Spraying-free metal-texture high-gloss high-weather-resistance PMMA/ASA alloy material and preparation method thereof

A metal texture and alloy material technology, which is applied in the field of automotive materials, can solve the problems of poor improvement of metal texture high-gloss alloys, difficulty in meeting environmental protection and product qualification rates, and achieve bright appearance, improved gloss, and good weather resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

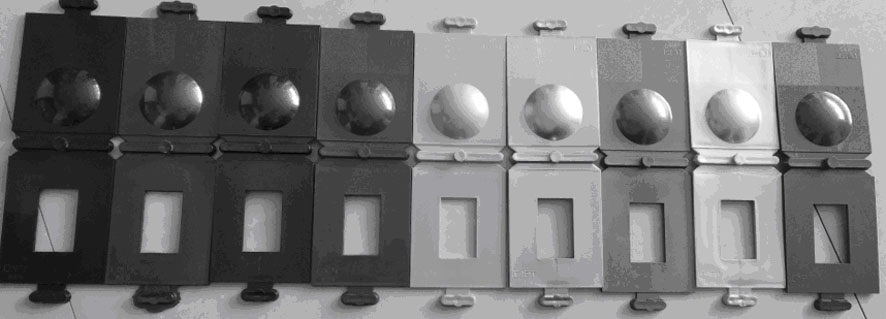

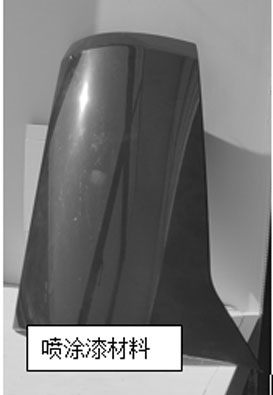

Image

Examples

Embodiment 5

[0047] On the basis of Example 1, the amount of glass powder was adjusted to 1.5Kg, the rest remained unchanged, the gloss (20° angle) was 80, the weather resistance decreased, and DE*=3.0.

[0048] On the basis of Example 1, the amount of glass frit was adjusted to 2.0Kg, the rest remained unchanged, the gloss (20° angle) was 78, the weather resistance decreased, and DE*=3.5.

Embodiment 6

[0050] On the basis of Example 1, the glass powder was replaced with mica pearlescent powder, the rest remained unchanged, the appearance had no flow marks, the gloss (20° angle) decreased to 80, and the weather resistance decreased, DE*=3.3.

Embodiment 7

[0052] On the basis of Example 1, the antioxidant 1076 was replaced with the antioxidant 1010, the rest remained unchanged, the appearance had no flow marks, the gloss (20° angle) was 83, and the weather resistance met the requirements.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com