Special-shaped insulation wear-resistant sand spraying rubber flexible pipe

A rubber hose, special-shaped technology, applied in the direction of hose, pipe, pipeline protection, etc., can solve the problems affecting the safety performance of locomotives, increase the running failure of locomotives, and adversely affect the connection, so as to reduce potential safety hazards, slow down rigid tension, The effect of avoiding axial twist problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

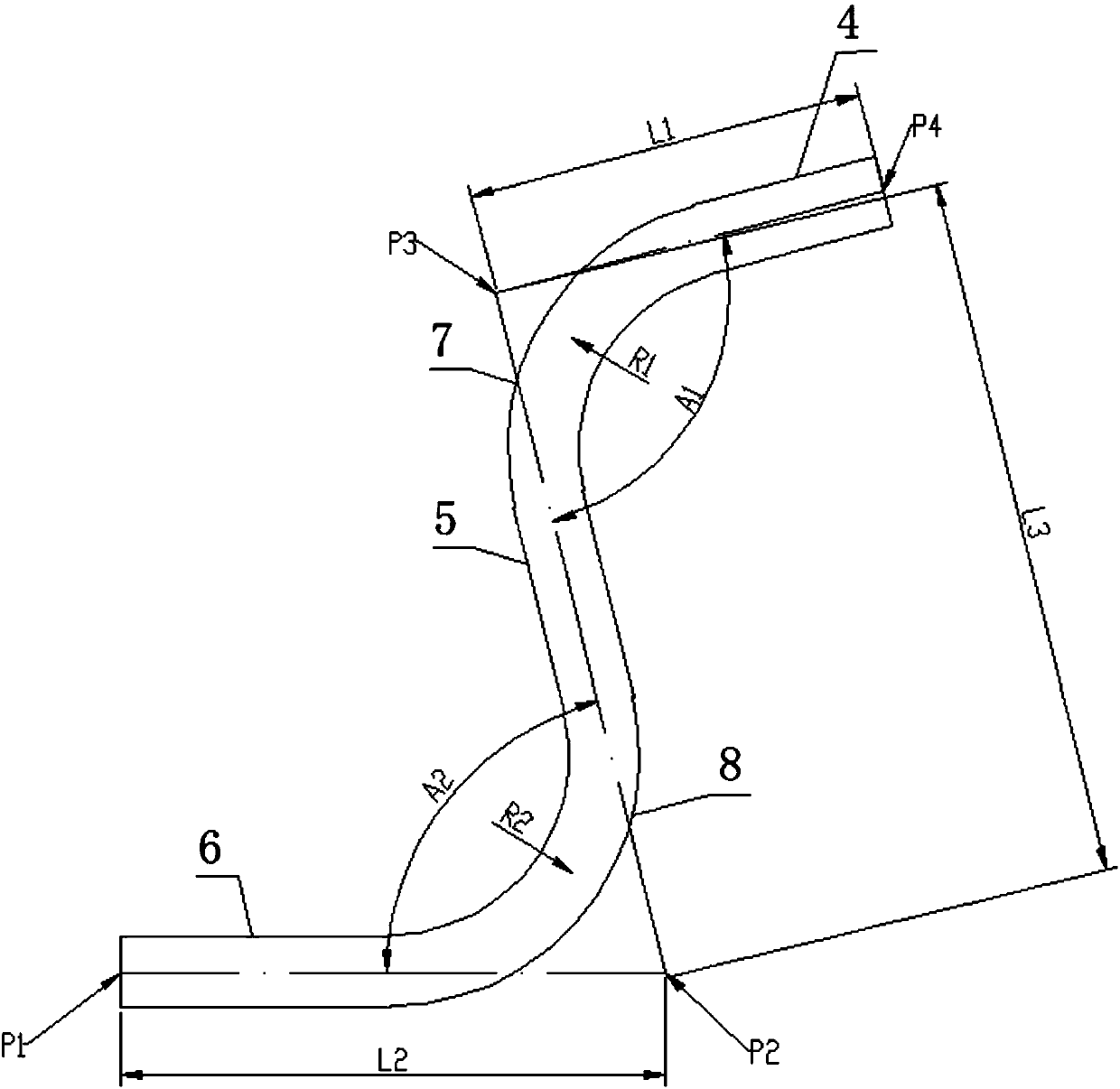

