OCM Fresnel Lens and moulding technology thereof

A technology of Fresnel lens and molding process, which is applied to lenses, other household appliances, optics, etc., can solve problems such as shortened service life, large thermal creep, and influence on power generation capacity, so as to ensure technical performance, reduce reflection loss, Effect of improving thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] Below in conjunction with accompanying drawing, the application is further described:

[0063] The present embodiment is OCM Fresnel lens, is used for HCPV module (see Figure 4 ) in optical components for gathering sunlight. The OCM Fresnel lens 1 is installed on the upper part of the module, and a high-concentration photovoltaic chip (solar cell) 3 is arranged at the focal spot, and a heat sink 4 is installed under the chip. A secondary condenser lens 105 is installed above the type photovoltaic chip 1 .

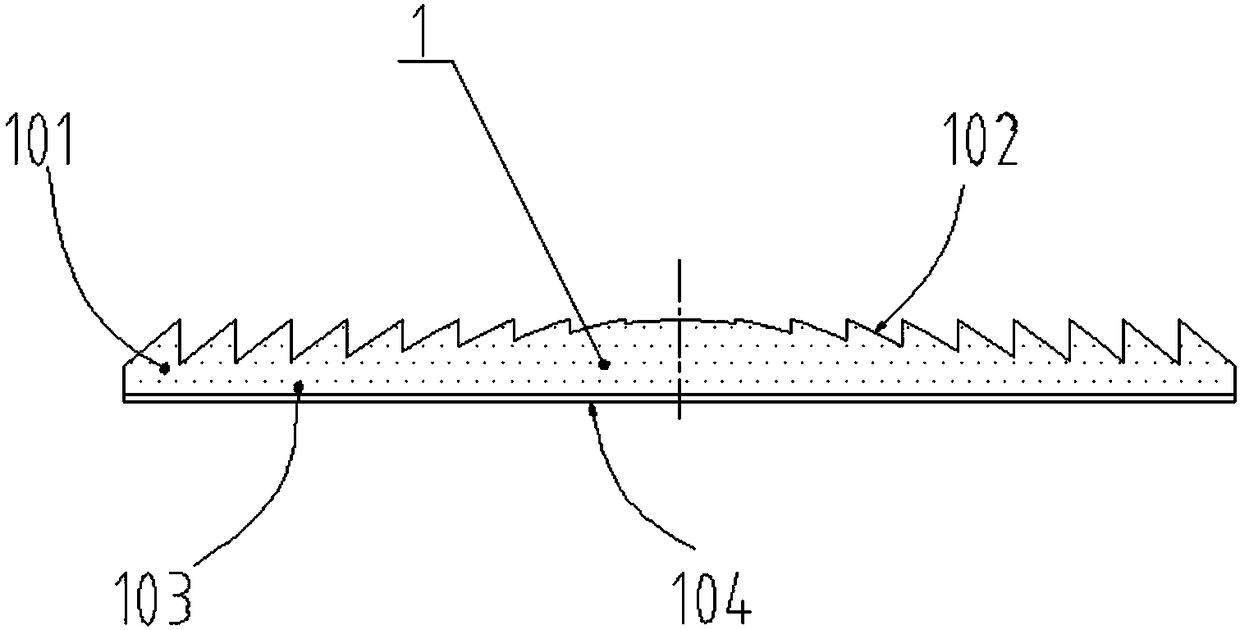

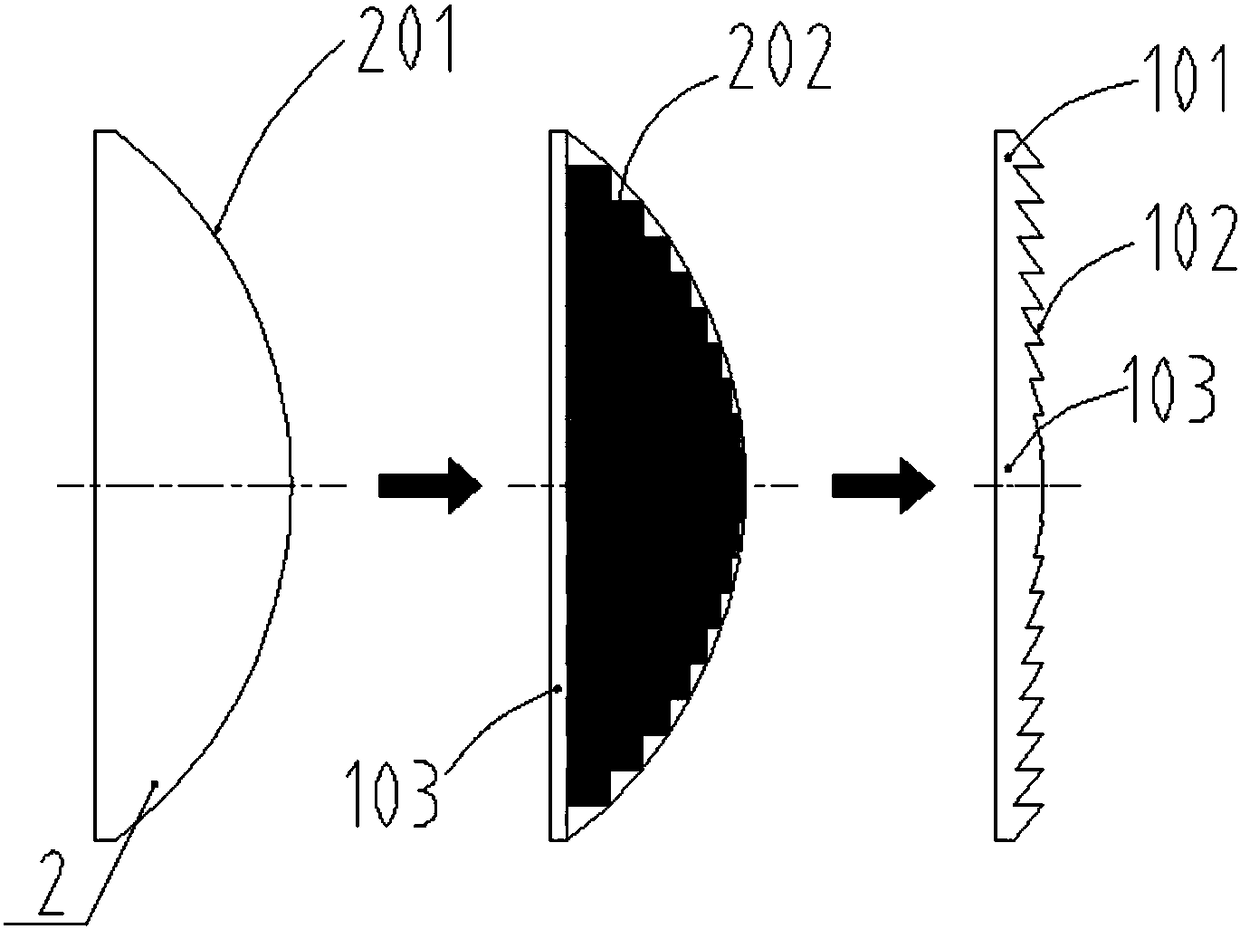

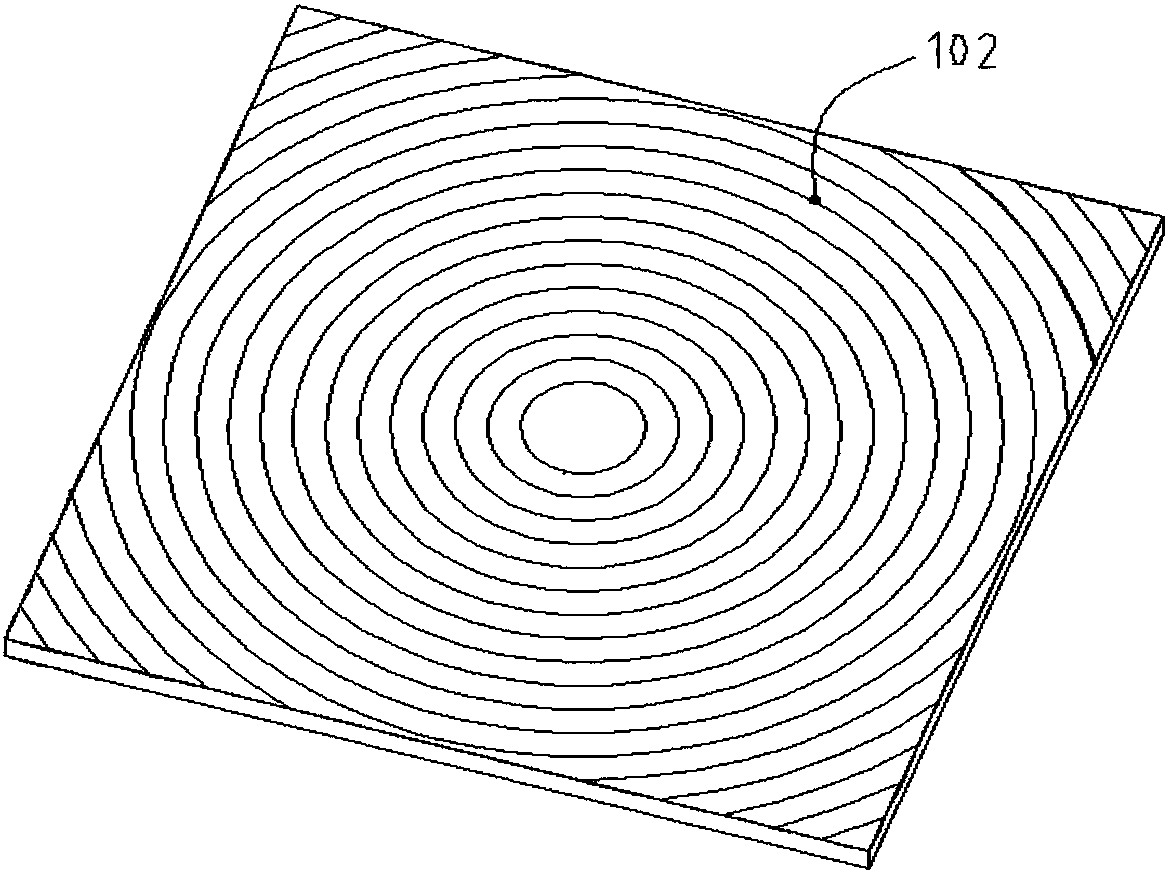

[0064] Depend on Figure 1~4 As shown, the appearance of this embodiment is a square thin plate, including an OCM (optical composite material) lens body 101 and an anti-reflection film 104 . On one side of the surface, several concentric serrated rings 102 are engraved at equal intervals; The toothed ring 102 assumes that the plano-convex lens 2 with the same optical parameters as the OCM Fresnel lens 1 is divided into several imaginary annular sleeves 202 at eq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com