Primer-topcoat acrylic resin coating and preparation method thereof

A technology of acrylic resin and coating, which is applied in the direction of anti-corrosion coating, polyurea/polyurethane coating, coating, etc. It can solve the problems that customers cannot bear, long construction line, and high humidity requirement in water-based coating construction environment, so as to reduce the pressure of investment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The present invention also provides a preparation method of the acrylic resin coating with the above-mentioned bottom surface integrated, comprising:

[0036] S1: Mix 50-70 parts of acrylic resin, 2-4 parts of dispersant, 1-2 parts of dispersing aid, and 5-11 parts of solvent, stir at 400-600 rpm for 10-15 minutes; then add 20-40 parts of pigment Filler, stir at 600-800rpm for 10-15min; continue to add 1-4 parts of solvent and stir until uniformly mixed, use a sand mill to grind to a suitable fineness; add 0.1-4 parts of other additives, stir until uniformly mixed to obtain Group A Minute;

[0037] S2: Mix 65-75 parts of hexamethylene diisocyanate, 25-35 parts of butyl acetate and 0.1-0.5 parts of water-absorbing agent to obtain component B;

[0038] S3: Mix component A and component B uniformly according to the weight ratio of 5-7:1 to obtain an acrylic resin coating with bottom and surface integrated.

[0039] In the preparation process, the organic solvent is added...

Embodiment 1

[0047] Preparation of yellow base-surface-in-one acrylic paint

[0048] S1: Add 58kg of acrylic resin, 5.2kg of propylene glycol methyl ether acetate, 5.2kg of methyl isobutyl ketone, 2kg of dispersant, and 1kg of dispersing aid into a suitable container, and stir (400-600rpm) for 10-15 minutes;

[0049] Add 9.4kg of yellow pigment and 14.5kg of anti-rust pigment while stirring. After adding, stir (600-800rpm) for 10-15 minutes;

[0050] Add 1.8kg propylene glycol methyl ether acetate along the container wall while stirring, and continue to stir for 15 minutes until uniform; start grinding and dispersing on the designated sand mill until the fineness meets the requirements;

[0051] During stirring (400-600rpm), add 2kg of silane coupling agent, 0.5kg of leveling agent, and 0.4kg of drier, and then stir (400-600rpm) for 15 minutes until completely uniform to obtain component A.

[0052] S2: 70kg of hexamethylene diisocyanate, 29.5kg of butyl acetate and 0.5kg of water-absorbi...

Embodiment 2-3

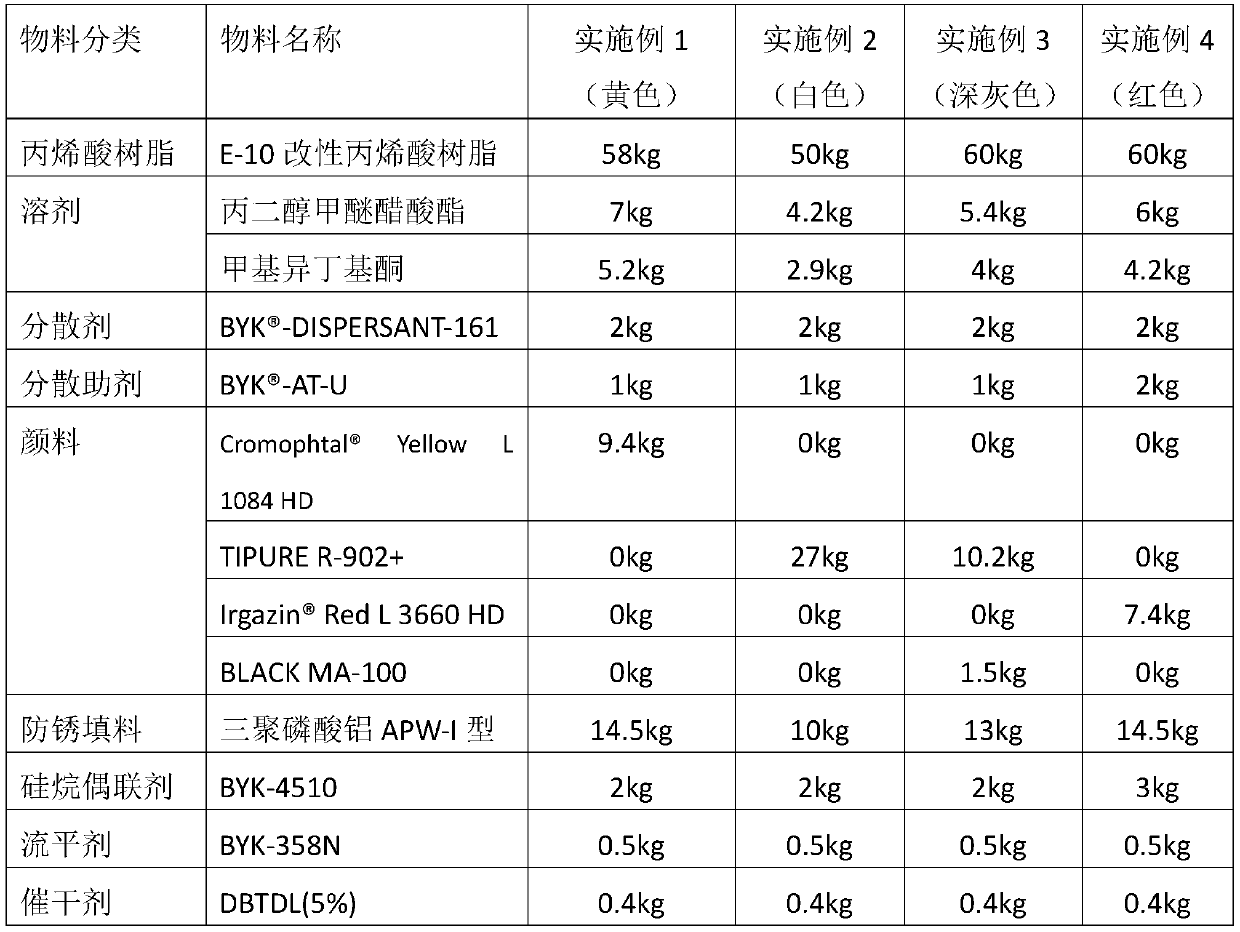

[0056] The raw material composition table of the coating prepared in Example 2-3 is shown in Table 1, and its preparation process is basically the same as that of Example 1.

[0057] The molecular weight of the E-10 modified acrylic resin in Example 2-3 is 1800, the solid content is 75%, the viscosity is 6 Pa.S, and the hydroxyl value is 120 mgKOH / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com