding wire for long-life weathering steel structure and preparation method of high-toughness gas shielded welding wire

A weather-resistant steel and long-life technology, applied in the field of high-toughness gas-shielded welding wire and its preparation, can solve the problem that impact toughness, corrosion resistance and low-temperature impact toughness cannot meet the requirements of long life, large-parameter high-speed trains, and long-term Long life, excellent corrosion resistance, low temperature impact toughness, and easy control are achieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

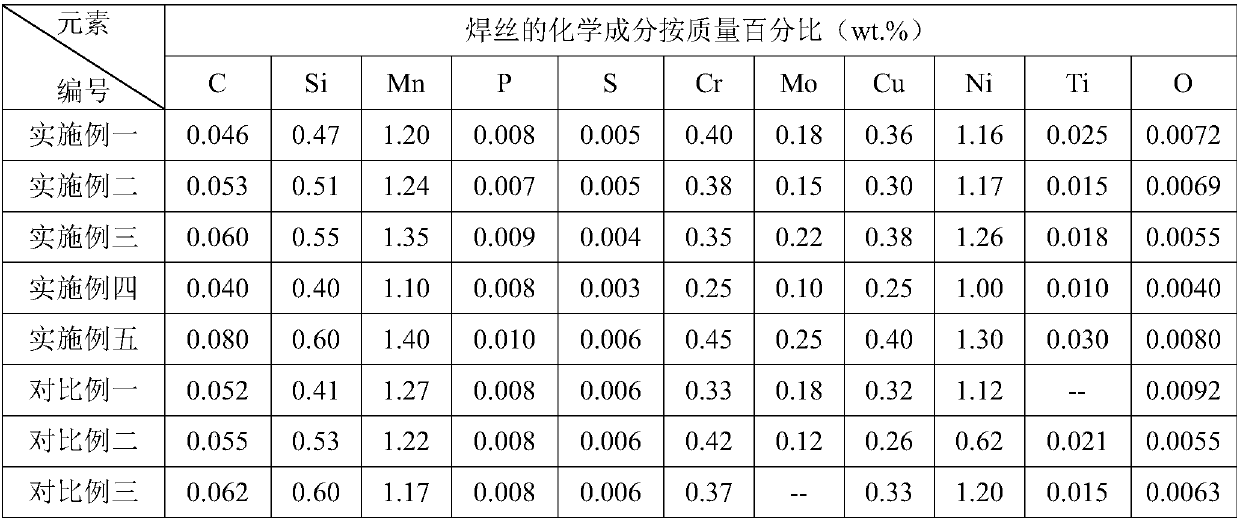

Embodiment 1

[0036] A high-toughness gas-shielded welding wire for long-life weather-resistant steel structures. The chemical composition of the welding wire is: C: 0.046wt.%, Si: 0.47wt.%, Mn: 1.20wt.%, P: 0.008wt.%, S: 0.005wt.%, Cr: 0.40wt.%, Mo: 0.18wt.%, Cu: 0.36wt.%, Ni: 1.16wt.%, Ti: 0.025wt.%, O: 0.0072 wt.%, the sum of unavoidable impurity elements ≤ 0.30wt.%, the balance is Fe.

[0037] The preparation method of the welding wire in this example is: the molten steel is desulfurized, smelted by refining outside the furnace or electroslag remelting, and continuously cast into a billet. The continuous casting process needs to match the superheat and casting speed to improve the equiaxed crystal Ratio, the billet is rolled into a φ5.5mm wire rod, peeled, pickled to remove surface scale, boronized, dried, drawn into wire, copper plated, and sized; the pickling removes surface oxide The chemical composition of the pickling solution for the skin is 400ɡ / L of sulfuric acid and 50ɡ / L of f...

