Inner tank and outer tank structural support

A technology of support structure, inner and outer tanks, applied in the field of machinery, can solve the problems of low reliability and large amount of support welding, and achieve the effect of reducing the risk of damage, reducing heat leakage, and reducing welding heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

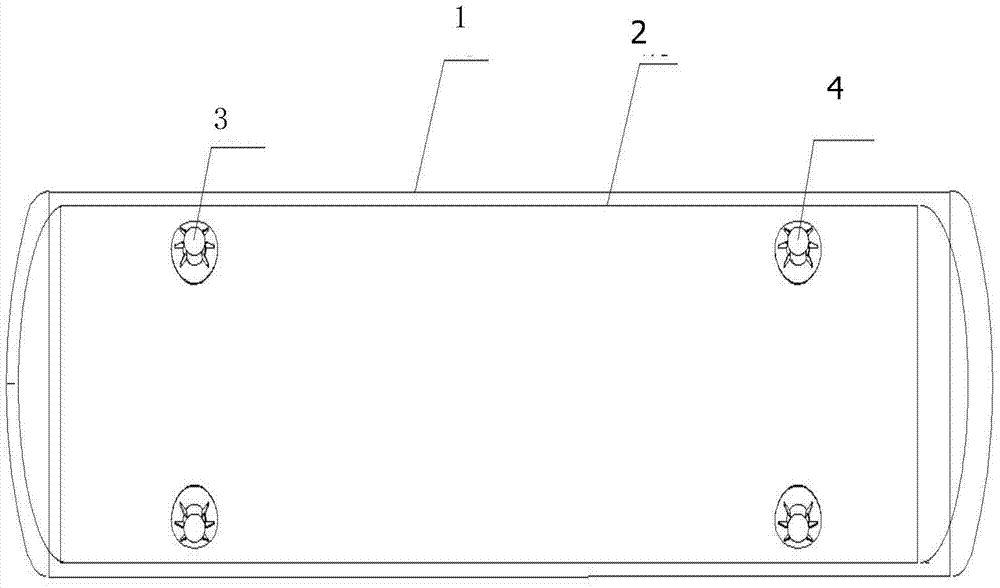

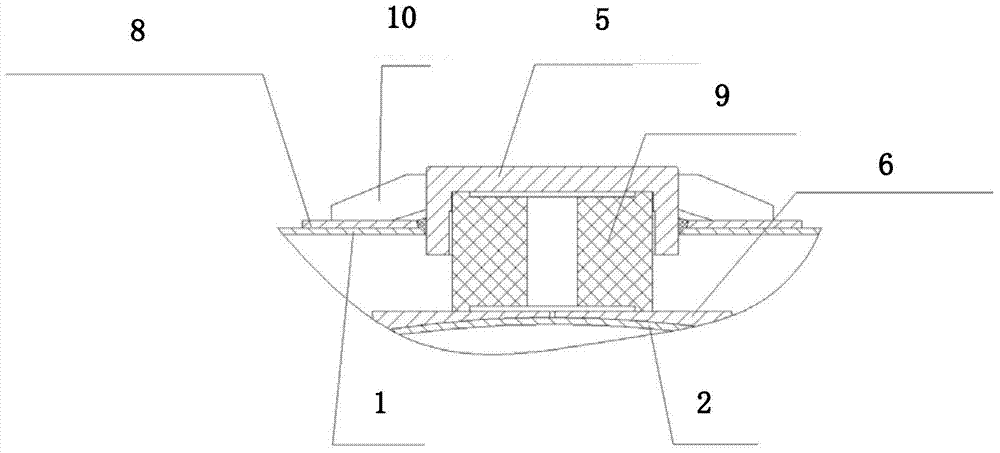

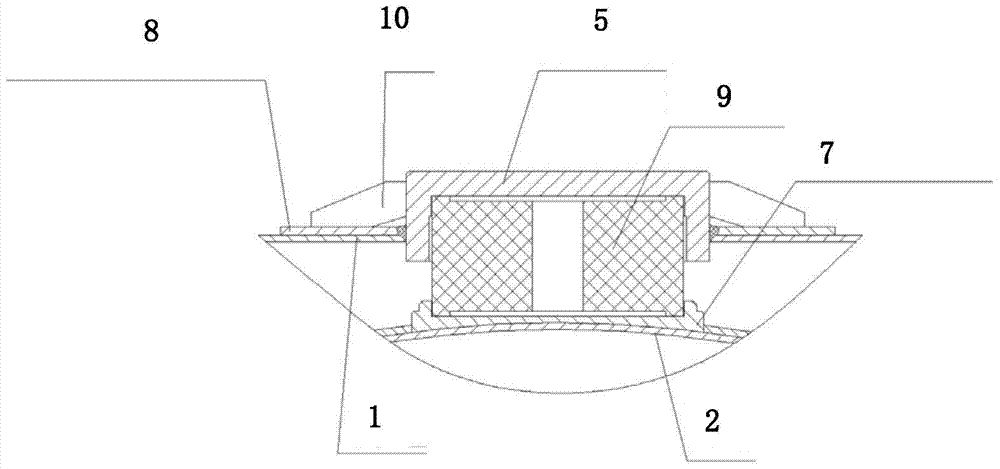

[0028] see Figure 1-4 , an inner and outer tank support structure, including a sliding support assembly 3 and a fixed support assembly 4 arranged between the inner tank 2 and the outer tank 1; the sliding support assembly 3 and the fixed support assembly 4 are respectively arranged on the inner tank 2 and the outer tank 1 The two ends between; the sliding support assembly 3 includes the outer tank support cover 5 arranged on the outer tank 1, the inner tank sliding support 6 arranged on the inner tank 2, the glass fiber reinforced plastics connecting the outer tank support cover 5 and the inner tank sliding support 6 Support 9; the fixed support assembly 4 includes an outer tank support cover 5 arranged on the outer tank 1, an inner tank fixed support 6 arranged on the inner tank 2, a glass fiber reinforced plastic support 9 connecting the outer tank support cover 5 and the inner tank fixed support 7; The outer tank 2 is also provided with an outer tank support cover reinforc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com