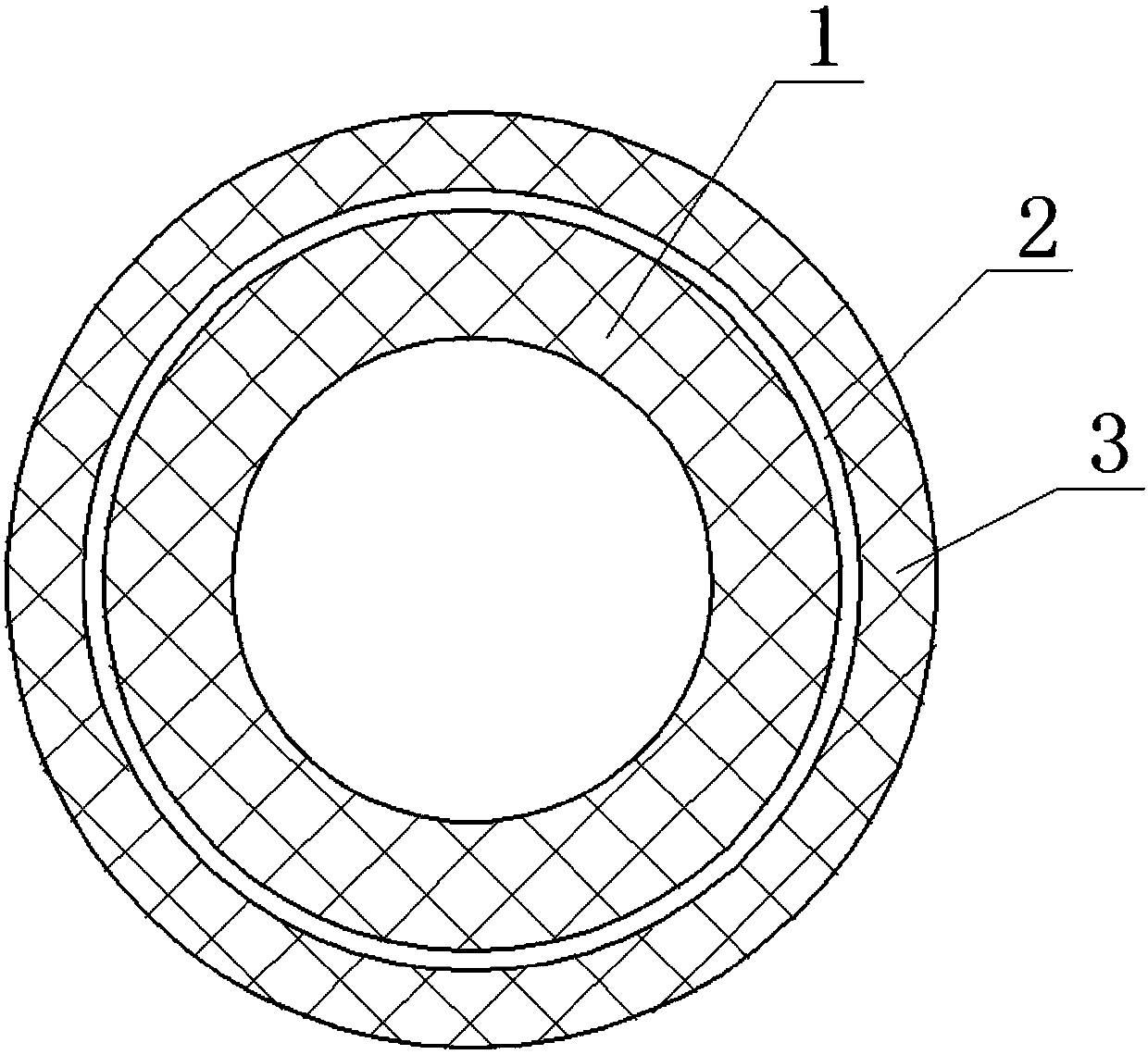

[0041] Such as figure 1 and figure 2 As shown, a special-shaped insulating wear-resistant sand-spreading rubber hose is an S-shaped rubber hose, which is composed of an inner rubber layer 1, a reinforcing layer 2 and an outer rubber layer 3 from the inside to the outside. ; There are installation positioning lines at both ends of the sand-spraying rubber hose, and a flow direction mark such as "←" is provided on the outer wall of the sand-spraying rubber hose.