Embodiment 2

[0040] A high-toughness gas-shielded welding wire for long-life weather-resistant steel structures. The chemical composition of the welding wire is: C: 0.053wt.%, Si: 0.51wt.%, Mn: 1.24wt.%, P: 0.007wt.%, S: 0.005wt.%, Cr: 0.38wt.%, Mo: 0.15wt.%, Cu: 0.30wt.%, Ni: 1.17wt.%, Ti: 0.015wt.%, O: 0.0069 wt.%, the sum of unavoidable impurity elements ≤ 0.30wt.%, the balance is Fe.

[0041] The preparation method of the welding wire in this example is the same as that in Example 1.

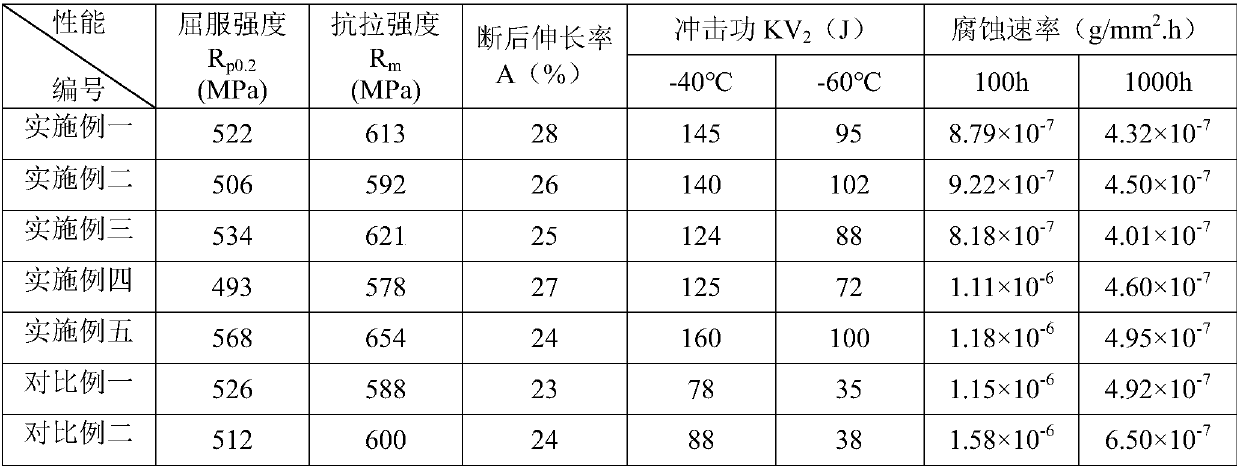

[0042] Perform the deposited metal performance test on the welding wire in this example: yield strength R p0.2 506MPa; tensile strength R m It is 592MPa; the elongation after breaking is 26%; the impact energy KV at -40°C 2 140J; impact energy KV at -60°C 2 is 102J; the corrosion rate of the deposited metal after periodic infiltration for 100h is 9.22×10 -7 g / mm 2 .h; The corrosion rate of the deposited metal after periodic infiltration for 1000h is 4.50×10 -7 g / mm 2 .h.

Embodiment 3

[0044] A high-toughness gas-shielded welding wire for long-life weather-resistant steel structures. The chemical composition of the welding wire is: C: 0.06wt.%, Si: 0.55wt.%, Mn: 1.35wt.%, P: 0.009wt.%, S: 0.004wt.%, Cr: 0.35wt.%, Mo: 0.22wt.%, Cu: 0.38wt.%, Ni: 1.26wt.%, Ti: 0.018wt.%, O: 0.0055 wt.%, the sum of unavoidable impurity elements ≤ 0.30wt.%, the balance is Fe.

[0045] The preparation method of the welding wire in this example is the same as that in Example 1.

[0046] Perform the deposited metal performance test on the welding wire in this example: yield strength R p0.2 534MPa; tensile strength R m It is 621MPa; the elongation after breaking is 25%; the impact energy KV at -40°C 2 124J; impact energy KV at -60°C 2 is 88J; the corrosion rate of the deposited metal after periodic infiltration for 100h is 8.18×10 -7 g / mm 2 .h; The corrosion rate of the deposited metal after 1000 hours of periodic infiltration is 4.01×10 -7 g / mm 2 .h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com