[0042] The S-type rubber hose includes the first straight pipe section 4, the second straight pipe section 5, the third straight pipe section 6, the first arc section 7 connecting the first straight pipe section 4 and the second straight pipe section 5, and the second straight pipe section 5 and the second arc section 8 of the third straight pipe section 6; the first straight pipe section 4 and the second straight pipe section 5 are respectively tangent to the first arc section 7; the second straight pipe section 5 a...

Embodiment 2

[0056] Replace the EPDM rubber composition in Example 1 with the CR rubber composition, and the others are the same as in Example 1.

[0057] The CR rubber composition is made of the following components by weight: chloroprene rubber: 100 parts, quick extruded carbon black N550: 5 parts, white carbon black: 60 parts, stearic acid: 0.5 parts, anti-aging agent 4010NA: 2 parts, anti-aging agent RD: 3 parts, plasticizer NB-4: 30 parts, vulcanizing agent S-80: 0.5 parts, coupling agent Si-69: 1.5 parts, magnesium oxide: 4 parts, zinc oxide: 5 parts, protective wax 654: 3 parts, accelerator NA-22: 1.5 parts, accelerator DM: 0.5 parts, accelerator 4000: 2 parts, flame retardant TL01: 40 parts, flame retardant 06B: 20 parts, flame retardant Fuel agent F2: 10 parts, carbon forming agent XC-103B: 18 parts, smoke suppressant Charmax LS-ZHS: 5 parts, smoke suppressant CharmaxLS-AOM: 10 parts.

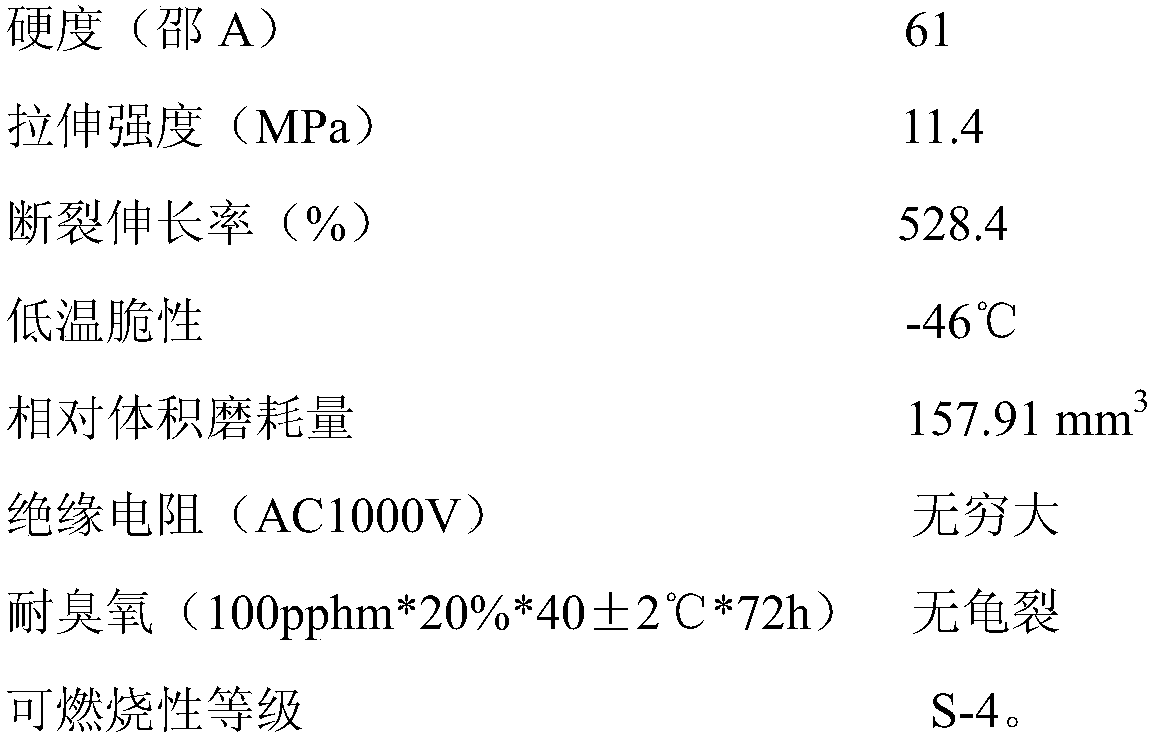

[0058] Table of physical properties of the rubber composition:

[0059]

[0060] The spe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com